Patents

Literature

138results about How to "Not easy to generate static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

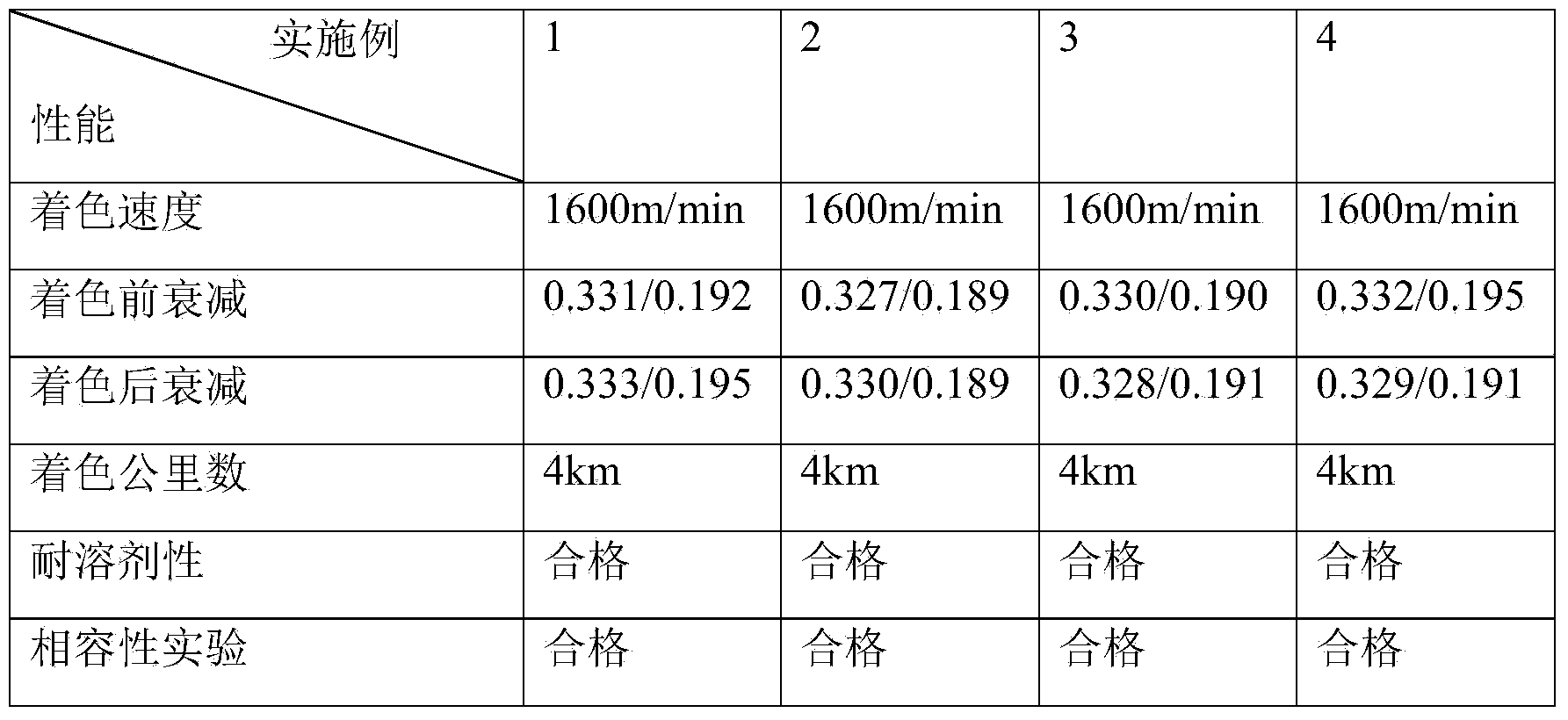

Optical fiber coloring ink with capacity of radiation curing

ActiveCN104263063ABright color does not fadeSmooth surface and good touchInksPhotoinitiatorOptical fiber cable

The invention relates to optical fiber coloring ink with capacity of radiation curing. The optical fiber coloring ink is characterized by comprising components in percentage by weight as follows: 1%-20% of color paste, 20%-40% of an activated diluent, 0.5%-4% of an auxiliary A, 40%-60% of UV resin and 3%-10% of a photoinitiator and an auxiliary initiator, and the percentage sum of the component is 100%. The optical fiber coloring ink with the capacity of radiation curing is high in curing speed and good in curing effect, an optical fiber colored by the ink has bright color and luster and smooth surface, is fadeless, touches good, and can be effectively distinguished in darker light.

Owner:武汉长盈鑫科技有限公司

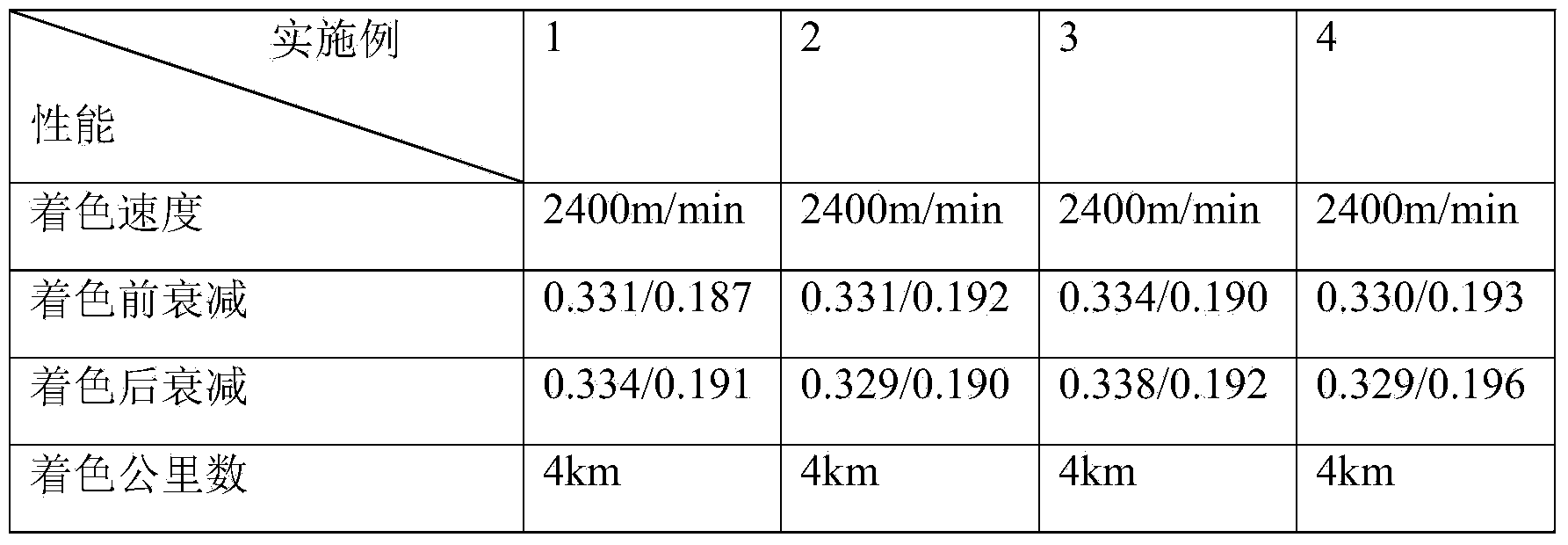

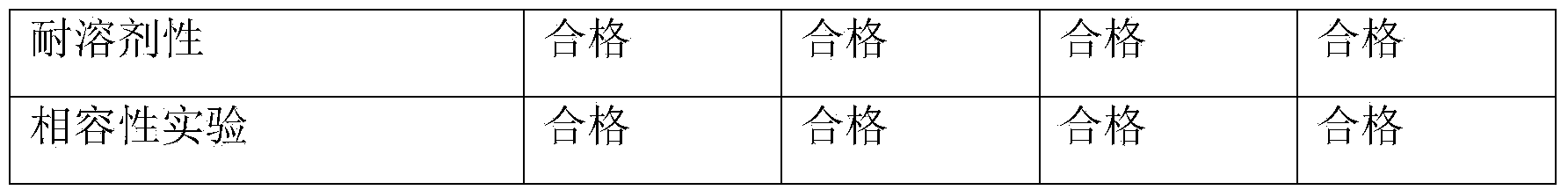

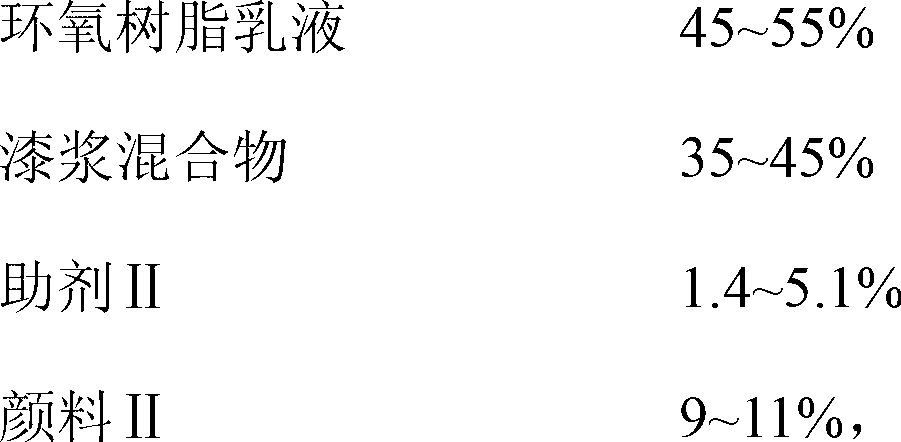

Waterborne epoxy conductive paint and preparation method thereof

ActiveCN102993903AImprove conductivityLow resistivityEpoxy resin coatingsElectrically-conductive paintsEpoxyEmulsion

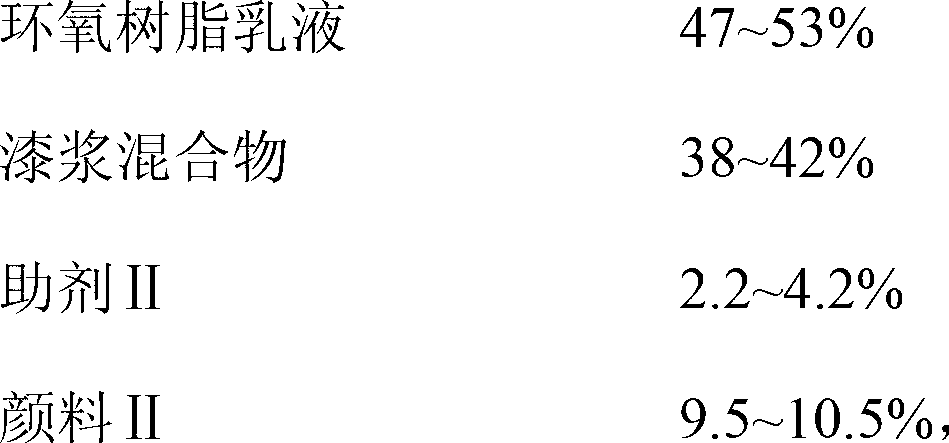

The invention discloses a waterborne epoxy conductive paint. The waterborne epoxy conductive paint mainly comprises a component A and a component B, wherein the component A comprises the following components in percentage by weight: 45%-55% of epoxy resin emulsion, 5%-45% of mill base mixture, 1.4%-5.1% of auxiliary agent II and 9%-11% of pigment II, and the sum of the components is 100%, wherein the mill base mixture comprises the following components in percentage by weight: 68%-73% of pigment I, 1.3%-4.6% of auxiliary agent I, 0.2%-0.6% of conductive agent and the balance of water; and the component B comprises a curing agent and an emulsifying agent. The waterborne epoxy conductive paint disclosed by the invention has the advantages of good conductibility, acid resistance, alkali resistance, heat resistance and chemical resistance, and can prevent the static accumulation inside an oil tank.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Production method of antifouling sofa fabric

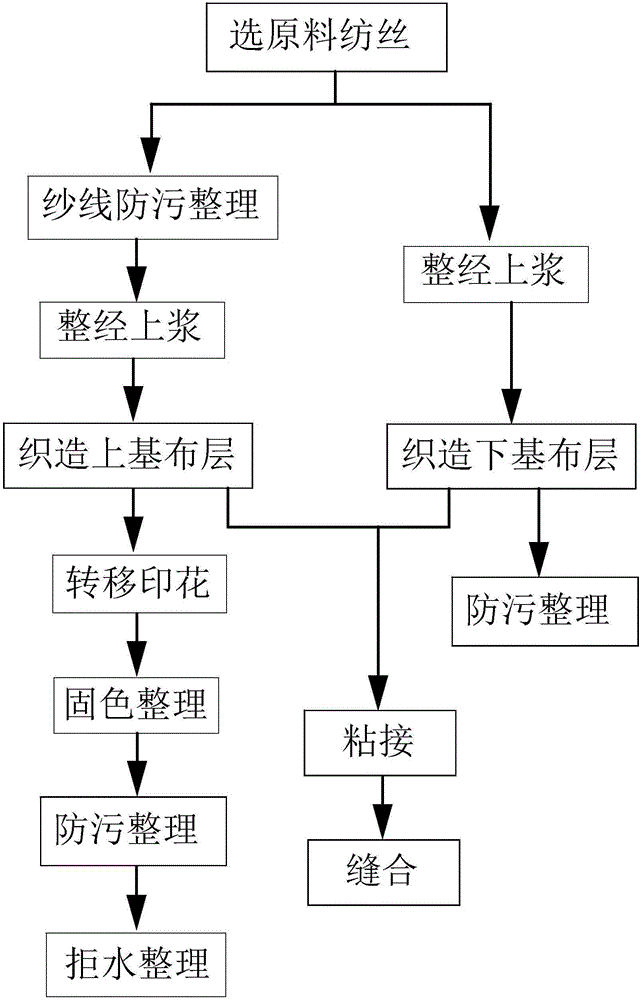

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

Surface-modified microcrystalline cellulose and preparation method thereof

The invention discloses surface-modified microcrystalline cellulose and a preparation method thereof, and belongs to the field of adjuvant preparation. The preparation method includes the steps that an inorganic acid solution is prepared for use; plant fiber is cut into proper dices for use; the inorganic acid solution is added into a reaction device, stirring is started, the plant fiber is put in and continuously stirred, a heating system is started to heat the solution till the solution nearly boils, and a heat preservation reaction is performed for certain time; a product formed after the reaction is filtered, and a filter cake is washed till the washing water is nearly neutral; pure water is added into a mixing device, stirring is started, polyethylene glycol is put in and stirred for 30 min, the materials are added into the mixing device, stirring continues to be performed for 60 min, and white uniform slurry is obtained; spray drying equipment is started for spray drying, and then the surface-modified microcrystalline cellulose product is obtained. The technology is simple, large-scale production is easy, and the obtained product is good in redispersibility and can be evenly dispersed in water more easily; the product is not likely to produce static and is better in formability.

