Field assembly type optical fiber connector

An active connector and on-site assembly technology, which is applied in the coupling of optical waveguides, can solve problems such as poor repeatability, large bending of optical fibers, and affecting optical performance, and achieve strong repeatability, high compression and tensile performance, and reliability. sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

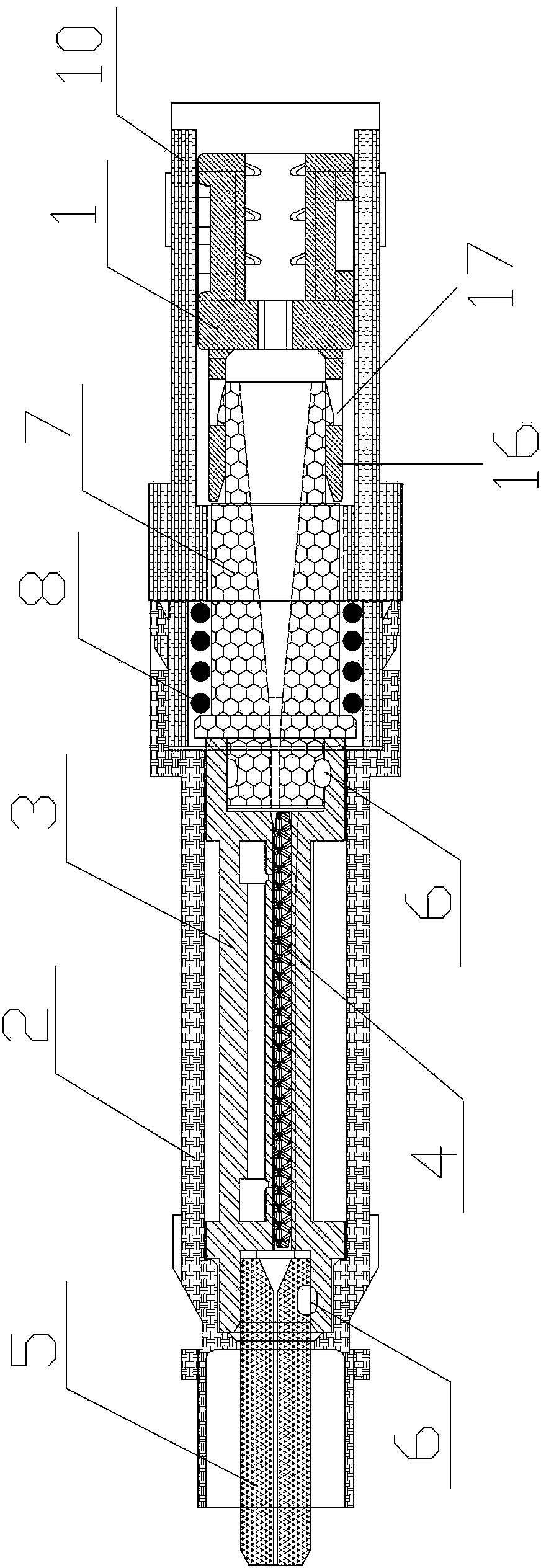

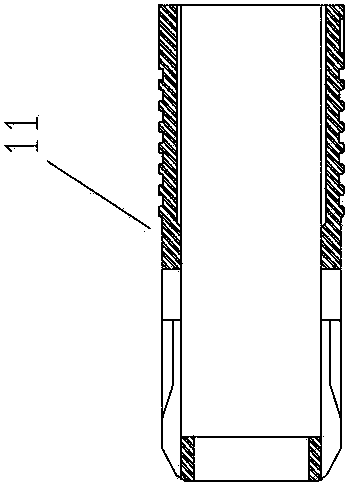

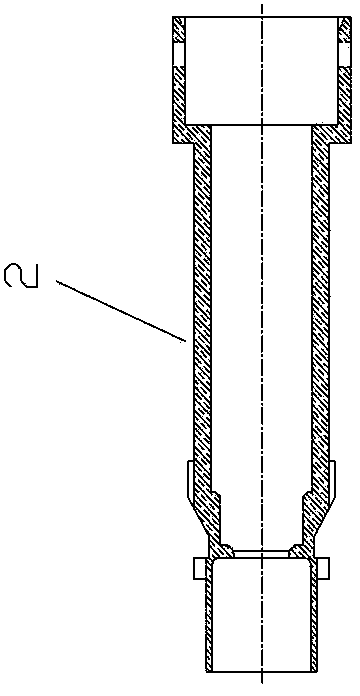

[0045] see Figure 1-27 , the field assembled optical fiber movable connector of the present invention consists of an inner shell, a box shell, a V-shaped groove aluminum sheet, a card slot insert, a plastic latch, a wire block, a spring, a metal clip spring, a spring seat, a wire fixing groove, a square Cover, key, dust cap, and short shell. After the end of the card slot ferrule is connected with the bare optical fiber, it is glued and inserted into the head of the box shell, and the card slot ferrule is connected to the box shell by pressing the plastic pin. fixed, the V-shaped groove aluminum sheet is located inside the box shell, the wire block is installed at the tail of the box shell, and the box shell and the wire block are fixed by plastic bolts, the metal clamp spring is set on the box shell, and the The spring is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com