Flexible low radiation window film and real time control method for producing the same

A low-radiation, real-time monitoring technology, applied in sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problem of poor corrosion resistance of silver, lack of real-time monitoring means for low-radiation film, and the effect of isolating ultraviolet light To achieve the effect of good heat insulation, good visible light transmittance, corrosion resistance and weather resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

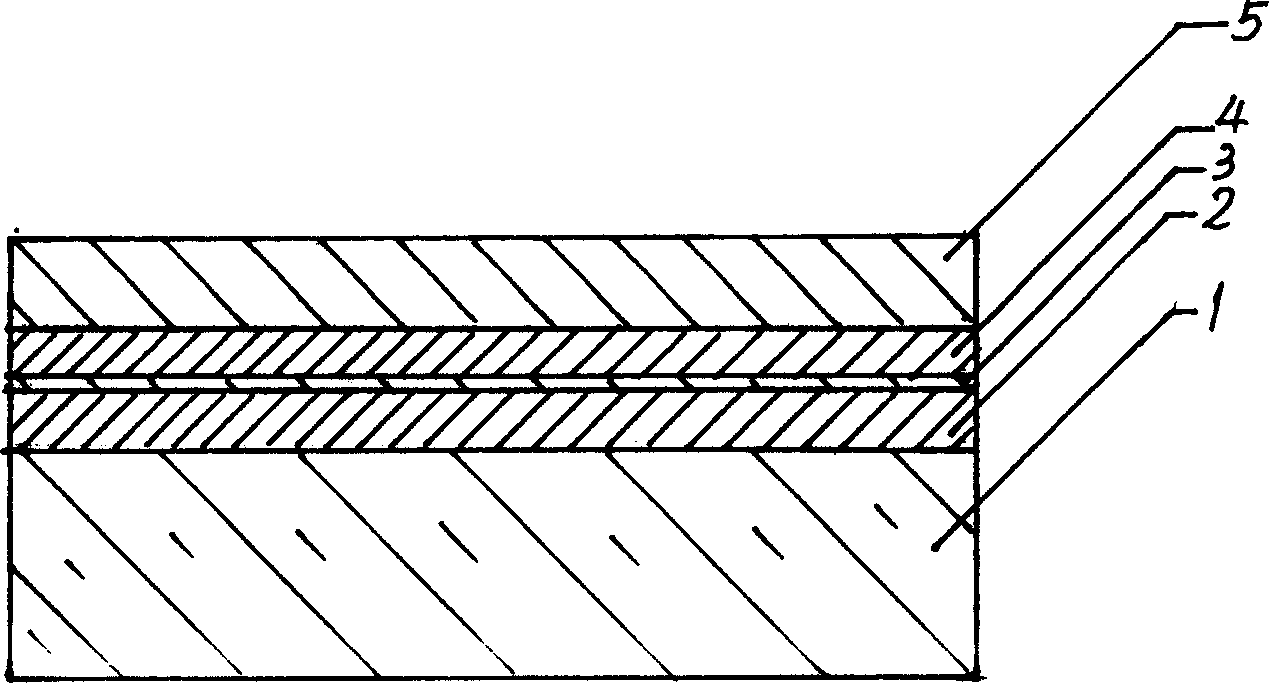

[0029] Embodiment 1: as figure 1 As shown, the flexible substrate 1 is a PET film with a thickness of 75 μm; SiO x Layer 2 thickness 25nm, SSO x Layer 3 has a thickness of 5 nm; Ag(Au) layer 4 has a thickness of 14 nm, and Ag:Au=85:15 (weight ratio). Product performance: Visible light transmittance is 82%, radiation rate is 0.14, and ultraviolet light absorption rate is 95%.

