Fluorine containing composition and fluorine containing polymer

A composition and polymer technology, applied in textiles and papermaking, chemical instruments and methods, other chemical processes, etc., can solve the problems of grey fabric pollution, roller pollution, etc., and achieve low adhesion and adhesive adhesion, good processing, Excellent water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

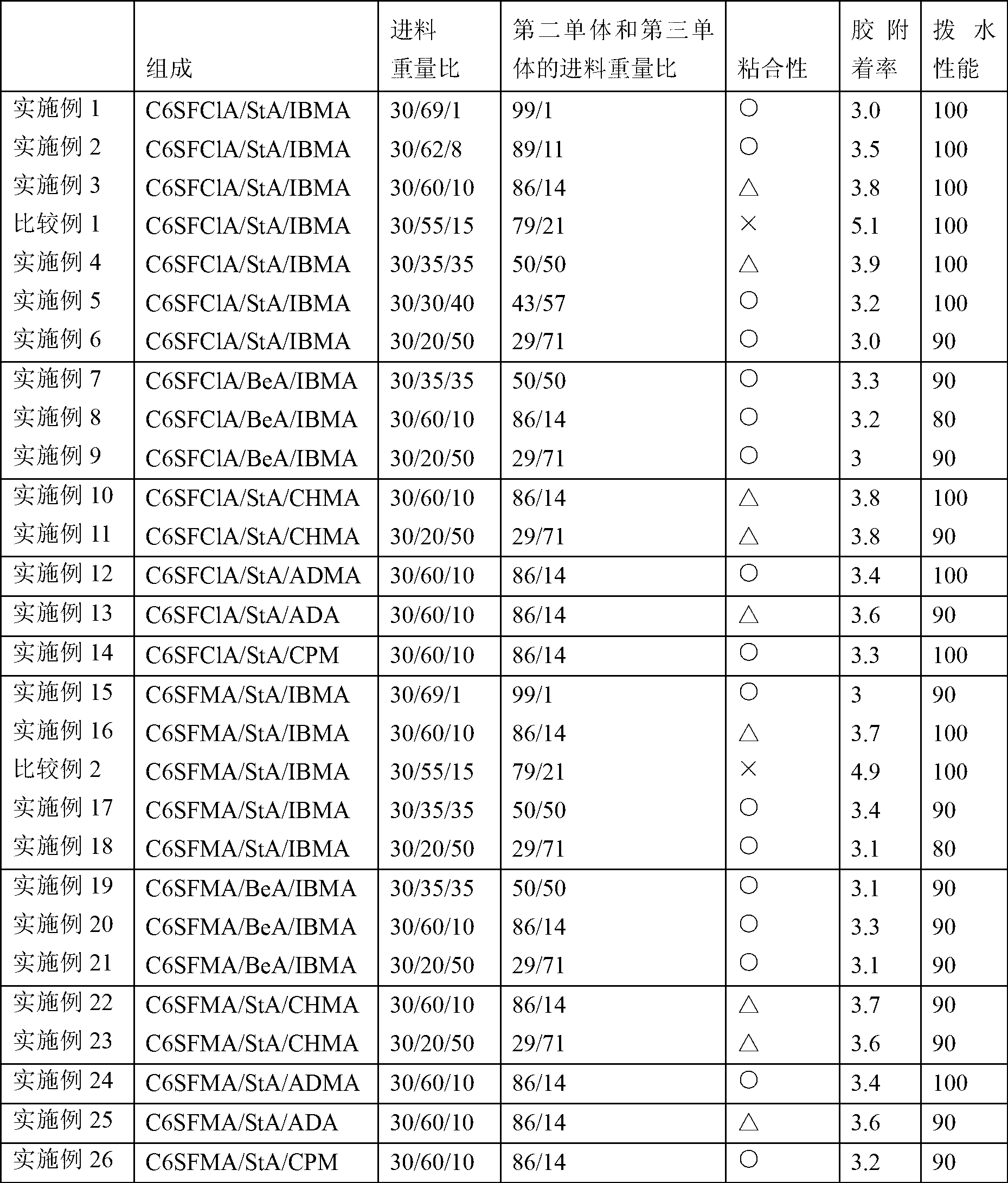

[0228] Hereinafter, although an Example is given and this invention is demonstrated in detail, this invention is not limited to these Examples.

[0229] Hereinafter, unless otherwise specified, parts, %, or ratios represent parts by weight, % by weight, or ratio by weight.

[0230] The test procedure is described below.