Owner:ANHUI SUNHERE PHARMA EXCIPIENTS

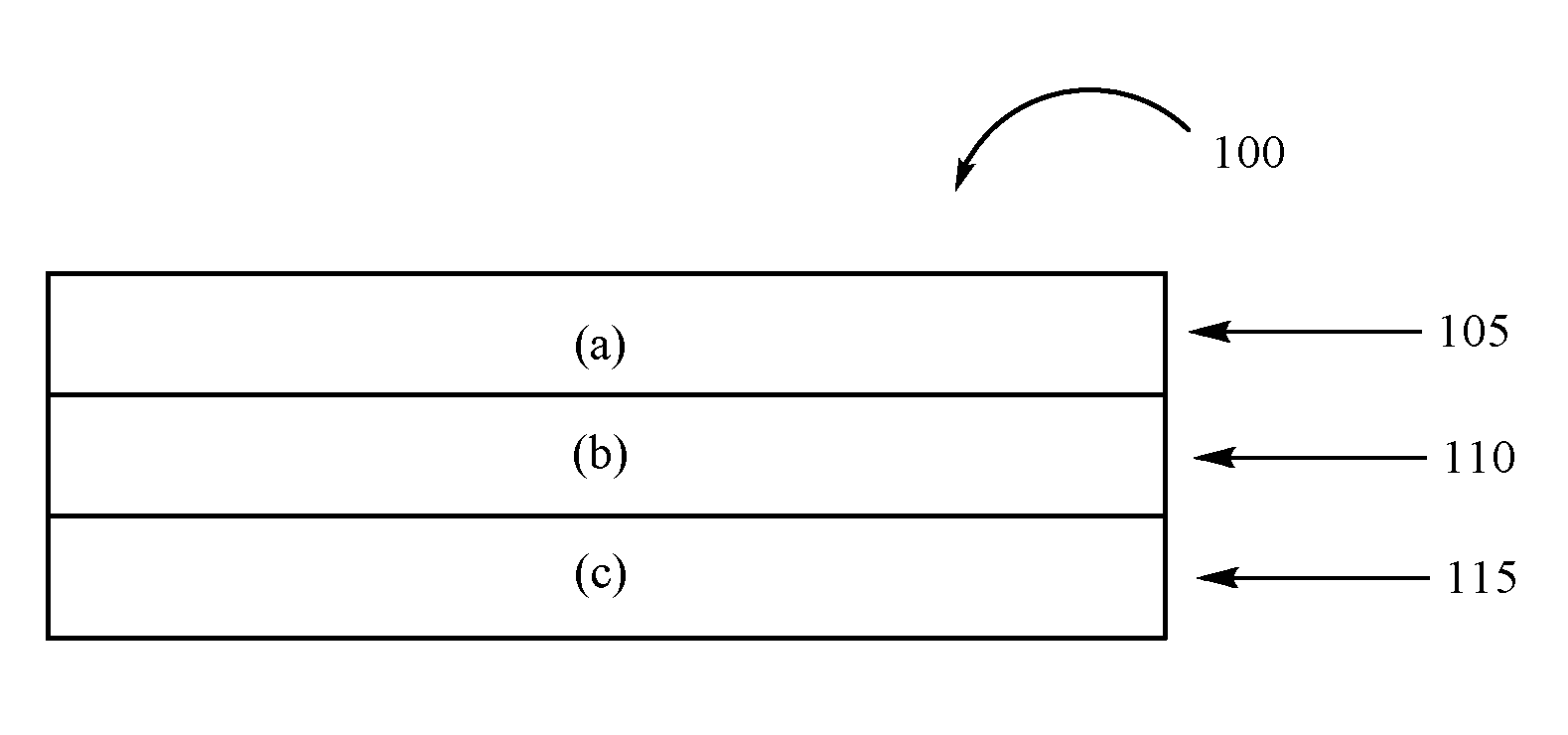

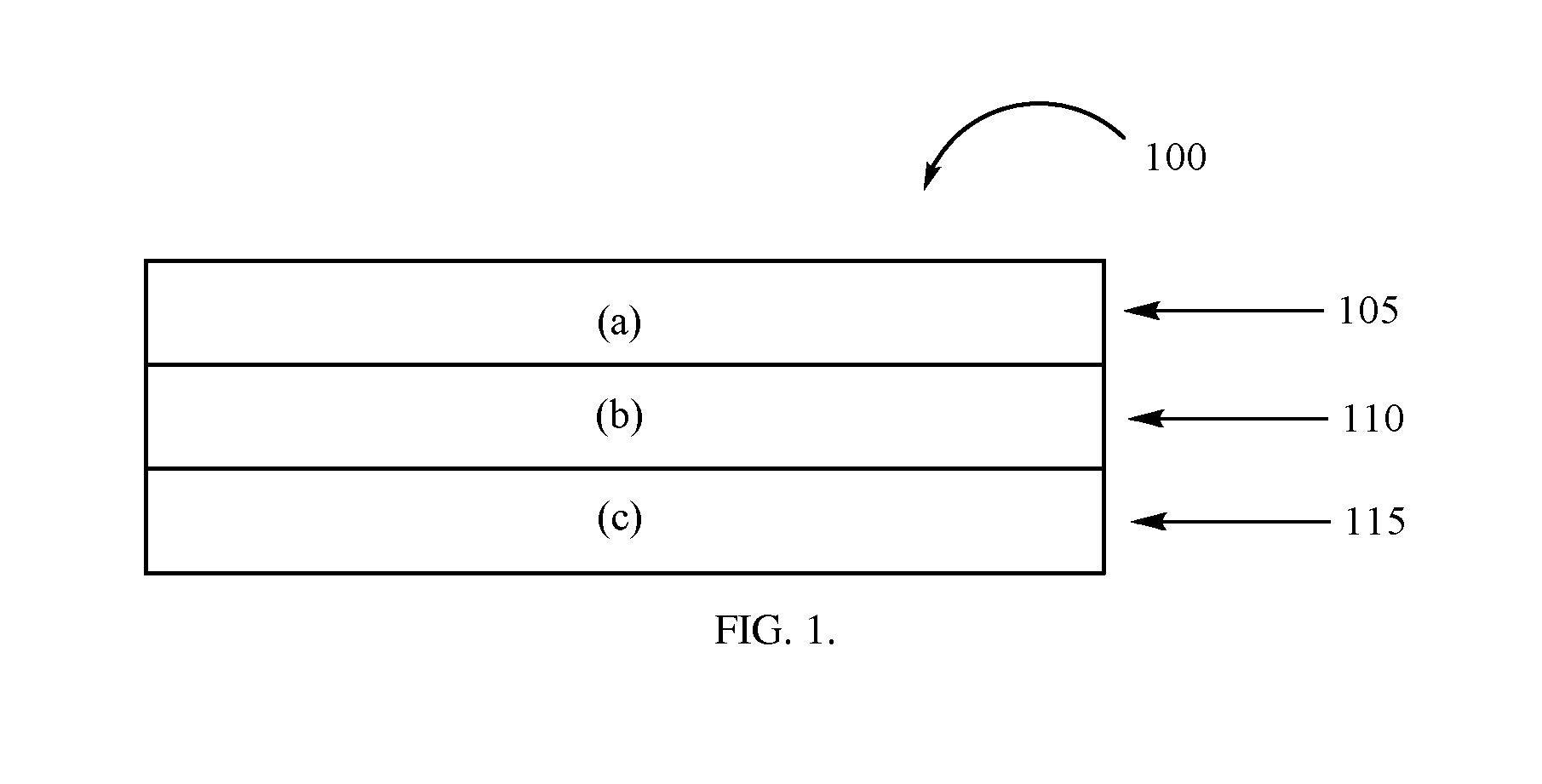

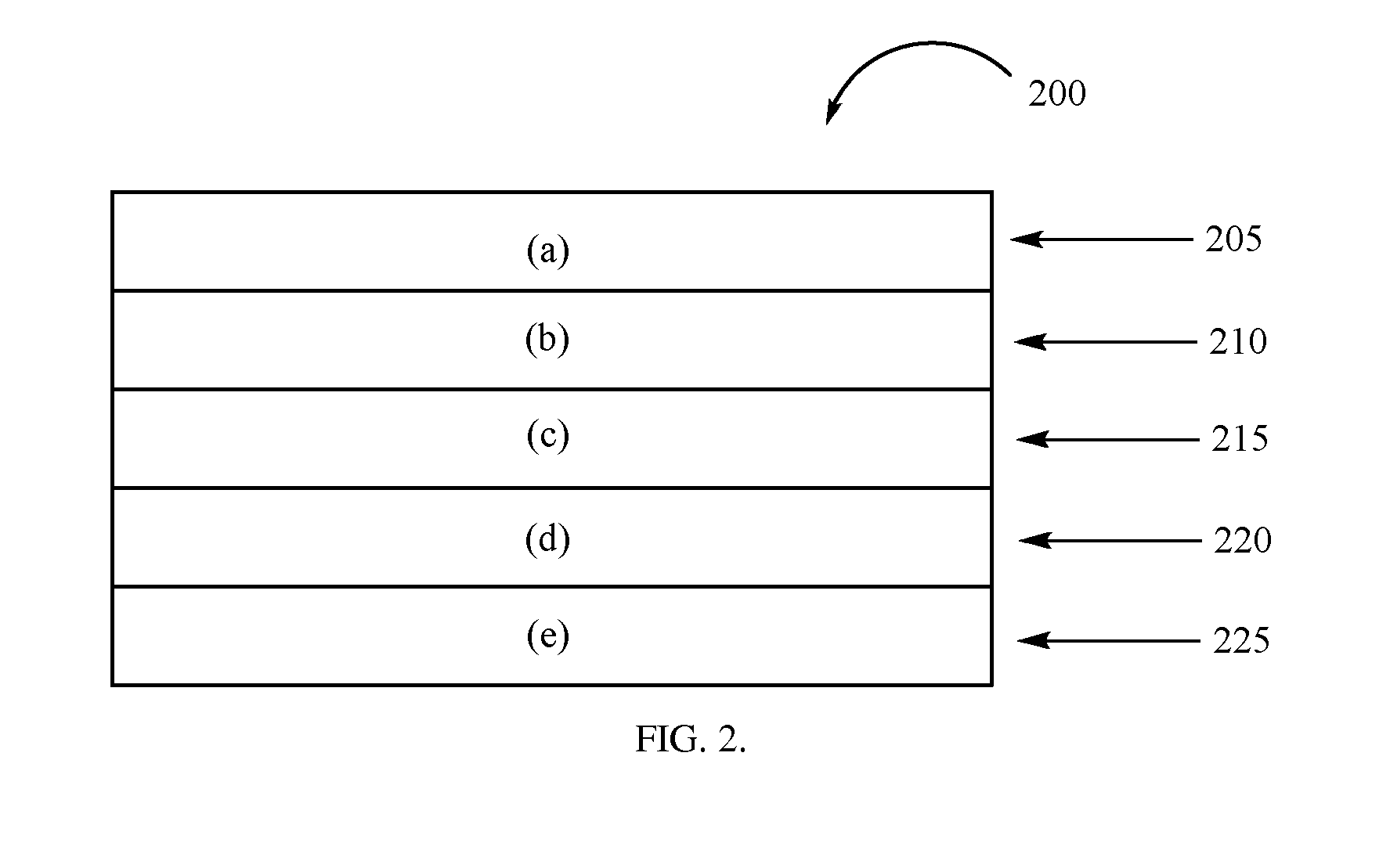

Multilayered structure and balloon including the same

InactiveUS20150336652A1High strengthHigh tensile strengthSynthetic resin layered productsDomestic containersNorborneneCyclo olefin polymer

Various embodiments of the present invention relate to a multilayered structure and balloon including the same. In various embodiments, the present invention provides a multilayered structure including at least one A layer (a) including a linear olefin polymer or copolymer, at least one B layer (b) including a cyclic olefin polymer or copolymer, and at least one A layer (c) including a linear olefin polymer or copolymer. The cyclic olefin polymer or copolymer of the at least one B layer is a polymer or copolymer of a substituted or unsubstituted norbornene.

Owner:VIAFLEX INC

Wool oil for production of fibers

The invention discloses wool oil for production of fibers. The wool oil is prepared by components including, by weight, 40-60 parts of spindle oil, 2-4 parts of lauryl polyoxyethylene ether (9), 1-2 parts of cocoyl methyl diethanolamine, 0.5-1 part of dimethyl silicone fluid, -805-10 parts of tweens, 1-2 parts of N,N-dimethyldodecylamine-N-oxide sol, 1-3 parts of sodium oleate, 1-3 parts of triethanolamine, 1-3 parts of glycerol and 0.5-1.5 parts of monododecyl potassium quercetin phosphate. The wool oil for production of fibers is capable of smoothing fibers and enabling the fibers to be soft and antistatic. Fibers treated by the wool oil are not easy to generate static electricity or anti-fuzzing during opening, combing, drawing and spinning, evenness and smoothness during slivering, roving and fine spinning are guaranteed, and further, fabrics knitted by the fibers treated with the wool oil are fine and smooth with neat and clear texture.

Owner:博罗县富得针织有限公司

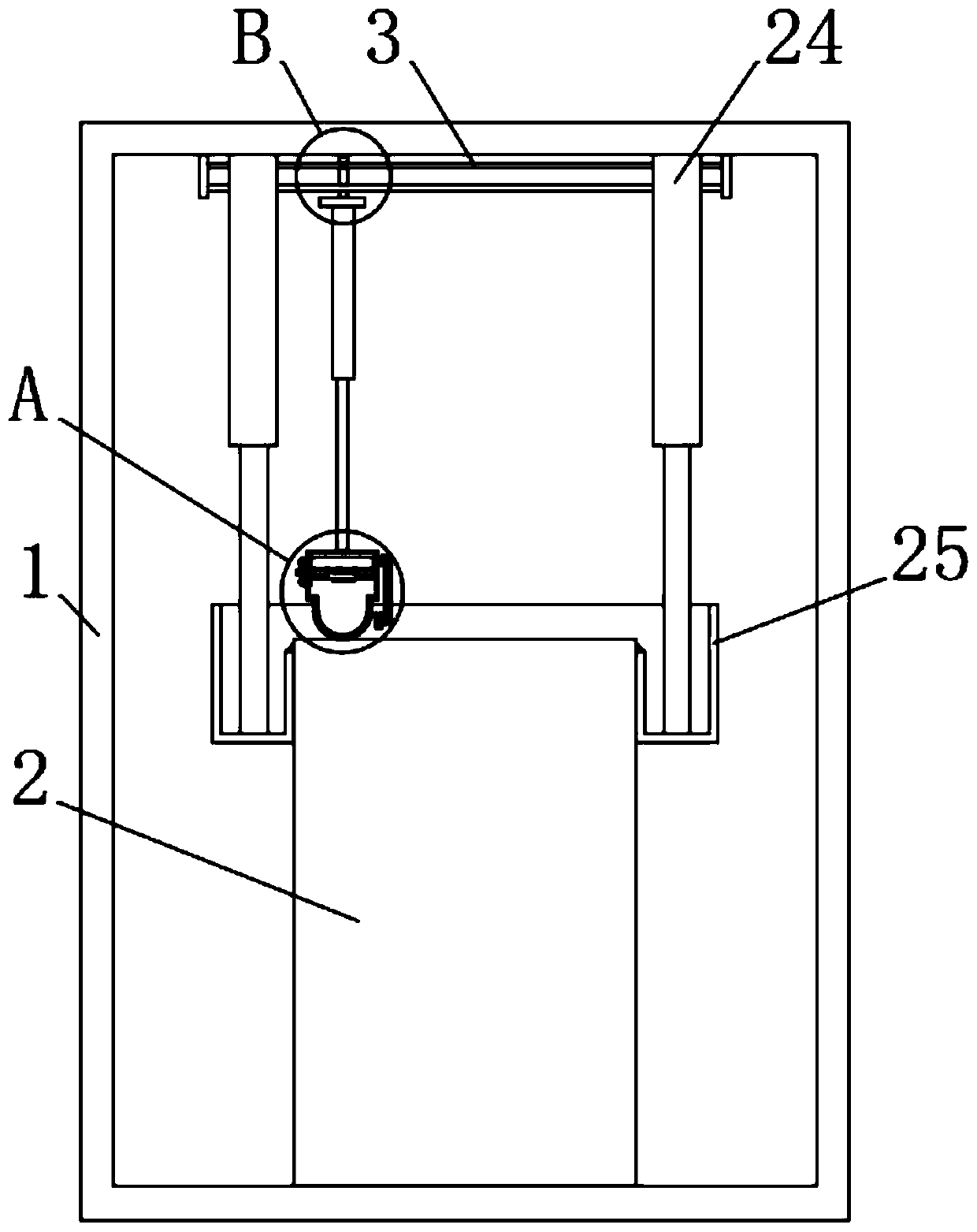

Equipment sweeping device for substation operation maintenance

ActiveCN111112157AEasy to disassembleEasy to placeDirt cleaningCleaning using toolsWater vaporDry ice

The invention discloses equipment sweeping device for substation operation maintenance, and belongs to the field of equipment maintenance. According to the equipment sweeping device for substation operation maintenance, in the scheme, a semiconductor refrigeration sheet is used for cooling the interior of a contact air bag, the contact air bag is expanded after dry ice strip sublimation, when a sponge pad sweeps the surface of a power transformation box, water steam in air encounters cold and is liquefied, accordingly, water drops are absorbed by the sponge pad, and dust is not prone to diffusion. Gas containing anti-static agent layer powder is blown to the sponge pad, the anti-static agent layer powder can be adsorbed into the sponge pad, and therefore when the power transformation box is swept, static electricity is not likely to be generated between the sponge pad and the power transformation box; and through the arrangement of a dust receiving frame, when the upper surface of thepower transformation box is swept, dust can be adsorbed by a dust absorption layer on the dust receiving frame, dust is not prone to being diffused to the side wall of the power transformation box, and the possibility of dust secondary pollution is reduced.

Owner:华普智能科技(重庆)有限公司

Multifunctional finishing liquor for cotton and linen-cotton fabrics

The invention relates to a textile finishing liquor, especially to a multifunctional finishing liquor for cotton and linen-cotton fabrics. The finishing liquor provided by the invention is prepared from the following raw materials according to the following weight part ratio: modified triazine-5: fatty alcohol: trimethylol ethylene urea: citric acid: chitosan: water =1.0-5.0:0.2-1.2:20-35:10-20:20-30:500-700. By the adoption of the multifunctional finishing liquor, fabrics are comfortable to wear; the appearance of fabrics is flat and smooth; wrinkle resistant, bacterinertness and ultraviolet resistance are obviously raised; light fastness is also improved; it is not easy to generate static electricity; and changes of mechanical properties are within an acceptable range. The multifunctional finishing liquor for cotton and linen-cotton fabrics has advantages of scientific and reasonable formula, less amount, low cost, raised production efficiency and good stability.

