Processing and production process of shampoo containing sakura moisturizing component

A production process and shampoo technology, applied in the directions of medical preparations containing active ingredients, hair care, skin care preparations, etc., can solve the problems of clogging pores, large molecular weight, redness and inflammation, etc. , The effect of moisturizing damaged hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

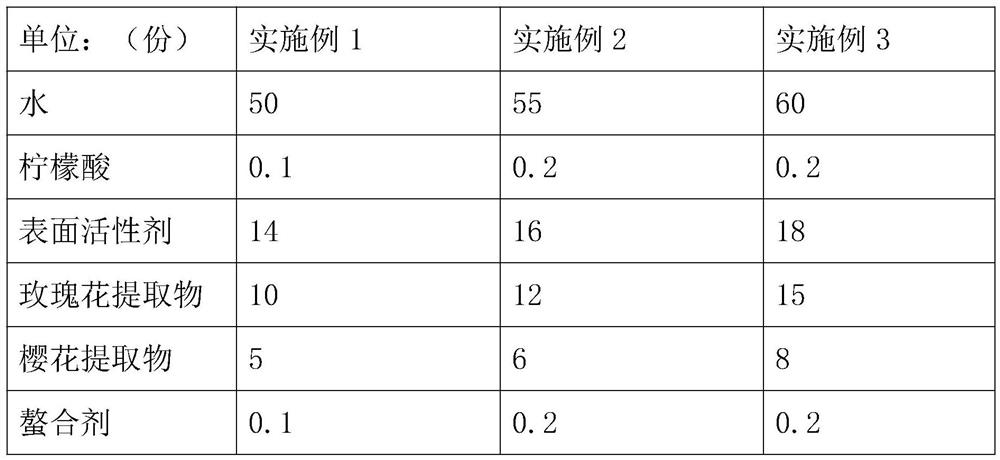

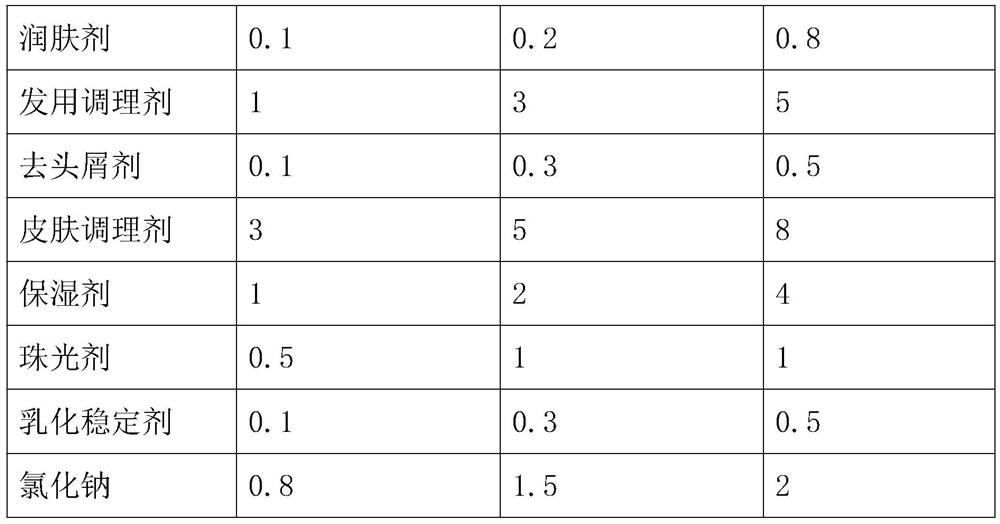

[0029] A shampoo containing cherry blossom moisturizing ingredients, its quality components include: 50-60 parts of water, 0.1-0.2 parts of citric acid, 14-18 parts of surfactant, 10-15 parts of rose flower extract, cherry blossom extract 5-8 parts, 0.1-0.2 parts of chelating agent, 0.1-1.0 parts of emollient, 1-5 parts of hair conditioner, 0.1-0.5 part of anti-dandruff agent, 3-8 parts of skin conditioner, 1- 4 parts, 0.5-1 part of pearlescent agent, 0.1-0.5 part of emulsion stabilizer, 0.8-2 part of sodium chloride.

[0030] Specifically, the shampoo contains dispersed particles dispersed in the water, the average particle diameter of the dispersed particles is below 145nm, and the average particle diameter of the dispersed particles is above 8nm, the amount of the dispersed particles is relative to the The total mass of the shampoo is 1.5% by mass or less.

[0031] Specifically, the surfactant includes sodium lauroyl sarcosinate and potassium cocoyl glycinate, and the surf...

Embodiment 2

[0049] The difference with embodiment 1 is:

[0050] The present invention also provides a processing and production process for shampoo containing cherry blossom moisturizing ingredients, comprising the following steps:

[0051] S1, respectively prepare 12 parts of rose extract and 6 parts of cherry blossom extract, add 55 parts of water, stir, slowly add 1 part of hair conditioner, disperse until there are no particles, add 0.2 parts of citric acid, and stir until uniform;

[0052] S2, mix 8 parts of surfactant, 0.2 part of chelating agent, 0.2 part of emollient, 0.15 part of anti-dandruff agent, 2.5 parts of skin conditioner and 1 part of hair conditioner, heat to 40-65 ° C, stir Dissolve; then add the solution obtained in step S1, stir evenly, heat to 70-85°C, and keep stirring for 0.5-1 hour;

[0053] S3, cooling the solution treated in the above step S2 to 50-65°C, adding 8 parts of surfactant and 0.15 part of anti-dandruff agent, stirring until uniform, and cooling to ...

Embodiment 3

[0056] The difference with embodiment 1 is:

[0057] The present invention also provides a processing and production process for shampoo containing cherry blossom moisturizing ingredients, comprising the following steps:

[0058] S1, respectively prepare 15 parts of rose extract and 8 parts of cherry blossom extract, add 60 parts of water, stir, slowly add 1.5 parts of hair conditioner, disperse until there are no particles, add 0.2 parts of citric acid, and stir until uniform;

[0059] S2, mix 9 parts of surfactant, 0.2 part of chelating agent, 0.8 part of emollient, 0.25 part of anti-dandruff agent, 4 parts of skin conditioner and 1.5 part of hair conditioner, heat to 40-65 ° C, stir Dissolve; then add the solution obtained in step S1, stir evenly, heat to 70-85°C, and keep stirring for 0.5-1 hour;

[0060] S3, cooling the solution treated in the above step S2 to 50-65°C, then adding 9 parts of surfactant and 0.25 part of anti-dandruff agent, stirring until uniform, and coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com