Cobalt-based catalyst reduction processing method used for Fischer-Tropsch synthesis

A cobalt-based catalyst and Fischer-Tropsch synthesis technology, applied in the field of coal chemical industry, can solve the problems of large influence on reaction performance, growth of catalyst particles, decline in catalyst activity, etc., to promote high dispersion, mild and controllable reduction conditions, and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

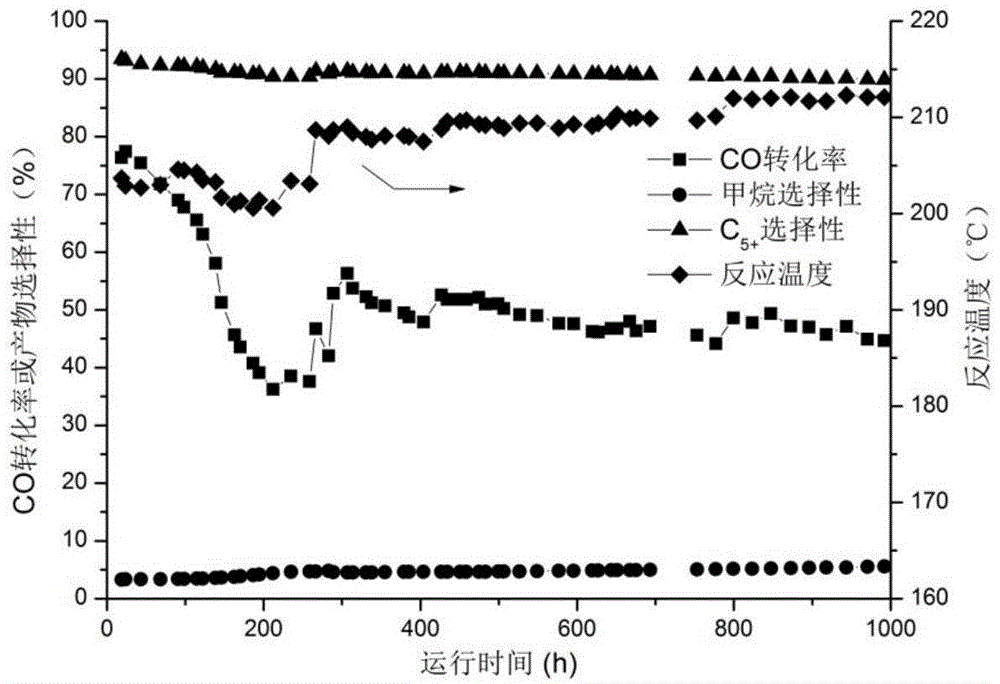

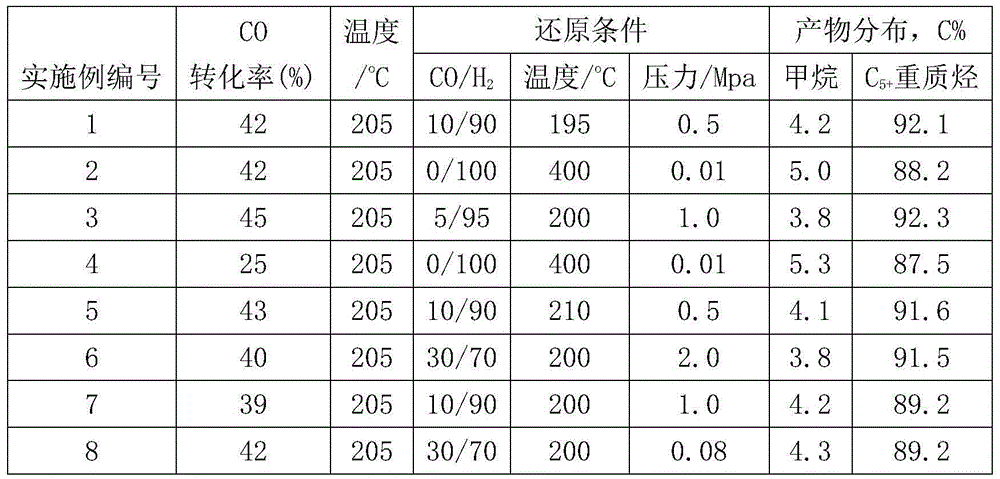

Embodiment 1

[0016] Co / ZrO after calcination 2 -SiO 2 Catalyst (300 DEG C, sieving to obtain particle diameter is 40~60 orders, 1.2g, wherein Co content is 20wt%, Zr content is 5%, and the remainder is SiO 2 ) mixed with quartz sand evenly, filled into an isothermal reactor, and pretreated with atmospheric hydrogen at 220°C and a space velocity of 2000kg / (h.L) for 24 hours; then the gas was switched to 10% CO and 90% H 2 Adjust the temperature to 195°C, adjust the pressure to 0.5MPa, keep the space velocity at 4000kg / (h.L), and reduce for 24h. CO and H in the mixed gas 2 The molar ratio is switched to 1:2, the temperature is adjusted to 205°C, the pressure is adjusted to 3.0MPa, the space velocity is adjusted to 3000kg / (h.L), and the Fischer-Tropsch synthesis reaction is carried out. The reaction results are shown in Table 1, and the performance curve of the catalyst is shown in figure 1 .