Owner:李晓梅

Pure cotton heavy bath mat weaving process

ActiveCN102691156AOvercome deformationOvercome elasticityBiochemical fibre treatmentBleaching apparatusYarnPulp and paper industry

The invention relates to a pure cotton heavy bath mat weaving process. Firstly fine staple cotton is spun into72.9tex of single yarns with the twist degree of 30-60 twists / 10cm, and then the single yarns are combined into four strands to make weak twist cone yarns with the twist degree of 15-25 twists / 10cm; then the weak twist cone yarns are warped and starched, and are woven into greige cloth by a variable-program beating-up loom with a specific fuzzing beating-up tissue; and the greige cloth is bleached through boiling, whitened, neutralized, softened, dried and sewed into a bath mat. According to the pure cotton heavy bath mat weaving process provided by the invention, pure cotton material is reasonably and effectively utilized in the field of bath mats, the defect that the bath mat made of the pure cotton material is deformed easily and has poor elasticity and poor durability, which can not be changed by technicists for a long time, are overcome, and the manufactured bath mat has the advantages of softness, comfort, good water absorbability, difficult generation of static electricity and the like of the pure cotton material, and can become a development trend of the bath mat weaving technology.

Owner:SUNVIM GROUP

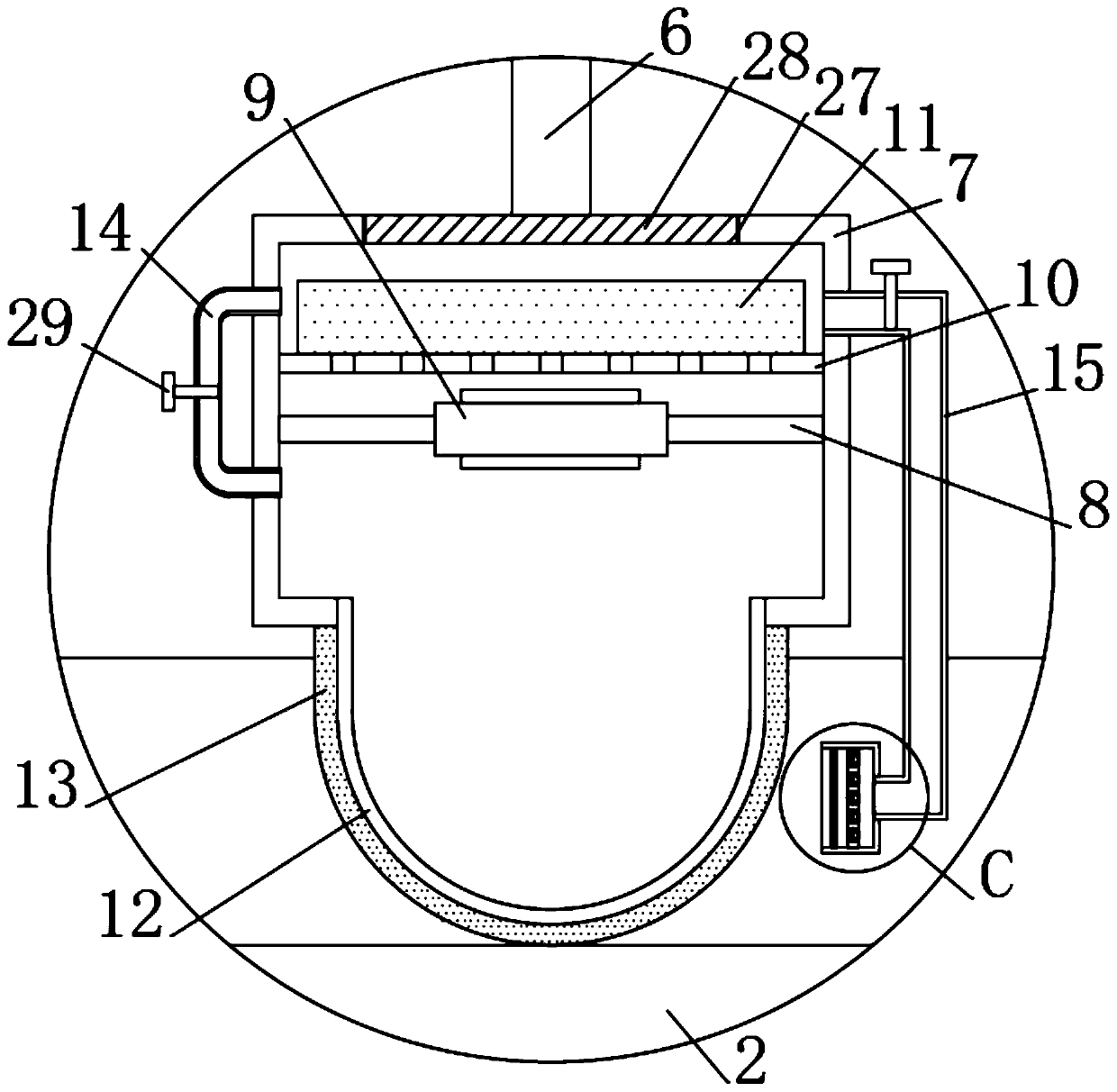

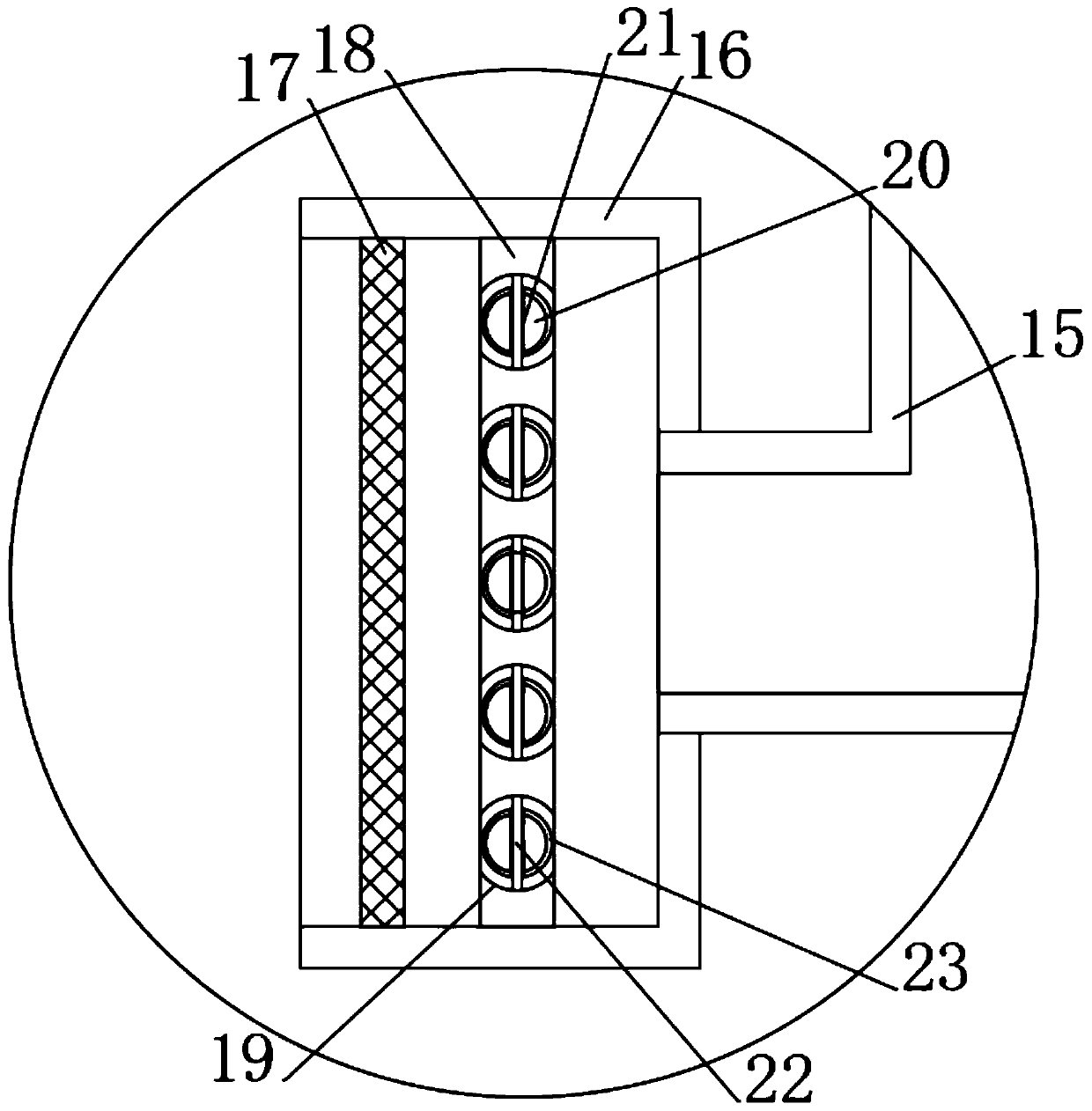

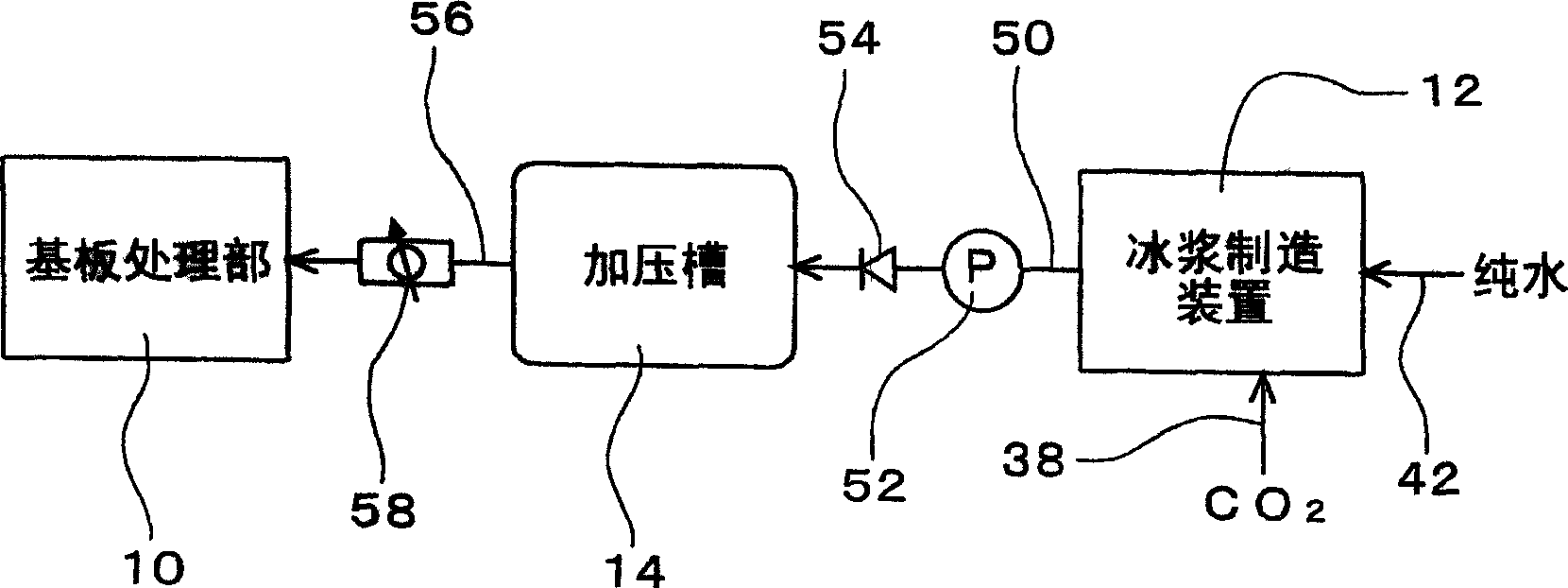

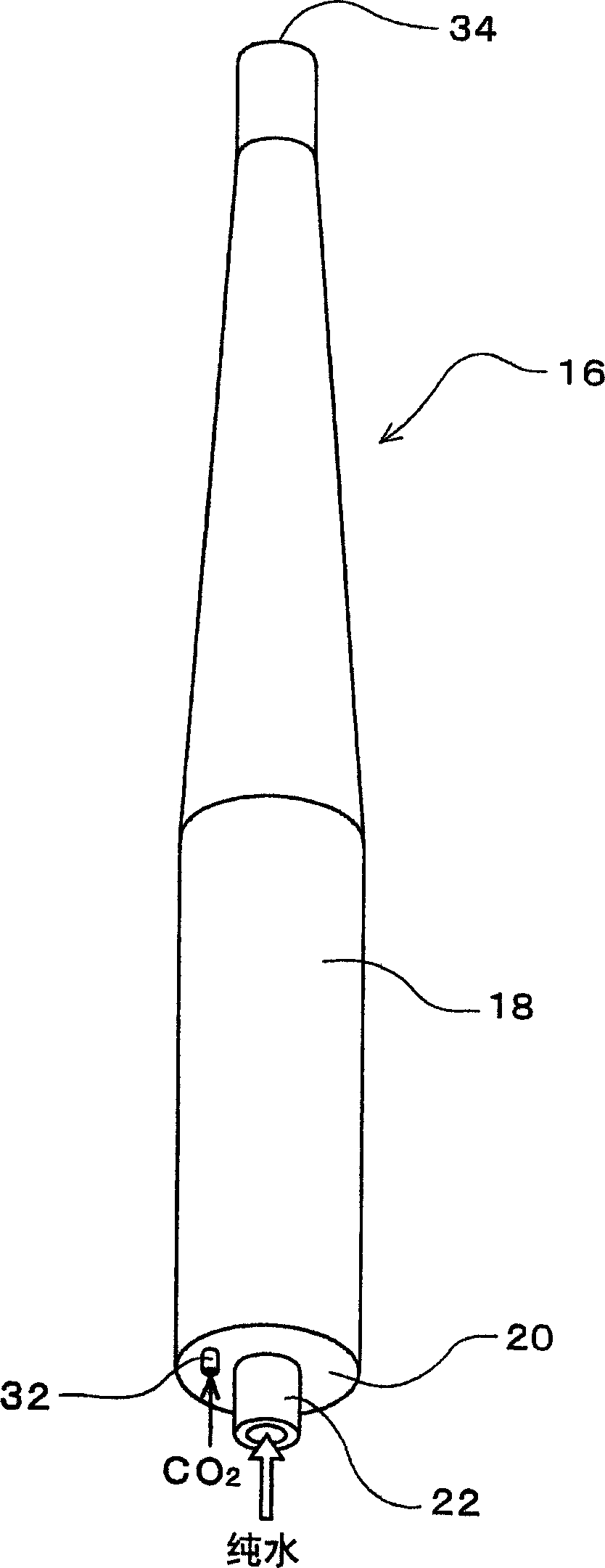

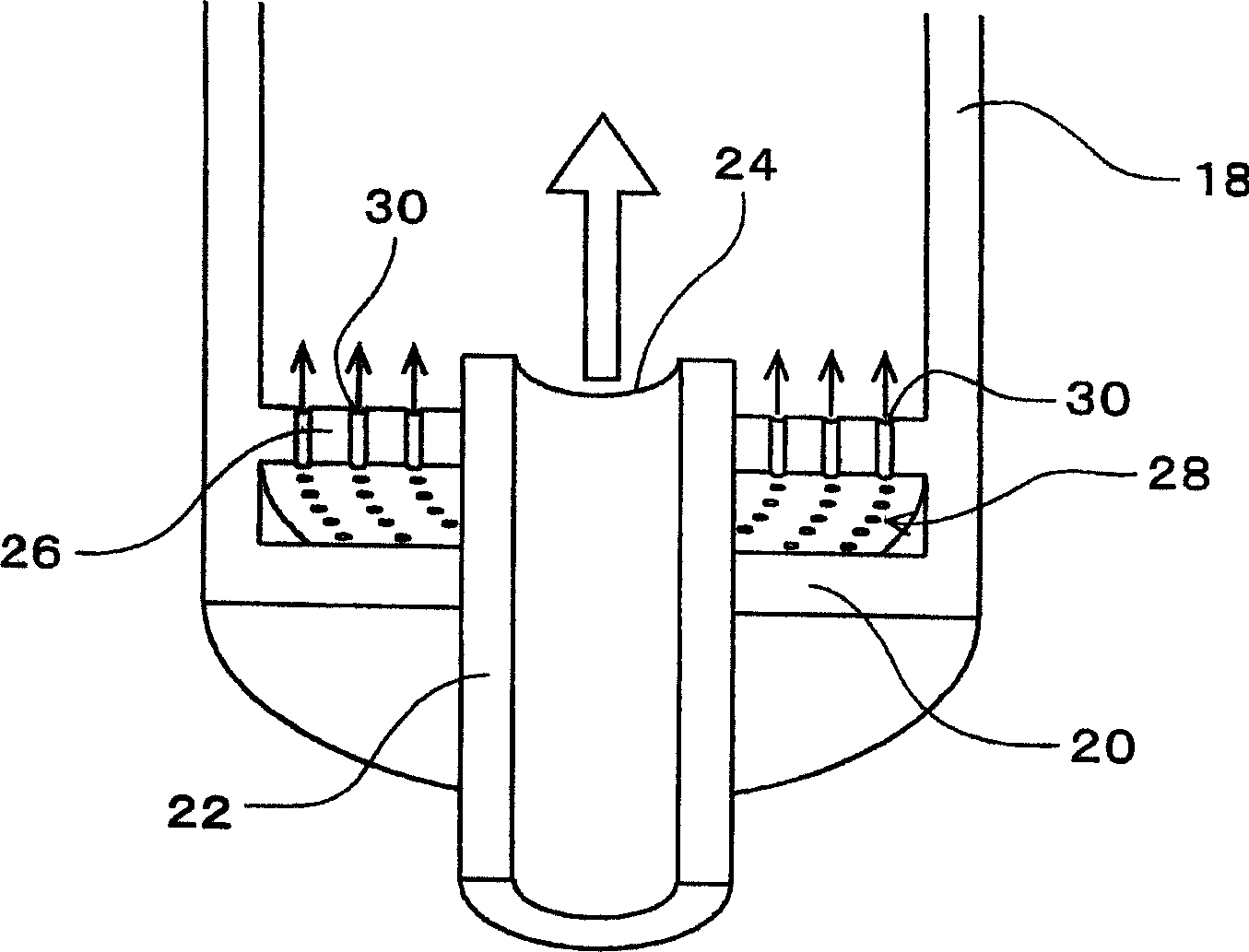

Substrate disposal device

InactiveCN1836799AEfficient removalPrevent local damage in such casesOther chemical processesLighting and heating apparatusMicroparticleEngineering

