Double-sided ink-jet printer

An inkjet printer, double-sided technology, applied in typewriters, printing devices, printing, etc., can solve the problems of long intervals between ink scraping, pattern damage, and high upgrade costs, so as to avoid poor cleaning effect, reduce relative movement, and save upgrades cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

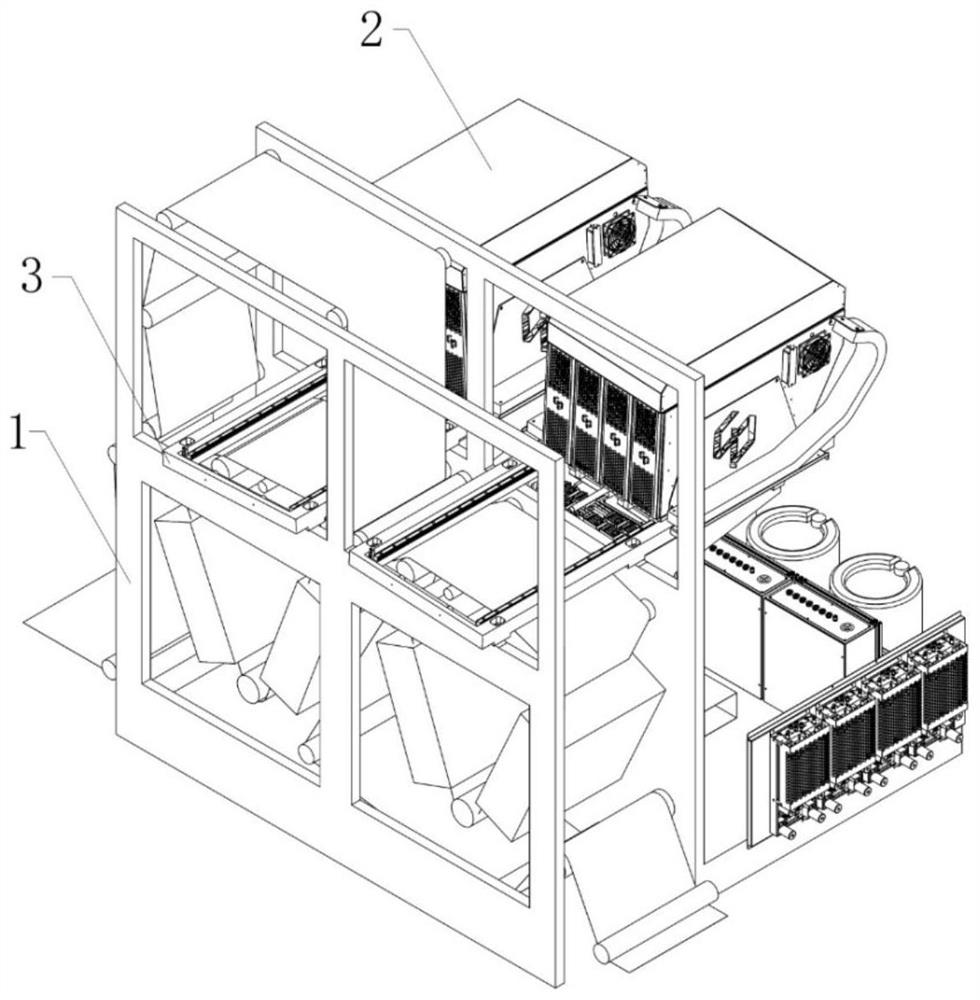

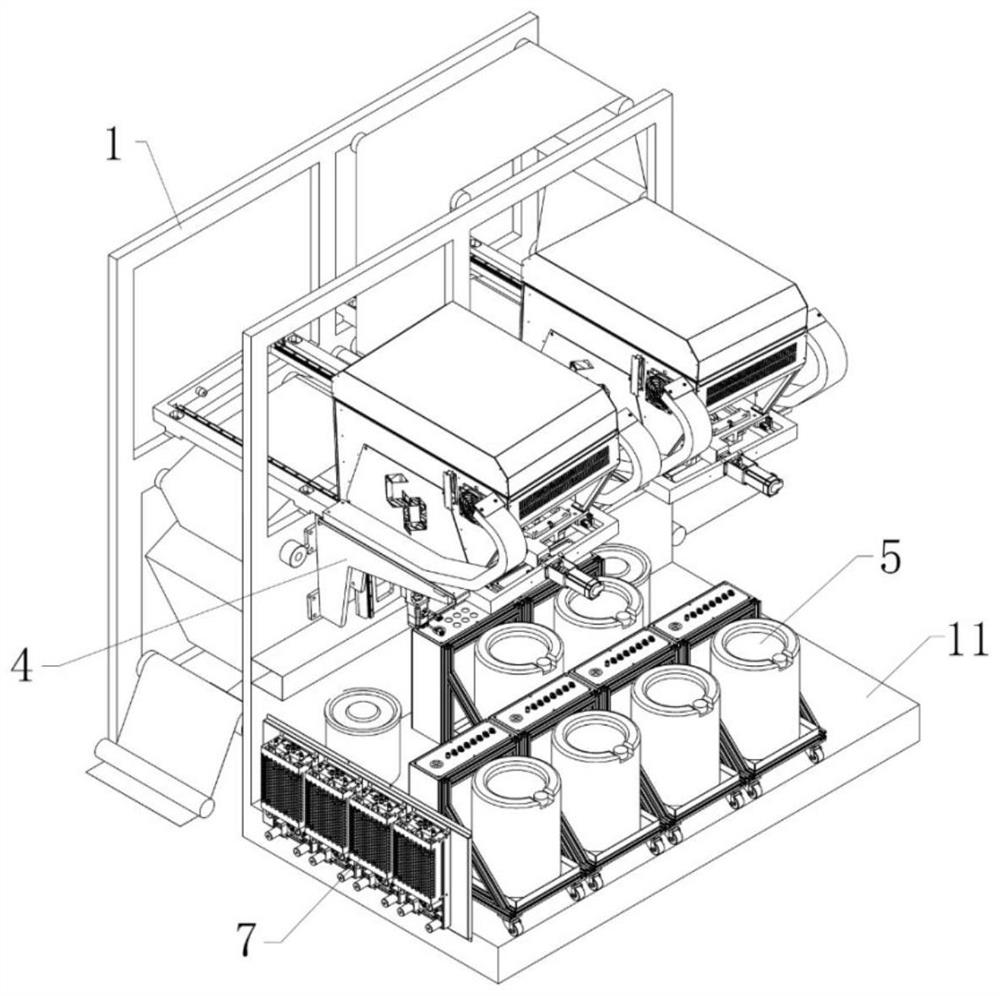

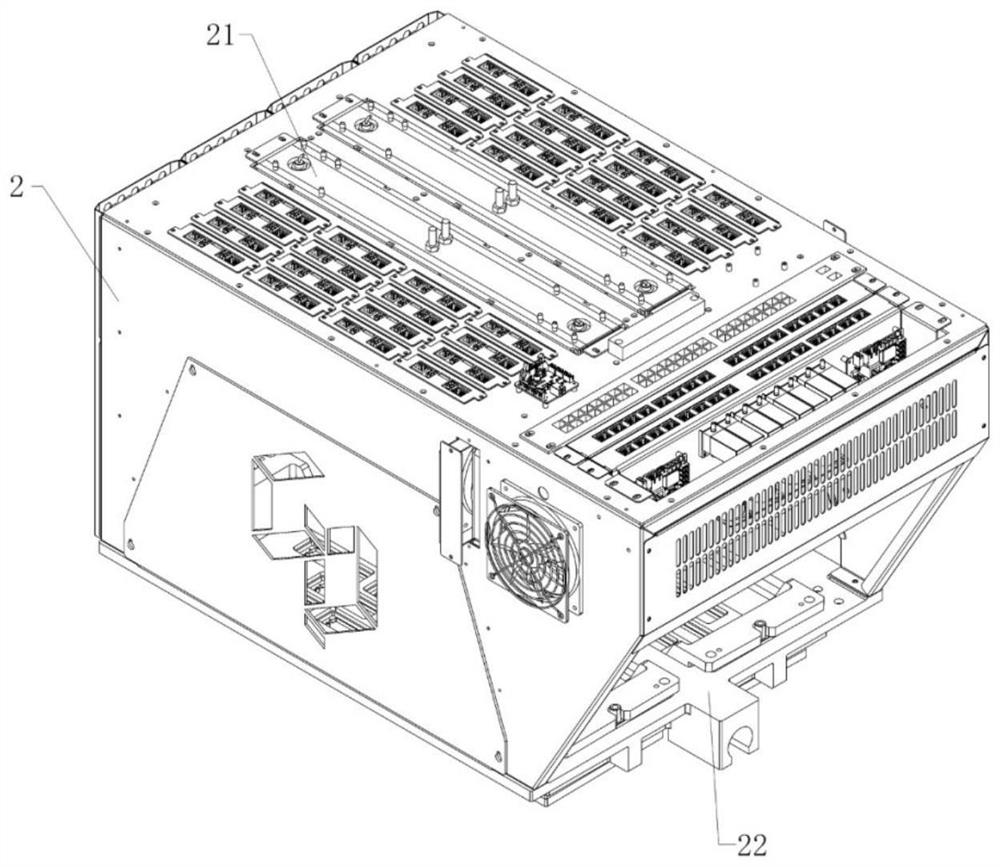

[0065] A double-sided inkjet printer, with reference to Figure 1 to Figure 4 , Figure 10 , Figure 21 and Figure 22 As shown, the improvement is that it includes a printing unit; the printing unit includes a main frame 1; a feeding device is installed on the main frame 1 for supporting and conveying the printing medium, and the feeding device includes Several supporting rollers, the printing medium forms four printing areas under the support of the supporting rollers, which are respectively the first printing area, the second printing area, the third printing area, and the fourth printing area; Y-axis transmission device 3; the top of the Y-axis transmission device 3 is equipped