Mechanical part cleaning agent

A technology of mechanical parts and cleaning agents, applied in the field of mechanical processing, can solve problems such as damage, damage to finished parts, and impact on product quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

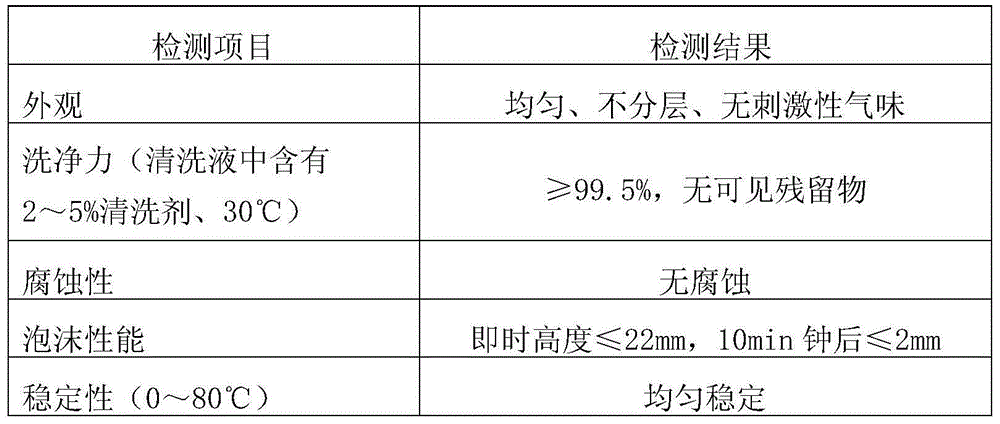

Image

Examples

example

[0010] Weigh each raw material respectively, and then mix and prepare respectively: nonionic surfactant, anionic surfactant, builder, defoamer, corrosion inhibitor, solubilizer and fatty acid; first, quantitative deionized water is heated to 50 ℃, add builder, corrosion inhibitor, defoamer, fatty acid and solubilizer in sequence under stirring and mix well, then cool to 40 ℃, then add nonionic surfactant, anionic surfactant, fluorocarbon surfactant , sodium subtilisin and N-methylpyrrolidone are stirred and mixed, and the prepared cleaning agent is a uniform and transparent liquid.

[0011] The concrete composition of cleaning agent is: the lauryl amine polyoxyethylene ether of 6 weight parts, the coconut oil fatty acid diethanolamide of 1.5 weight parts, the lauryl betaine of 2.4 weight parts, the lauryl betaine of 1.2 weight parts Glucoside, the sodium dodecylbenzenesulfonate of 3 parts by weight, the Na-CP of 2.5 parts by weight 4 , 0.12 parts by weight of sodium metasilic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com