Patents

Literature

124results about How to "Prevent static buildup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antistatic layer for electrically modulated display

InactiveUS7087351B2Overcome lack of conductivityPrevent static buildupLiquid crystal compositionsDischarge tube luminescnet screensAntistatic agentDisplay device

The present invention relates to a display comprising at least one substrate having at least one electrically modulated imaging layer thereon, at least one patterned electrically conductive layer, and at least one antistatic layer.

Owner:EASTMAN KODAK CO

Antistatic layer for electrically modulated display

InactiveUS20060068329A1Overcome lack of conductivityPrevent static buildupLiquid crystal compositionsDischarge tube luminescnet screensAntistatic agentDisplay device

The present invention relates to a display comprising at least one substrate having at least one electrically modulated imaging layer thereon, at least one patterned electrically conductive layer, and at least one antistatic layer.

Owner:EASTMAN KODAK CO

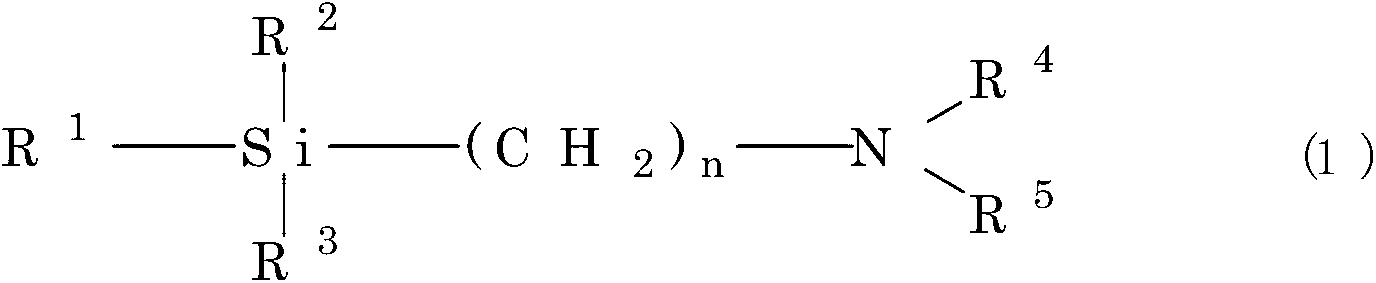

Electrostatic-resistant heat conducting plastic

InactiveCN101280109AReduce hardnessLow costHeat-exchange elementsHeat conductingConductive materials

The invention relates to the technical field of thermal conductive materials, particularly to an anti-static thermal conductive plastic, comprising the following components based on weight proportion: 30-70% of plastic substrate, 40-75% of filler, 0.1-1% of coupling agent and 0.1-1% of dispersant; the filler is zinc sulfide, which has low hardness and small abrasion to equipment; the plastic of the invention can be applied to a plurality of electronic isolation boards, semiconductor equipment casings and outer shells of mobile communication devices and can effectively prevent electronic components being damaged by static accumulation and graft, which is an anti-static thermal conductive plastic.

Owner:东莞金富亮塑胶颜料有限公司 +1

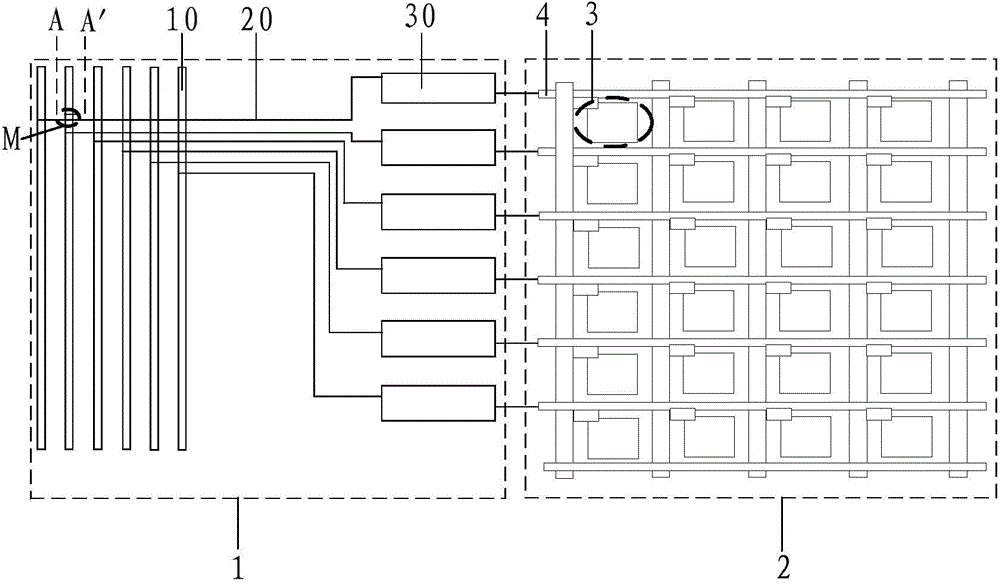

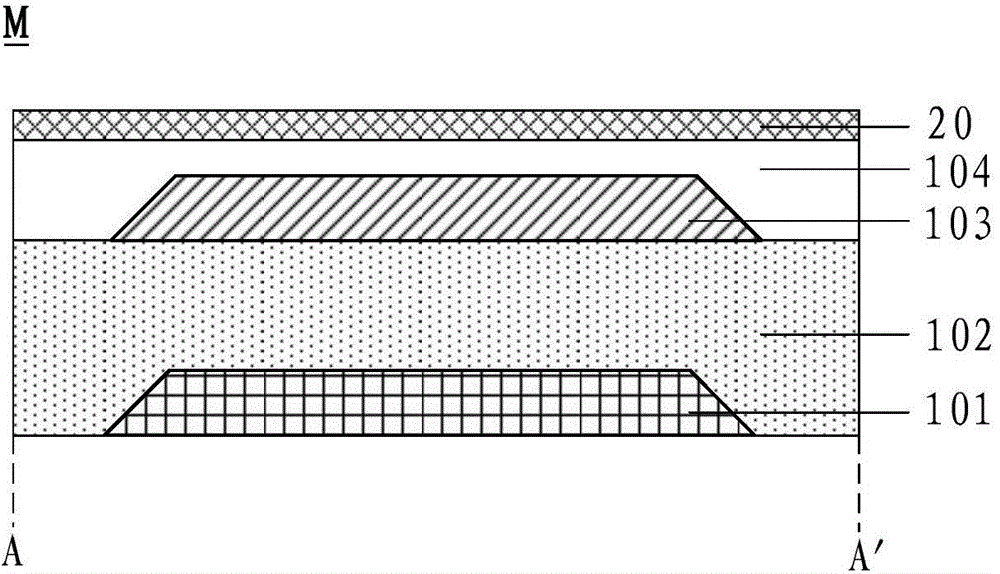

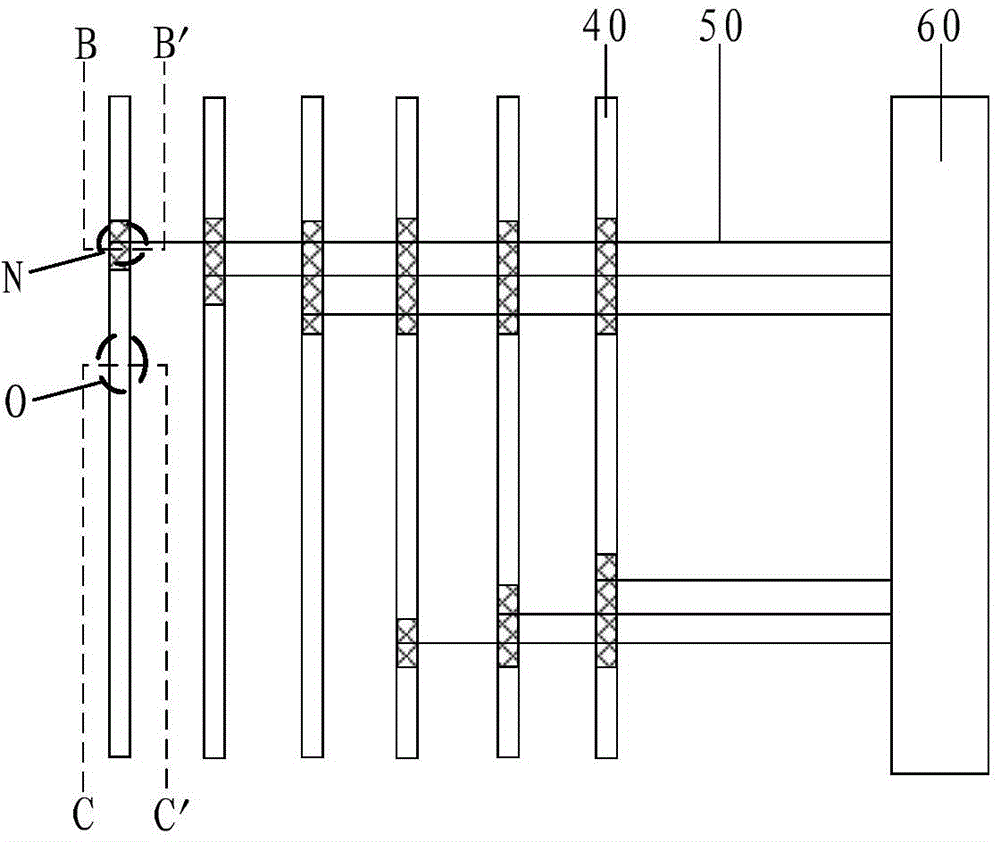

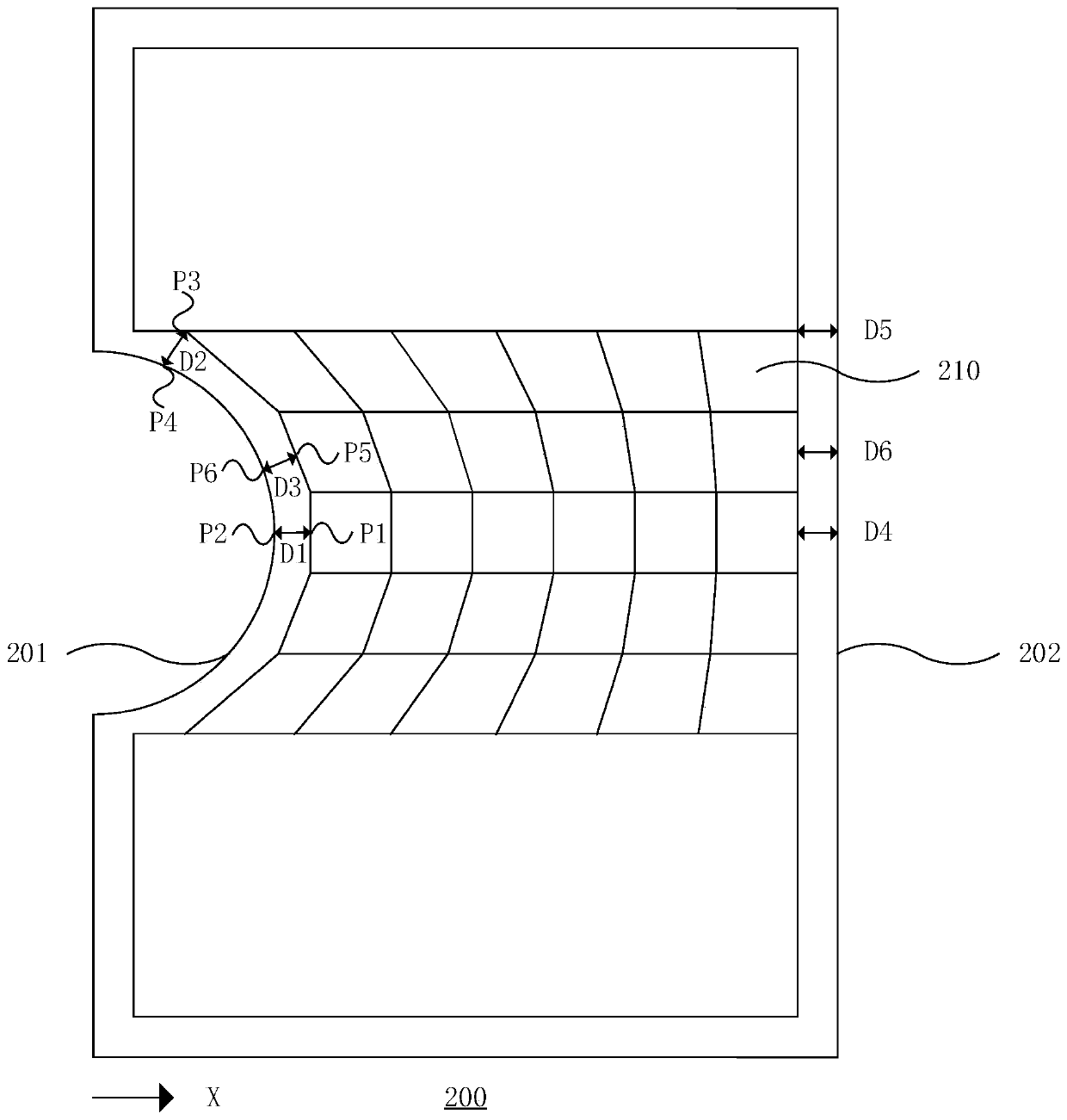

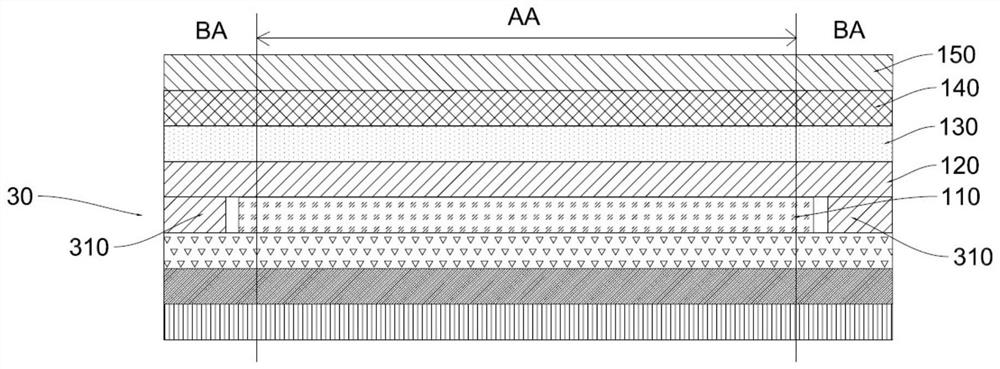

Array substrate and display device

ActiveCN104617106APrevent static buildupImprove insulation performanceStatic indicating devicesSolid-state devicesDisplay deviceSignal lines

The invention provides an array substrate and a display device, relates to the technical field of display, and aims at solving the problem of static accumulation or short circuit caused by a metal connecting wire and a source / drain electrode line of a clock signal line. The array substrate comprises a plurality of signal lines, a plurality of connecting lines and a driving module; the connecting lines are used for connecting the signal lines with the driving module and inputting a signal to the driving module; the connecting lines are positioned above the signal lines, and an insulating layer is arranged on the signal lines; the signal lines are insulated from the connecting lines through the insulating layer; at least one connecting line is intersected to other at least one signal line when connecting with the signal lines; the area in which the signal lines are intersected with the connecting lines comprises a first electrode line, and other areas comprises a first electrode line and a second electrode line. The invention relates to the manufacturing of the array substrate and the display device comprising the array substrate.

