Dynamic clean maintenance system and method for high power terminal optical system

An optical system and high-power technology, applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problem of not being able to effectively guarantee the cleanliness of the terminal optical components and even the terminal cavity, and the surface of the optical components Issues not effectively addressed, limiting drive load capacity and high throughput operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

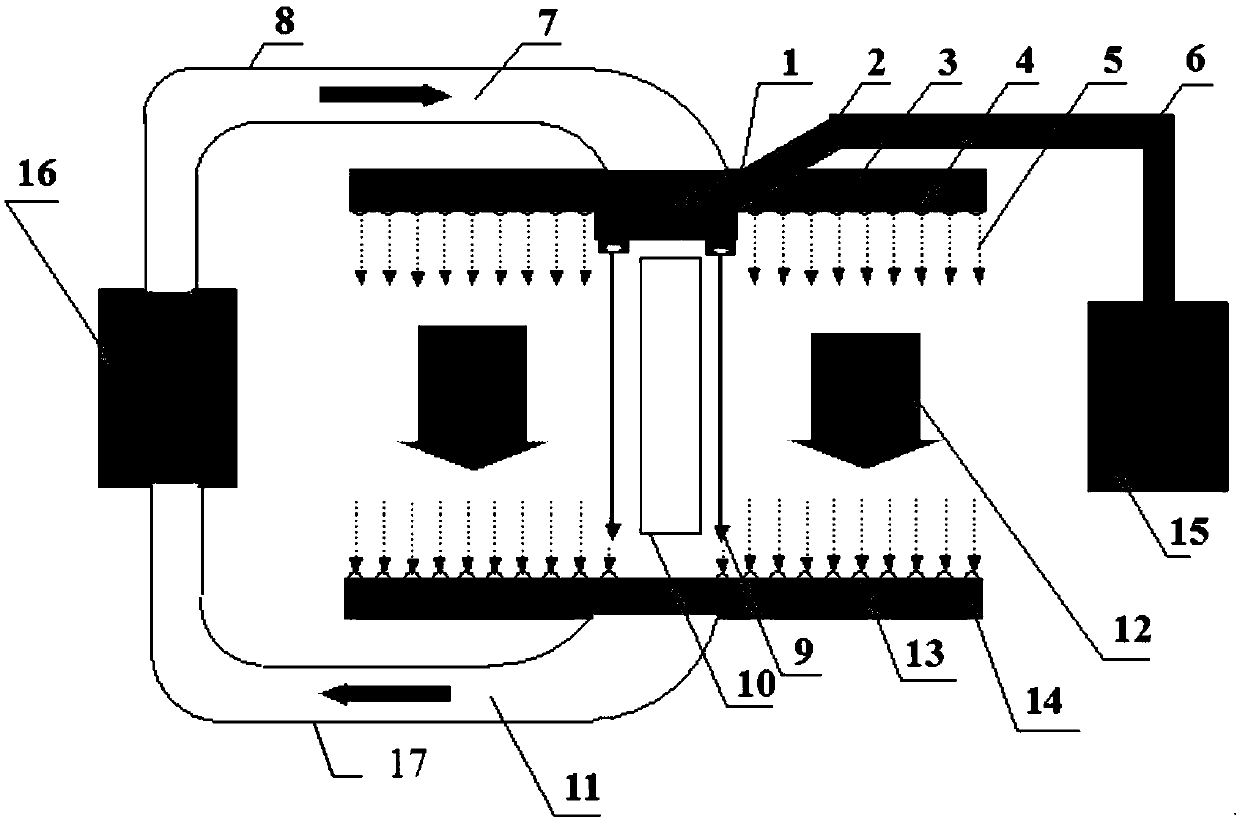

[0030] Such as figure 1 Shown is a schematic diagram of a dynamic cleanliness maintenance system for a high-power terminal optical system, wherein the optical element (10) in the single-beam terminal optical system is a frequency-doubled crystal element, and the optical element (10) is located in the terminal optical Inside the cavity of the system, between the fundamental frequency window and the frequency tripler crystal, the element size is 430mm. In practical applications, due to laser ablation during laser targeting, a large amount of high-speed moving dust and aerosol pollutants will be formed in the cavity of the terminal optical system. A vortex will form nearby, causing dust and aerosol pollutants to fail to get out of the cavity in time, and there is even a danger of adhering to the surface of the optical element.

[0031] In order to improve the use environment of the optical element (10), it will be processed by the system for maintaining dynamic cleanliness of th...