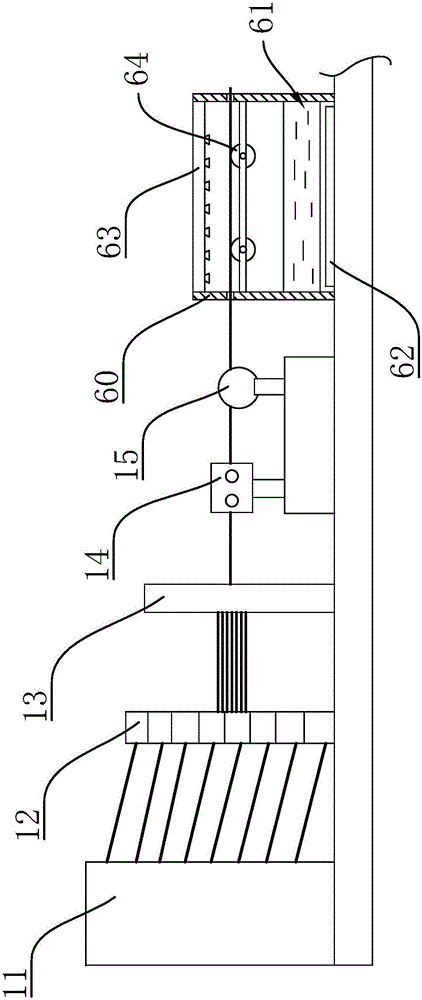

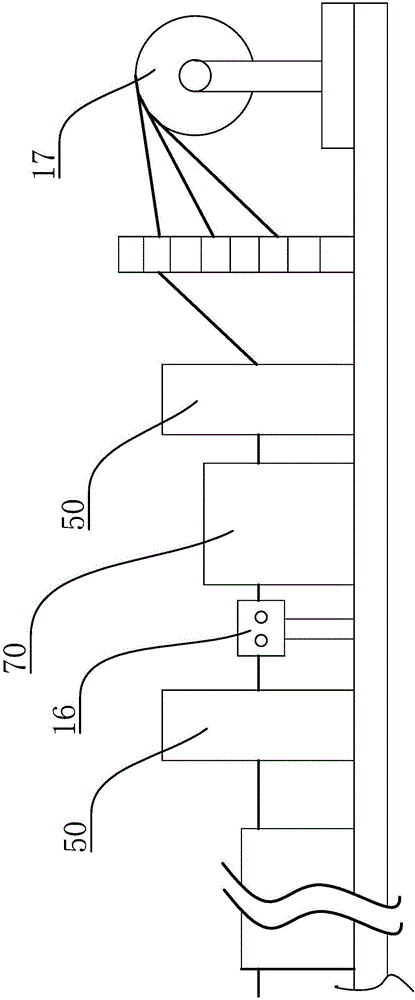

PROBLEM TO BE SOLVED: To provide a device capable of uniformly treating without unevenness, when treating a substrate by supplying a treatment liquid containing fine ice particles onto the surface of the substrate, and not damaging a coating formed on the substrate. ŽSOLUTION: The device includes a substrate treatment unit 10 for treating the substrate, an ice slurry maker 12 causing pure water to contain fine ice particles, a means for dissolving a gas in ice slurry, a pressurizing pump 52 and a pressurizing tank 14 for pressurizing the ice slurry, and an ice slurry supply pipe 56 for supplying the pressurized ice slurry with the gas dissolved to the substrate treatment unit 10. Ž

Owner:DAINIPPON SCREEN MTG CO LTD

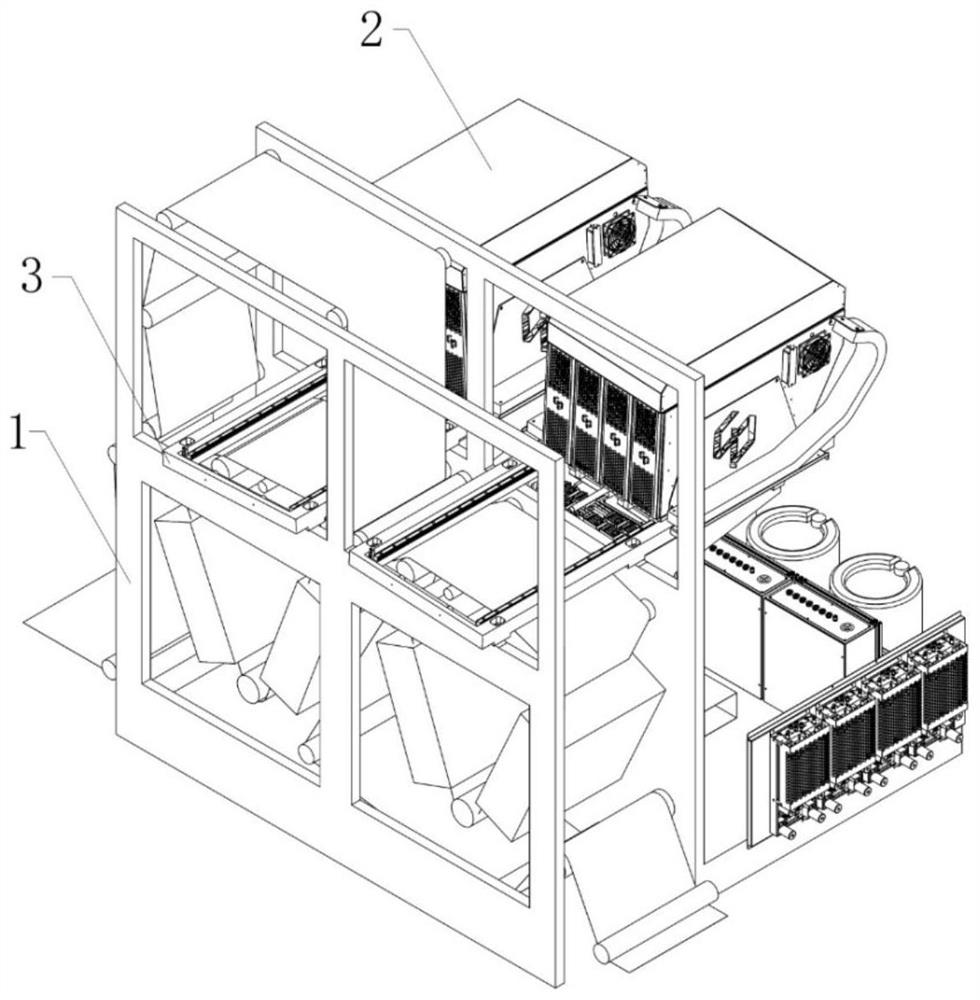

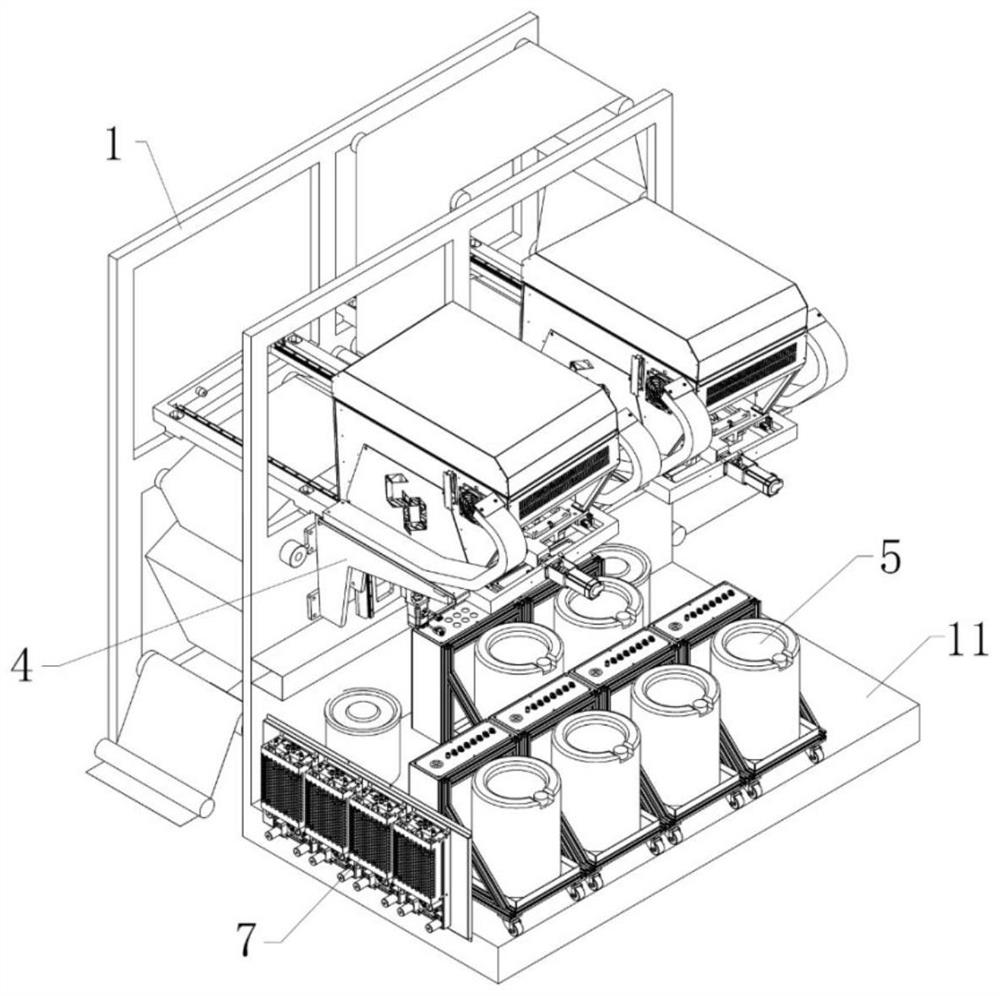

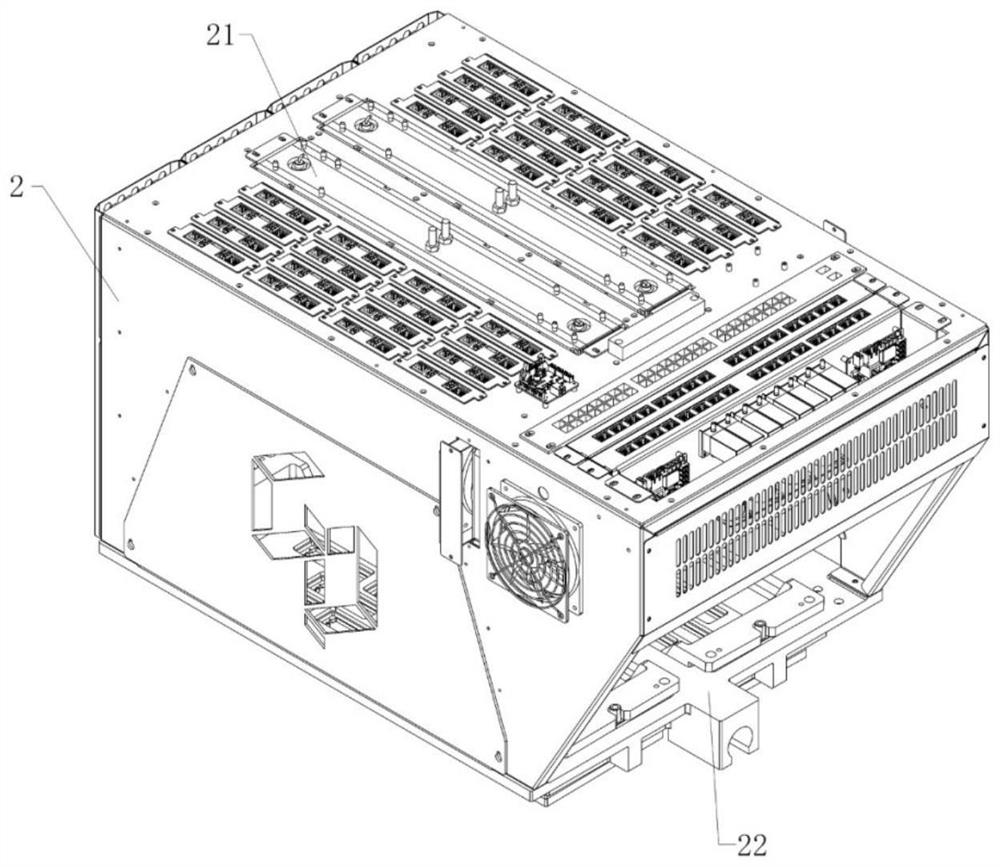

Double-sided ink-jet printer

ActiveCN113733761AReduce contact areaReduce jitterTypewritersOther printing apparatusComputer printingInk printer

The invention relates to a double-sided ink-jet printer. The double-sided ink-jet printer comprises a printing unit; the printing unit comprises a main frame; a feeding device is mounted on the main frame, the feeding device comprises a plurality of supporting rollers, and a printing medium forms four printing areas under the supporting of the supporting rollers; a Y-axis transmission device is arranged above the printing area; a printing trolley is driven by the Y-axis transmission device to move forwards to the position above the printing area and move backwards to the position above the nozzle maintenance area; a printing nozzle is mounted in the printing trolley, and the bottom surface of the printing nozzle is parallel to a printing medium below the printing nozzle; a constant-temperature secondary ink box is arranged above the printing nozzle; a nozzle maintenance device mounted below the Y-axis transmission device is arranged in the nozzle maintenance area; and an independent ink supply device is arranged behind the main frame. The double-sided ink-jet printer has the beneficial effects that the double-sided ink-jet printer can adapt to iterative upgrading of the printing function, the upgrading speed is high, the upgrading period is short, the upgrading cost is low, the nozzle cleaning effect is good, and the printing quality is high.

Owner:BEIJING ZHONGDIAN YUANDE TECH CO LTD

Diamond-doped aluminum-based composite heat radiation material and preparation method thereof

The invention discloses a diamond-doped aluminum-based composite heat radiation material and a preparation method thereof. The heat radiation material is prepared from, by weight, 63-65 parts of aluminum, 2-5 parts of diamond nanopowder, 4-5 parts of aluminum nitride, 5-7 parts of ceramic powder, 4-8 parts of graphite powder, 1-4 parts of multi-walled carbon nano-tube, 5-8 parts of vanadium diboride, 1-2 parts of zirconium diboride, 8-10 parts of gold tailings, 1-3 parts of glycerol, 1-2 parts of triethanolamine, 0.4-0.8 parts of sodium borate, 1-5 parts of an assistant and 2-6 parts of a halogen-free fire retardant. Compared with traditional aluminum heat radiation materials, the material disclosed in the invention integrates the advantages of aluminum, aluminum nitride, diamond, the ceramic powder, the graphite powder and the multi-walled carbon nano-tube, and also has good heat conduction and insulating performances; the added assistant can enhance the compatibility among the above raw materials, and improves the sintering effect, so the material has the advantages of difficult generation of static electricity on the surface, solidness, corrosion resistance, durability, and good heat radiation capability, can well protect LED lights, and effectively prolongs the service life of the lights.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

Touch screen cleaning fluid and preparation method thereof

InactiveCN104263538AReduce the possibility of two electrostatic pollutionLow costNon-ionic surface-active compoundsDetergent compounding agentsAmmonium dodecyl sulfatePrinting ink

The invention discloses a touch screen cleaning fluid. The touch screen cleaning fluid comprises the following components in parts by weight: 1-3 parts of ammonium lauryl sulfate, 5-9 parts of lauryl alcohol polyoxyethylene, 2-6 parts of coco fatty acid diethanol amide, 1-3 parts of citric acid, 58-88 parts of ethyl alcohol, 3-9 parts of deionized water and 2-5 parts of cineole. The touch screen cleaning fluid disclosed by the invention is lower in cost and simple in technology, and is safe and non-corrosive for various types of glass and the like. The touch screen cleaning fluid does not contain toxic or corrosive substances such as sulfur and benzene, and mirror-like silver and printing ink do not fall off after the touch screen cleaning fluid is used. Moreover, static electricity is unlikely to be generated after the cleaning fluid is used, the possibility that secondary pollution of static electricity after the treatment of a touch screen is prevented from being generated, the components of washing agent are environment-friendly and reliable and are harmless to human bodies and free of irritation for human bodies.

