Antistatic scratch-proof transparent BOPET film, and preparation method thereof

An antistatic and anti-scratch technology, applied in the field of PET materials, can solve problems such as abnormal quality, easy scratches, and high static electricity, and achieve high mechanical strength, cost savings, and improved production line yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

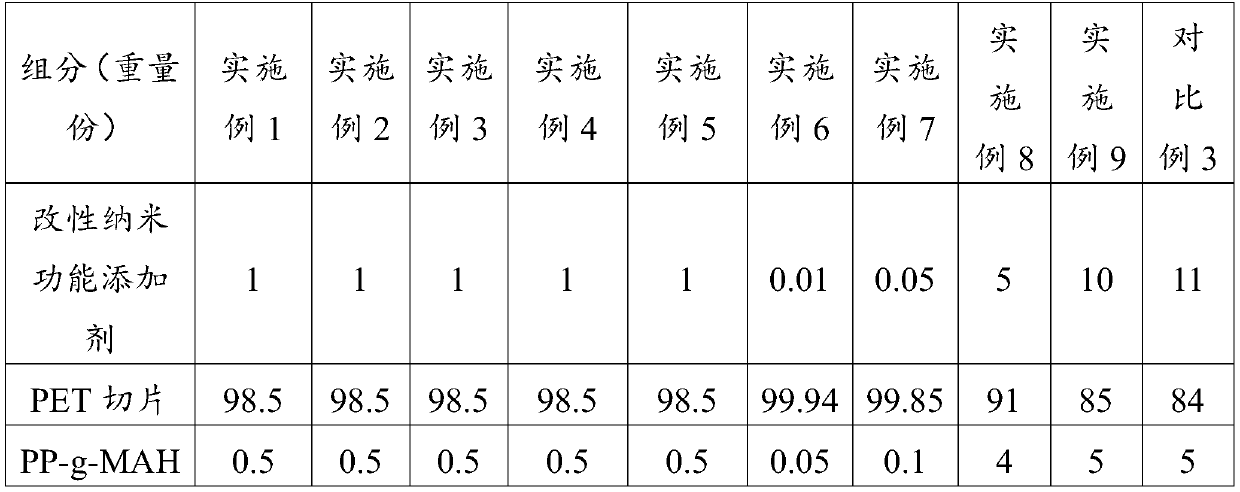

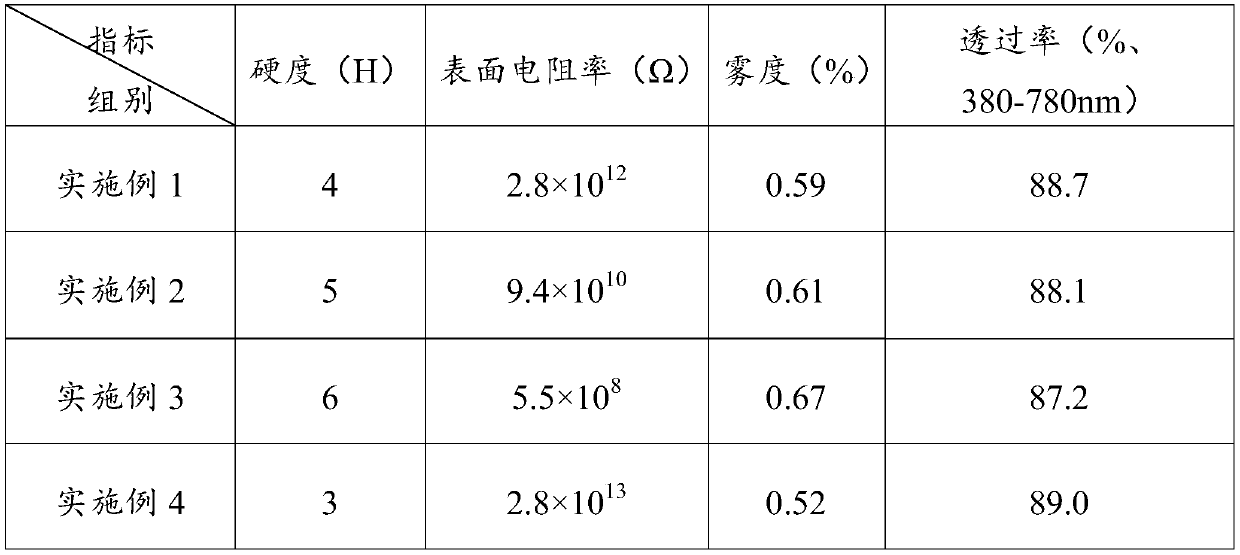

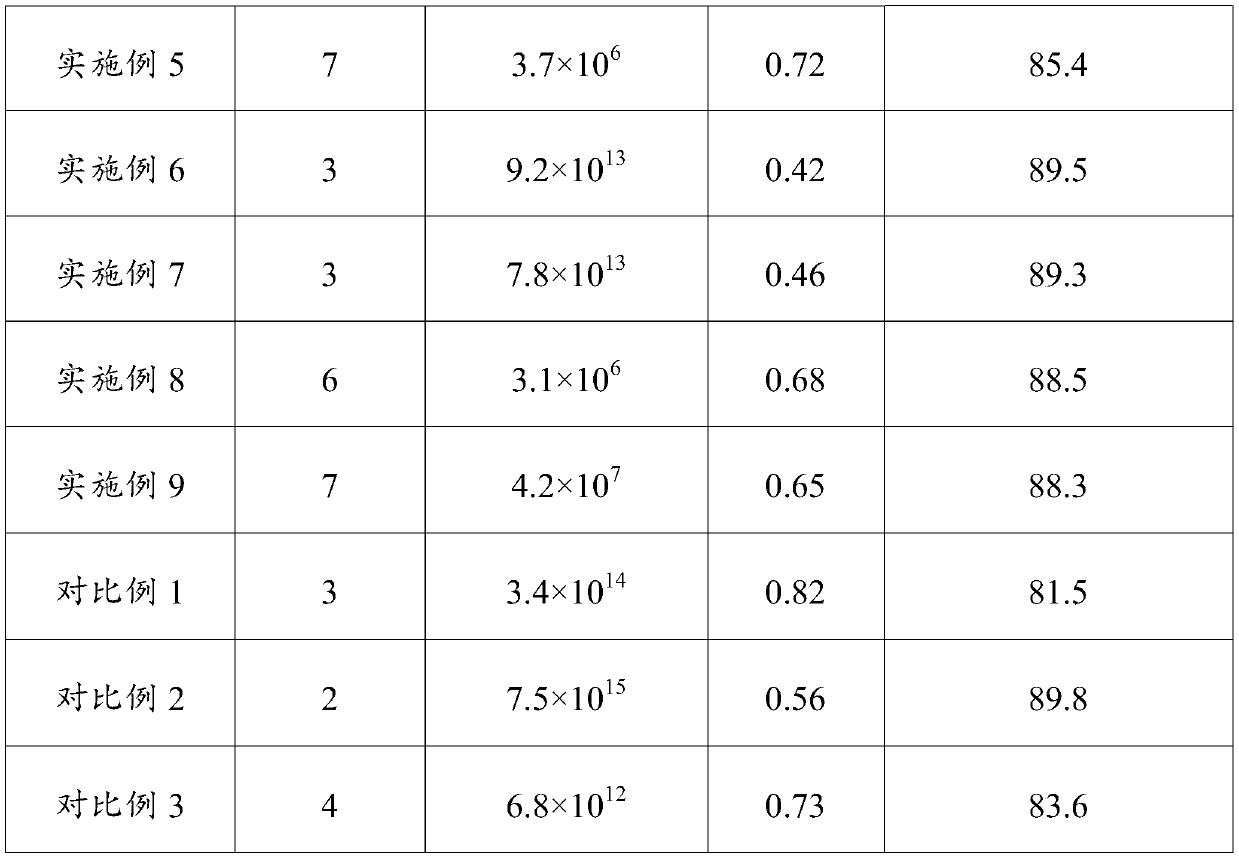

[0037]An embodiment of the antistatic anti-scratch transparent BOPET film of the present invention, the antistatic anti-scratch transparent BOPET film of the present embodiment comprises 1 weight part of nano-modified PET chips and 99 weight parts of PET chips . The formulation of the nano-modified PET chips is shown in Table 1.

[0038] In this embodiment, the preparation method of the modified nano-functional additive is as follows: 1 part by weight of graphene with 2 layers is first refluxed with nitric acid at a high temperature of 100° C. for 6 hours, so that active groups such as hydroxyl groups and carboxyl groups are generated on the surface; and then Place in an aqueous ethanol solution, add 6 parts by weight of γ-mercaptopropyltrimethoxysilane (KH590), stir mechanically at room temperature for 4 hours, and then wash the unreacted KH590 on the graphene surface with toluene several times; finally the surface has been chemically modified KH590 The graphene is placed in...

Embodiment 2

[0044] An embodiment of the antistatic anti-scratch transparent BOPET film of the present invention, the antistatic anti-scratch transparent BOPET film of the present embodiment comprises 1.5 parts by weight of nano-modified PET chips and 98.5 parts by weight of PET chips . The formulation of the nano-modified PET chips is shown in Table 1.