[0231] Spray water repellency test

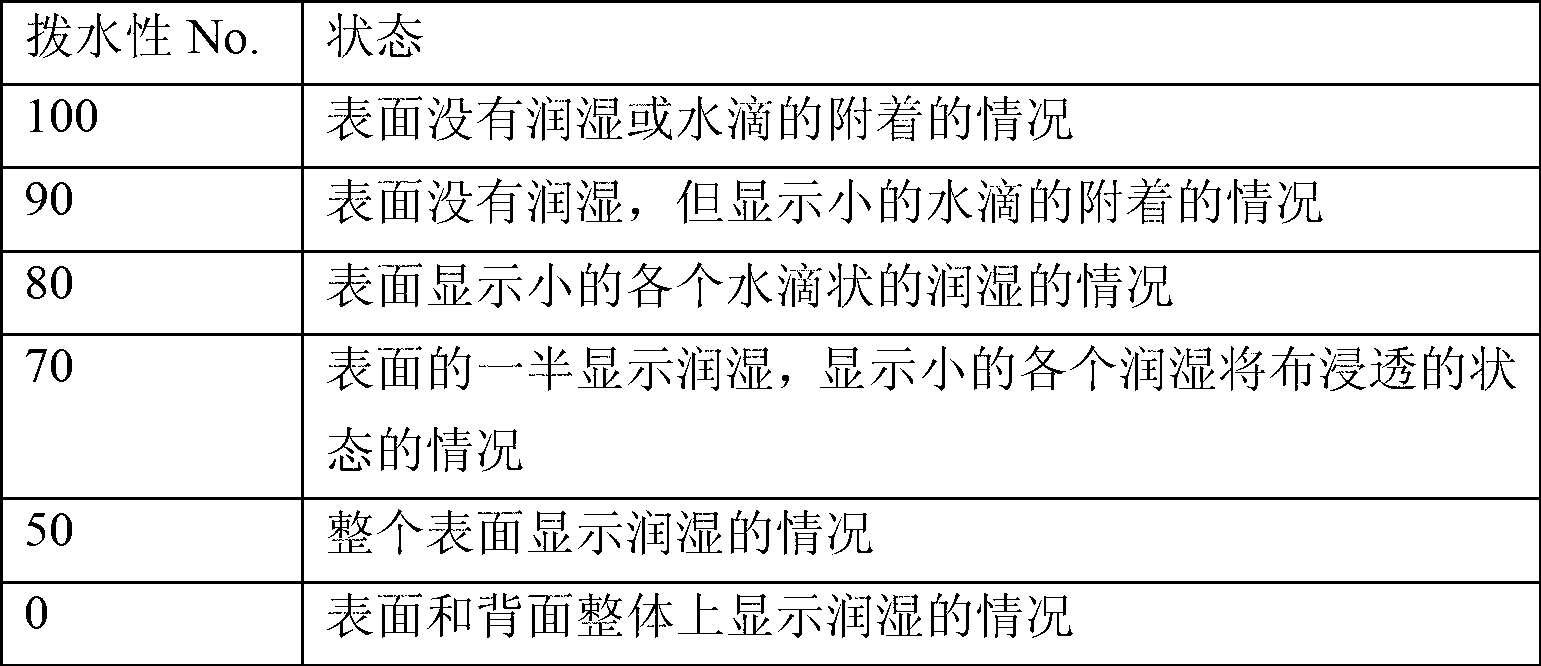

[0232] A spray water repellency test was performed in accordance with JIS-L-1092. The spray water repellency test is represented by water repellency No. (as shown in Table 1 described below).

[0233] Use a glass funnel with a volume of at least 250ml and a nozzle capable of spraying 250ml of water in 20-30 seconds. The test piece frame is a metal frame with a diameter of 15 cm. Three test piece sheets having a size of approximately 20 cm×20 cm were prepared, and the sheets were fixed to the test piece fixing frame so that the sheets were not wrinkled. Place the center of the spray in the center of the sheet. Water...

manufacture example 1

[0249] Add CF to a 300mL autoclave 3 CF 2 -(CF 2 CF 2 ) n -CH 2 CH 2 OCOC(Cl)=CH 2 (n=2.0) (C6SFClA) 18.63g, stearyl acrylate (StA) 42.84g, isobornyl acrylate (IBMA) 0.62g, pure water 110g, dipropylene glycol monomethyl ether 18.62g, octadecyltri Methyl ammonium chloride 2.57g, polyoxyethylene lauryl ether (EO: 20. EO represents the number of ethylene oxide units) 2.65g, polyoxyethylene isotridecyl ether (EO: 3) 1.21g, under stirring, It was emulsified and dispersed by ultrasonic waves at 60°C for 15 minutes. After nitrogen substitution in the reaction flask, 0.62 g of lauryl mercaptan, 0.31 g of 2,2-azobis(2-amidinopropane) 2 hydrochloride (hereinafter referred to as V-50) and 9 g of water were added. solution, reacted at 60°C for 5 hours to obtain an aqueous dispersion of the polymer. The composition of the polymer is substantially identical to that of the feed monomer.