with a printing carriage 2, and the printing carriage 2 moves forward to the top of the printing area under the drive of the Y-axis transmission device 3, and moves backward to The top of the nozzle maintenance area; the bottom of the printing cart 2 is equipped with a bottom plate, and the print...

Embodiment 2

[0074] On the basis of embodiment 1, with reference to Figure 20 and Figure 21 As shown, the support rollers include a first support roller 61, a second support roller 62, and a third support roller 63 installed on the left side of the main frame 1, and the support rollers also include a first support roller installed on the right side of the main frame 1. The fourth support roller 64, the fifth support roller 65, and the sixth support roller 66 on the side; the height of the first support roller 61 is lower than the height of the third support roller 63, and the second support roller 62 is located at the Between the first support roller 61 and the third support roller 63, and above the line connecting the first support roller 61 and the third support roller 63, the printing medium is on the first support roller 61, Under the support of the second supporting roller 62 and the third supporting roller 63, the adjacent first printing area and the second printing area are forme...

specific Embodiment approach

[0077] 1) Printing media layout method 1: such as Figure 21 As shown, the printing medium is wound up and then down under the action of the guide roller, and passes through the second printing area and the first printing area in sequence from right to left, and is turned over under the support of the guide roller below and then upwards. Go around and pass through the third printing area and the fourth printing area once from left to right. The printing medium is arranged in a V-shaped structure via guide rollers under the printing area. A drying device is provided on the side of the V-shaped. For drying the printed printing medium, the arrangement of V-shaped guide rollers makes the number of drying devices that can be set in the space the largest, and the drying area is the largest, making the drying effect better; the structural arrangement of each roller , so that the surface of the printing medium after printing is not in direct contact with the roller, but is in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com