3D manipulator for massage chair

A massage chair and manipulator technology, used in massage auxiliary products, roller massage, vibration massage, etc., can solve the problems of slippage, reduce transmission efficiency, affect the stability of massage chairs, etc., and achieve cost reduction, convenience and maintenance-free use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

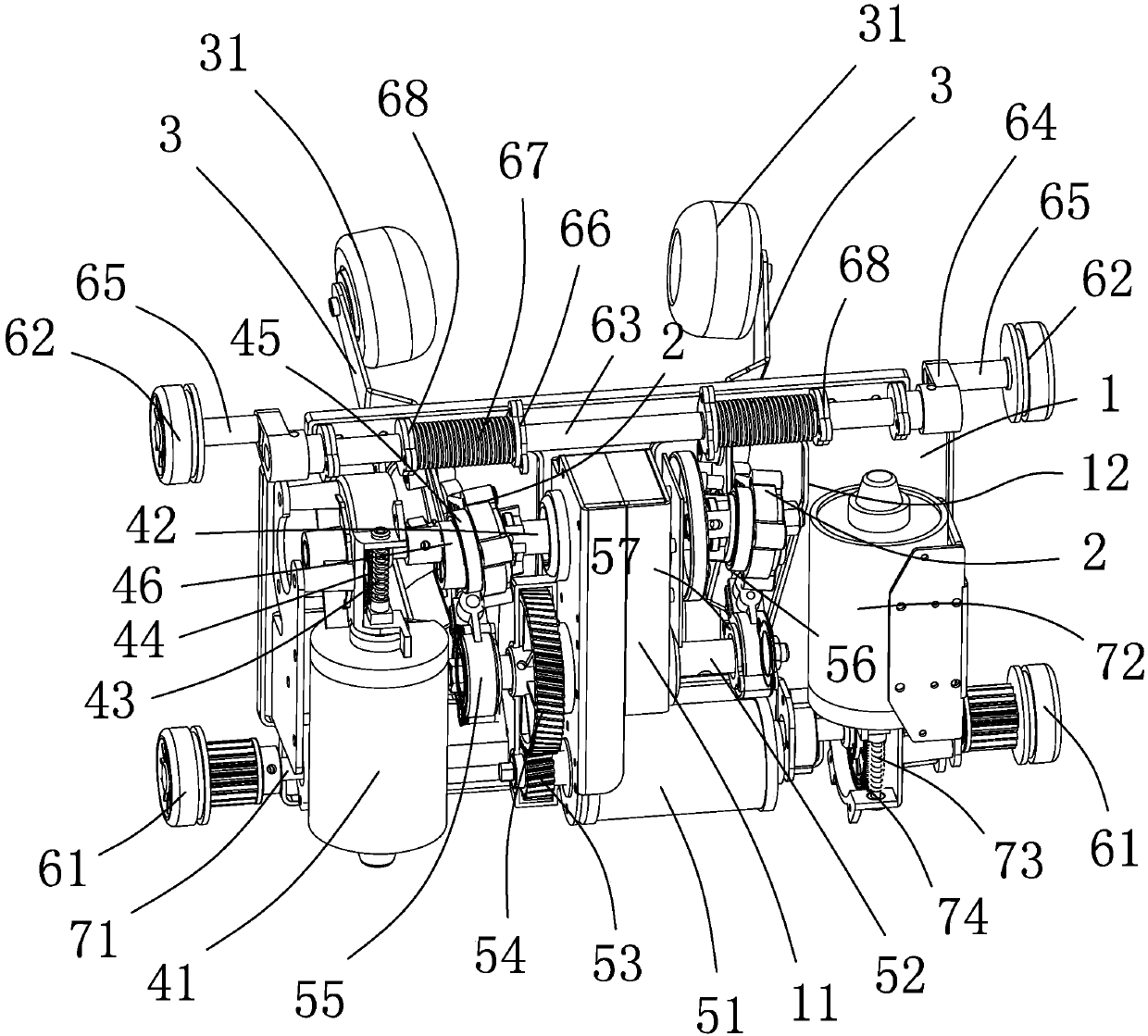

[0018] An embodiment of a 3D manipulator for a massage chair of the present invention is figure 1Shown: including walking board 1, two swing arms 2 are arranged at the rear end of walking board 1, and two swing arms 2 are pin-connected with crank arm 3 protruding to the front of walking board 1, and massage arm 3 is provided with The ball 31, the rear end of the walking board 1 is provided with a kneading component that drives the swing arm 2 to move to realize the kneading massage action, a knocking component that drives the swing arm 2 to move to realize the percussion massage movement, and drives the walking board 1 to move along the massage chair guide rail. The walking assembly for walking, the kneading assembly includes a kneading motor 41, a kneading eccentric shaft 42 and a kneading transmission mechanism, the output shaft of the kneading motor 41 is fixed with a first worm 43, and the kneading eccentric shaft 42 is fixed with a A worm 43 meshes with the first helical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com