Owner:王纬

Dust remover for filtering combustible dust-containing gas

InactiveCN111001231AImprove processing efficiencyEasy to handleDispersed particle filtrationTransportation and packagingEngineeringDust particles

The invention discloses a dust remover for filtering combustible dust-containing gas. According to the invention, a plurality of first guide pipes are arranged at one end of a supporting plate at equal intervals; a second guide pipe is welded and fixed at one ends of the first guide pipes; a plurality of third guide pipes are arranged at one end of the supporting plate at equal intervals; one endsof the third guide pipes are welded and fixed with a fourth guide pipe; and by arranging the fourth guide pipe and the second guide pipe, the first guide pipes are internally communicated with the second guide pipe, so that condensed nitrogen circularly flows in the first guide pipes, the first guide pipes can cool a filtering core, and after gas enters a filtering box, the gas passes through a filtering core to filter and separate dust particles, the dust particles are not prone to generate static electricity through cooling and humidity increasing, the mass of the dust particles is increased due to humidity increasing, the dust particles are prone to sinking into the bottom end of a dust accumulation box, and the accumulated dust is conveniently treated so as to substantially improve the dust treatment efficiency in gas and conveniently achieve subsequent accumulated dust treatment.

Owner:安徽华创环保设备科技有限公司

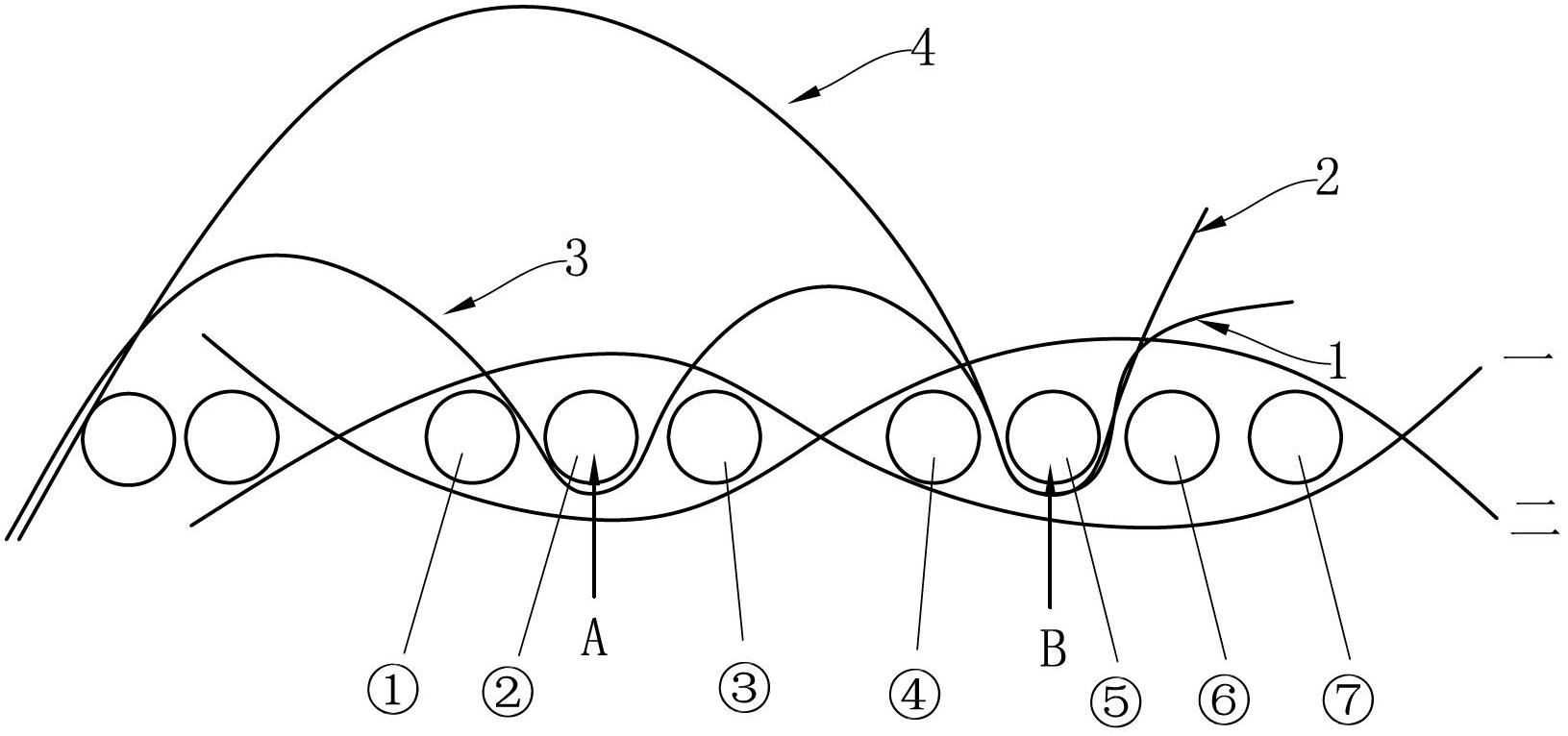

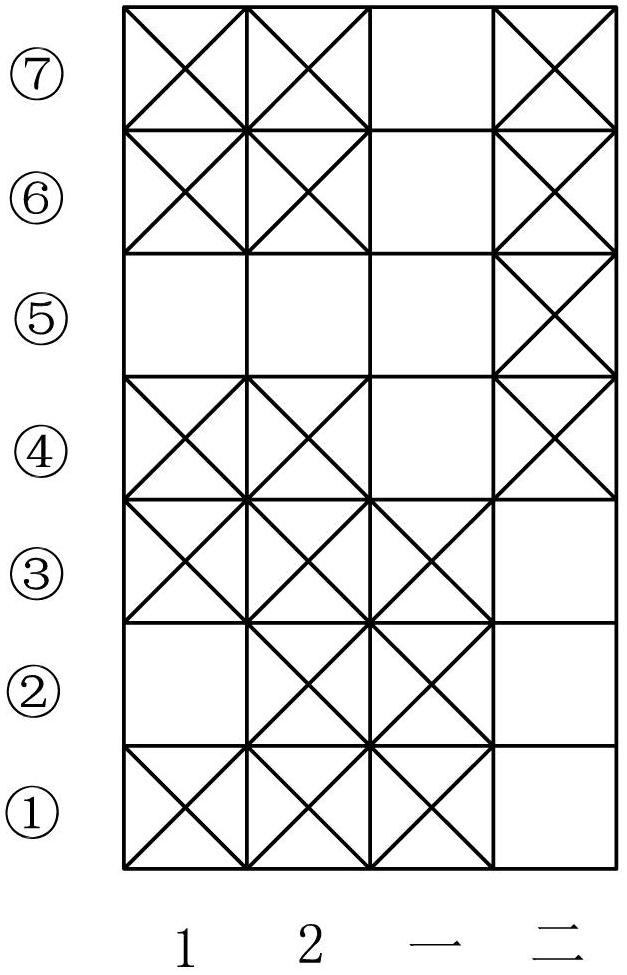

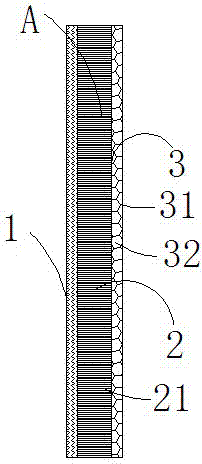

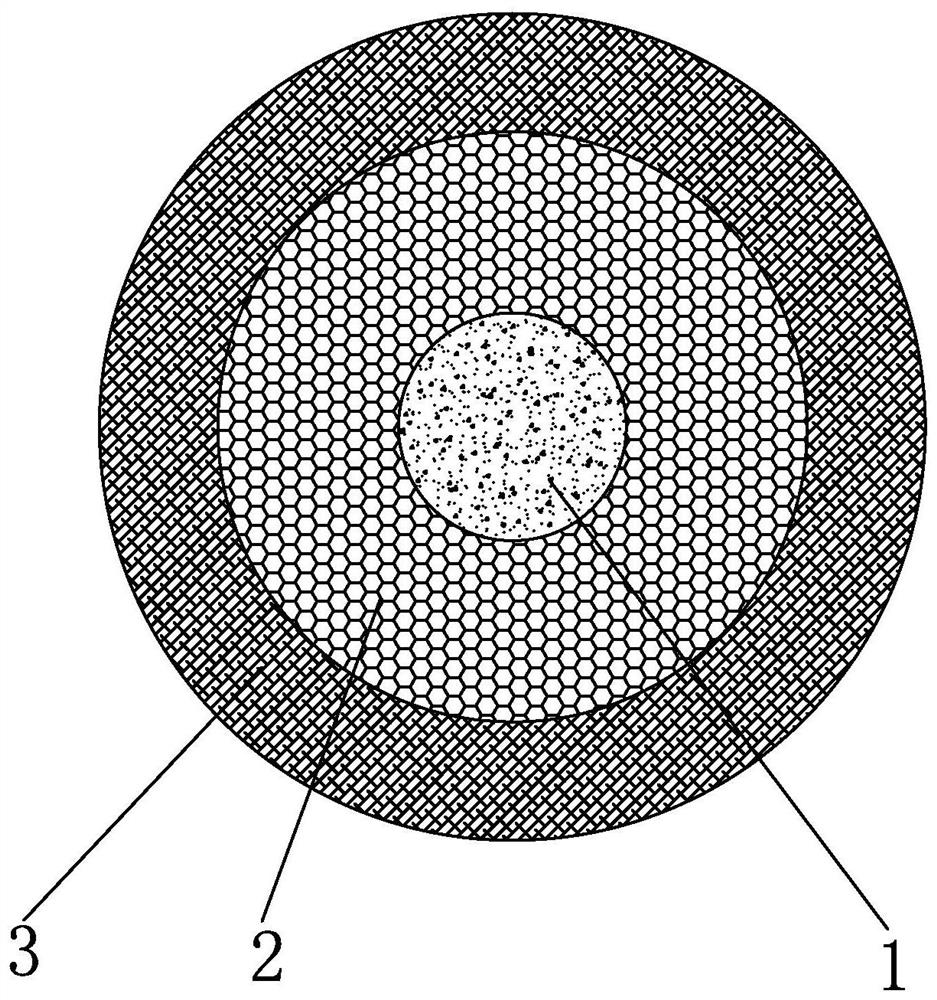

Fiber air-permeable mat with multi-layer structures and manufacture method thereof

InactiveCN102864563AEfficient removalNot easy to generate static electricityUpholstery manufactureWeft knittingEngineeringAirflow

The invention discloses a fiber air-permeable mat with multi-layer structures. The fiber air-permeable mat comprises a mat body, wherein the mat body comprises an upper fiber layer, a middle air-permeable layer and a bottom layer which are formed by weaving in one step from top to bottom. Micropores allowing air flowing through are formed on the upper fiber layer and communicated with the middle air-permeable layer which is a hollow layer formed by vertical silks, and the bottom layer comprises venting holes formed by mesh edges. The upper ends of the vertical silks are connected with the upper fiber layer in a hook weaving mode, the lower ends of the vertical silks are connected with the mesh edges in a hook weaving mode, and the vertical silks are in perpendicular match with the upper fiber layer and the bottom layer. The fiber air-permeable mat has the advantages of being novel in structure, light in weight and good in air permeability and radiating performance.

Owner:梁瑞德

Production method of skin-moistening moisture-keeping paper special for mothers and infants

PendingCN108642966AGentle to the touchIncrease humidityNon-fibrous pulp additionSpecial paperFiberStart stop

The invention discloses a production method of skin-moistening moisture-keeping paper special for mothers and infants. The skin-moistening moisture-keeping paper comprises the following component: a bleached soft wood and broadleaf wood pulp plate. The skin-moistening moisture-keeping paper is prepared through the following steps: S1, taking the bleached soft wood and broadleaf wood pulp plate asslurry, and respectively dispersing the slurry into long-fiber slurry and short-fiber slurry by a hydraulic pulper; S2, beating the long-fiber slurry to a beating degree of 19-22 degrees SR through adisc mill, defibering the short-fiber slurry through a high-frequency defibering machine, mixing the defibered short-fiber slurry with the long-fiber slurry according to a proportion of 60:40, and beating the obtained mixture to a beating degree of 26-30 degrees SR through a leveling mill; S3, adding a softening agent of 0.8-1.2 kg / T; S4, enabling the prepared slurry to form original paper; S5, carrying out spraying by a spraying device; S6, linking the start-stop of the spraying device with a rewinder program, and reeling up a coiled paper roll by a rewinder; and S7, carrying out packaging. According to the invention, plant extracts are used as raw materials, skins are not damaged easily, the preparation is simple, and the product quality is improved.

Owner:ZHEJIANG JINGXING PAPER

Efficient waterproof dustproof fiber cement board

The invention discloses an efficient waterproof dustproof fiber cement board, and belongs to the technical field of building materials. According to the invention, bamboo shoots are crushed and mixedwith alkali liquor, so that the space between fiber components can be filled with tiny calcium carbonate components, and the formed mixture is mixed with citric acid liquid for hydrolysis. A micelle solution is prepared by polymerizing monomers such as N-dodecylacrylamide, the internal stability is improved, and through combination with the components of a composite hydrophobic dustproof base material, the water resistance of the formed fiber cement board is improved and the fiber cement board is not easily contaminated by dust. Bamboo shoots are treated, filling of multiple inorganic macromolecular components is combined, fibers and inorganic macromolecules are subjected to net capture by utilizing hydrophilic and hydrophobic effects shown by a carbon nanotube network at different temperatures, the waterproof property is improved, the dustproof property is also provided, and a prepared amphiphilic binary copolymer has the effect of supplementing and improving the waterproof property and the dustproof property from the aspect of an internal structure. The fiber cement board solves the problems that a common fiber cement board at present is poor in waterproofness and prone to beingcontaminated by dust.