Embodiment 2

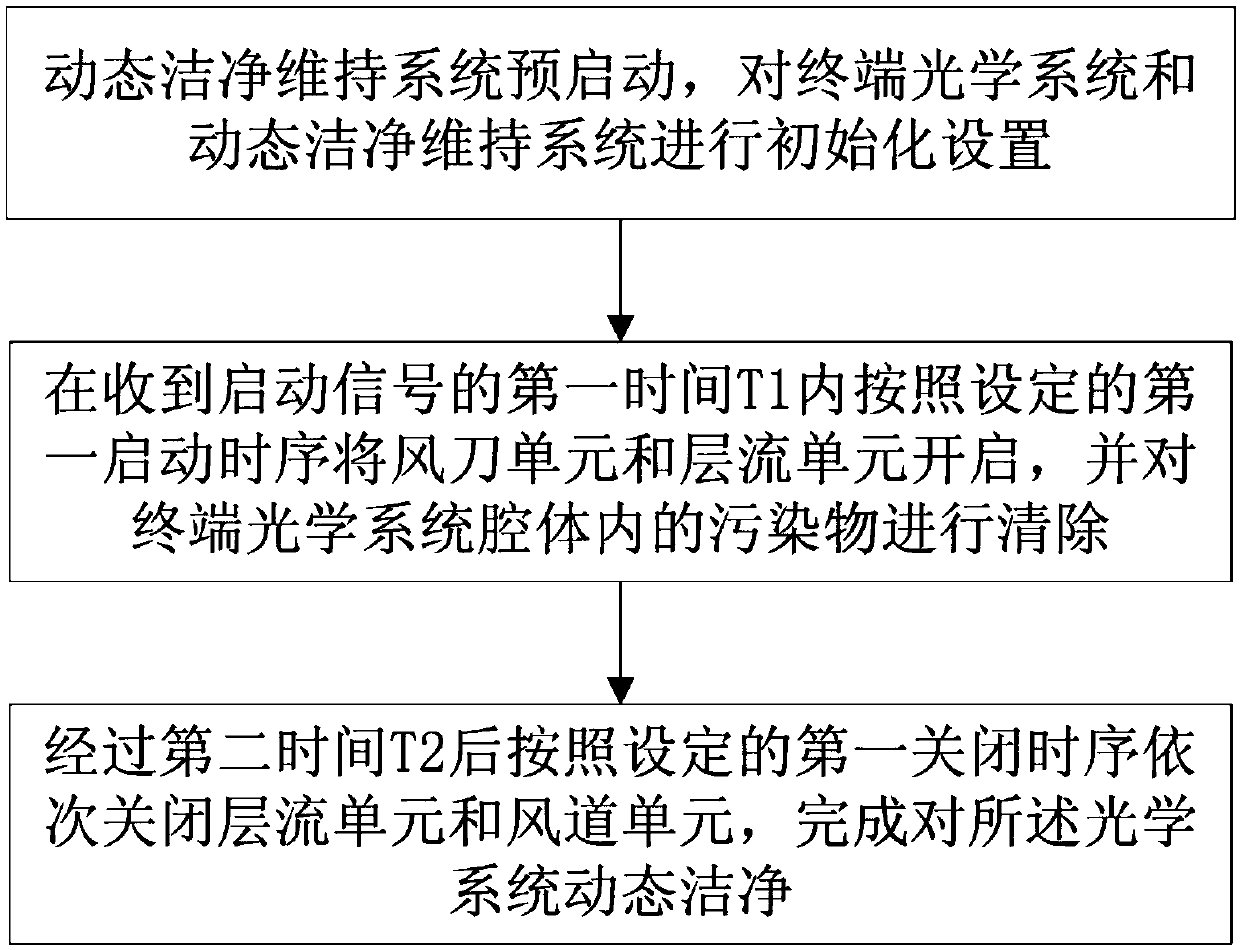

[0042] This embodiment is a method for maintaining dynamic cleanliness of high-power terminal optical systems. The method is implemented based on any of the aforementioned dynamic cleanliness maintenance systems for terminal optical systems, such as figure 2 As shown, the specific implementation steps of the method are as follows:

[0043] Step S1, the dynamic cleanliness maintenance system is pre-started, the terminal optical system and the dynamic cleanliness maintenance system are initialized, and the laminar flow unit is opened in a small cycle according to the set pre-startup operation;

[0044] According to the 430mm caliber of the optical element and the limitation of the use angle, the size of the pollutants to be cleaned and purged is on the order of microns, and the optical design of the coupled terminal system, it is determined that the distance between the double frequency crystal and the front and rear elements must not be less than 100mm. At the same time, in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com