High-stiffness coated reflecting film and preparation method thereof

A technology of reflective film and high stiffness, which is applied in the field of reflective film, can solve problems affecting the use of backlight modules, uneven light reflection, poor stiffness, etc., and achieve the effect of overcoming the defect of pressing white spots, simple process, and improved stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

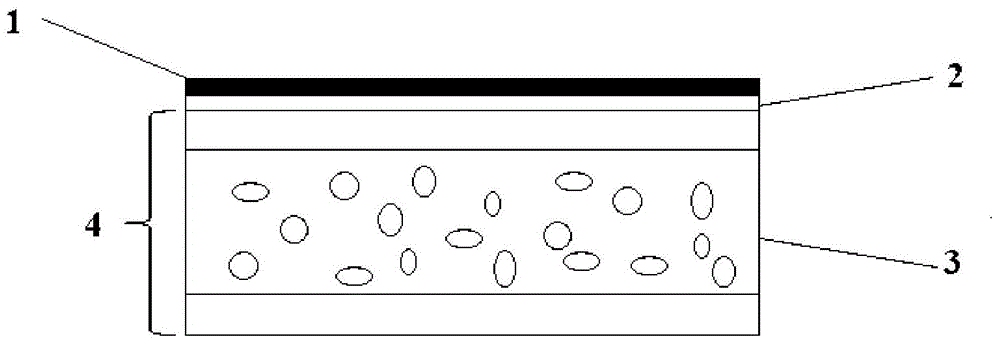

Image

Examples

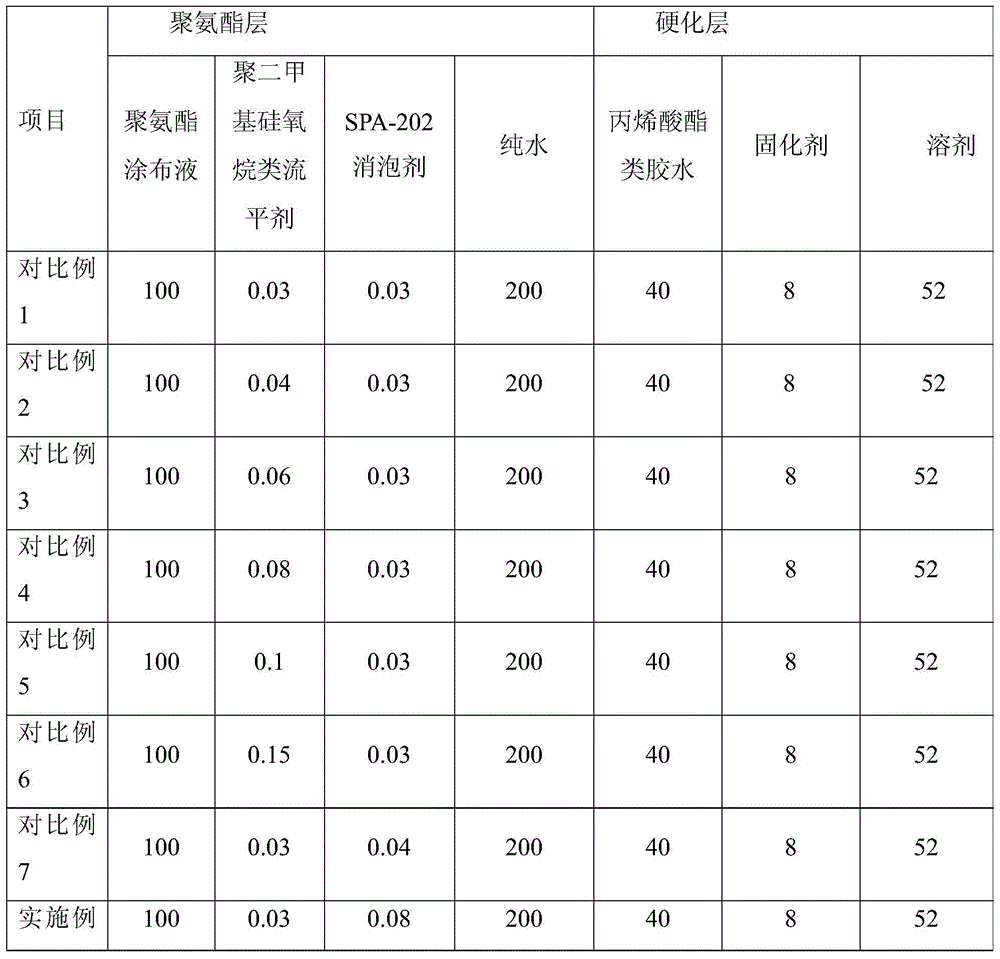

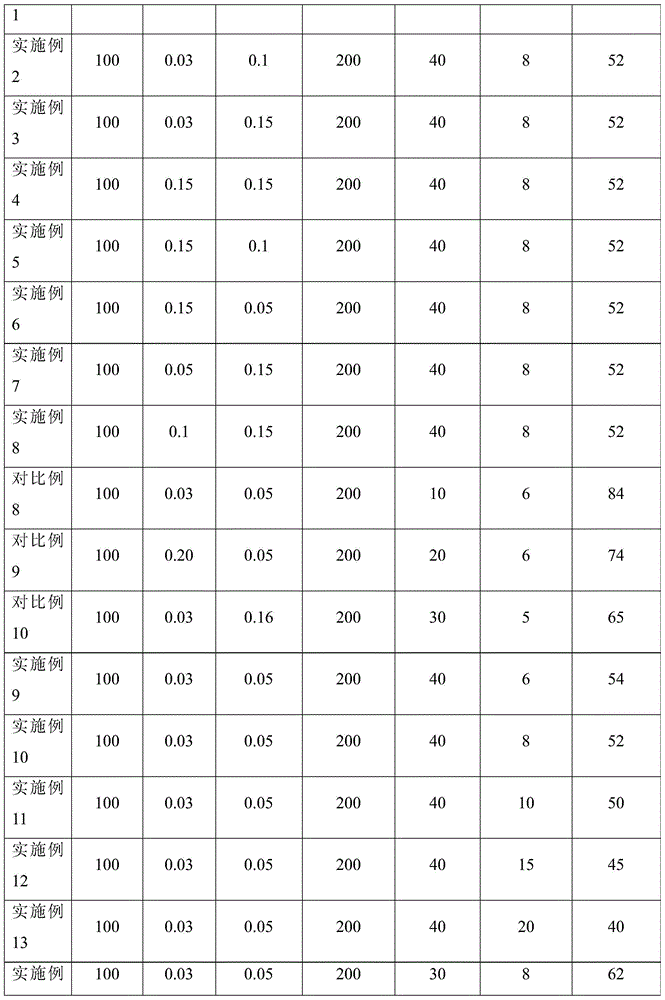

Embodiment 1

[0063] Take 100 parts of polyurethane coating liquid, 0.03 parts of polydimethylsiloxane leveling agent, 0.08 parts of SPA-202 defoamer, 200 parts of pure water, mix them evenly with a stirrer and apply them on the reflective film. Heat and dry in an oven at 130°C for 5 minutes; then take 40 parts of acrylic glue, 8 parts of m-XDA curing agent, and 52 parts of solvent, mix them evenly with a stirrer, and then apply them on the reflective film of the existing polyurethane layer, and place them in the oven Dry at 120°C for 1min, then use a high-pressure mercury lamp at 800mj / cm 2 The above-mentioned reflective film is irradiated with high energy to make it UV harden, and finally a high-stiffness coated reflective film is obtained.

Embodiment 2

