Substrate disposal device

A substrate processing device and substrate technology, applied in lighting and heating equipment, applications, cleaning methods and appliances, etc., can solve the problems of metal film damage, ice particles and uneven impact energy on the substrate surface, and achieve efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

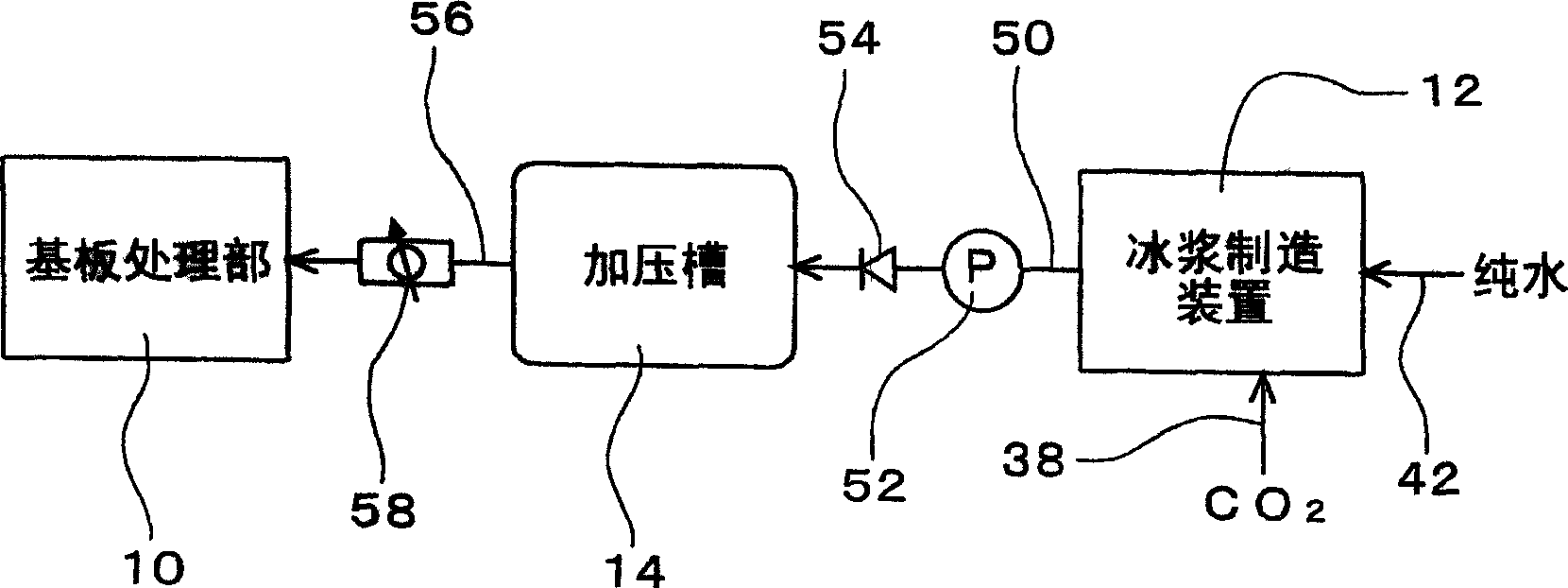

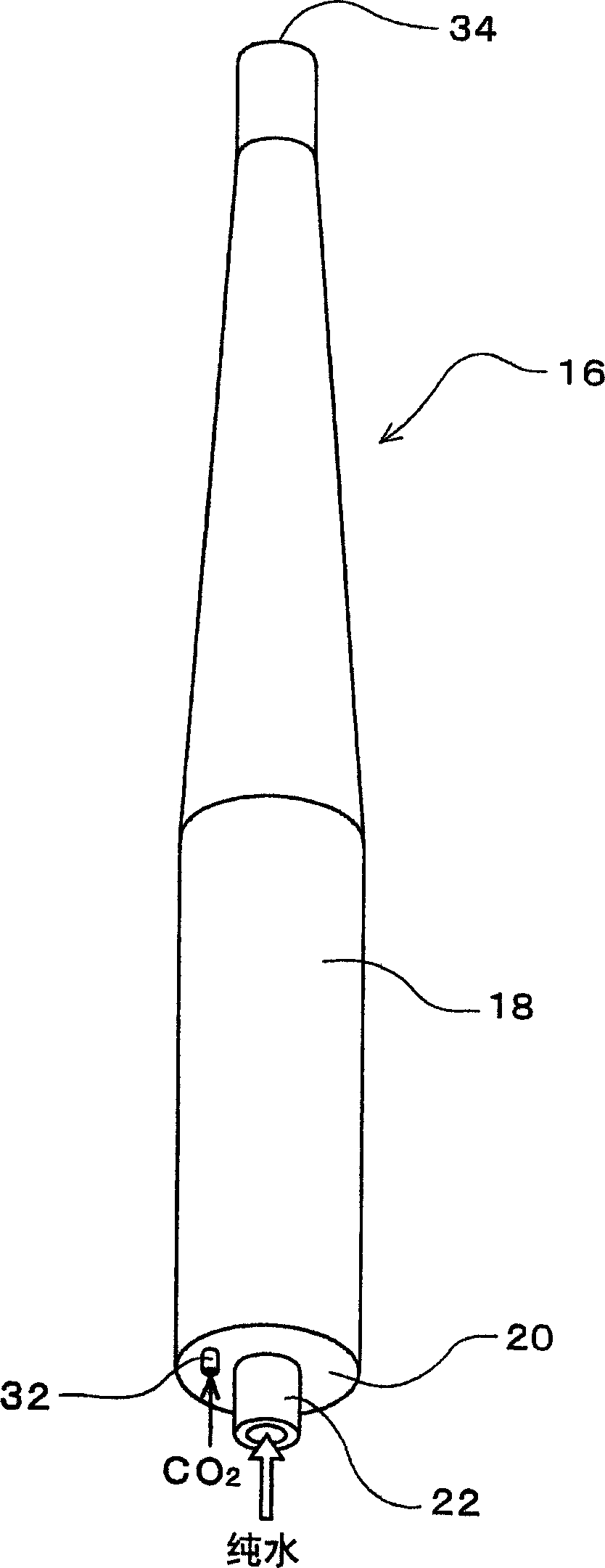

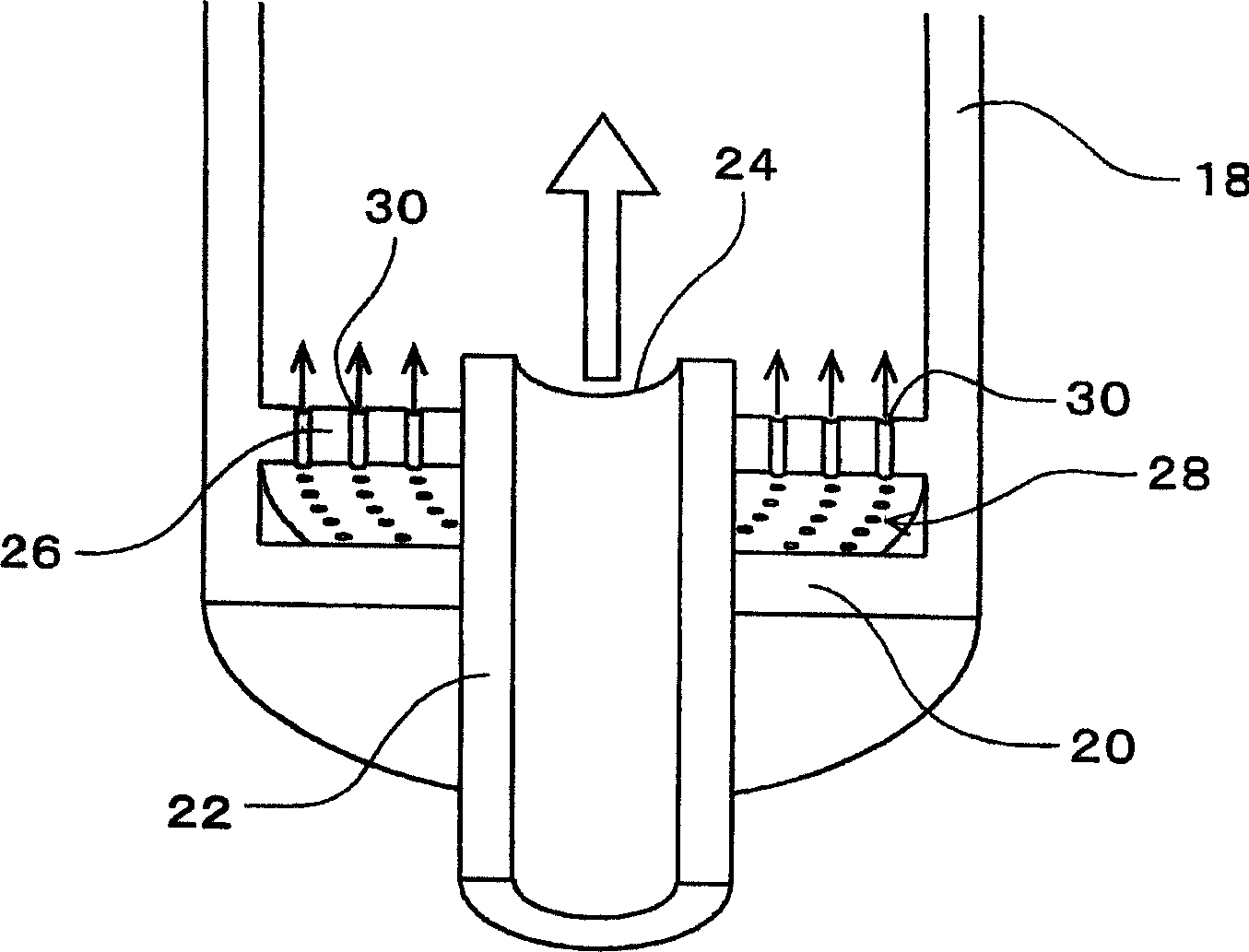

[0032] Figure 1 to Figure 5 Showing an example of an embodiment of the present invention, figure 1 It is a schematic diagram showing a substrate processing apparatus, and in this example, an overall configuration of a substrate cleaning apparatus. in addition, figure 2 It is a perspective view of the appearance of the main body of the ice slurry manufacturing apparatus, which is one of the structural elements of the substrate cleaning apparatus, image 3 It is an enlarged perspective view of a part of the state in which the main body of the ice slurry production device is cut vertically, Figure 4 is a block diagram of the ice slurry manufacturing device, Figure 5It is a schematic front view showing an example of the structure of the substrate processing unit of the substrate cleaning apparatus.

[0033] This substrate cleaning apparatus includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com