Owner:BOE TECH GRP CO LTD

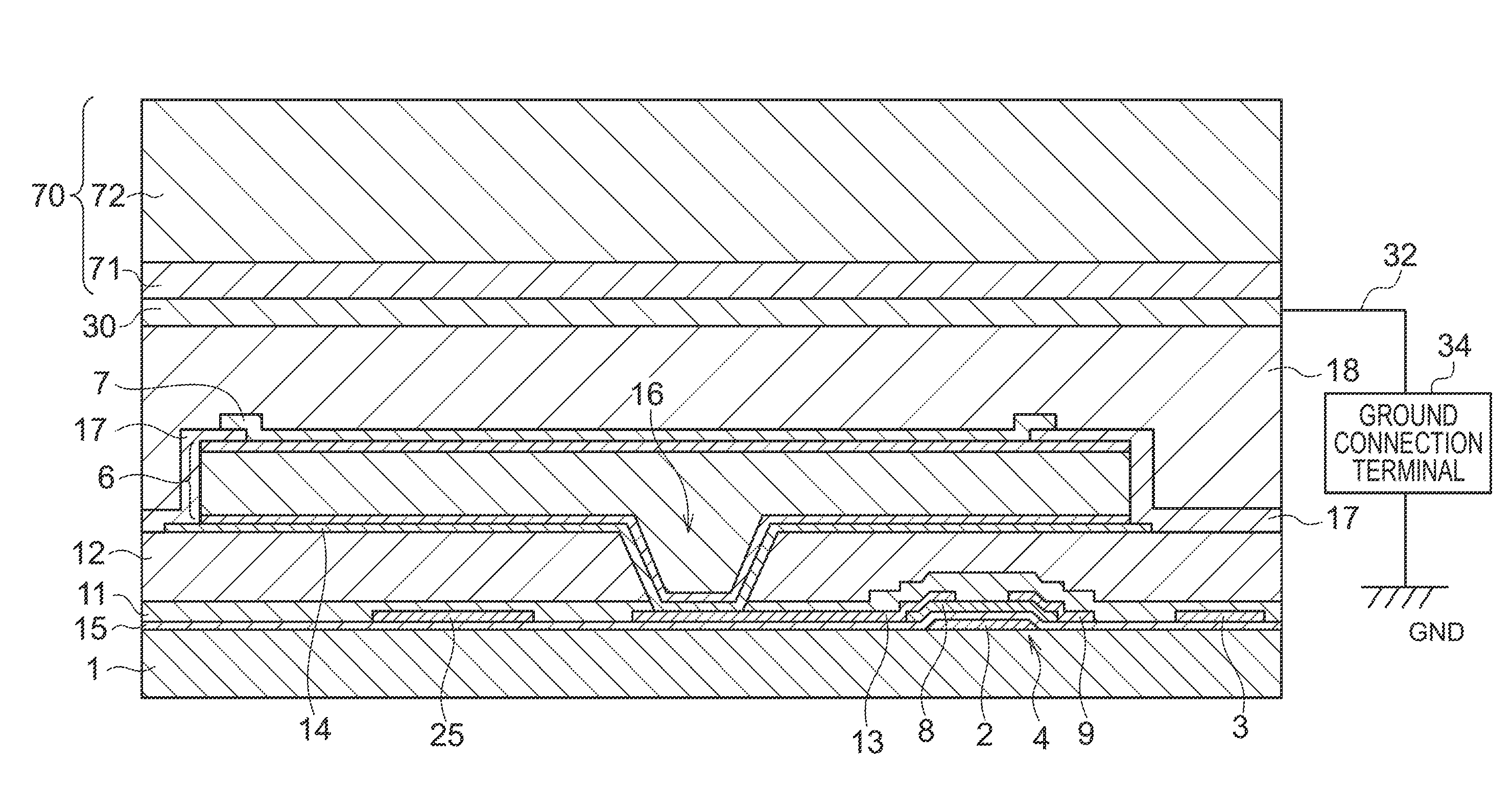

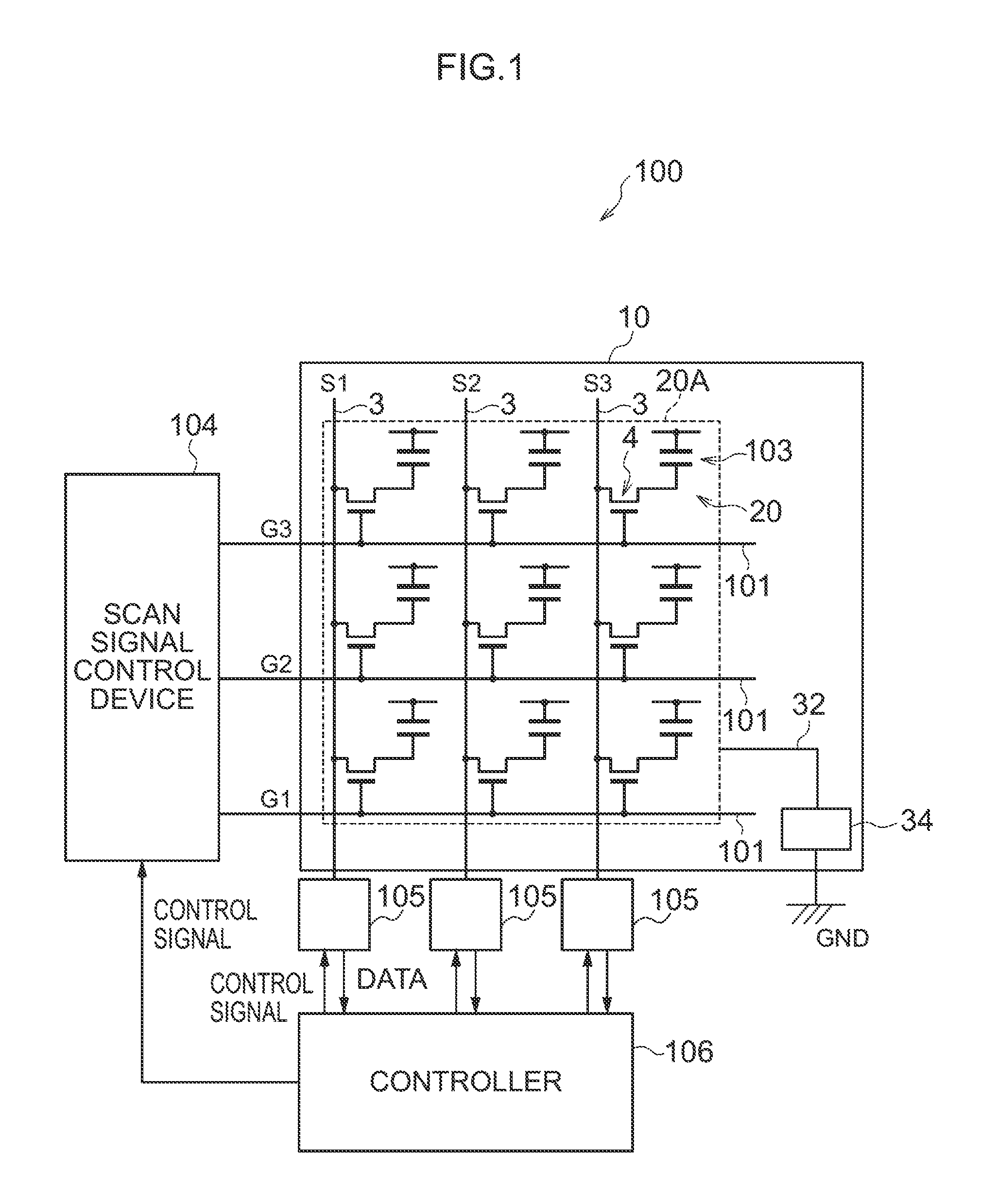

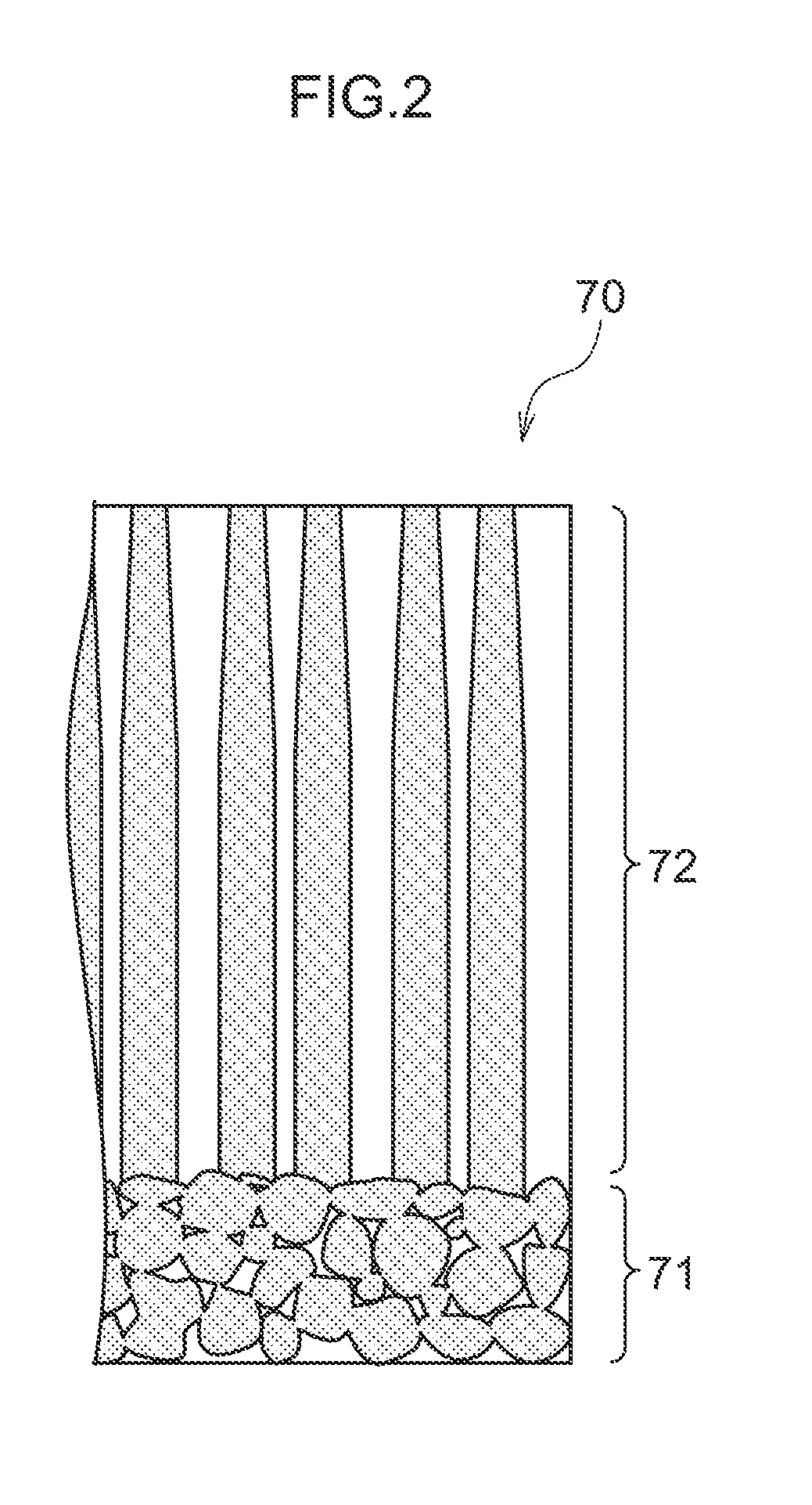

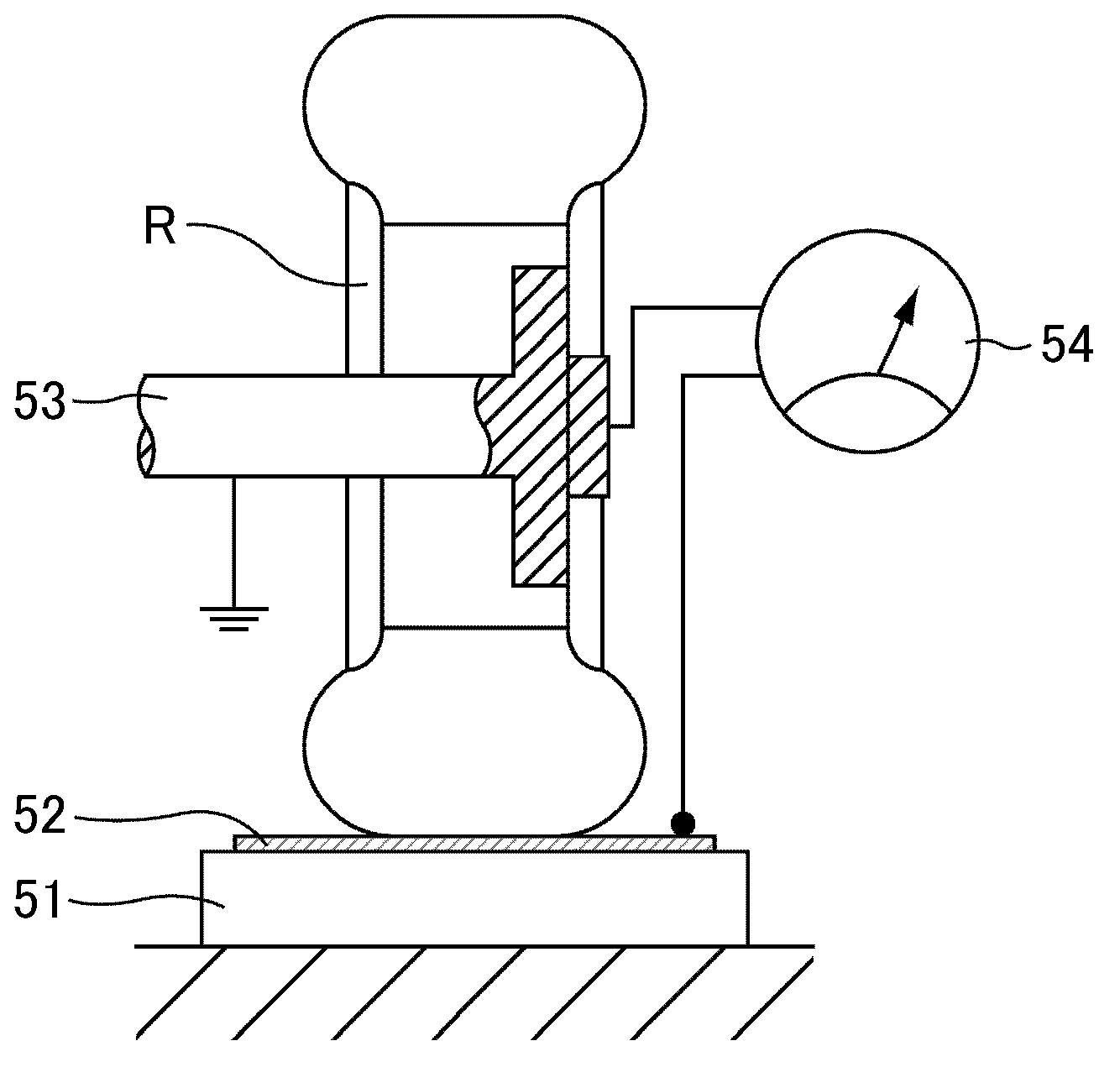

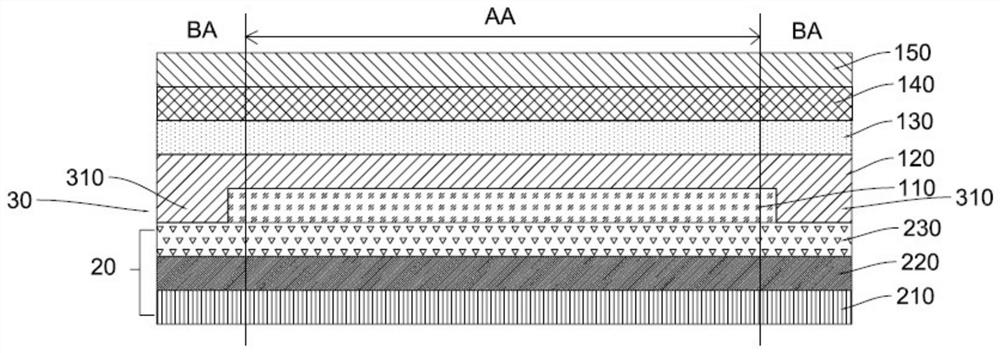

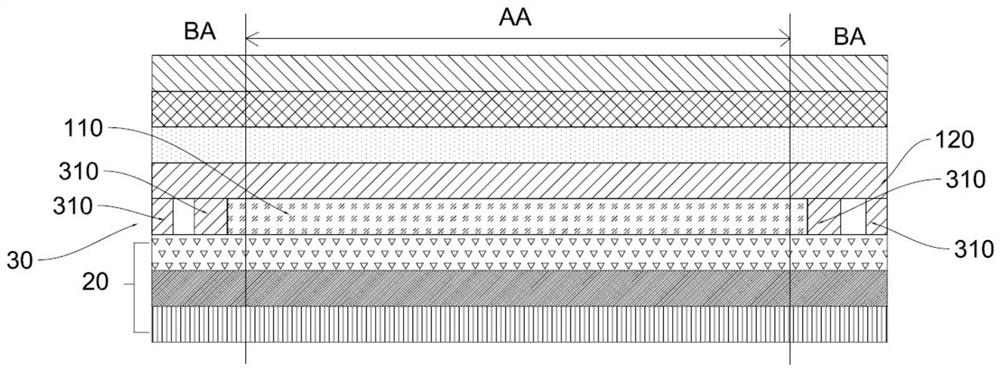

Photoelectric conversion substrate, radiation detector, radiographic image capture device, and manufacturing method of radiation detector

InactiveUS20130048863A1Prevent electrostatic destruction of photoelectricAvoid destructionSolid-state devicesMaterial analysis by optical meansEngineeringPhotoelectric conversion

A photoelectric conversion substrate includes: plural pixels, each provided with a sensor portion and a switching element that are formed on the substrate, the sensor portion including a photoelectric conversion element that generates charge according to illuminated light, and the switching element reading the charge from the sensor portion, a flattening layer that flattens the surface of the substrate having the switching elements and the sensor portions formed thereon, a conducting member formed over the whole face of the flattening layer; and a connection section that connects the conducting member to ground.

