A kind of high texture automobile interior material and preparation method thereof

A car interior and texture technology, applied in the field of materials, can solve the problems of floating fibers, rough surface of parts, and unsatisfactory car interior parts, etc., and achieve the effect of uniform dispersion, low gloss, and excellent appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

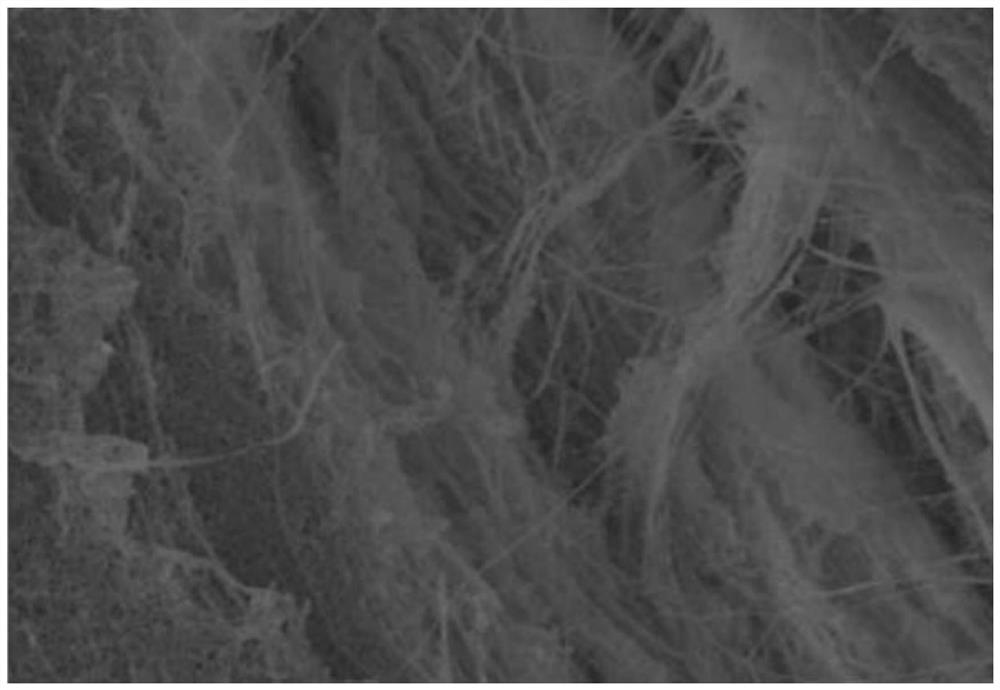

Image

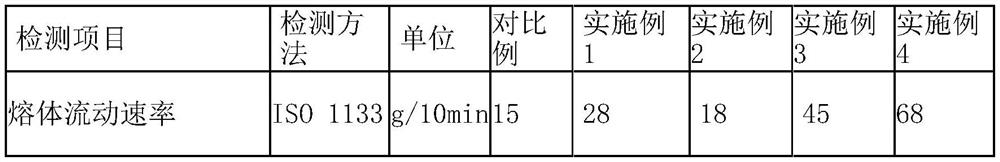

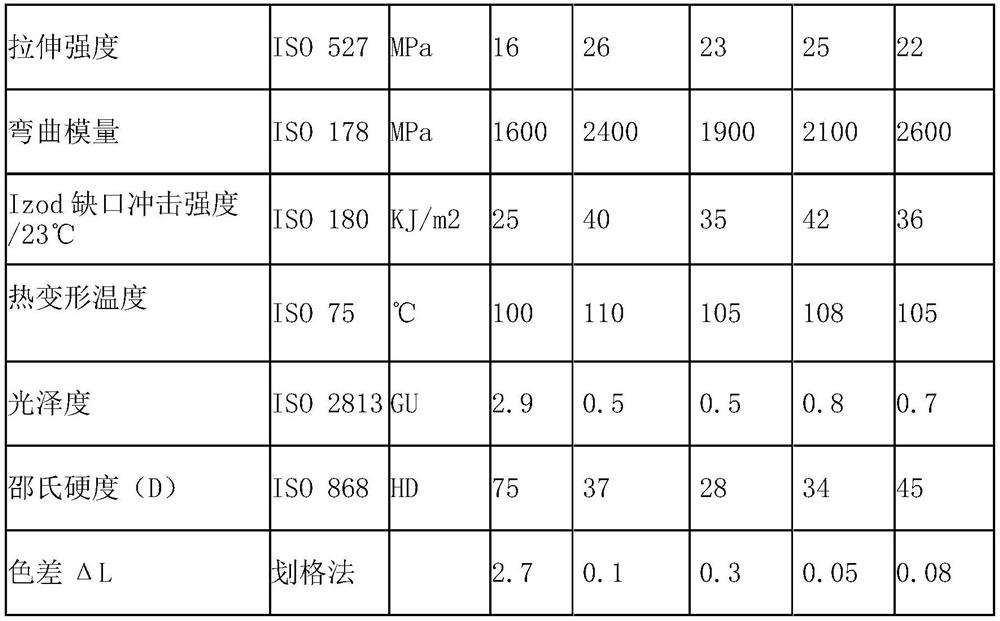

Examples

Embodiment 1

[0035] A method for preparing a high-quality automotive interior material, comprising the following steps:

[0036] Step 1: Add 40 parts of polypropylene with a melt index of 30g / 10min, 25 parts of PET, 5 parts of ethylene-acrylic acid copolymer, 1 part of antioxidant 168, 1 part of silicone, and 1 part of light stabilizer 3808 into the mixer Mix in medium for 1-3 minutes, then add the mixed material into the twin-screw extruder, undergo plasticization, strong shear dispersion, extrusion, stranding, air-drying, and granulation; wherein, after the material exits the die of the extruder, Using high-speed stretching method, the stretching speed is 3000r / min, so that the ratio of material diameter to die diameter is equal to 1:40, and at the same time, it quickly enters the cooling water tank, cools and shapes, and obtains oriented fiber reinforced polypropylene composite material; twin-screw extruder Cylinder temperature 180-280 ℃.

[0037] Step 2: Put the oriented fiber-forming...

Embodiment 2

[0040] A method for preparing a high-quality automotive interior material, comprising the following steps:

[0041] Step 1: 70 parts of polypropylene with a melt index of 60g / 10min, 10 parts of polyamide 6, 2 parts of ethylene-acrylic acid copolymer, 1 part of antioxidant 1098, 0.2 parts of ethylene bisstearamide, light stabilizer Add 0.3 parts of 3808 into the mixer and mix for 1-3 minutes, then add the mixed material into the twin-screw extruder, and undergo plasticization, strong shear dispersion, extrusion, stranding, air-drying, and granulation; among them, the material comes out After the die of the extruder, the high-speed stretching method is adopted, and the stretching speed is 1500r / min, so that the ratio of the diameter of the material to the diameter of the die is equal to 1: 20, and at the same time, it quickly enters the cooling water tank, cools and shapes, and obtains oriented fiber-reinforced polypropylene composite. Materials; Twin-screw extruder barrel tempe...

Embodiment 3

[0045] A method for preparing a high-quality automotive interior material, comprising the following steps:

[0046] Step 1: 60 parts of polypropylene with a melt index of 20g / 10min, 20 parts of polyamide 66, 8 parts of vinyl chloride-acrylate copolymer, 1 part of antioxidant 168, 0.6 part of silicone, and 0.4 part of light stabilizer 3808 Add it into the mixer and mix for 1-3min, then add the mixed material into the twin-screw extruder, go through plasticization, strong shear dispersion, extrusion, drawing, air-drying, and granulation; among them, the material comes out of the extruder After the die, the high-speed drawing method is adopted, and the drawing speed is 2500r / min, so that the ratio of the diameter of the material to the diameter of the die is equal to 1:30. The barrel temperature of the screw extruder is 180-280°C.

[0047] Step 2: Put the oriented fiber-forming polypropylene composite material obtained in Step 1, 8 parts of SEBS, 5 parts of whiskers, and 5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com