Owner:佛山市世为创意家具有限公司

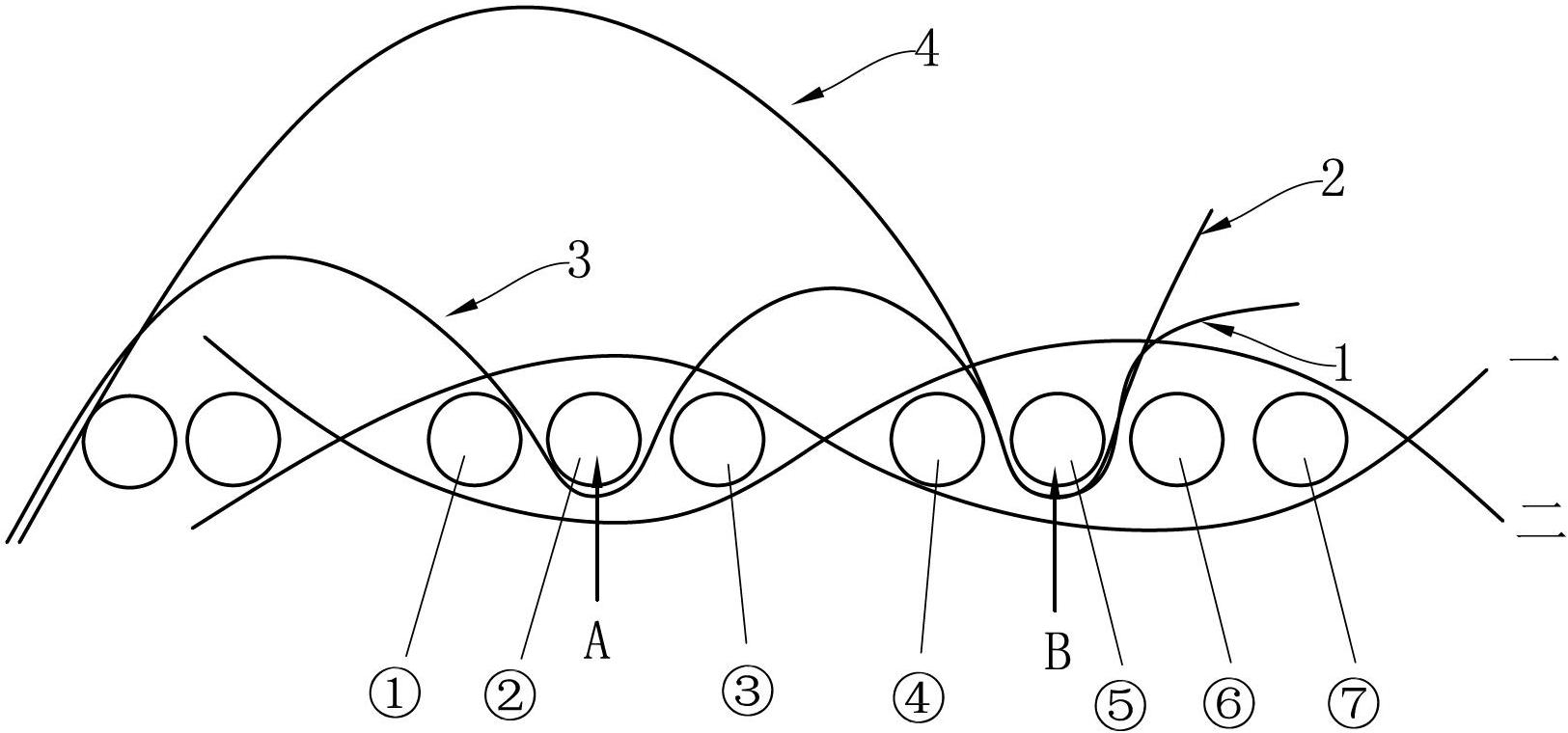

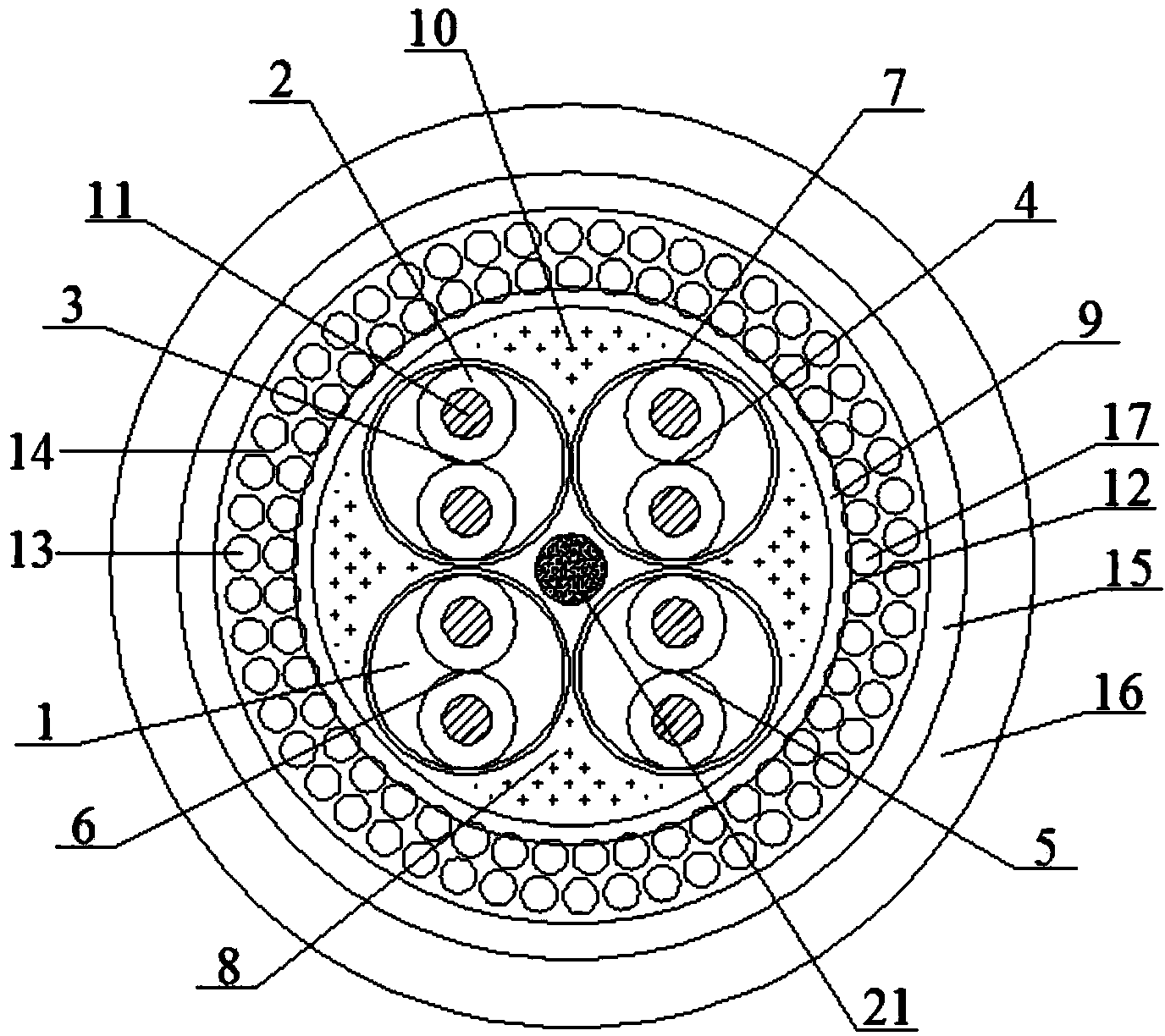

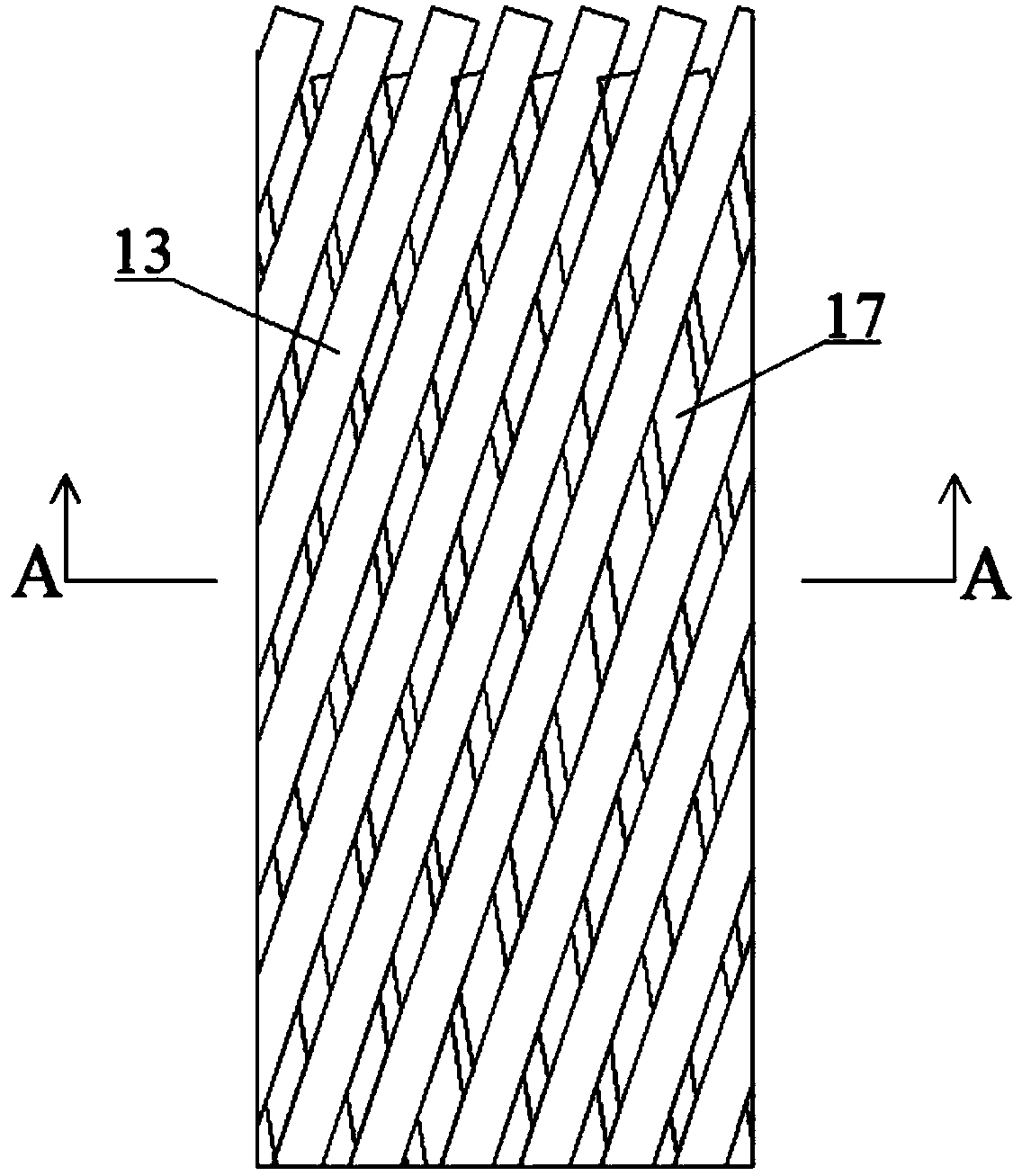

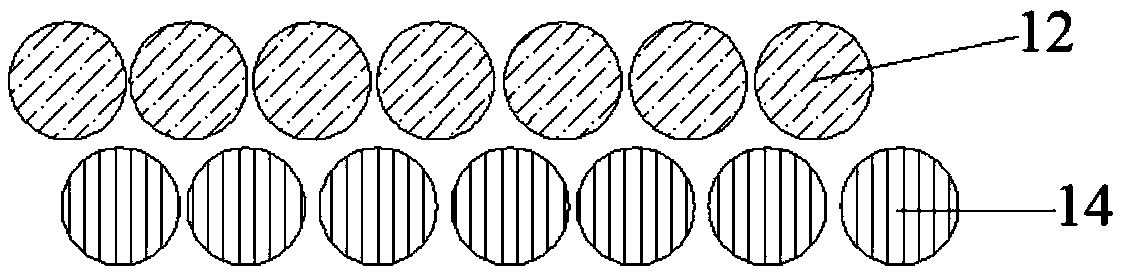

Stretch- and fatigue-resistant shielding soft data cable

ActiveCN104036869AReduce coefficient of frictionIncrease coefficient of frictionInsulated cablesInsulated conductorsYarnElectrical conductor

The invention discloses a stretch- and fatigue-resistant shielding soft data cable which comprises eight metal conductor units and an aramid reinforcement element, wherein the metal conductor units comprise aramid fiber arranged at the centers, inner conducting layers and outer conductor layers; four symmetric insulated wire pairs are twisted around the outer surface of the aramid reinforcement element to form a cable core; a second polytetrafluoroethylene layer longitudinally wraps the outer surface of the cable core, gaps between the second polytetrafluoroethylene layer and the four symmetric insulated wire pairs are filled with a plurality of cotton yarns, a cotton fiber thread is wound around the outer surface of the second polytetrafluoroethylene layer to form a buffer sliding layer, the winding direction of the cotton fiber thread is opposite to the twisting direction of the four symmetric insulated wire pairs, a plurality of metal wires are wound around the outer surface of the buffer sliding layer in parallel to form a metal shielding layer, the winding direction of the metal wires in the metal shielding layer is opposite to that of the cotton fiber thread, and a third polytetrafluoroethylene layer wraps the outer surface of the metal shielding layer. The stretch- and fatigue-resistant shielding soft data cable has the advantages of low friction coefficient, softness, stretch resistance and no friction static generation, and stable structural and electrical performance after frequent moving still can be guaranteed.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Method for manufacturing wool top, Qinglun and Jinlun interweaving wool

The producing method of the feather strip, the nylon and the acrylic interlacing wool relates to the producing method of the wool. According to the designing process provided by the invention, the producing method of the feather strip, the nylon and the acrylic interlacing wool includes: the feather strip, the nylon and the acrylic are combined to the combining strip, firstly, it is performed by the pin combing, the wide combing and presenting the wet under the common temperature, secondly, it can be deposited under the common temperature through the thin yarn machine spinning, the thin yarn through the constant temperature depositing is befell in the head single canister to combining twist, then, it is befell in the second single canister to shake the yarn and dye, finally, the ball is formed. The interlacing wool is produced from the feather strip, the nylon and the acrylic. The invention has many merits such as the comfort and the breathing freely, the bright color, the firmness and the clean-resisting, the keeping warm and without the bad side effect.

Owner:刘宏彪

Adding method of flame inhibitor of coal mine permitted detonator explosive

The invention discloses an adding method of a flame inhibitor of a coal mine permitted detonator explosive. The method comprises the following steps: 1, adding polyvinyl alcohol into water, and heating for dissolving to form an aqueous solution of polyvinyl alcohol; 2, adding the flame inhibitor into the cooled aqueous solution of polyvinyl alcohol, and fully stirring to form a suspension; and 3, putting the prepared explosive particles in the drum of a drum coating machine, allowing the drum to rotate, adding the suspension obtained in step 2 in a dropwise manner to wet the particles, introducing hot air for drying, adding the suspension, and repeating the above suspension addition and drying process until no suspension is residual, and drying to prepare a flame inhibitor-containing explosive. Compared with the prior art, the method has the following substantial characteristics: the coating rate of the flame inhibitor is high, so the cost is reduced; the content of the flame inhibitor coated in the explosive can be easily adjusted; the surface of the particles is uniformly coated with a water-soluble film, so the surface of the particles is smooth, and the fluidity of the particles is improved; crystals of the flame inhibitor coated on the surface of the particles unlikely generate a static effect, so the static accumulation of the particles is reduced; and polyvinyl alcohol is a water-soluble polymer, and water is used as a solvent, so no organic solvent volatilizes in the production process, and the method is nontoxic and has no pollution.

Owner:NANJING UNIV OF SCI & TECH

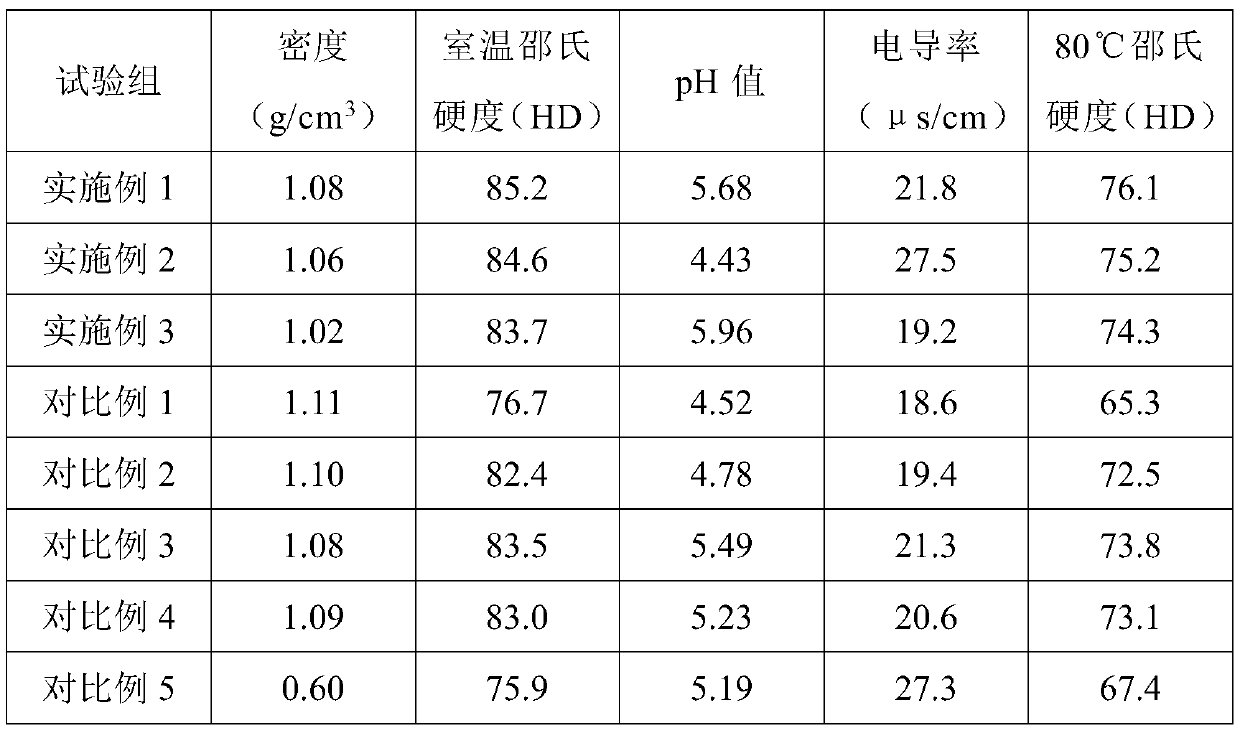

Specific acidic plastic plate for photovoltaic diamond wire cutting and preparation method thereof

The invention discloses a specific acidic plastic plate for photovoltaic diamond wire cutting and a preparation method thereof. The plastic plate comprises the following raw materials: matrix resin and an auxiliary agent, and is prepared through the steps of raw material mixing, granulation, extrusion molding, polishing, cutting, detection, packaging and the like. The plastic plate prepared by theinvention meets the requirement of a large circulation system of a diamond wire cutting process, is easy to recycle, can be recycled, and meets the environmental protection requirement of continuousutilization; in a silicon rod cutting process using the diamond wire, impurities adhering to the diamond wire are reduced, the abrasion probability of the diamond wire is reduced, the cost is saved, the superior product rate of silicon wafers is increased, and therefore the production efficiency is effectively improved. Compared with the prior art, the prepared plastic plate is better in shore hardness and equivalent in pH value and conductivity, and has remarkable progress.

