Method for preparing graphene-based conductive pearlescent pigment

A pearlescent pigment, graphene-based technology, applied in the wet preparation of dyeing pigments, inorganic pigment processing, chemical instruments and methods, etc. The effect of simplicity and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

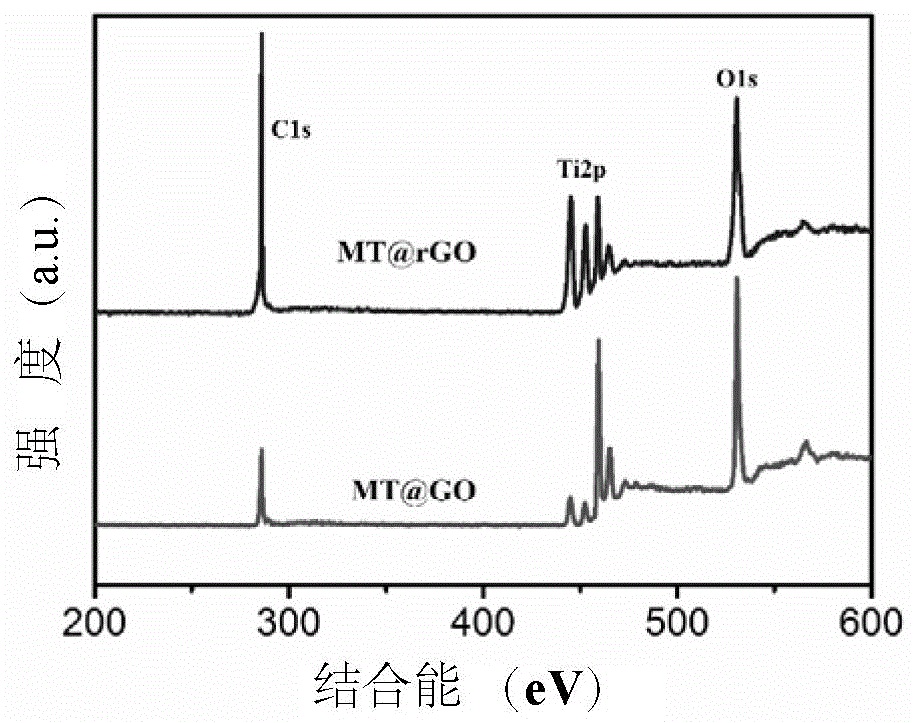

[0061] The preparation method of the invention has the advantages of simple process, environmental protection, small side effects, strong controllability, good repeatability, low cost, excellent product performance and easy implementation of large-scale production.

[0062] In the present invention, the metal reduction method is used for the first time in the preparation of graphene-based conductive pearlescent pigments, and the purpose of significantly improving the electrical conductivity of the composite pigments is achieved under the premise of the same graphene doping amount and optical properties of the pearlescent pigments. The method of the present invention has the characteristics of simple operation, environmental protection, high efficiency and low cost, and the prepared conductive composite material has outstanding advantages such as adjustable color, high conductivity, high stability, etc., and is widely used for conductive pearlescent pigments and conductive interf...

