Fine denier vortex spinning yarn and spinning process

A technology of vortex spinning and vortex spinning, which is applied in yarn, textile and paper making, etc. It can solve the problems of poor yarn strength, easy fluffing and pilling, and difficulty in spinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

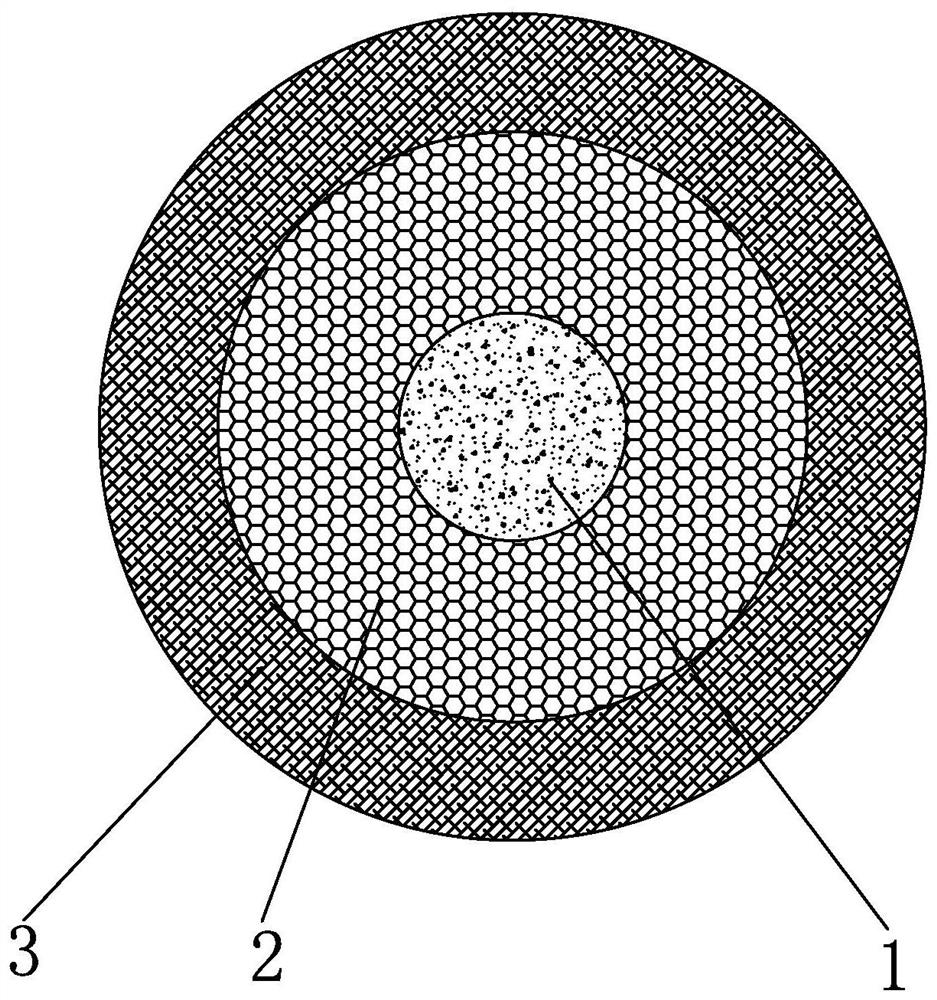

[0021] combine figure 1 , this embodiment provides a fine-denier vortex spun yarn, including a yarn body. The invention is a high-count yarn, which is used for the production of high-quality light and thin fabrics. The fineness of the yarn body is controlled at 4.9-8.4tex. The yarn body is a core filament 1 , a first wrapping fiber layer 2 and a second wrapping fiber layer 3 . The core yarn 1 is fine denier spandex yarn. Preferably, the fine-denier spandex yarn is a 20D filament. The first wrapping fiber layer 2 is spirally wrapped around the core filament 1 . The first wrapping fiber layer 2 adopts special-shaped acrylic fiber with fine denier. The second wrapping fiber layer 3 is helically wrapped outside the first wrapping fiber layer 2 . The second wrapped fiber layer 3 adopts holy hemp fiber.

[0022] In order to simplify the subsequent production process, reduce production costs, and improve the environmental protection of the production process, the special-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com