Owner:广西拓源新材料有限公司

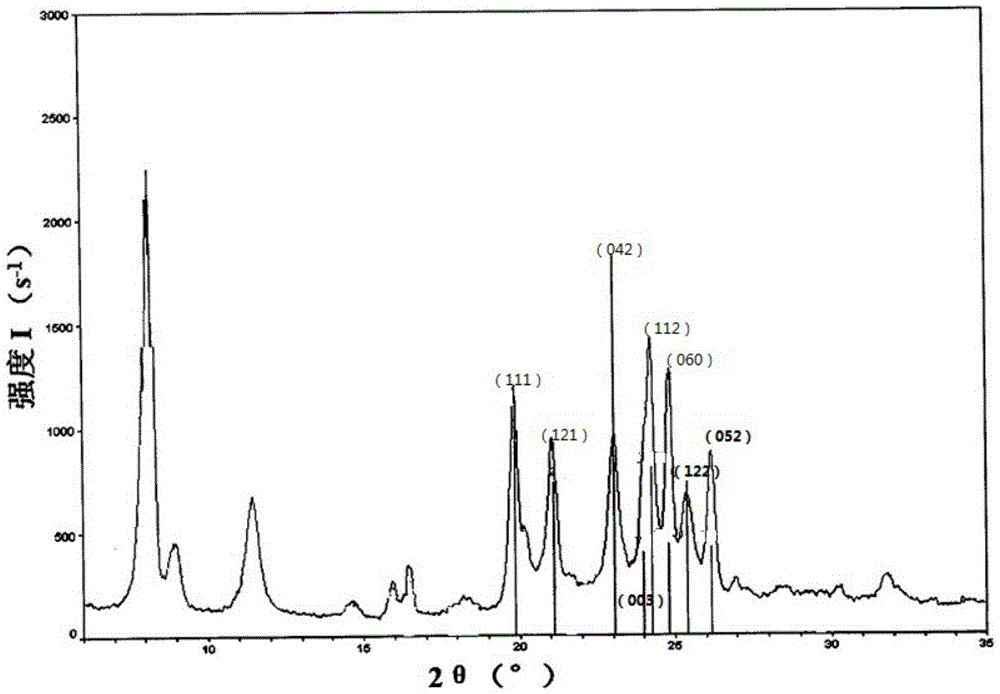

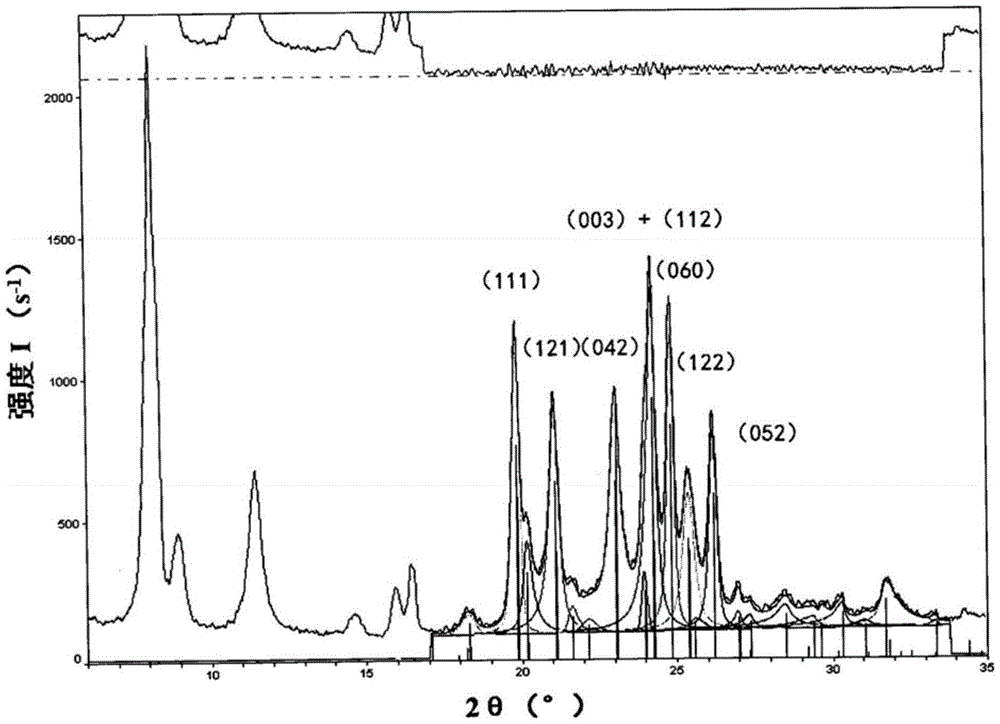

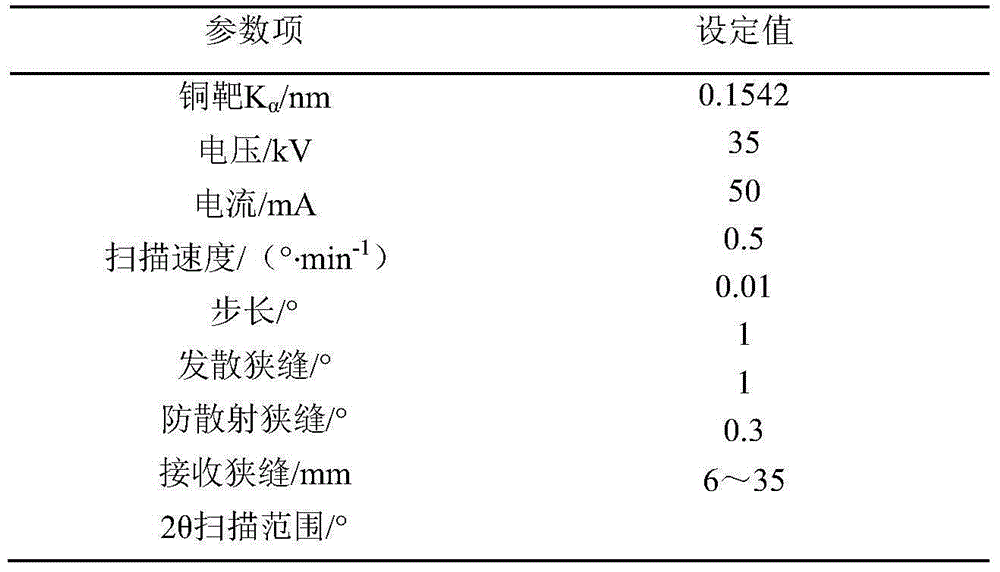

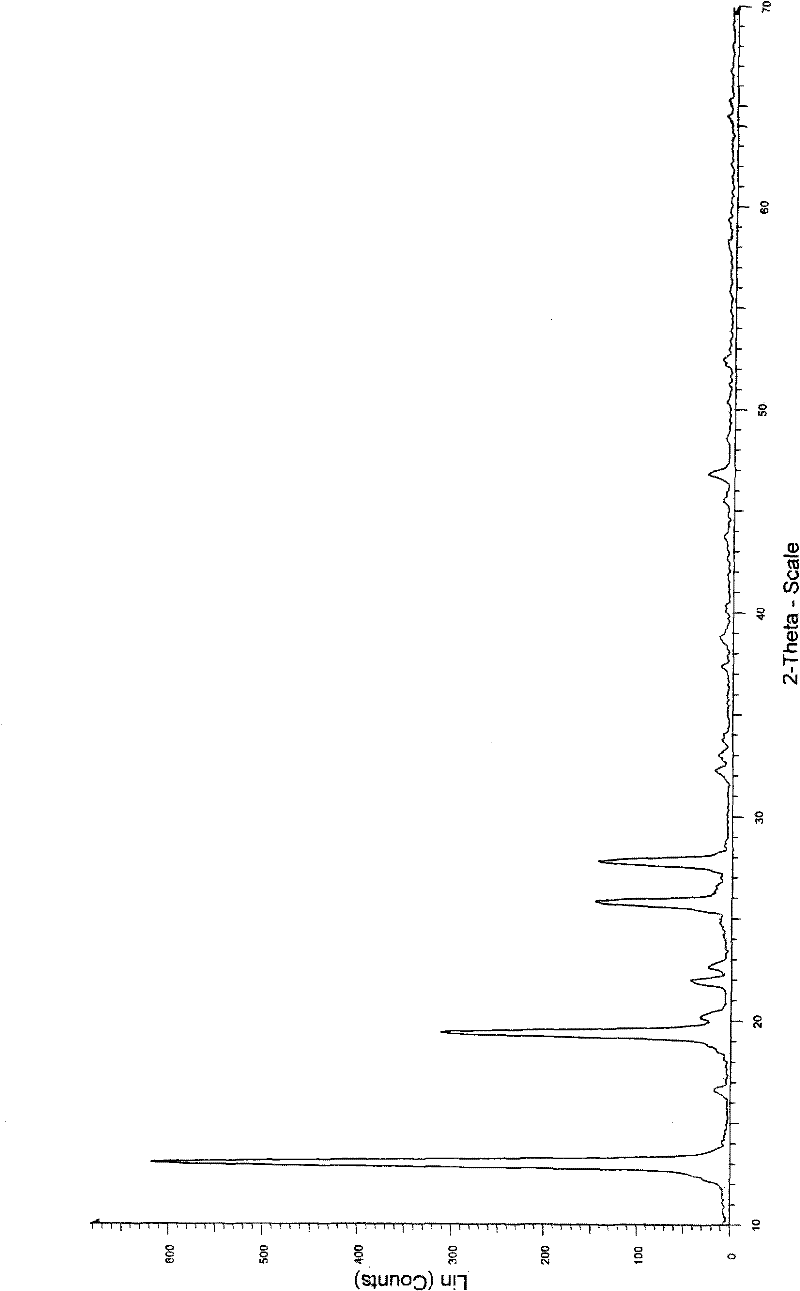

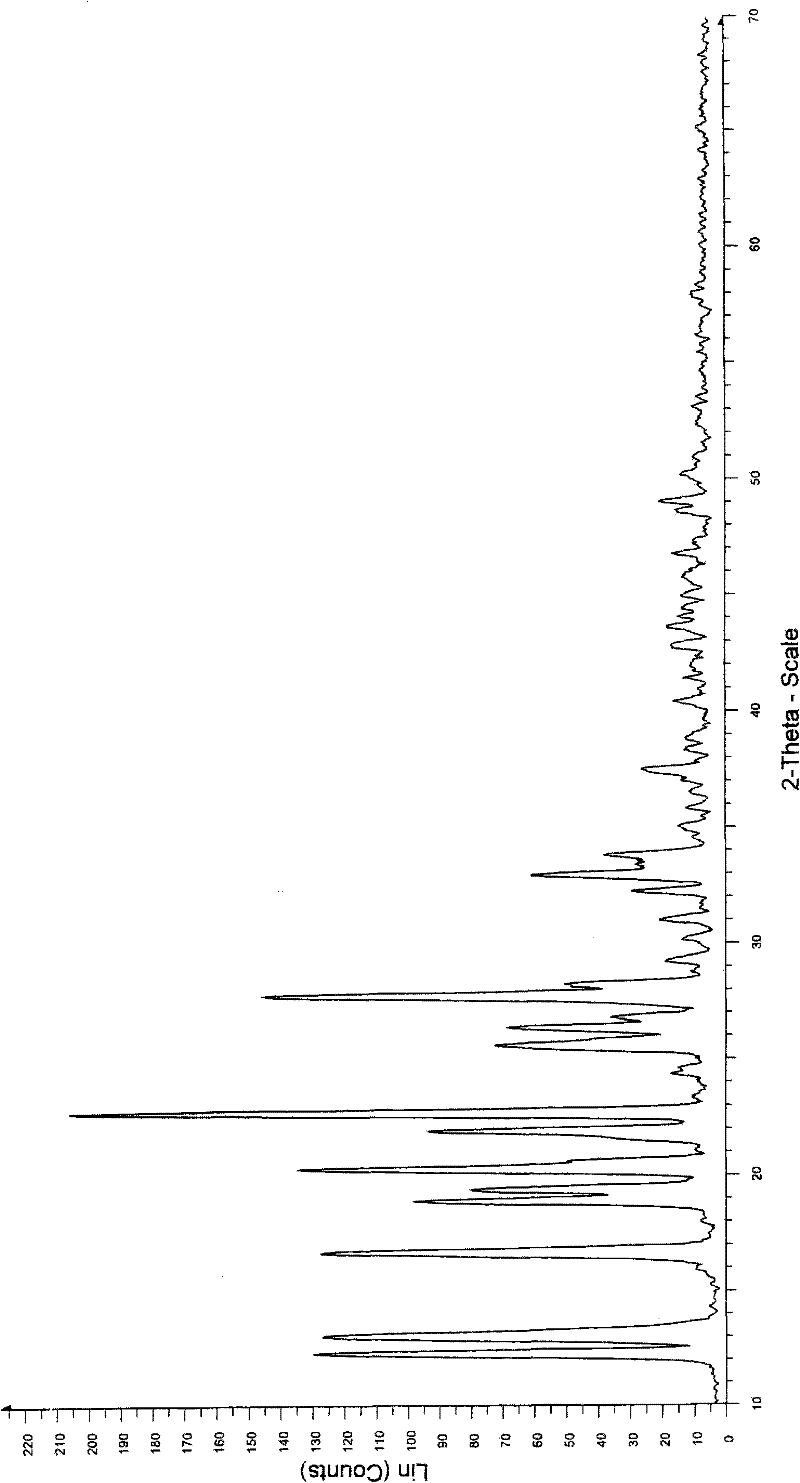

Method for determining ZSM-23 molecular sieve relative crystallinity

ActiveCN106168583ANot easy to generate static electricityDoes not damage the structurePreparing sample for investigationMaterial analysis using radiation diffractionPeak areaMolecular sieve

A method for measuring the relative crystallinity of ZSM-23 molecular sieves, comprising the following steps: a, pretreatment of samples: grinding, sieving, roasting and activating ZSM-23 molecular sieve standard samples and industrial samples to be tested, and controlling temperature and humidity to absorb water Four steps to prepare the standard sample to be tested and the industrial sample to be tested; b. Determination of the working conditions of the powder X-ray diffractometer; c. Measurement: measure and collect the powder X-ray diffraction data; d. Calculation: use powder X-ray diffraction The chemometric peak division method of the diffraction data processing system software measures the 8 crystal planes of the sample (111), (121), (042), (003), (112), (060), (122), (052) The peak area integration intensity count values of the diffraction peaks are summed, and the relative crystallinity of the industrial sample to be tested is calculated by the external standard method.

Owner:PETROCHINA CO LTD

Antibacterial and anti-mite blended non-woven fabric based on polylactic acid fibers

InactiveCN110791879ASolve the lack of natural antibacterial and anti-mite effectsGood biocompatibilityNon-woven fabricsUndergarmentsEngineeringNonwoven fabric

The invention discloses an antibacterial and anti-mite blended non-woven fabric based on polylactic acid fibers. The blended non-woven fabric is prepared by mixing the polylactic acid fibers with absorbent cotton. The specific preparation process comprises the following steps: preparing raw materials; feeding the the raw materials into a disc plucker; feeding the raw materials into a multi-bin cotton mixer; feeding the raw materials into a finishing machine; feeding the raw materials into a carding machine; feeding the raw materials into a cross lapping machine; feeding the raw materials intoa fiber drafting machine; carrying out spunlace treatment; feeding the raw materials into a coiling machine; carrying out drying treatment; feeding the raw materials into a splitting machine; and packaging and warehousing. The problem that an existing all-cotton spunlaced non-woven fabric does not have natural antibacterial and anti-mite effects is solved, and after a certain proportion of polylactic acid fibers are blended in all-cotton, the natural antibacterial and anti-mite characteristics of the polylactic acid fibers are utilized, so that the blended non-woven fabric also has the naturalantibacterial and anti-mite functions.

Owner:安庆市嘉欣医疗用品科技股份有限公司

Silica sol containing dyeing agent for wig composite fiber and preparation method thereof

InactiveCN105220529AImprove adhesionHigh level dyeingDyeing processReactive dyePVA - Polyvinyl alcohol

The invention discloses a silica sol containing dyeing agent for wig composite fiber. According to the dyeing agent, a reactive dye is employed to prepare a dyeing solution, cationic etherified starch is employed to conduct cationization treatment on polyvinyl alcohol, cationized polyvinyl alcohol reacts with the reactive dye to obtain a reactive dyeing solution, which has high adhesion and dying uniformity, and certain retarding and protecting effects, and can improve the dyeing effect of composite fiber. The added silica sol has good permeability, and can reach the efficacy of color fixing, toughening, spinnability improvement and the like after combing with composite fiber. The wig fiber treated by the dyeing agent provided by the invention has firm and uniform color, is heat resistant and stain resistant, is tough and durable, and is difficult to generate static electricity.