Owner:FUJIFILM CORP

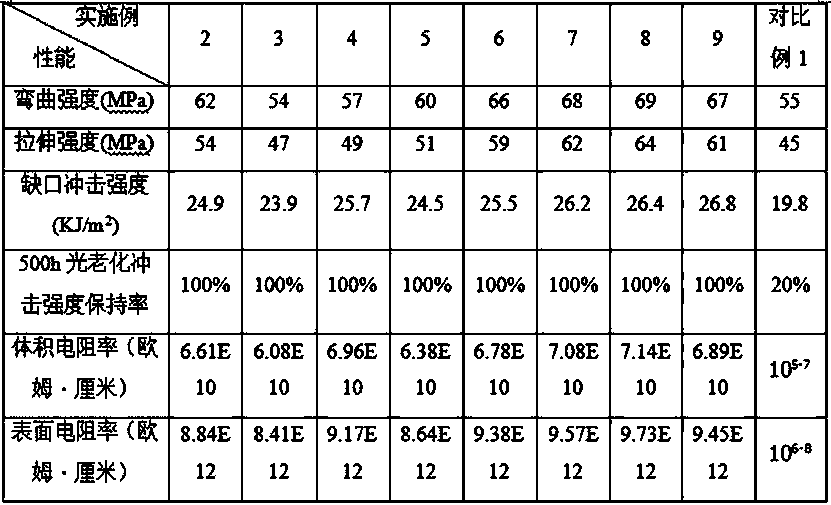

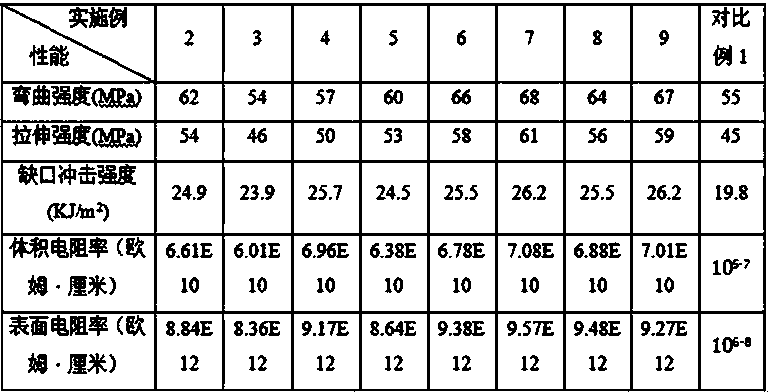

Antistatic anti-aging plastic and preparation method thereof

ActiveCN103396596AImprove notched impact strengthImprove bending strengthPolymer sciencePolyvinyl chloride

The invention discloses an antistatic anti-aging plastic and a preparation method thereof. The antistatic anti-aging plastic is mainly prepared from the following raw materials in parts by weight: 110-130 parts of HDPE (high-density polyethylene), 40-55 parts of PVC (polyvinyl chloride), 30-40 parts of PA6 (polyamide 6), 10-15 parts of coupling agent, 10-12 parts of hydroxymethyl fatty amine, 10-20 parts of shock-resistant modifier, 14-18 parts of polyalcohol, 5-10 parts of antistatic agent, 10-20 parts of carbon black, 5-10 parts of antioxidant, 10-20 parts of DOP (dioctyl phthalate), 10-15 parts of ultraviolet absorbent, 5-10 parts of epoxy octyl stearate and 1-5 parts of barium stearate. The preparation method comprises the following steps: thoroughly mixing the components uniformly, adding the mixture into a double screw extruder, granulating by melting and plastification under certain conditions, and carrying out injection molding on the granules under certain conditions. The method disclosed by the invention is simple in technique, and convenient for large-scale production; and the product has the advantages of high notch impact strength, high bending strength, high hardness, and favorable antistatic and aging resistance.

Owner:ANHUI ANYUAN PLASTIC

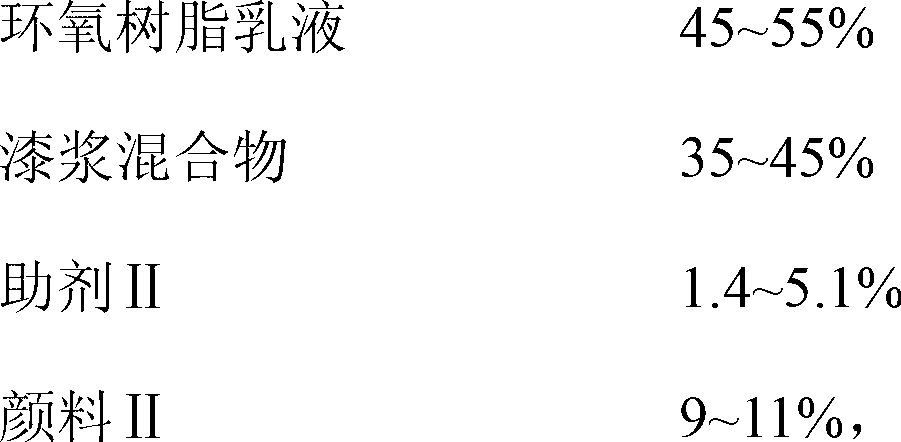

Waterborne epoxy conductive paint and preparation method thereof

ActiveCN102993903AImprove conductivityLow resistivityEpoxy resin coatingsElectrically-conductive paintsEpoxyEmulsion

The invention discloses a waterborne epoxy conductive paint. The waterborne epoxy conductive paint mainly comprises a component A and a component B, wherein the component A comprises the following components in percentage by weight: 45%-55% of epoxy resin emulsion, 5%-45% of mill base mixture, 1.4%-5.1% of auxiliary agent II and 9%-11% of pigment II, and the sum of the components is 100%, wherein the mill base mixture comprises the following components in percentage by weight: 68%-73% of pigment I, 1.3%-4.6% of auxiliary agent I, 0.2%-0.6% of conductive agent and the balance of water; and the component B comprises a curing agent and an emulsifying agent. The waterborne epoxy conductive paint disclosed by the invention has the advantages of good conductibility, acid resistance, alkali resistance, heat resistance and chemical resistance, and can prevent the static accumulation inside an oil tank.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Conductive heat conducting material and method for manufacturing same

InactiveCN101333320AExtend your lifeReduce the temperatureNon-conductive material with dispersed conductive materialHeat-exchange elementsHeat conductingPlastic materials

The invention relates to thermally and electrically conductive material and a fabrication method thereof. The thermally and electrically conductive material contains 10-30wt% expanded graphite, 8-20wt% crystalline flake graphite nano powder, 2-5wt%nano supramoly, and 45-80wt%plastic; wherein the expanded graphite is at granularity of 30-200 mesh and expansion multiple of 100-500 times and contains above 90% carbon, less than0.1% ash, less than 0.1% water, less than 300ppm sulphur and less than 0.01% iron; the flake graphite nano powder is at granularity of less than 100 nanometer and contains more than 90%carbon, less than 0.1% ash, less than 0.1%water, less than 300ppm sulphur and less than 0.01% iron; the nano supramoly D50 is 0.1-3 microns, with specific surface area more than 40m<2> / g; the plastic material contains polystyrene, acrylonitrile- butadiene- cinnamene, polyimide, makrolan, etc. In the fabrication process, above materials are put into a double screw extruder and are extruded in the hopper of the extruder for 1-12h under 50-120 DEG C, then are mixed for 2-5min in the double screw extruder under 140-290 DEG C; finally the materials are molded through extrusion or injection at pressure of 100-200MPa.

