Polyquaternium antistatic agent and preparation method thereof

A technology of antistatic agent and polyquaternium, which is applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of complex follow-up processing, low product purity, long reaction time, etc., and reduce gelation, chain The effect of smooth response and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

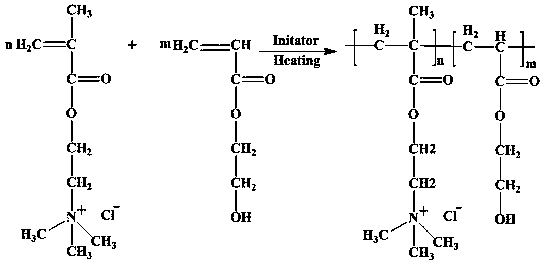

Method used

Image

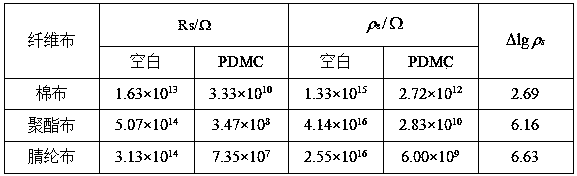

Examples

Embodiment 1

[0030] (1) Weigh 3.5kg of DMC monomer, 0.5kg of HEA monomer and 6kg of water into the reactor and make initial monomer DMC and HEA solutions, the mass fractions are 35% and 5% respectively;

[0031] (2) Open the nitrogen valve, remove the air in the reaction bottle at a nitrogen rate of 600 mL / min, and reduce the nitrogen rate to 50 mL / min after 30 minutes;

[0032] (3) Weigh 0.01% of the total mass of the reaction monomer DMC and HEA Na 4 0.4g EDTA and 0.6% NaHSO 3 24g joins in the reactor;

[0033] (4) Weigh 24g of the initiator potassium persulfate KPS accounting for 0.6% of the total mass of the reaction monomer DMC and HEA and prepare a 0.05 g / ml initiator solution, heat the reaction solution to 40°C, and stir at 300 r / min Slowly add potassium persulfate (KPS) initiator solution to the reactor for 1 hour (drop rate 8 mL / min). After adding the initiator, keep the temperature and react for 2 hours;

[0034] (5) Raise the temperature at 1°C / min to 65°C, stir at a rate of...

Embodiment 2

[0038] (1) Weigh 2.5kg of DMC monomer, 0.25kg of HEA monomer and 7.25kg of water into the reactor and make initial monomer DMC and HEA solutions, the mass fractions are 25% and 2.5% respectively;

[0039] (2) Open the nitrogen valve, remove the air in the reaction bottle at a nitrogen rate of 600 mL / min, and reduce the nitrogen rate to 50 mL / min after 30 minutes;

[0040] (3) Weigh 0.05% of the total mass of the reaction monomer DMC and HEA Na 4 EDTA 1.375g and 2% NaHSO 3 55g joins in the reactor;

[0041] (4) Weigh 41.25g of the initiator potassium persulfate KPS accounting for 1.5% of the total mass of the reaction monomer DMC and HEA and prepare a 0.25g / ml initiator solution, heat the reaction solution to 50°C, and stir at 300 r / min Evenly add potassium persulfate (KPS) initiator solution to the reactor, the addition time is 1 hour (drop rate 2.8 mL / min), after adding the initiator, keep the temperature and react for 1.5 hours;

[0042] (5) Raise the temperature to 70 ℃ ...

Embodiment 3

[0046] (1) Weigh 1.5kg of DMC monomer, 0.1kg of HEA monomer and 8.4kg of water into the reactor and make initial monomer DMC and HEA solutions, the mass fractions are 15% and 1% respectively;

[0047] (2) Open the nitrogen valve, remove the air in the reaction bottle at a nitrogen rate of 600 mL / min, and reduce the nitrogen rate to 50 mL / min after 30 minutes;

[0048] (3) Weigh 0.1% of the total mass of the reaction monomer DMC and HEA Na 4 EDTA 1.6g and 4% NaHSO 3 64g joins in the reactor;

[0049] (4) Weigh 48g of potassium persulfate KPS, an initiator accounting for 3% of the total mass of the reaction monomer DMC and HEA, and prepare a 0.5 g / ml initiator solution, raise the temperature of the reaction solution to 50°C, and stir at 300 r / min Properly add potassium persulfate (KPS) initiator solution to the reactor for 1 hour (dropping rate 1.6 mL / min). After adding the initiator, keep the temperature and react for 1 hour;

[0050] (5) Raise the temperature at 1°C / min to 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com