Embodiment 2

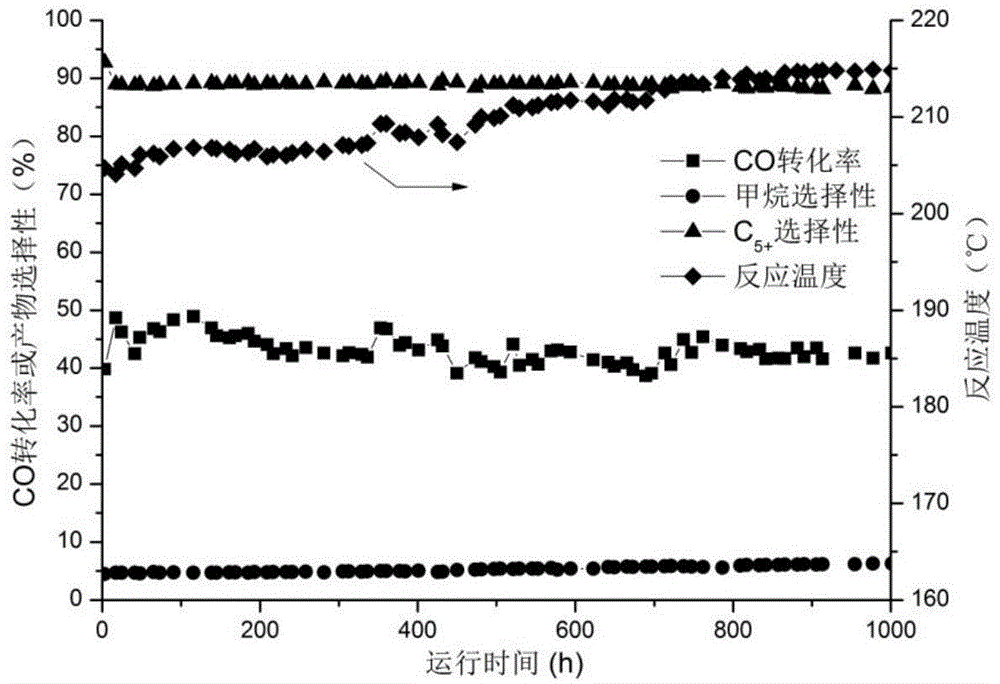

[0018] Co / ZrO after calcination 2 -SiO 2 Catalyst (300 DEG C, sieving to obtain particle diameter is 40~60 orders, 1.2g, wherein Co content is 20wt%, Zr content is 5%, and the remainder is SiO 2 ) mixed with quartz sand evenly, filled into the isothermal reactor, first pretreated with atmospheric hydrogen at 220°C and space velocity of 2000kg / (h.L) for 24h, then gradually raised the temperature to 400°C, and kept the space velocity at 4000kg / (h.L), reduction for 24h. CO and H in the mixed gas 2 The molar ratio is switched to 1:2, the temperature is adjusted to 205°C, the pressure is adjusted to 3.0MPa, the space velocity is adjusted to 3000kg / (h.L), and the Fischer-Tropsch synthesis reaction is carried out. The reaction results are shown in Table 1, and the performance curve of the catalyst is shown in figure 2 . control figure 1 and figure 2 It can be seen that compared with the catalyst (embodiment 2) processed by the low-temperature pressurized reduction procedure ...

Embodiment 3

[0020] Co / ZrO after calcination 2 -TiO 2 Catalyst (300 DEG C, sieving to obtain particle diameter is 40~60 orders, 1.2g, and wherein Co content is 20wt%, Zr content is 5%, and remainder is TiO 2 ) mixed with quartz sand evenly, packed into an isothermal reactor, and pretreated with atmospheric hydrogen at 220°C and a space velocity of 2000kg / (h.L) for 24 hours; then the gas was switched to 5% CO and 95% H 2 Adjust the temperature to 200°C, adjust the pressure to 1.0MPa, keep the space velocity at 4000kg / (h.L), and reduce for 24h. CO and H in the mixed gas 2 The molar ratio was switched to 1:2, the temperature was adjusted to 205°C, the pressure was adjusted to 3.0MPa, the space velocity was adjusted to 3000kg / (h.L), and the Fischer-Tropsch synthesis reaction was carried out. The reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com