Processing technology of waterproof oil-proof ironing-resistant TPU table cloth cushion

A waterproof and oil-proof, processing technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of not bright enough color, no oil-proof function, not resistant to dirt, etc., to create colors and patterns. Low cost, high practical value and promotion value, excellent water and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

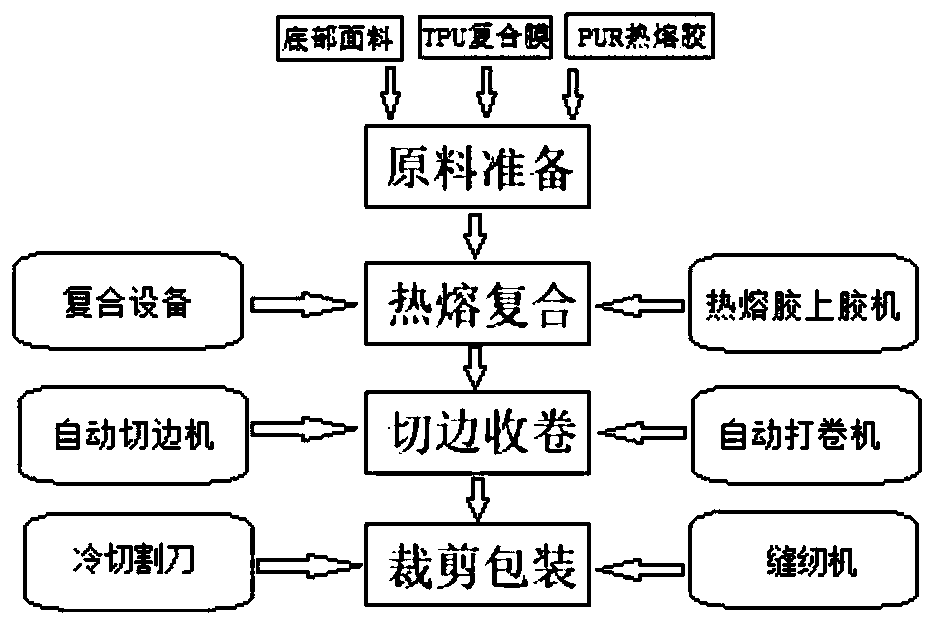

Method used

Image

Examples

Embodiment Construction

[0021] Here, it should be noted that the functions and methods involved in the present invention are merely conventional adaptive applications of the prior art. Therefore, the improvement of the present invention to the prior art lies in the connection relationship between the hardware, rather than the functions and methods themselves. Improve. The description of the functions and methods in the present invention is to better illustrate the present invention so as to better understand the present invention.

[0022] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0023] It should be noted that, unless otherwise specified, the technical terms or scientific terms used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com