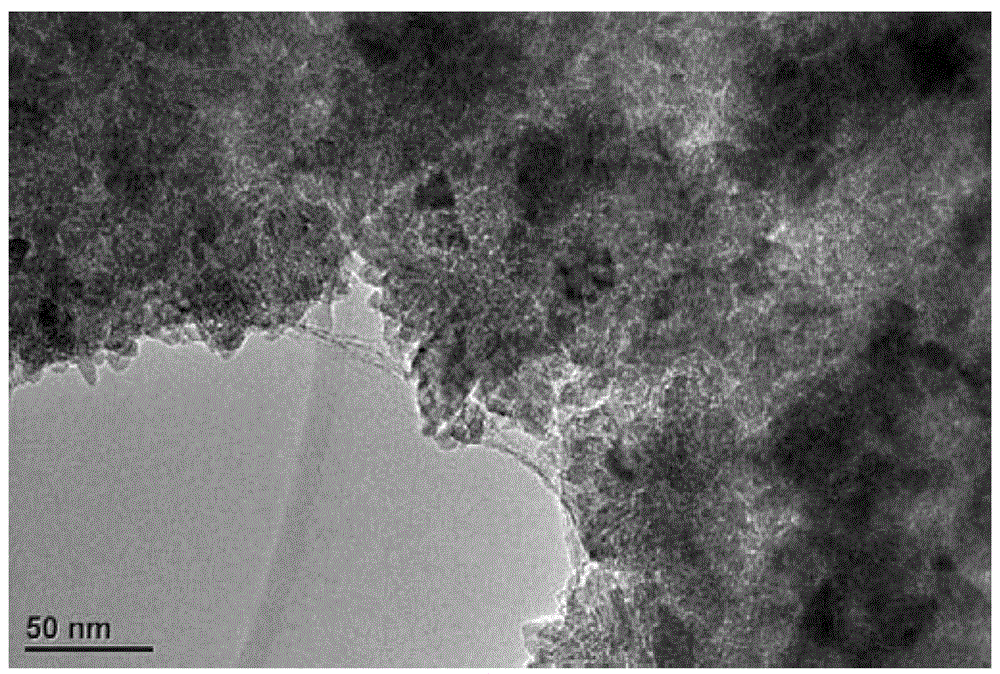

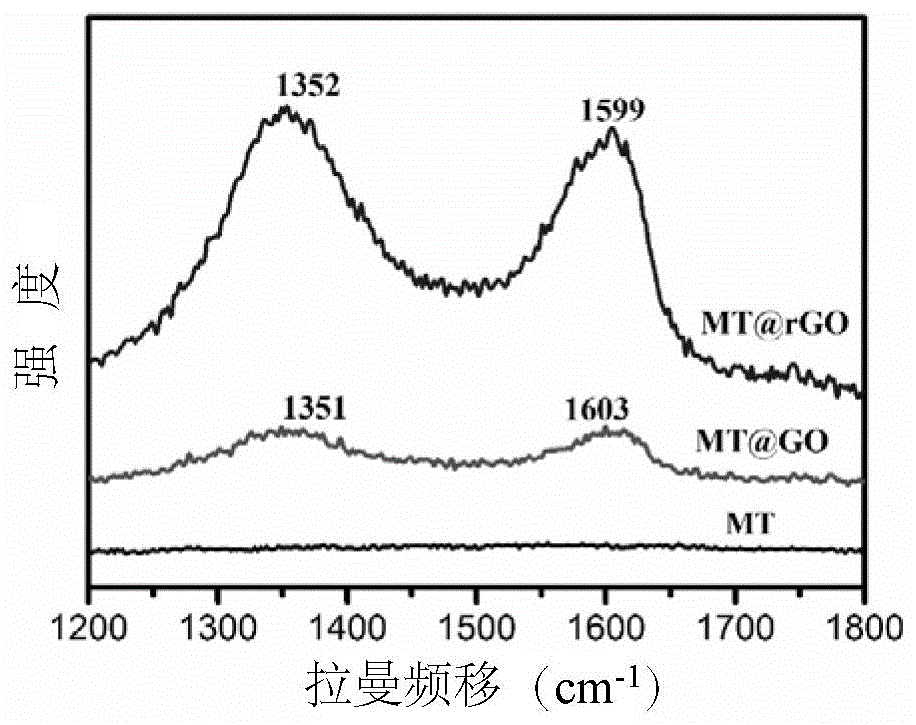

Embodiment 1

[0065] Add 500mL of concentrated sulfuric acid, 10g of sodium nitrate, 60g of potassium permanganate and 10g of graphite to the reactor in turn, stir at room temperature for 5 days, add 100mL of 80°C hot water dropwise into the reactor at a constant speed, and centrifuge and wash after the heat release is complete. Until the solution is neutral, dilute to 1000mL to obtain a graphene oxide aqueous solution with a concentration of 10mg / mL, pH=6. Prepare the mica powder into a 10% suspended aqueous solution, adjust the pH to 2.0 with concentrated hydrochloric acid, heat and stir at 80°C, 2mol / L TiCl 4 The aqueous solution was added dropwise to the suspension, and NaOH solution was added dropwise at the same time to stabilize the pH value at 2. After the dropwise addition was completed, heating and stirring was continued for 2 hours, and the mica titanium pearlescent pigment was obtained by suction filtration and washing. Disperse the prepared mica titanium pearlescent pigment at ...

Embodiment 2

[0067] Add 500mL of concentrated sulfuric acid, 10g of sodium nitrate, 60g of potassium permanganate and 10g of graphite to the reactor in turn, stir at room temperature for 5 days, add 100mL of 80°C hot water dropwise into the reactor at a constant speed, and centrifuge and wash after the heat release is complete. Until the solution is neutral, dilute to 1000mL to obtain a graphene oxide aqueous solution with a concentration of 10mg / mL, pH=5. Prepare the mica powder into a 10% suspended aqueous solution, adjust the pH to 2.0 with concentrated hydrochloric acid, heat and stir at 80°C, 2mol / L TiCl 4 The aqueous solution was added dropwise to the suspension, and NaOH solution was added dropwise at the same time to stabilize the pH value at 1.5. After the dropwise addition was completed, heating and stirring was continued for 2 hours, and the mica titanium pearlescent pigment was obtained by suction filtration and washing. Ultrasonic disperse 10 g of the obtained powder in an aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com