Owner:晟茂(青岛)先进材料有限公司

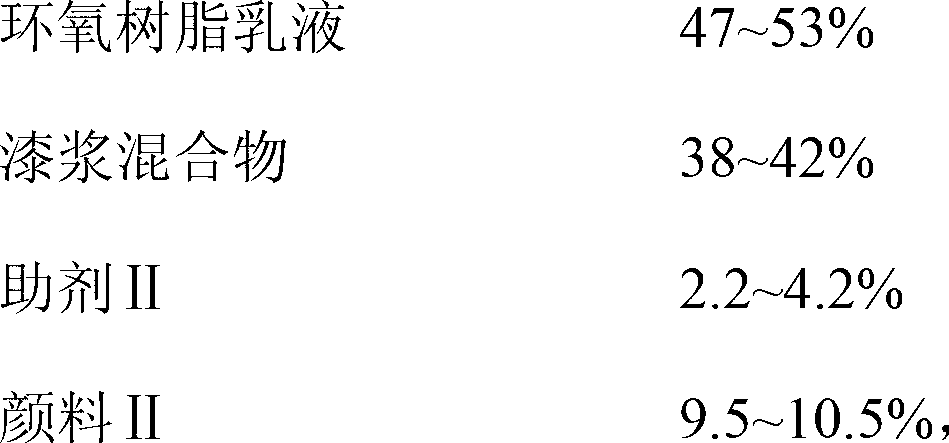

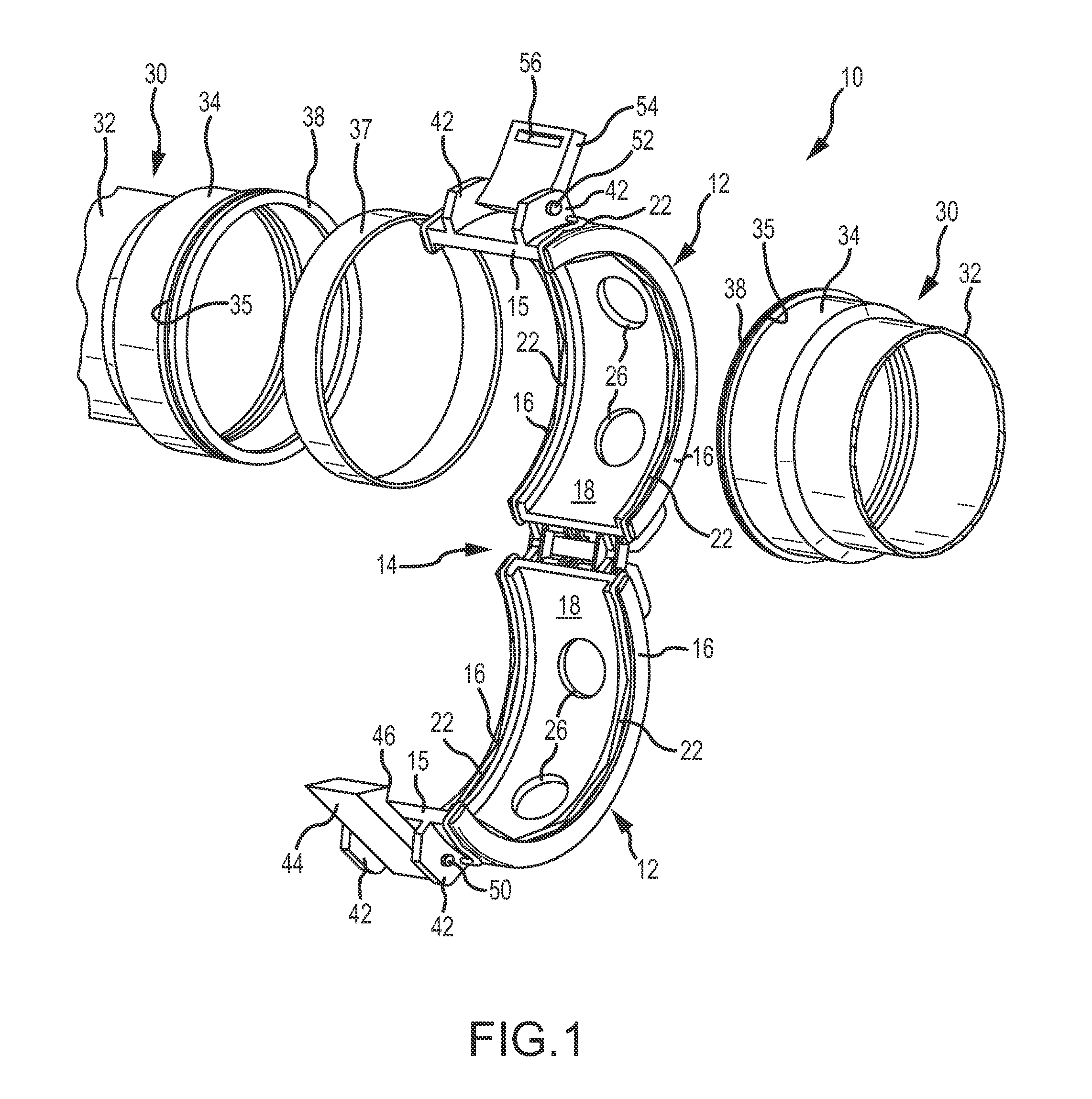

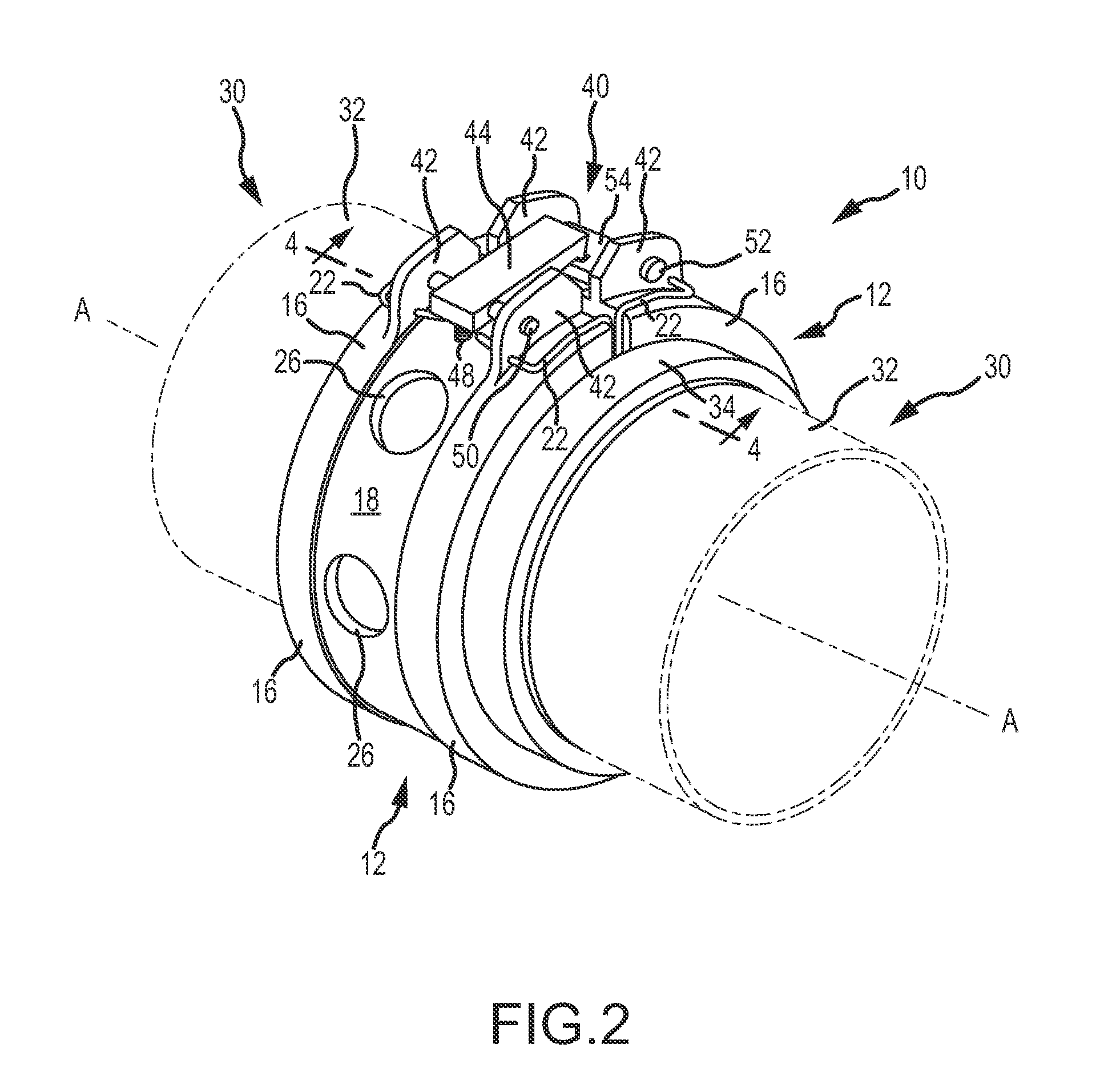

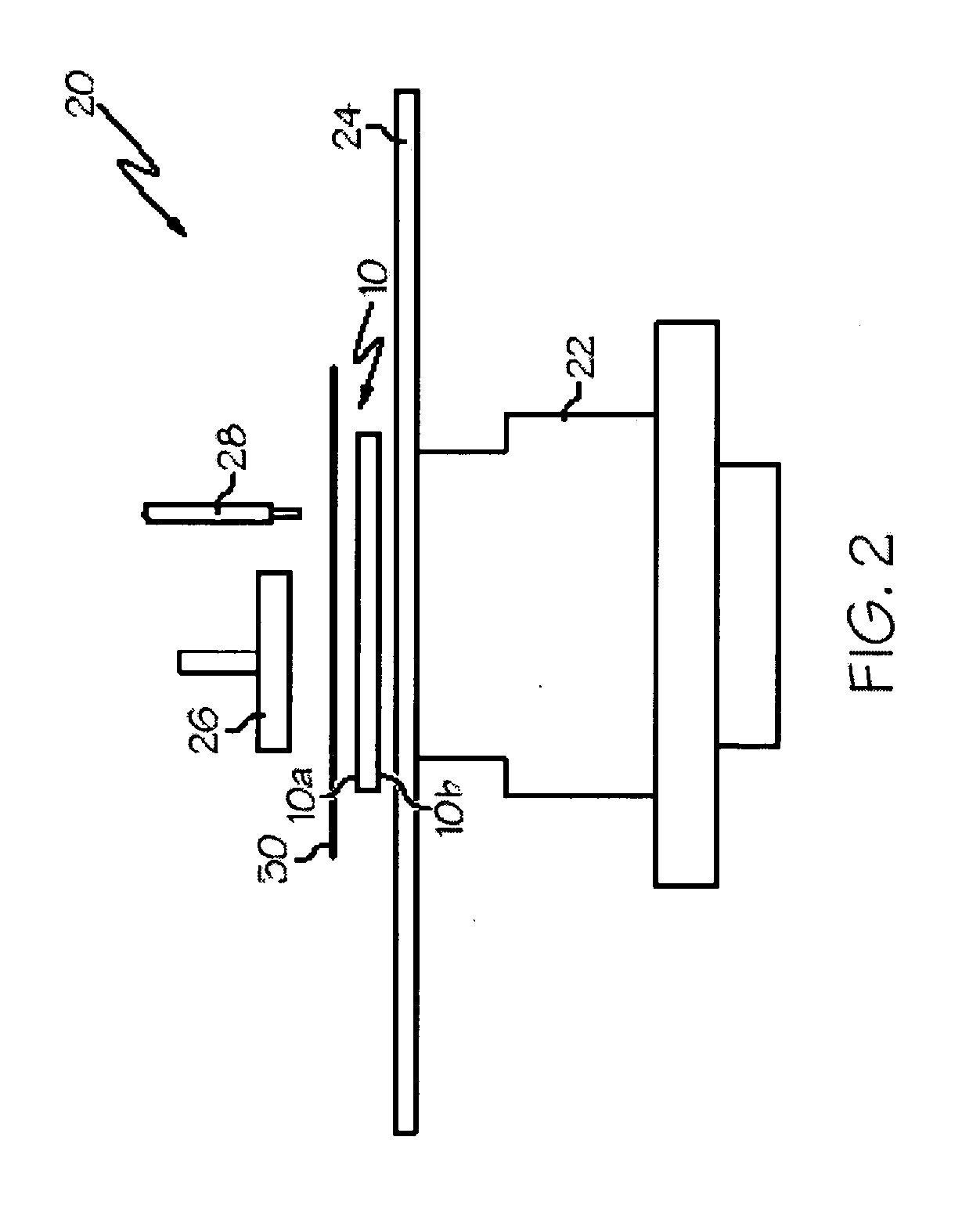

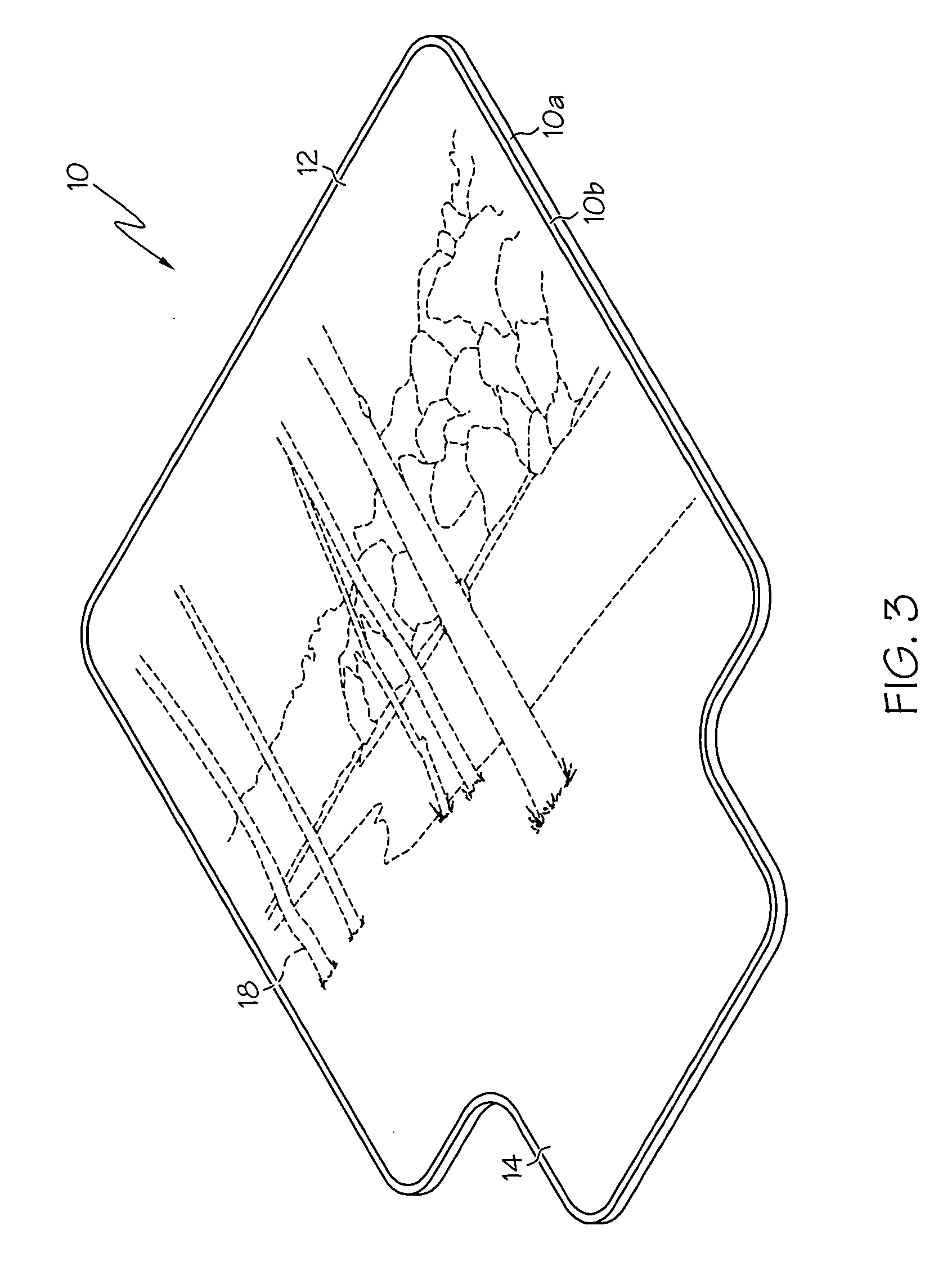

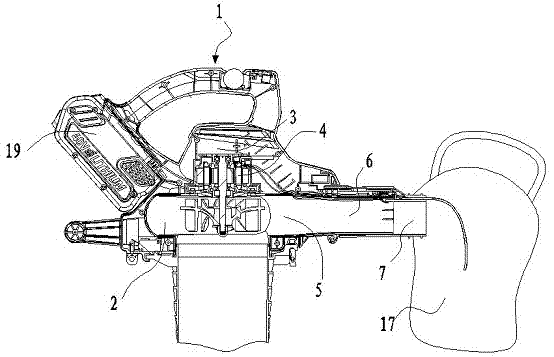

Latching mechanisms for clamshell type couplers

ActiveUS20150102600A1Sufficient electrical conductivityPrevent static buildupFlanged jointsPipe couplingsCouplingEngineering

Latching mechanisms in multiple embodiments connect clamshell type couplers comprising a pair of arcuate coupling halves joined at a hinge. One embodiment includes a biased catch lever that engages a corresponding latch plate. Another embodiment includes a plurality of latching extensions that engage an opposing latching housing, along with biased locking buttons for selectively locking the mechanism. Another embodiment includes dual rotatable latching arms for interconnecting the coupling halves, each arm having a latching cam for selectively locking the mechanism. Another embodiment includes a rotatable latching arm and a receiving bracket for receiving the latching arm for selectively locking the mechanism. Another embodiment includes an over center hinge mechanism including three cooperating and rotatable latch plates. Another embodiment includes cooperating cassette mechanisms, each having connector extensions for connecting the cassette mechanisms to one another for selectively locking the mechanism. Methods are also disclosed for selectively locking the latching mechanisms