[0065] Take 100 parts of polyurethane coating solution, 0.03 parts of polydimethylsiloxane leveling agent, 0.1 part of SPA-202 defoamer, 200 parts of pure water, mix them evenly with a stirrer, and apply them on the reflective film, and place Heat and dry in an oven at 130°C for 5 minutes; then take 40 parts of acrylic glue, 8 parts of m-XDA curing agent, and 52 parts of solvent, mix them evenly with a stirrer, and then apply them on the reflective film of the existing polyurethane layer, and place them in the oven Dry at 120°C for 1min, then use a high-pressure mercury lamp at 800mj / cm 2 The above-mentioned reflective film is irradiated with high energy to make it UV harden, and finally a high-stiffness coated reflective film is obtained.

Embodiment 3

[0067] Take 100 parts of polyurethane coating solution, 0.03 parts of polydimethylsiloxane leveling agent, 0.15 parts of SPA-202 defoamer, 200 parts of pure water, mix them evenly with a stirrer, and then apply them on the reflective film. Heat and dry in an oven at 130°C for 5 minutes; then take 40 parts of acrylic glue, 8 parts of m-XDA curing agent, and 52 parts of solvent, mix them evenly with a stirrer, and then apply them on the reflective film of the existing polyurethane layer, and place them in the oven Dry at 120°C for 1min, then use a high-pressure mercury lamp at 800mj / cm 2 The above-mentioned reflective film is irradiated with high energy to make it UV harden, and finally a high-stiffness coated reflective film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com