Embodiment 2

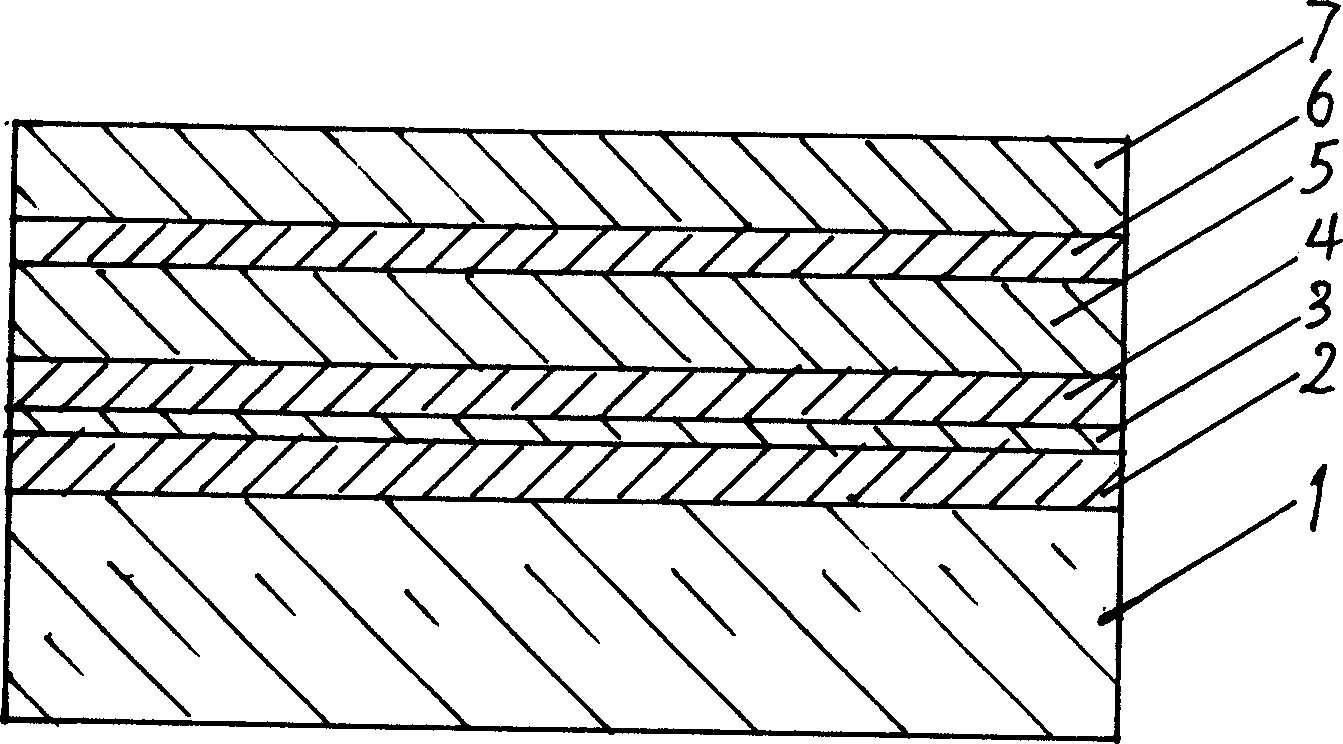

[0030] Embodiment 2: as figure 2 As shown, the flexible substrate 1 is a PET film with a thickness of 23 μm; SiO x Layer 2 thickness 25μm, SSO x The thickness of layer 3 is 2 nm; the thickness of Ag(Au) layers 4 and 6 are both 9 nm, and Ag:Au=85:15 (weight ratio). The thicknesses of the ITO layers 5 and 7 are both 85nm.

[0031] Product performance: Visible light transmittance is 78%, radiation rate is 0.11, and ultraviolet light absorption rate is 90%.