Owner:EATON INTELLIGENT POWER LTD

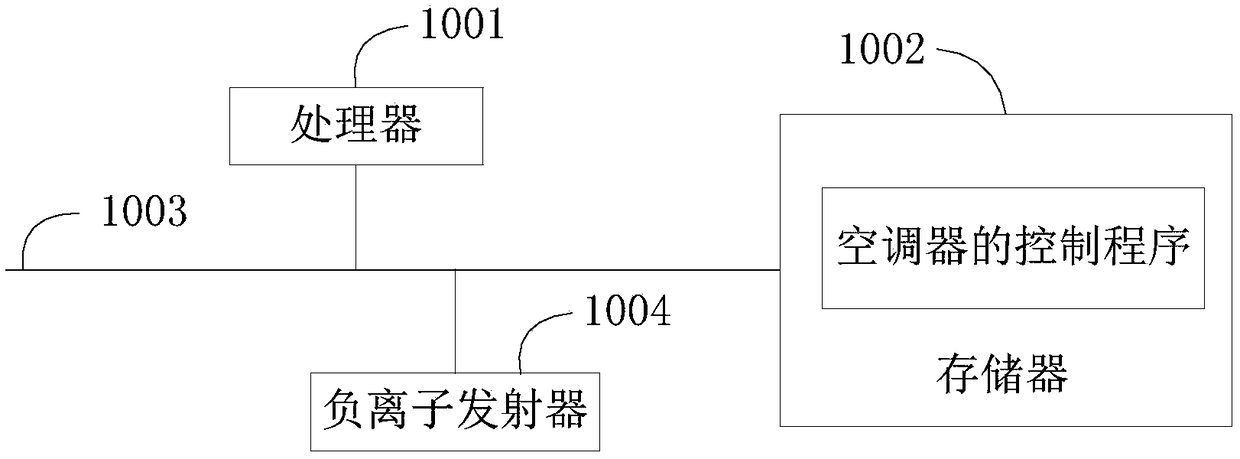

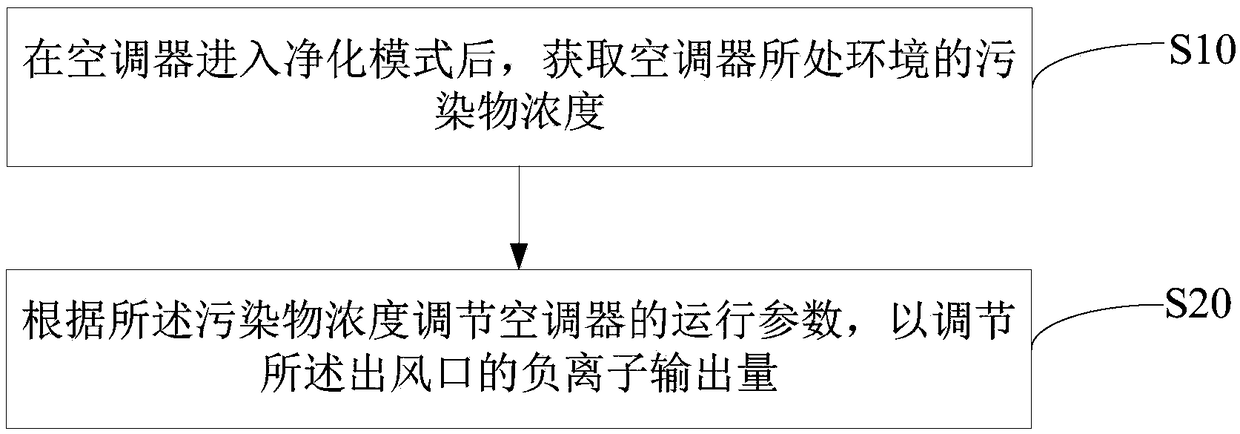

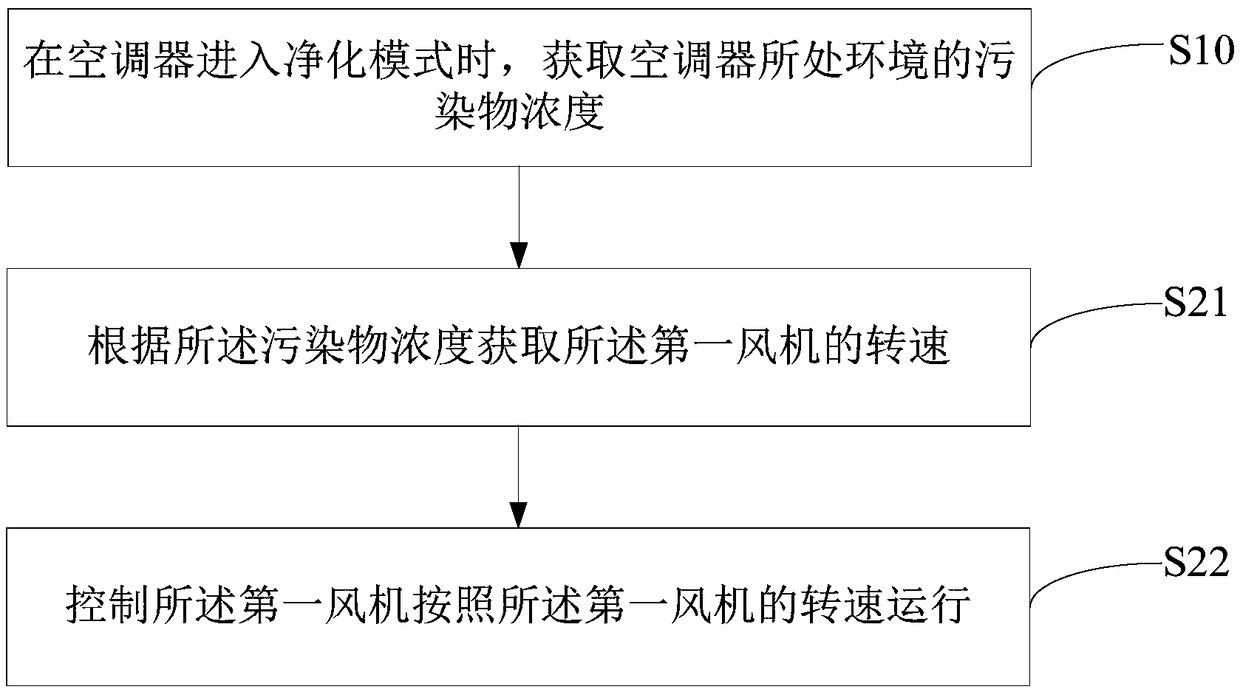

Control method and device for air conditioner, air conditioner and storage medium

ActiveCN109114770AAvoid the problem that the output of negative ions cannot be reasonably configuredPrevent static buildupMechanical apparatusLighting and heating apparatusEngineeringStatic Charges

The invention discloses a control method for an air conditioner. The air conditioner comprises a negative ion emitter, and the negative ion emitter is arranged at an air outlet of the air conditioner.The control method for the air conditioner comprises the steps that after the air conditioner enters a purification mode, the pollutant concentration of the environment where the air conditioner is located is acquired; and running parameters of the air conditioner are adjusted according to the pollutant concentration in order to adjust the negative ion output quantity of the air outlet, and the high the pollutant concentration is, the large the negative ion output quantity is. The invention further discloses a control device for the air conditioner, an air conditioner and a storage medium. The purpose that the running parameters of the air conditioner are adjusted according to the pollutant concentration of the environment where the air conditioner is located in order to adjust the negative ion output quantity of the air outlet of the air conditioner is achieved, the problem that the air conditioner can not reasonably configure the negative ion output quantity is avoided, an electrichand phenomenon generated due to negative ion static charge accumulation is prevented, and meanwhile the dust removal effect is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Antistatic plastic and preparation method thereof

ActiveCN103396618AImprove notched impact strengthImprove bending strengthPhosphorous acidPolymer science

The invention discloses an antistatic plastic and a preparation method thereof. The antistatic plastic is mainly prepared from the following raw materials in parts by mass: 110-130 parts of PVC (polyvinyl chloride), 30-35 parts of PP (polypropylene), 30-40 parts of ABS (acrylonitrile-butadiene-styrene), 10-15 parts of fatty group sulfonate, 5-8 parts of tribasic lead sulfate, 4-8 parts of catalyst, 5-10 parts of antistatic agent, 10-20 parts of carbon black, 6-10 parts of hydroxymethyl fatty amine, 10-20 parts of shock-resistant modifier, 10-15 parts of graphite, 3-6 parts of cocatalyst, 5-10 parts of dibasic lead phosphite and 1-5 parts of white oil. The preparation method comprises the following steps: thoroughly mixing the components uniformly; adding the mixture into a double screw extruder; granulating by melting and plastification under certain conditions; and carrying out injection molding on the granules under certain conditions. The method disclosed by the invention is simple in technique, and convenient for large-scale production; and the product has the advantages of high notch impact strength, high bending strength, high hardness, and favorable antistatic property.

Owner:ANHUI ANYUAN PLASTIC

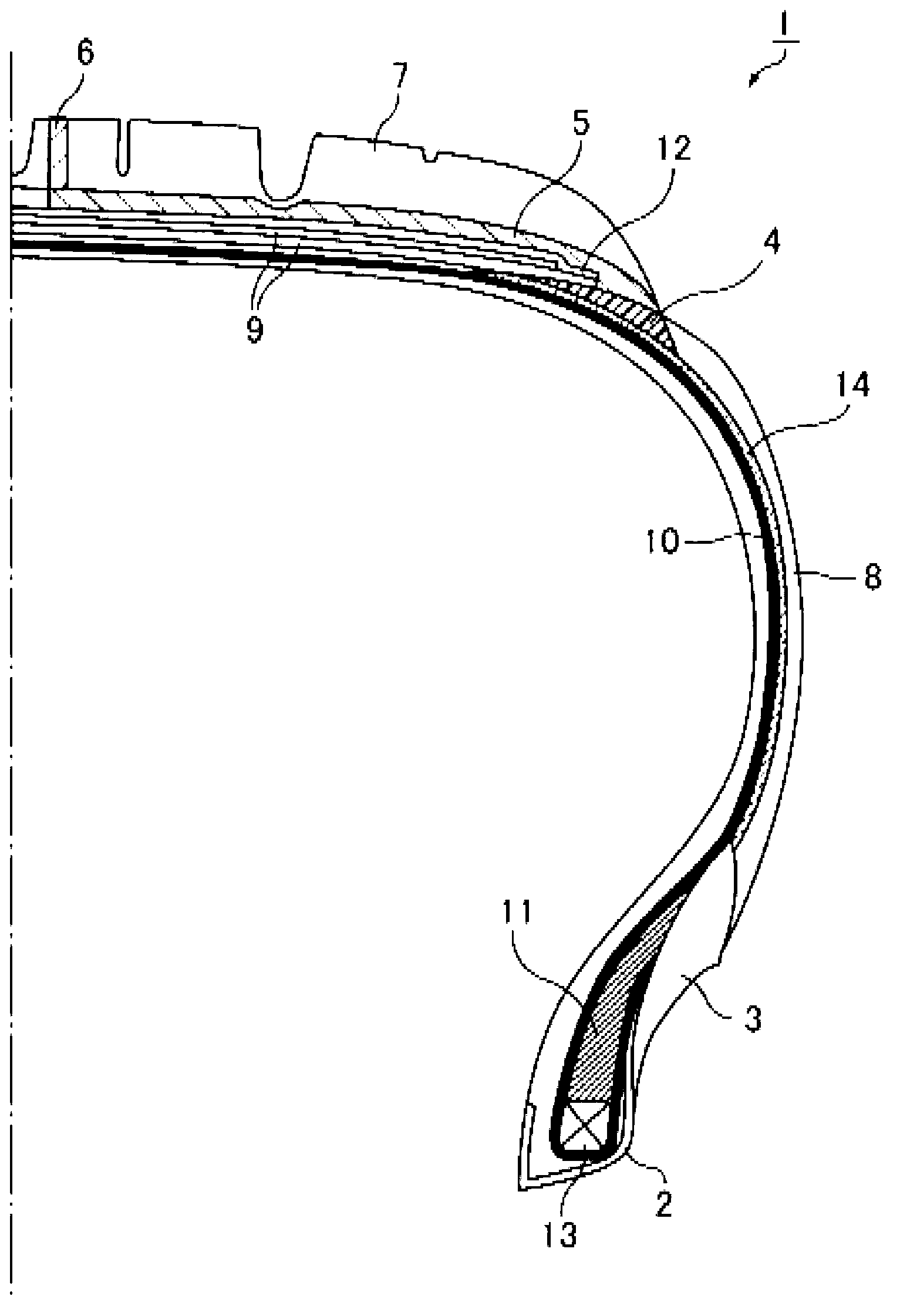

Rubber Composition For Tire, And Pneumatic Tire

ActiveCN103205031APrevent static buildupIncrease resistanceSpecial tyresWheelsRolling resistancePolyolefin

Provided is a pneumatic tire using a rubber composition which makes it possible to keep rolling resistance low, prevent the accumulation of static electricity during the running of the tire, suppress an increase over time in electrical resistance of the tire, and improve durability. The present invention relates to a rubber composition, including: a rubber component including two or more diene rubber; and carbon black having a nitrogen adsorption specific surface area of 400 m 2 / g or more in an amount of 5 to 30 parts by mass per 100 parts by mass of the rubber component, wherein the rubber composition has a degree of carbon black dispersion determined by counting agglomerates based on JIS K 6812 "Method for the assessment of the degree of pigment or carbon black dispersion in polyolefin pipes, fittings and compounds" of 90% or more.

Owner:SUMITOMO RUBBER IND LTD

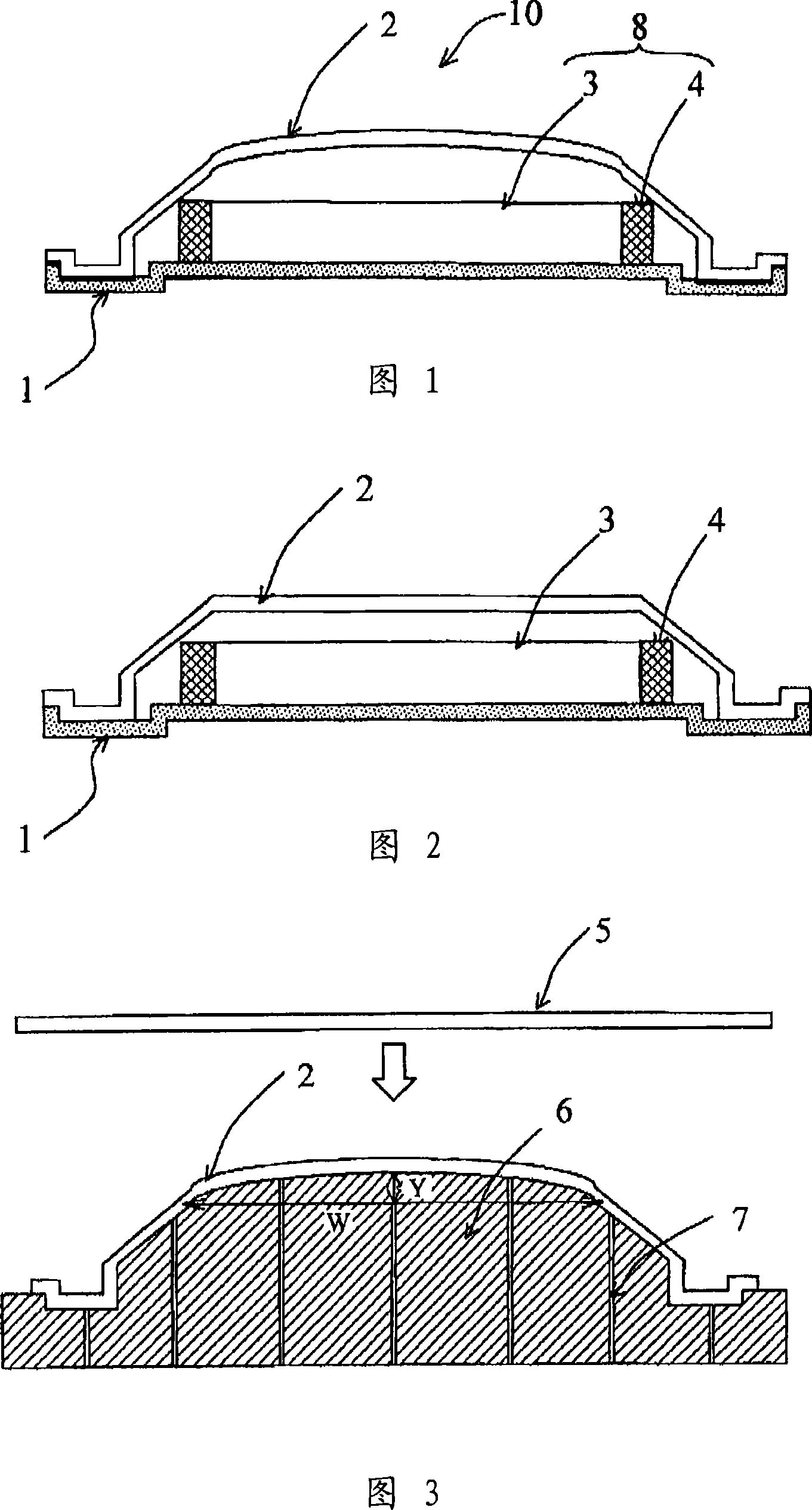

Protection film components containing vessel and manufacturing method thereof

InactiveCN101086612AAvoid defacementGuaranteed qualitySemiconductor/solid-state device manufacturingRemovable lids/coversEngineeringMechanical engineering

Owner:SHIN ETSU CHEM IND CO LTD

Method for inhibiting powder bed electron beam 3D printing powder from splashing

ActiveCN111570792AImprove conductivityImprove thermal conductivityAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgySurface roughness

The invention relates to a method for inhibiting powder bed electron beam 3D printing powder from splashing. The method comprises the following steps that first-round electron beam scanning preheatingis carried out on powder in a forming section of a powder bed; second-round electron beam scanning preheating is conducted on powder in a preset area of the powder bed, wherein the preheating currentof each time of second-round electron beam scanning preheating ranges from 5 mA to 40 mA, and the scanning speed ranges from 2 m / s to 20 m / s; and the powder on the preset area after second-round electron beam scanning preheating is melted, and third-round of electron beam scanning preheating is carried out on the powder on the forming section of the powder bed. By the adoption of the method, splashing of the powder is basically avoided in the 3D printing process, and a component obtained after 3D printing is high in density and small in surface roughness.