Owner:ANHUI FORTUNE FASHION CULTURE

Novel anti-static fabric

InactiveCN103380997ANot easy to generate static electricityImprove the protective effectYarnProtective garmentMetal fibersMoisture

The invention discloses a novel anti-static fabric. The novel anti-static fabric comprises, by weight percentage, 50%-55% of metal fibers, 25%-30% of jute fibers and 15%-20% of cotton fibers, and is woven by blending the metal fibers, the jute fibers and the cotton fibers, and the cotton fibers are long-stapled cotton fibers. Therefore, according to the novel anti-static fabric, metal fibers are utilized for eliminating static due to friction between a human body and clothes, and the protective performance is good; the cotton fibers and the jute fibers absorb moisture and are breathable, soft and comfortable, and static is not easy to occur; and the novel anti-static fabric is suitable for manufacturing anti-static clothes.

Owner:SUZHOU XINHANFANG TEXTILE

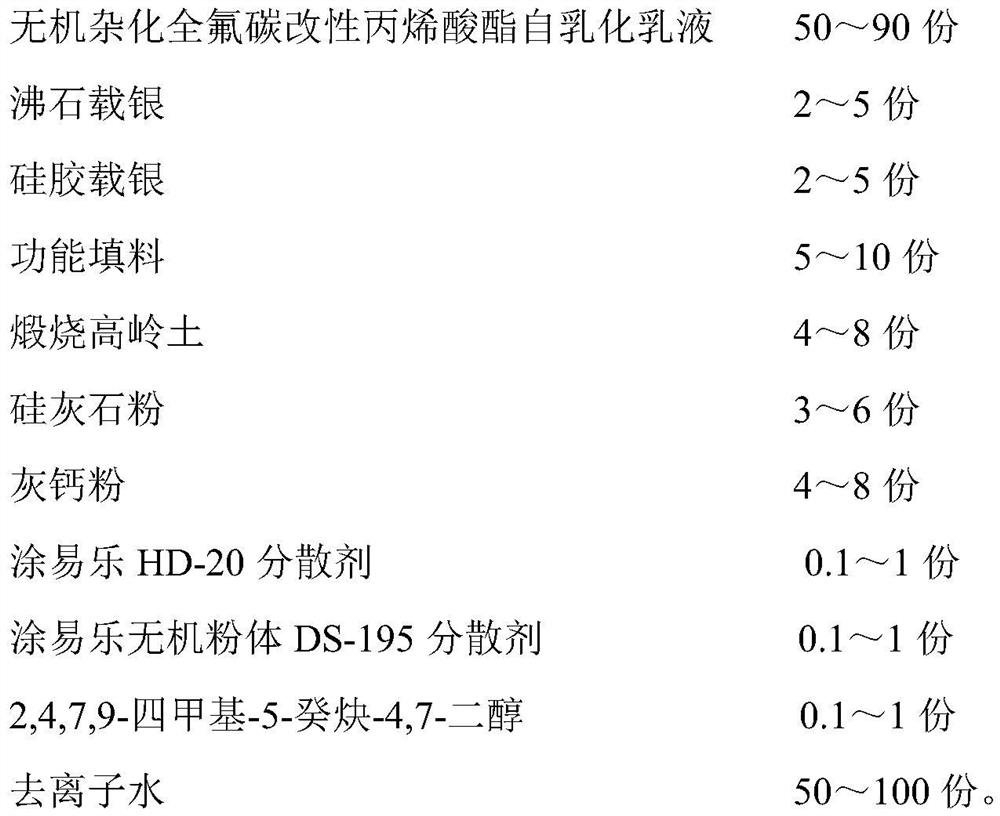

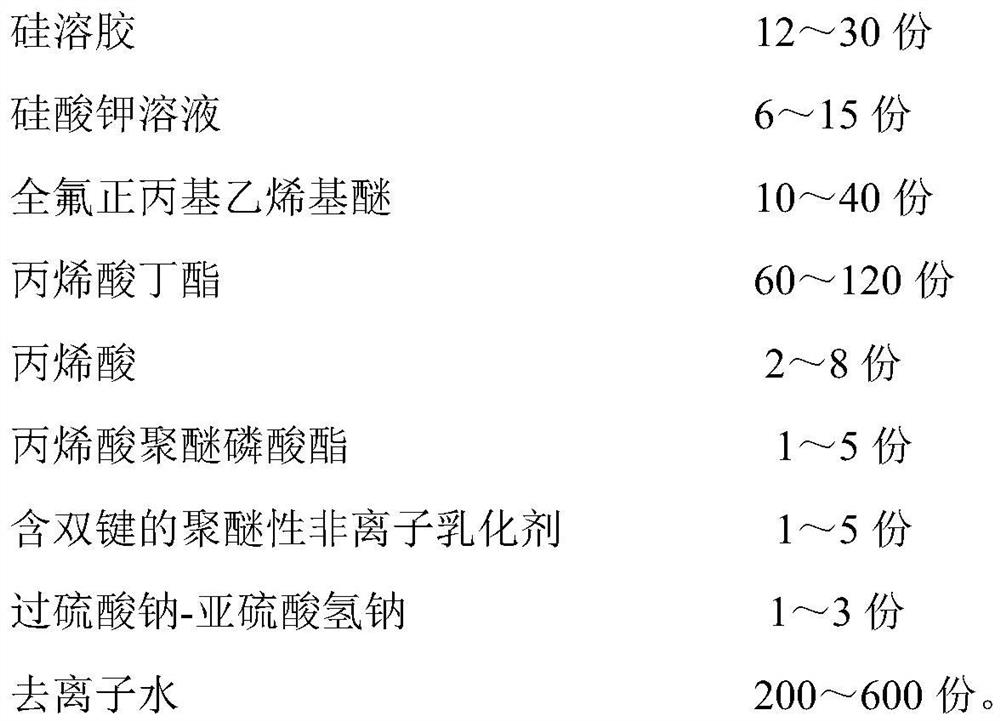

Organic-inorganic antibacterial antifouling interior wall coating and preparation method thereof

ActiveCN112920667AChemically resistantFlame retardantFireproof paintsAntifouling/underwater paintsMeth-Kaolin clay

The invention relates to the technical field of coatings, in particular to an organic-inorganic antibacterial antifouling interior wall coating and a preparation method thereof. The coating is prepared from an inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, zeolite-loaded silver, silica gel-loaded silver, a functional filler, calcined kaolin, wollastonite powder, ash calcium powder, a Taieasy HD-20 dispersing agent, a Taieasy inorganic powder DS-195 dispersing agent, 2, 4, 7, 9-tetramethyl-5-decyne-4, 7-diol and deionized water. The inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion is used as a base material, and zeolite-loaded silver and silica gel-loaded silver are used as a composite inorganic mildew preventive, so that the coating has the characteristics of chemical corrosion resistance, flame retardance, fire prevention and environmental protection of an inorganic coating and the advantages of strong adhesive force and good scrubbing resistance of an organic coating; the coating is safe and non-toxic, excellent in mildew-proof performance and long in mildew-proof validity period.

Owner:ZIBO VOCATIONAL INST

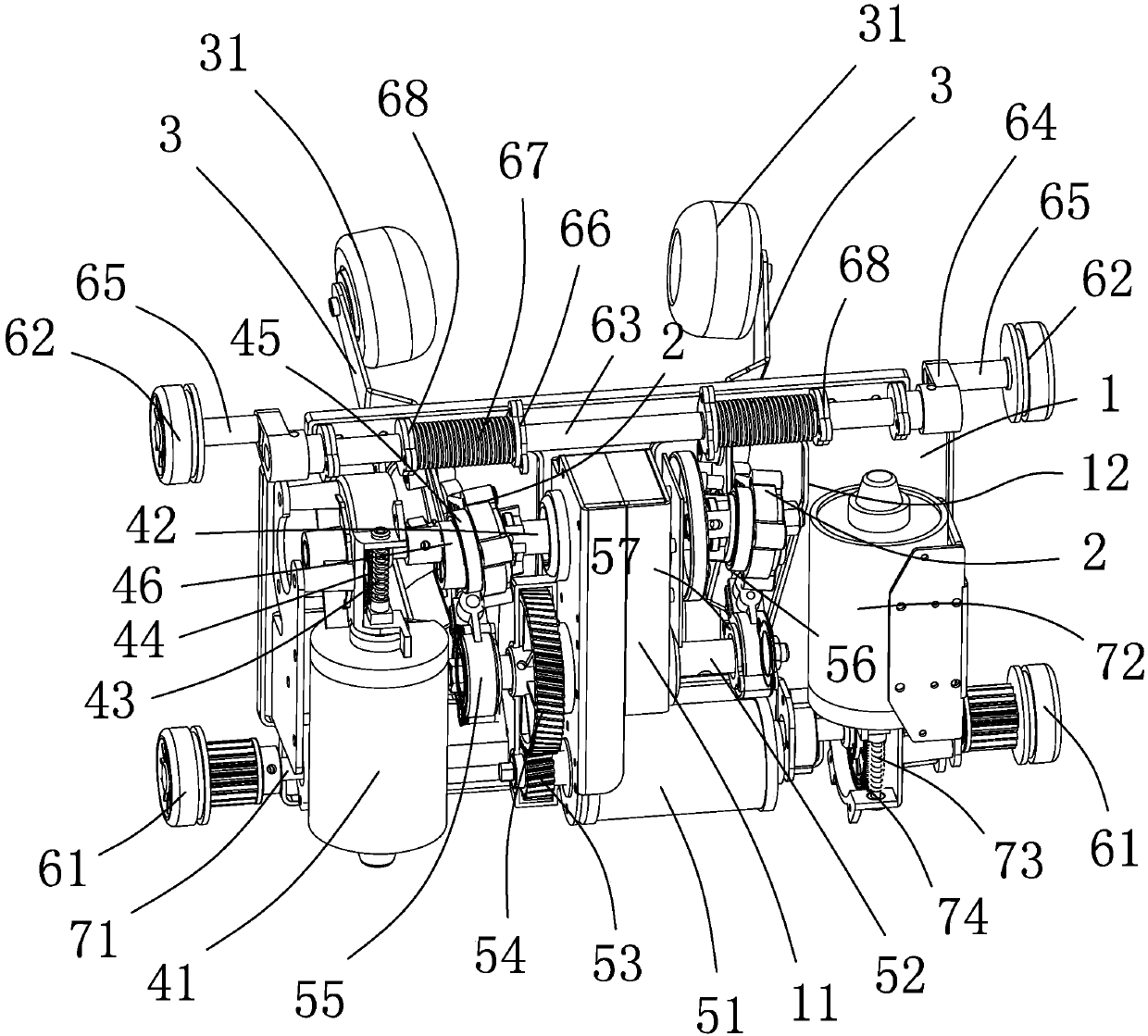

3D manipulator for massage chair

PendingCN107773381AImprove interchangeabilityEasy maintenance-free useChiropractic devicesVibration massageMassageEngineering

The invention discloses a 3D manipulator for a massage chair. The 3D manipulator comprises a traveling plate, wherein two swing arms are arranged at the rear end of the traveling plate; crank arms extending to the front of the traveling plate are hinged to the two swing arms; massage balls are arranged on the crank arms; a massage assembly for driving the swing arms to move to realize massage actions, a knocking assembly for driving the swing arms to move to realize knocking massage motion and a traveling assembly for driving the traveling plate to travel along guide rails of the massage chairare arranged at the rear end of the traveling plate. Compared with the prior art, the 3D manipulator for the massage chair is simple in structure, lower in cost, higher in transmission efficiency andlonger in service life, static electricity is not produced easily, and people with different heights and body sizes have better comfort.

Owner:温州市坤元电气制造有限公司

Fine denier vortex spinning yarn and spinning process

The invention discloses a fine denier vortex spinning yarn. The fine denier vortex spinning yarn comprises a yarn body; the yarn body is 4.9 tex to 8.4 tex; the yarn body comprises a core yarn, a first wrapping fiber layer and a second wrapping fiber layer; the core yarn is made of fine denier spandex filaments; the first wrapping fiber layer spirally wraps outside the core wire; the first wrapping fiber layer is made of fine denier profiled acrylic fibers; the second wrapping fiber layer spirally wraps outside the first wrapping fiber layer; and the second wrapping fiber layer is made of Shengma fibers. The fine denier vortex spinning yarn is formed by spinning the fine denier spandex filaments, the fine denier profiled acrylic fibers and the Shengma fibers through the vortex spinning technology, the yarn body forms a composite covering yarn structure by means of different characteristics of the blend fibers, the different blend fibers complement each other, and the high count yarn with excellent comprehensive performance is formed.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

Crystal form of Dimethylamino Arglabin hydrochloride

ActiveCN102190663AHigh purityEasy to manufactureOrganic active ingredientsOrganic chemistryFiltrationX-ray

The invention relates to a novel crystal form of Dimethylamino Arglabin hydrochloride, a preparation method and therapeutic use thereof. The crystal form of Dimethylamino Arglabin hydrochloride provided in the invention, and has characteristic peaks at 13.02+ / -0.2, 19.38+ / -0.2, 25.80+ / -0.2, and 27.70+ / -0.2 when using Cu-Ka radiation with lambda of 1.5405 and 2theta to represent X-ray diffraction spectra, wherein, the diffraction peak intensity of the peaks at 13.02+ / -0.2 is 100%. The crystal form of Dimethylamino Arglabin hydrochloride provided in the invention is scalelike crystallization, and is characteristics in that: the filtration is simple; drying is easy so as to achieve the stable performance during the drying; the crystal form is easy to be dissolved in water so as to achieve short dissolution time and decrease the degradation; the crystal form is static-free so as to be helpful for preparing following preparation products; and the crystal form has high purity of crystal with obvious effects of purification and is convenient for industrialized production.

Owner:INNOVSTONE THERAPEUTICS LTD

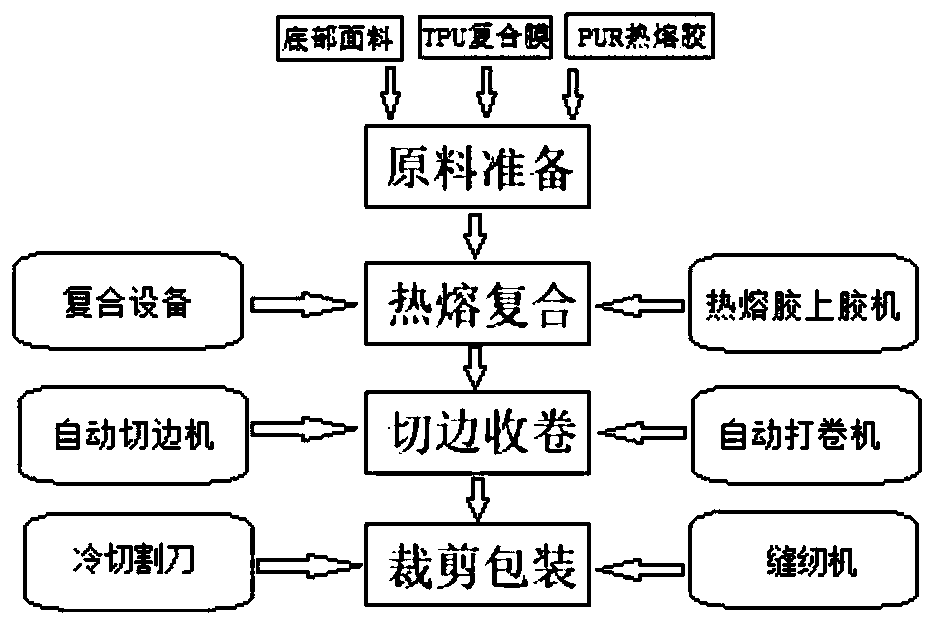

Processing technology of waterproof oil-proof ironing-resistant TPU table cloth cushion

InactiveCN111469419AStrong oil resistance and water resistanceExcellent water and oil repellencyFlat articlesEconomic benefitsProcess engineering

The invention discloses a processing technology of a waterproof oil-proof ironing-resistant TPU table cloth cushion. The processing technology takes a TPU composite film, a base fabric and a PUR hot melt adhesive as raw materials, and adopts a hot-pressing composite processing mode for forming. The processing technology mainly comprises the four steps of raw material preparation, hot-melting compounding, trimming and rolling, and cutting and packaging. The processed table cloth finished product has the characteristics of no washing, easy cleaning, oil resistance, water resistance and the like;and the production and manufacturing process is more environment-friendly. According to the processing technology, the two different materials of the TPU composite film and the bottom fabric can be well combined, the product is a non-toxic environment-friendly material, and the processing technology can be applied to the production and manufacturing of table cloth, can also be applied to other technical fields, and has great economic benefits.

Owner:项官能

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com