[0250] Carry out adhesive adhesion test and adhesion test. Table A shows the test results.

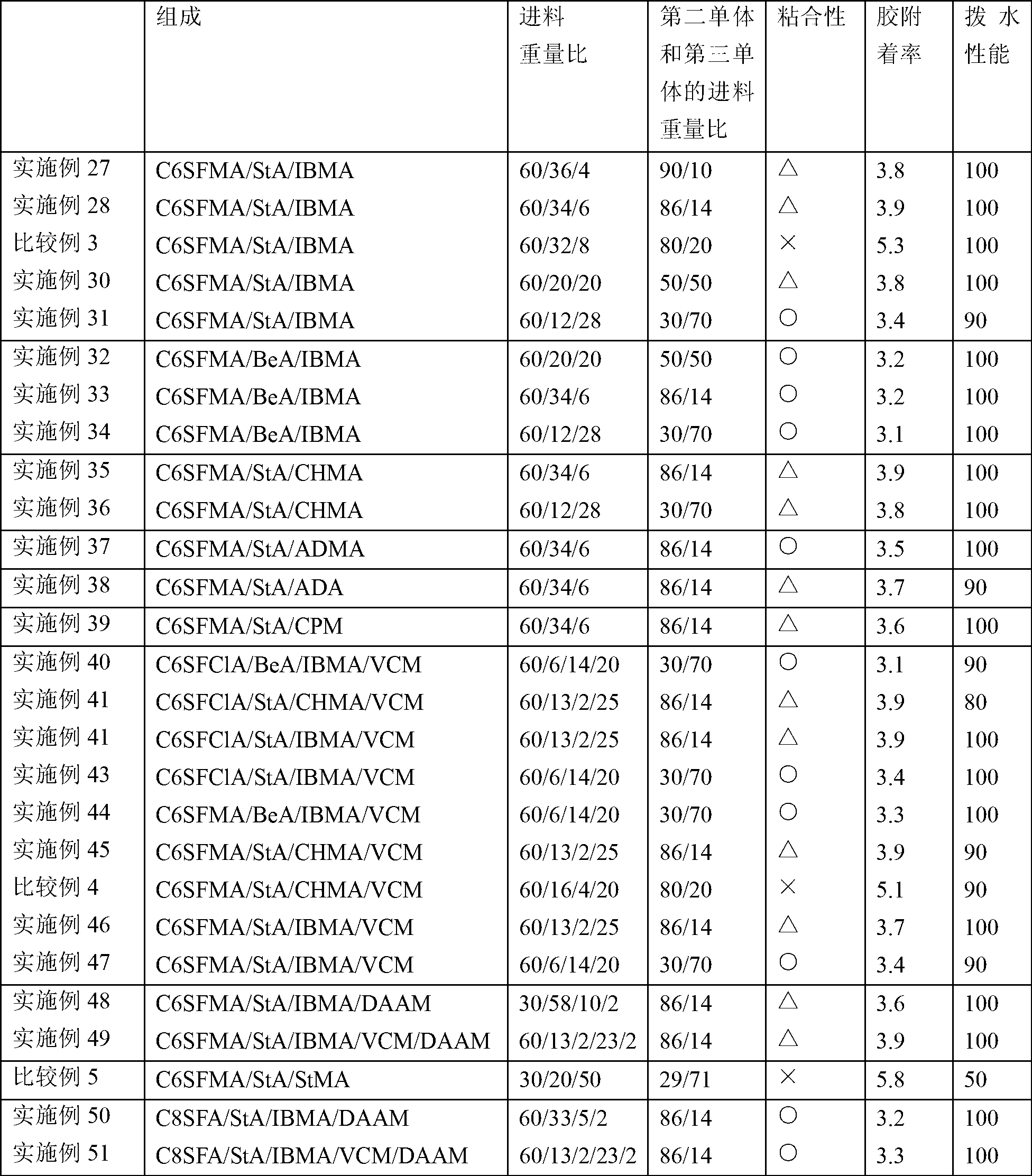

manufacture example 2~51 and comparative manufacture example 1~4

[0252] Monomers having the compositions (kinds and weight ratios of feed monomers) shown in Table A were polymerized in the same procedure as in Production Example 1 to prepare an aqueous polymer dispersion. The composition of the polymer is substantially identical to that of the feed monomer.

[0253] Table A shows the test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com