Owner:广州赛隆增材制造有限责任公司

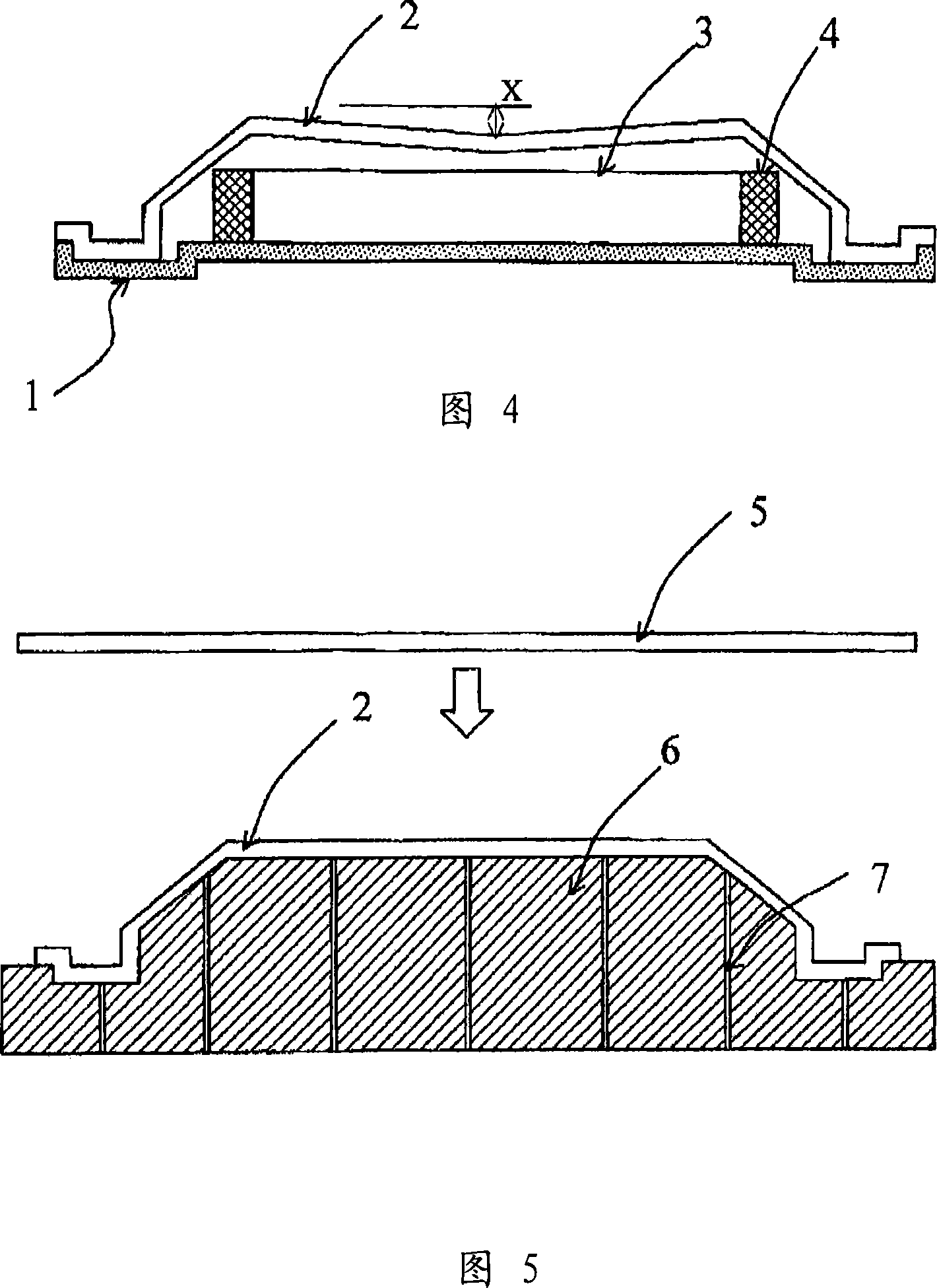

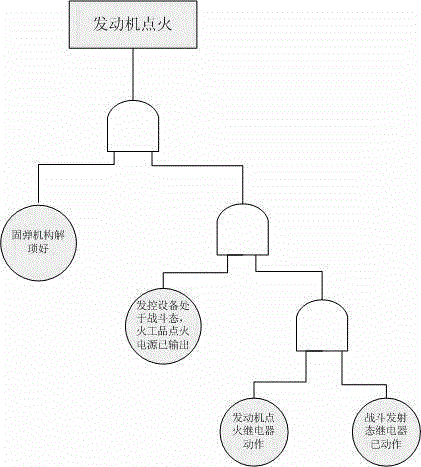

Launching method of guided missile safe launching system

ActiveCN104457420AIncrease the selection levelGuaranteed reliabilityLaunching weaponsLaunch controlControl system

The invention provides a launching method of a guided missile safe launching system. The safe launching system comprises a launching control system and a launching box / barrel. The launching control system comprises an ignition power source and a launching control unit. The launching control unit comprises a combat launching command relay, an engine ignition relay and a resistor. The launching box / barrel comprises a napalm bomb mechanism microswitch. After an initiating explosive device is connected with the resistor in parallel, one end of the circuit is sequentially connected with the napalm bomb mechanism microswitch, a first set of contact switches of the engine ignition relay and a first set of contact switches of the combat launching command relay in series; the other end of the circuit is grounded and then is sequentially connected with a second set of contact switches of the engine ignition relay and a second set of contact switches of the combat launching command relay in series. According to the safe launching system, the safety performance in missile launching can be improved.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

Nano-siller antibiotic composition

The nanometer silver antiseptic mixture consists of nanometer silver solution, water emulsion type polyurethane resin PU-50, Nivelon, penetrant m-1038C and water mixed together. The nanometer silver antiseptic mixture is prepared into spraying agent sprayed to the surface of object, and may be adhered firmly to maintain the nanometer silver ion for long term and result in lasting sterilizing effect. It may be used for car, bus, hotel, hospital, household, etc.

Owner:陈汉洲

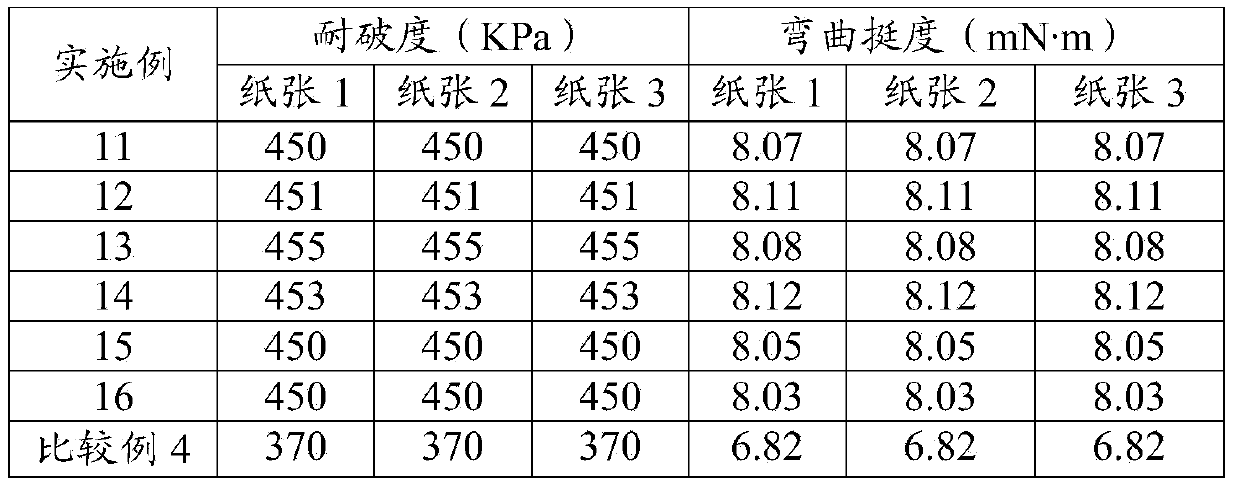

Phenol aldehyde resin and preparation method thereof, and automobile filter paper

ActiveCN104177574AImprove conductivityHigh burst resistanceFiltration separationFilter paperAlcoholGraphene

The invention provides a phenol aldehyde resin which is prepared by reacting phenol compounds, aldehyde compounds and graphene, wherein the mole ratio of the phenol compounds to the aldehyde compounds is 1:(1.0-2.5), and the mass ratio of the graphene to the phenol compounds is (0.01-2):100. The invention provides a preparation method of the phenol aldehyde resin, which comprises the following steps: carrying out first reaction on the phenol compounds, an alkaline catalyst, the aldehyde compounds and the graphene to obtain a reaction product, wherein the temperature of the first reaction is 60-90 DEG C; and carrying out second reaction on the reaction product and alcohol compounds to obtain the phenol aldehyde resin. The invention also provides an automobile filter paper prepared from the phenol aldehyde resin in the technical scheme, or prepared from the phenol aldehyde resin prepared by the method in the technical scheme. The phenol aldehyde resin provided by the invention comprises graphene, and thus, has favorable electric conductivity.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

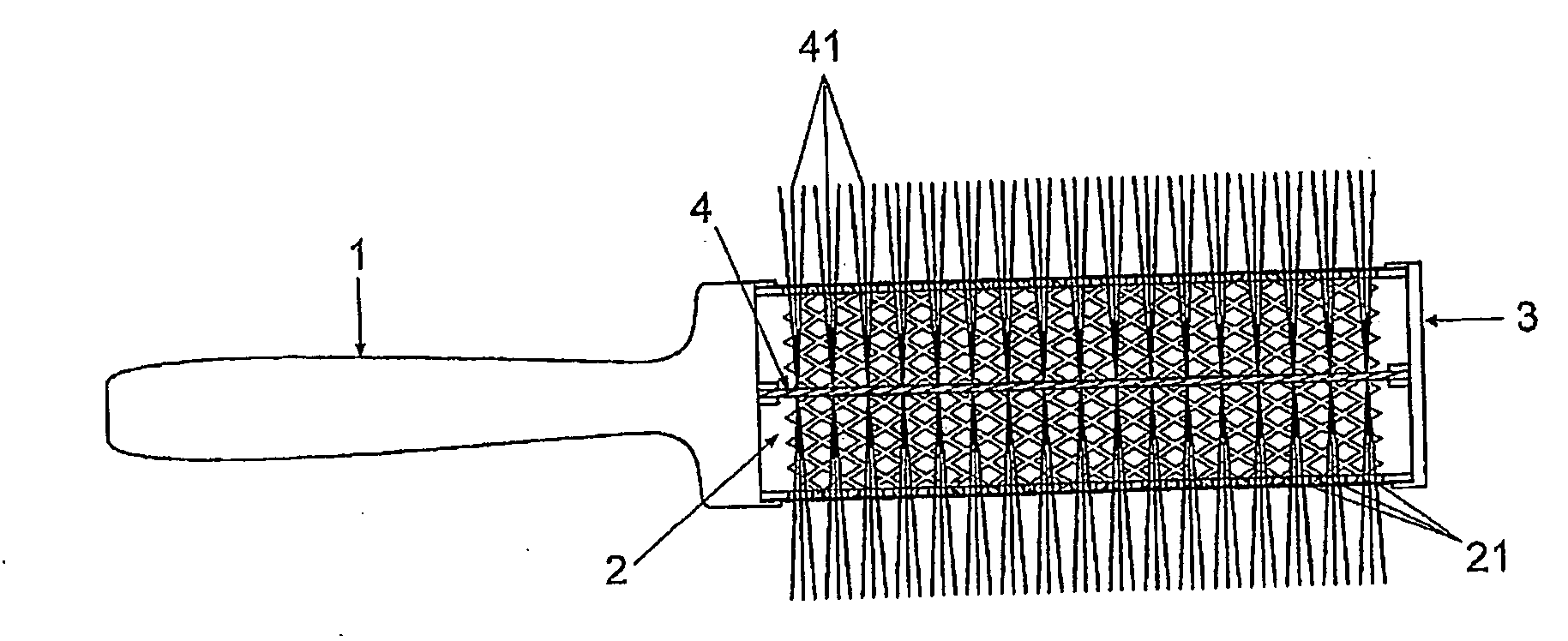

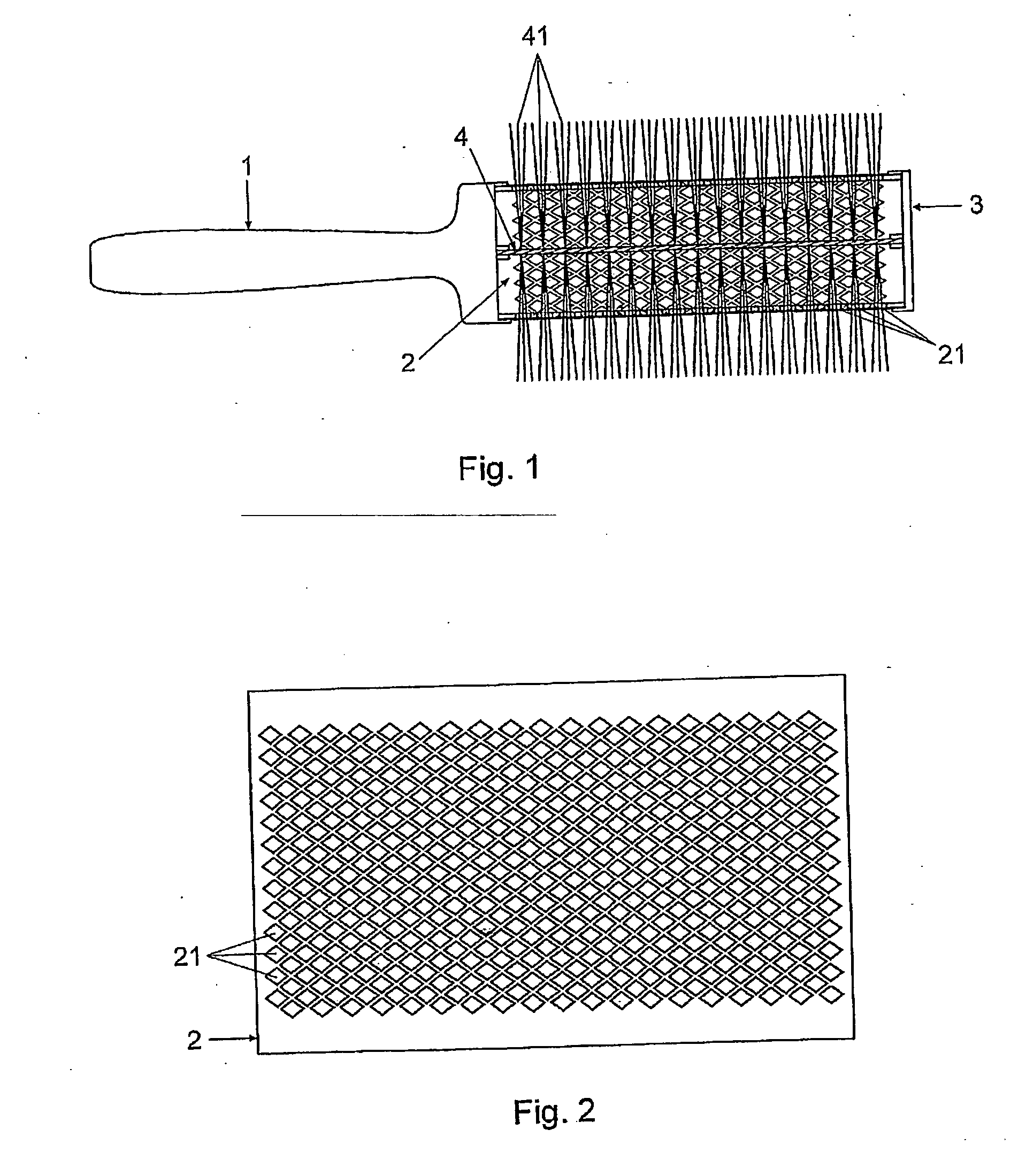

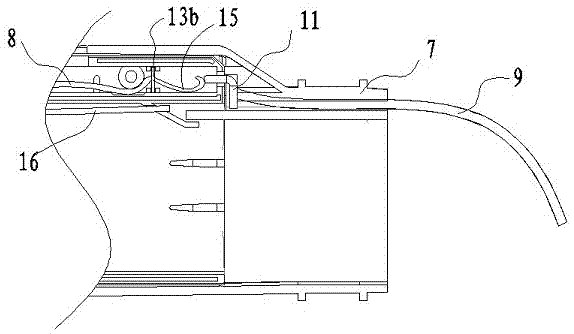

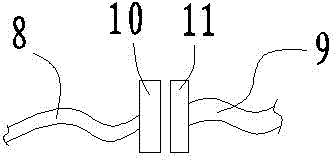

Hair Brush

ActiveUS20090165234A1Long useful lifeBrilliant and reinforced hairBrush bodiesBristle carriersPlastic materialsEngineering