Embodiment 3

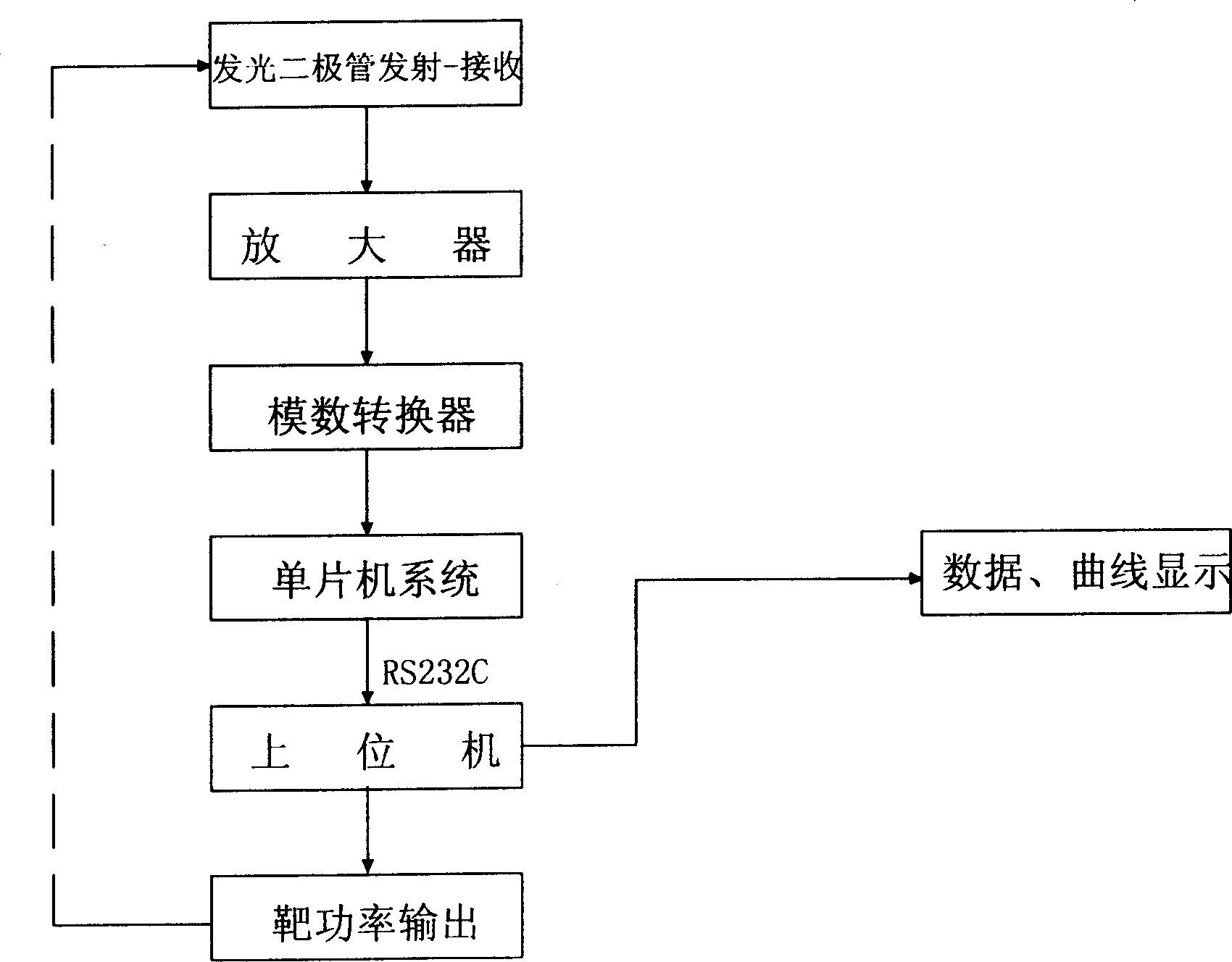

[0032] Embodiment 3: see image 3 and Figure 4 , the real-time monitoring method process such as image 3 As shown in the block diagram, using the Figure 4 The multi-target magnetron sputtering roll-to-roll coating machine implementation of shown prior art, Figure 4 When the middle receiving (putting) material roller 23 rotates clockwise, it is a receiving roller, and when the receiving (releasing) material roller 21 rotates counterclockwise, it is a receiving roller. 1. Four light-emitting diode emitting probes (i.e., light-emitting probes 24) are evenly distributed horizontally on one side, and four light-receiving probes 20 are correspondingly arranged on the other side of the base film 1. The emitted light of the probes 24 is perpendicular to the running direction (plane) of the base film 1 , select the light transmittance of four wavelengths of 470nm, 560nm, 660nm, and 880nm for real-time monitoring, and the infrared transmittance of 880nm wavelength can judge wheth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com