[0045] In this embodiment, the preparation method of the modified nano-functional additive is as follows: 1 part by weight of graphene with 2 layers is first refluxed with nitric acid at 120° C. for 5 hours, so that active groups such as hydroxyl groups and carboxyl groups are generated on the surface; and then Place in an aqueous ethanol solution, add 10 parts by weight of γ-mercaptopropyltrimethoxysilane (KH590), stir mechanically at room temperature for 6 hours, and then wash the unreacted KH590 on the graphene surface with acetone several times; finally the surface has been chemically modified KH590 The graphene was placed in DMF sol...

Embodiment 3

[0051] An embodiment of the antistatic anti-scratch transparent BOPET film of the present invention, the antistatic anti-scratch transparent BOPET film of the present embodiment comprises 3 parts by weight of nano-modified PET chips and 97 parts by weight of PET chips . The formulation of the nano-modified PET chips is shown in Table 1.

[0052] In this embodiment, the preparation method of the modified nano-functional additive is as follows: 1 part by weight of two layers of graphene is first treated with a mixed acid of sulfuric acid and nitric acid at a high temperature of 100 ° C for 5 hours, so that hydroxyl groups, carboxyl groups, etc. active group; then be placed in ethanol aqueous solution, add the gamma-mercaptopropyltrimethoxysilane (KH590) of 1 weight part, normal temperature mechanical stirring 5h, then repeatedly wash the unreacted KH590 of graphene surface with toluene; The graphene whose surface has been chemically modified KH590 is placed in DMF solvent with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Haze | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com