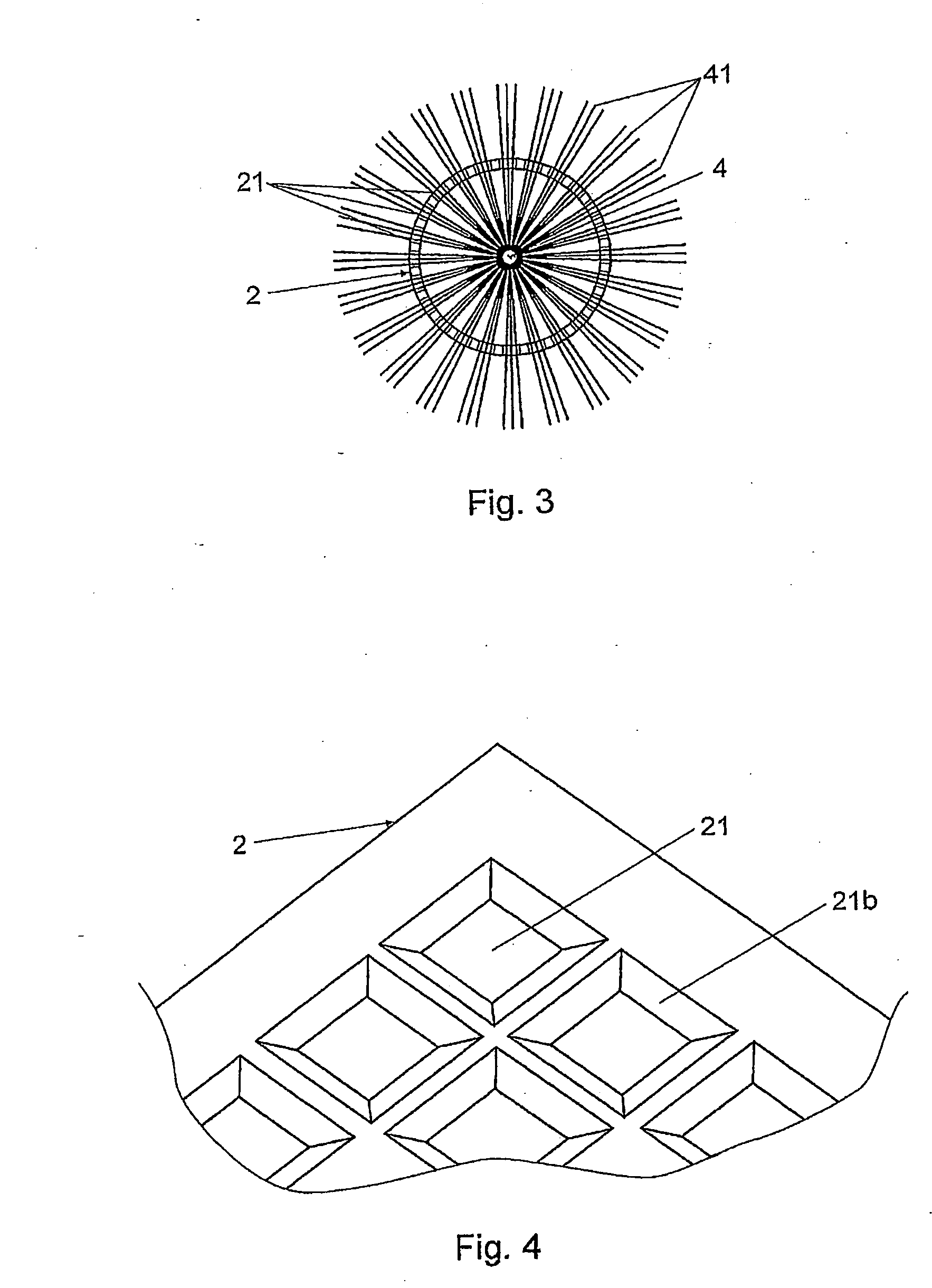

This brush is made up of: a handle (1); an aluminium tubular body (2) which is coated with an artificial plastic material, vinyl fluoride polymer, and holes (21) with polygonal shape, arranged in a herringbone pattern, which end in bevelling (21, 21b) and are arranged forming oblique lines in respect of the longitudinal axle of the brush; nylon fibres (41), ionized by means of radiation, fixed helicoidally to a supporting centre (4), located inside the tubular body, emerging the said fibres (41) through the holes (21) of the tubular body, and a front top (3) that closes the fore end of the above said tubular body.

Owner:DOLS IND DE PELUQUERIA SA

High-temperature resistant conductive polytetrafluoroethylene hot melting adhesive tape and production method thereof

The invention relates to a high-temperature resistant conductive polytetrafluoroethylene hot melting adhesive tape and belongs to the technical field of hot melting adhesive tape production technology. The high-temperature resistant conductive polytetrafluoroethylene hot melting adhesive tape comprises a base layer and a hot melting adhesive layer, wherein the base layer is coated with a polytetrafluoroethylene film layer; the hot melting adhesive layer is a polyethylene layer; conductive particles are uniformly dispersed in the polytetrafluoroethylene film layer and are conductive carbon black and / or metal particles. According to the technical scheme, the conductive particles are dispersed in the base layer of the hot melting adhesive tape, so that the base layer is enabled to have the electrical conductivity, and as polytetrafluoroethylene self has the high-temperature resistance, the hot melting adhesive tape is enabled to have the advantages of high-temperature resistance and good electrical conductivity; in addition, a carbon nano tube is doped in the polytetrafluoroethylene film layer, so that the charge transporting capacity of the hot melting adhesive tape is further improved, the scratch resistance of the polytetrafluoroethylene film layer is also improved, the service life of the hot melting adhesive tape under special circumstances is prolonged, and the benefits are remarkable. The invention further relates to a production method of the high-temperature resistant conductive polytetrafluoroethylene hot melting adhesive tape.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

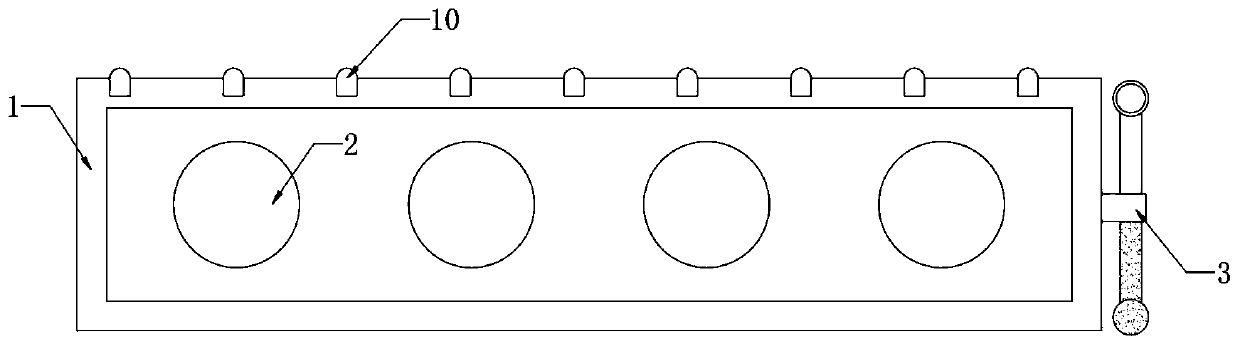

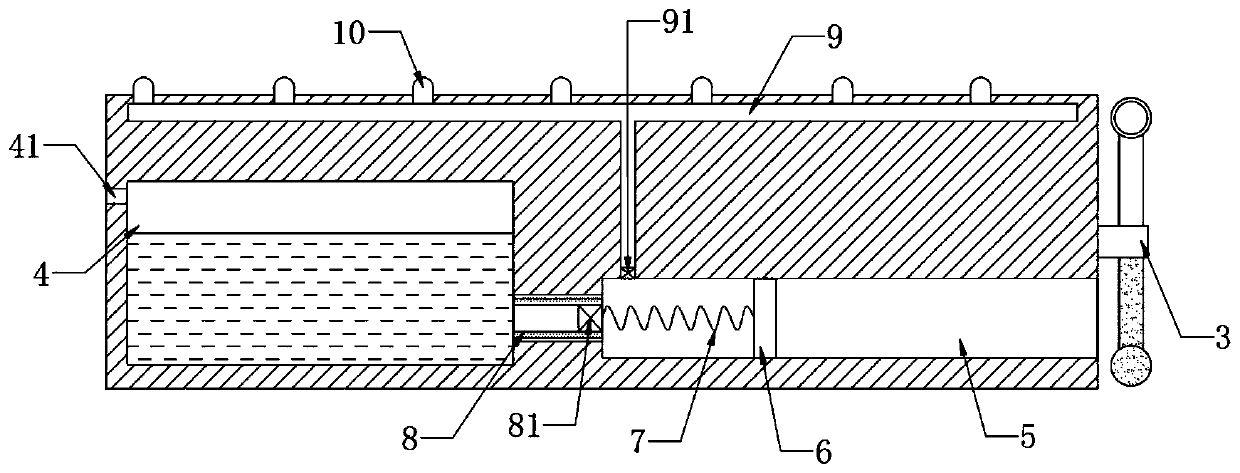

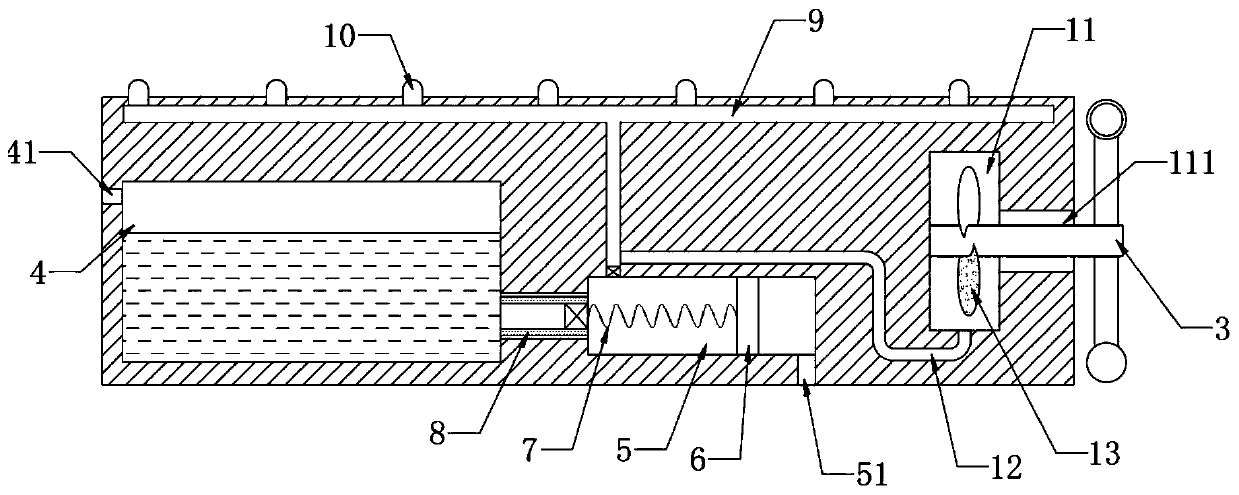

High-rise LED wall washing lamp with self-cleaning function

InactiveCN111536457ANo manual maintenanceEasy to cleanMechanical apparatusLighting elementsEngineeringLamp shell

The invention discloses a high-rise LED wall washing lamp with a self-cleaning function. The lamp comprises a transparent lamp shell, and a plurality of LED lamp beads are installed in the transparentlamp shell. A liquid storage cavity is formed in the side wall of the transparent lamp shell. A liquid pumping groove is further formed in the side wall of the transparent lamp shell; the liquid storage cavity is communicated with the liquid pumping groove through a liquid guide pipe, a pumping device for pumping liquid in the liquid storage cavity is installed in the liquid pumping groove, a first one-way valve is installed in the liquid guide pipe, a three-way pipe communicated with the interior of the liquid pumping groove is embedded in the transparent lamp shell, and a second one-way valve is installed at the water inlet end of the three-way pipe. Water in the liquid storage cavity is continuously pumped into the liquid guide pipe, then is discharged into the spraying pipe from the three-way pipe and finally flows to the surface of the lamp shell, so that dust particles attached to the surface of the lamp shell can be flushed, wind energy is utilized for cleaning, energy conservation and environmental protection are achieved, meanwhile, manual maintenance is not needed, and cleaning is rapid and convenient.

