Manufacturing method of antifouling sofa fabric

A production method and anti-fouling technology, which is applied in the field of home textiles, can solve the problems of reducing the service life of sofas, not having waterproof and oil-proof anti-fouling properties, and stains and oils are not easy to clean, and achieves a significant anti-fouling effect and is not easy to absorb dust. , the effect of not easy to absorb dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

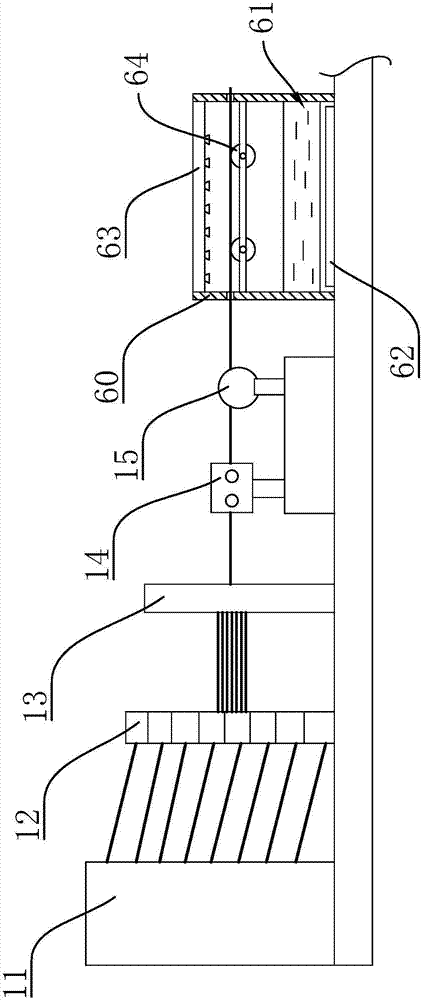

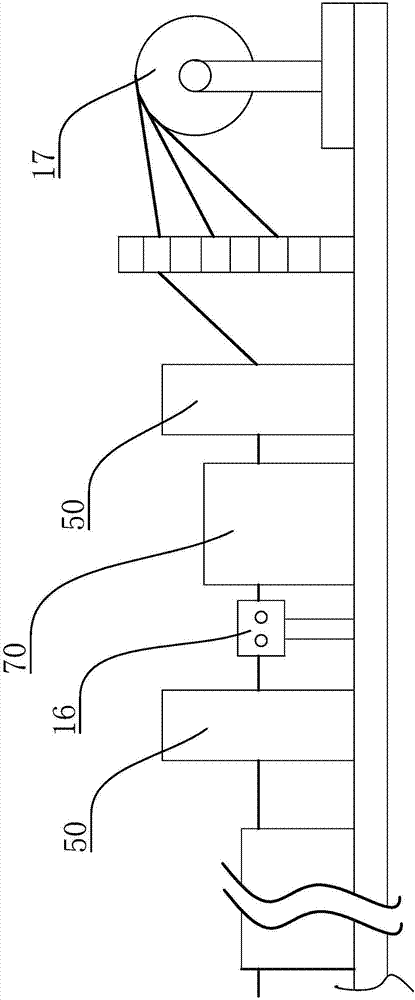

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

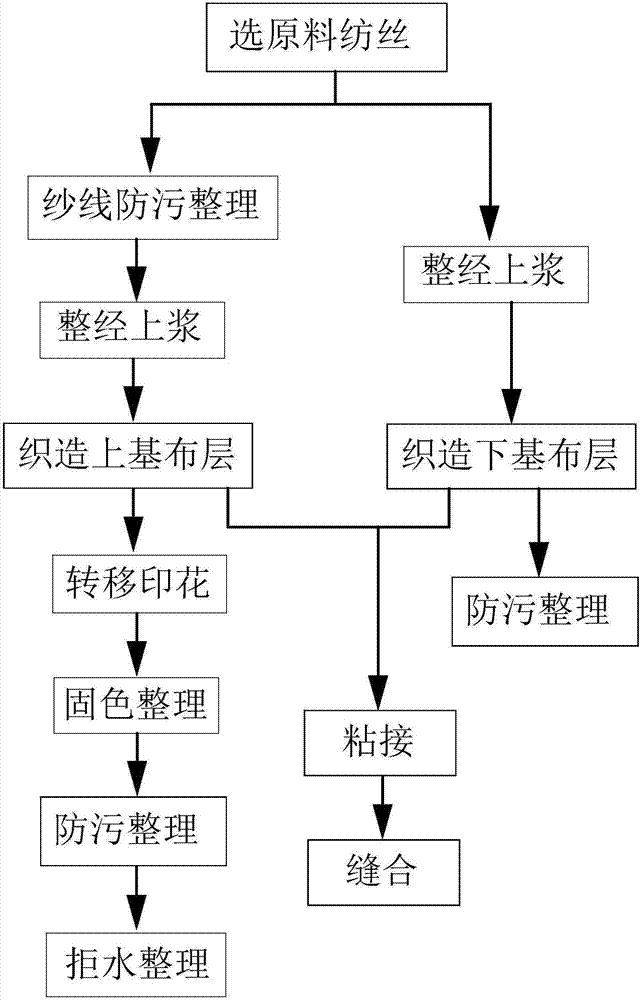

[0043] Such as Figure 1 to Figure 10 As shown, the invention provides a kind of preparation method of antifouling sofa fabric, comprises the steps:

[0044] (1) Selection of raw materials for spinning: polyester and viscose fibers are selected for blending, and the obtained polyester-viscose blended yarns are used as the first warp and first weft yarns; polyester, cotton fibers and flax fibers are selected for blending, and an appropriate amount of Silver ions or copper ions, the resulting polyester-cotton-linen blended yarn is twisted as the second warp yarn and the second weft yarn;

[0045] (2) Yarn antifouling finishing: prepare the nano antifouling agent solution, immerse the first weft yarn in the nano antifouling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com