Owner:付慢利

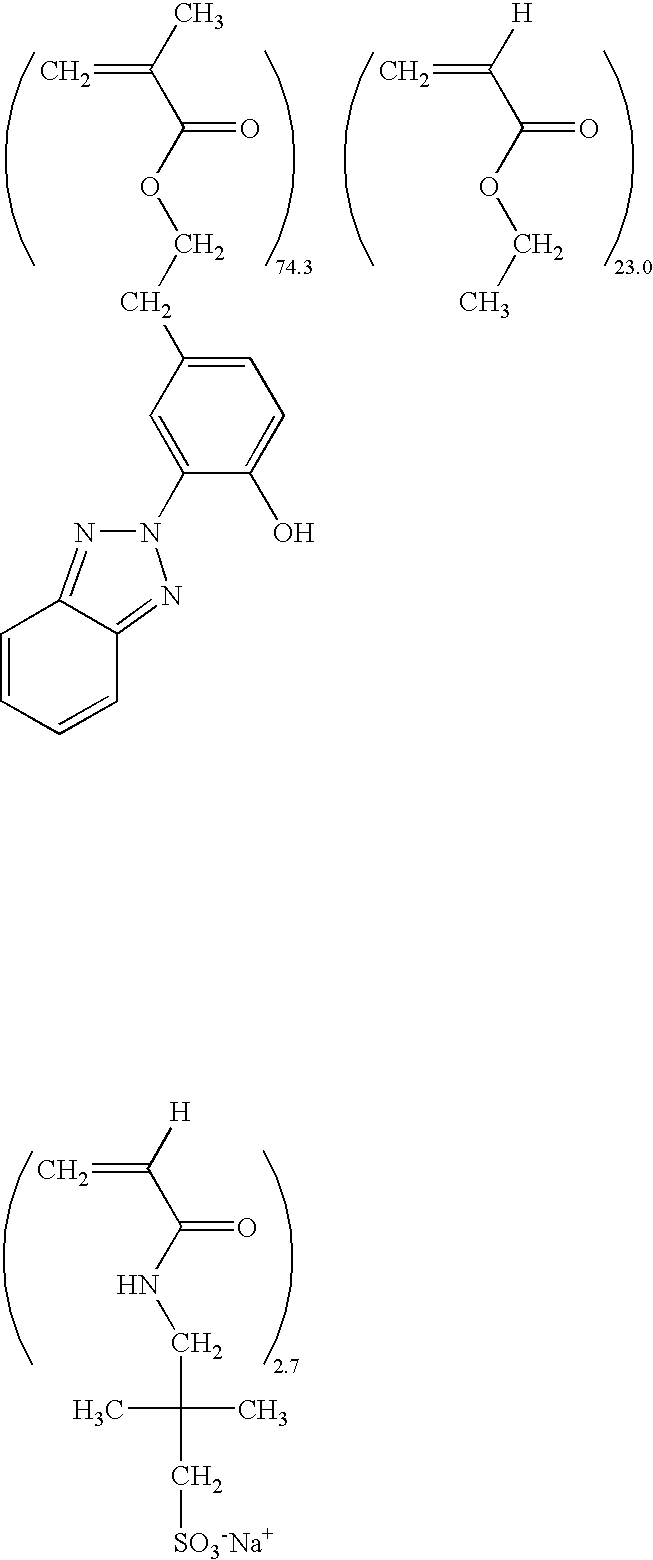

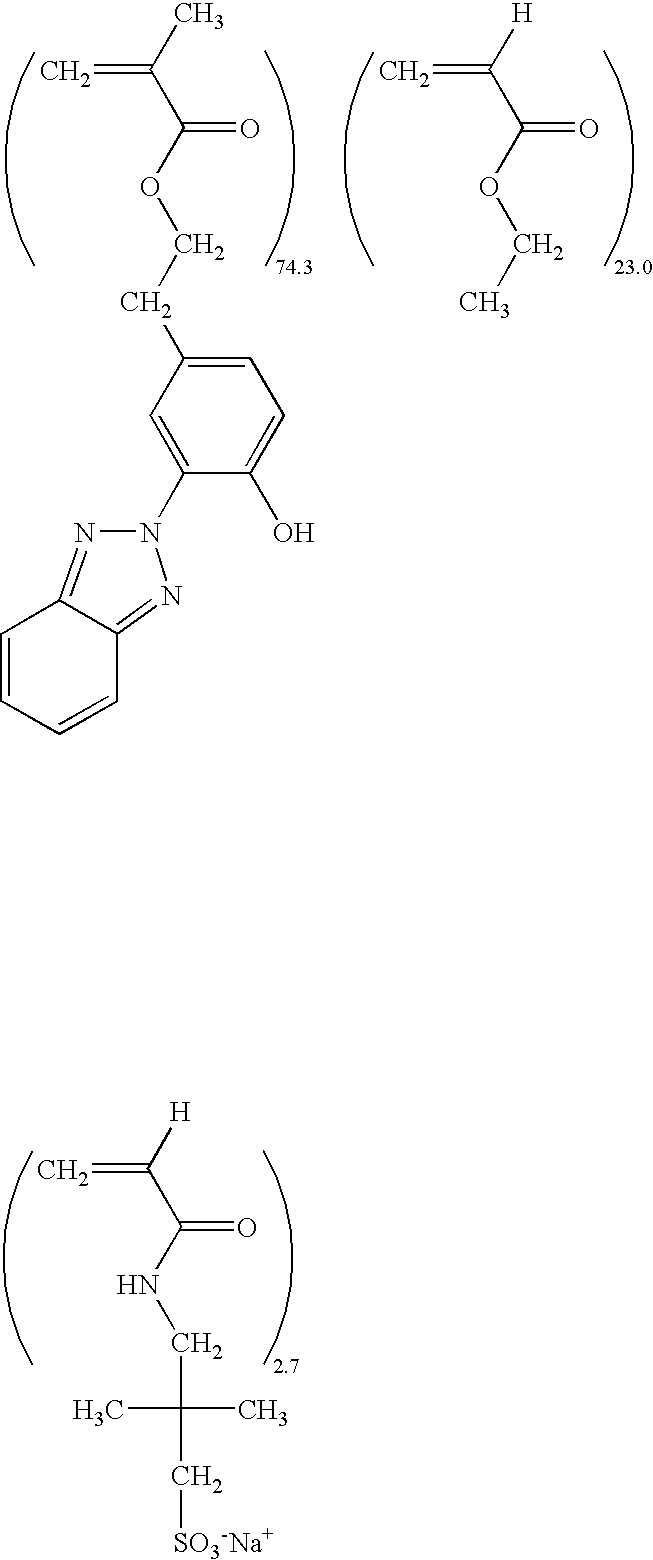

Pressure-sensitive adhesive film

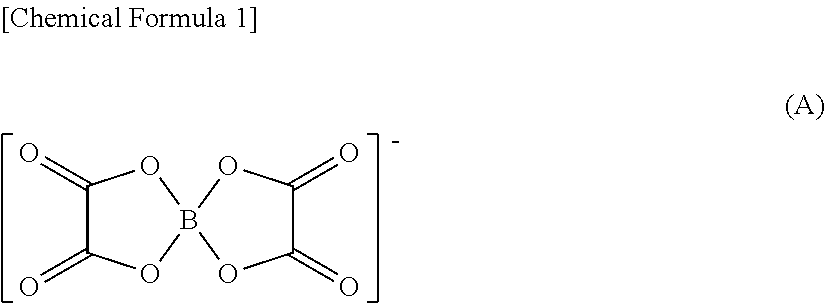

InactiveUS20140099504A1Improve adhesionPrevented from generating peeling electrification voltageFilm/foil adhesivesEster polymer adhesivesUltimate tensile strengthAlkali metal

A pressure-sensitive adhesive film, including a substrate and a pressure-sensitive adhesive layer provided on at least one side of the substrate, wherein the pressure-sensitive adhesive layer contains a (meth)acryl-based polymer, an alkali metal salt, and a crosslinking agent, and the pressure-sensitive adhesive layer contains 2 parts by weight or less of the crosslinking agent based on 100 parts by weight of the (meth)acryl-based polymer, the pressure-sensitive adhesive film having an adhesive strength of 0.5 N / 25 mm or more as measured at a tension rate of 0.3 m / minute after it is placed on an adherend of an acrylic panel under conditions of 23° C. and 50% RH for 30 minutes, and uses for the film.

Owner:NITTO DENKO CORP

Latex special for dry method dustless paper and its preparing method

InactiveCN1554829AHigh molecular weightHigh viscosityWater-repelling agents additionFiberWet strength

The present invention relates to latex specially for dry process dustless paper and its preparation process, and belongs to the field of special chemical. butyl acrylate, methyl acrylate, ethoxyl acrylate, styrene, acrylic acid and butyl methacrylate as monomers, are added with deionized water, emulsifier, NaHCO3 and initiator to produce branch chain connection to form copolymer. The present invention can meet the requirement of producing dustless paper and is favorable to spraying. The present invention has high fiber combining strength of paper, high dry and wet strength, simple production operation and stable product quality.

Owner:李泽潜 +3

Anti-static agent for fuel oil and preparation method thereof

ActiveCN105296026APerformance impactGood compatibilityLiquid carbonaceous fuelsFuel additivesAlkylphenolGlycerol

The invention relates to an anti-static agent for fuel oil and a preparation method thereof and belongs to the technical field of oil gas additives. The anti-static agent for the fuel oil is prepared from, by weight, 15-18 parts of alkylphenol ethoxylates acrylate copolymers, 5-8 parts of sorbitol, 0.2-0.5 part of tragacanth gum, 0.1-0.2 part of agar, 10-14 parts of glycerol, 2-5 parts of triethanolamine, 0.2-0.9 part of diethanol amine, 0.5-0.8 part of calcium chloride, 2-5 parts of silicon dioxide, 3-5 parts of stearamidopropyl dimethyl (2-hydroxyl) ethyl ammonium nitrate and 25-28 parts of ethylene glycol. The anti-static agent for the fuel oil and the fuel oil have good compatibility, can effectively prevent electrostatic accumulation, can reduce electrostatic pressure generated in the operation process of the fuel oil and eradicate danger.

Owner:山东聚力防静电科技有限公司

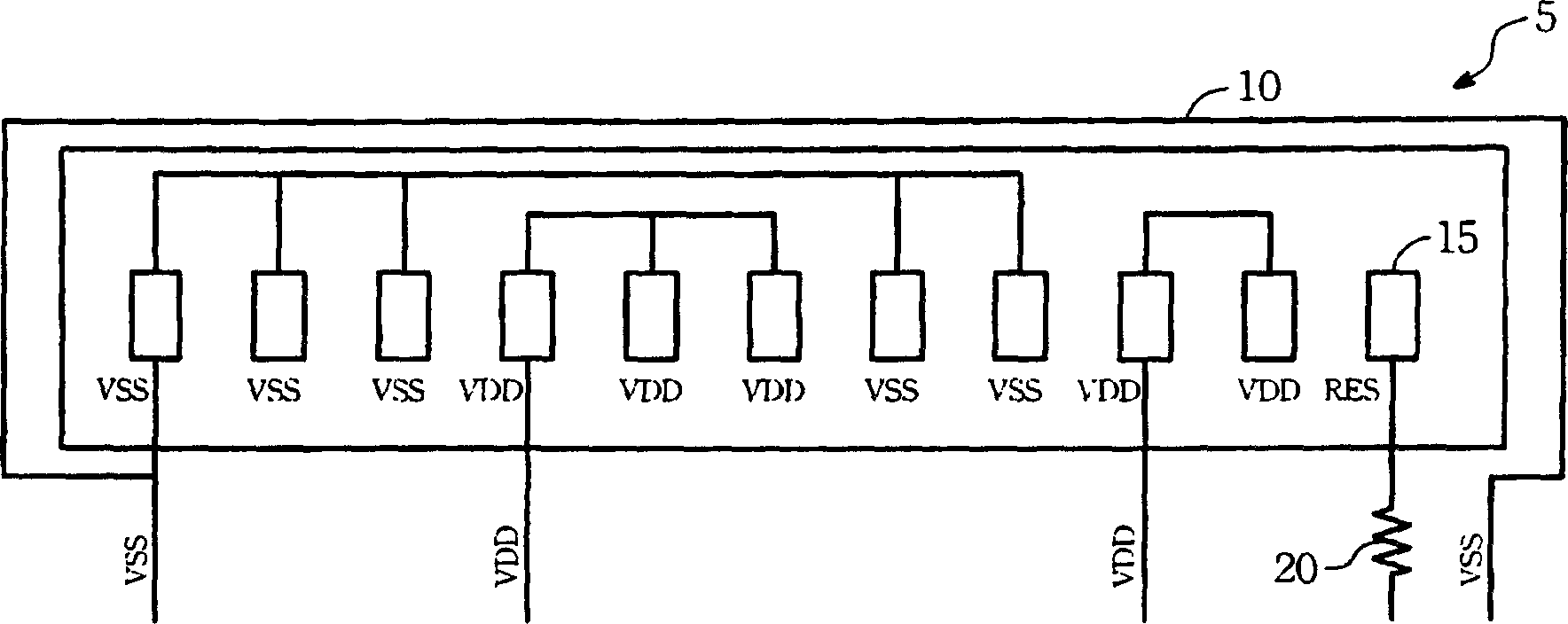

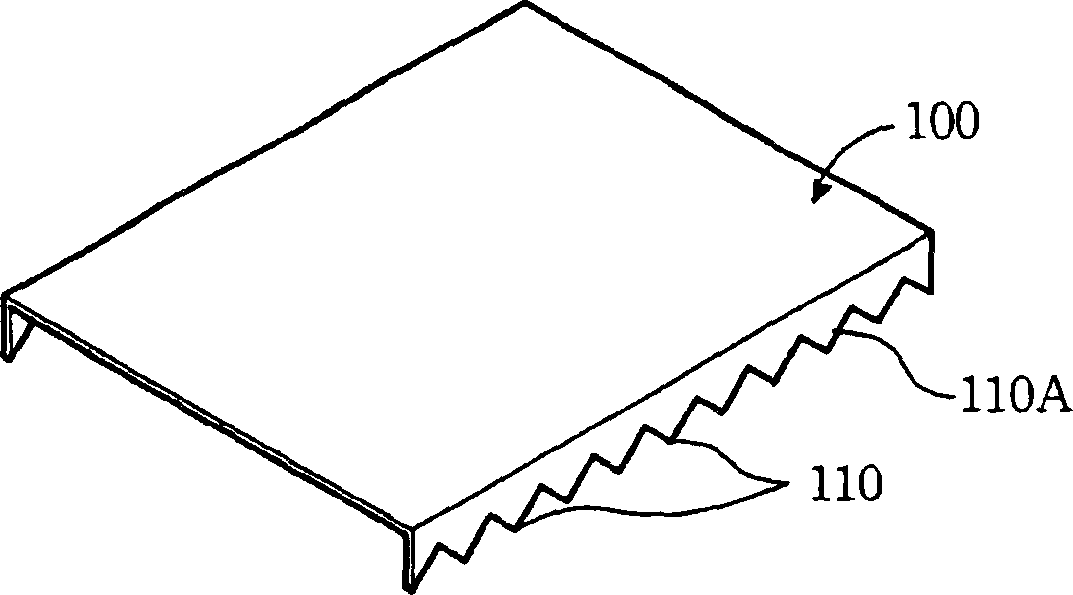

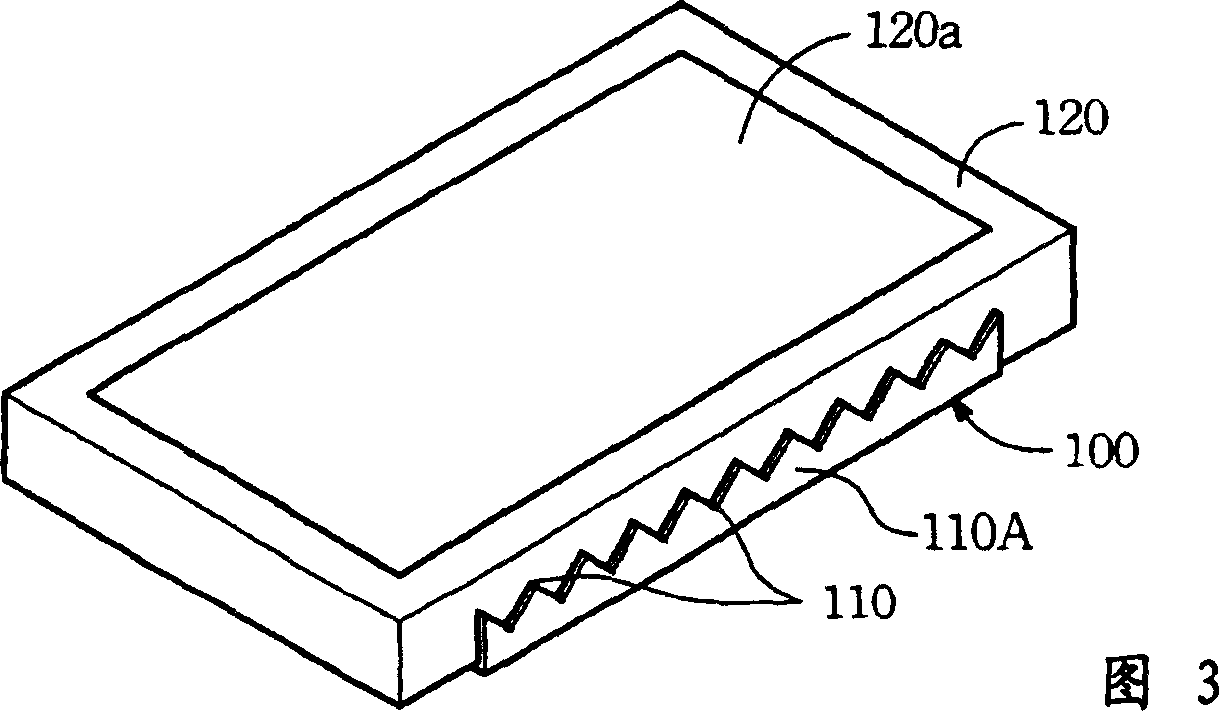

Static discharge protector for liquid crystal screen

InactiveCN1808218APrevent static buildupShielding from electromagnetic interferenceStatic indicating devicesSemiconductor/solid-state device detailsLiquid-crystal displayComputer module

Disclosed is a static discharge proof device on liquid crystal screen which comprises: a liquid crystal display module which is placed on a metal covering of tip with toothing-type flange and is packaged with shell body. Wherein, the metal covering of toothing-type tip can prevent statistic charge accumulation and release large amount of suddenly incoming statistic charge to prevent statistic charge from entering into liquid crystal screen via slit on electronic device, also, prevent electromagnetic wave from interfering liquid crystal display module and related circuits.

Owner:BENQ CORP

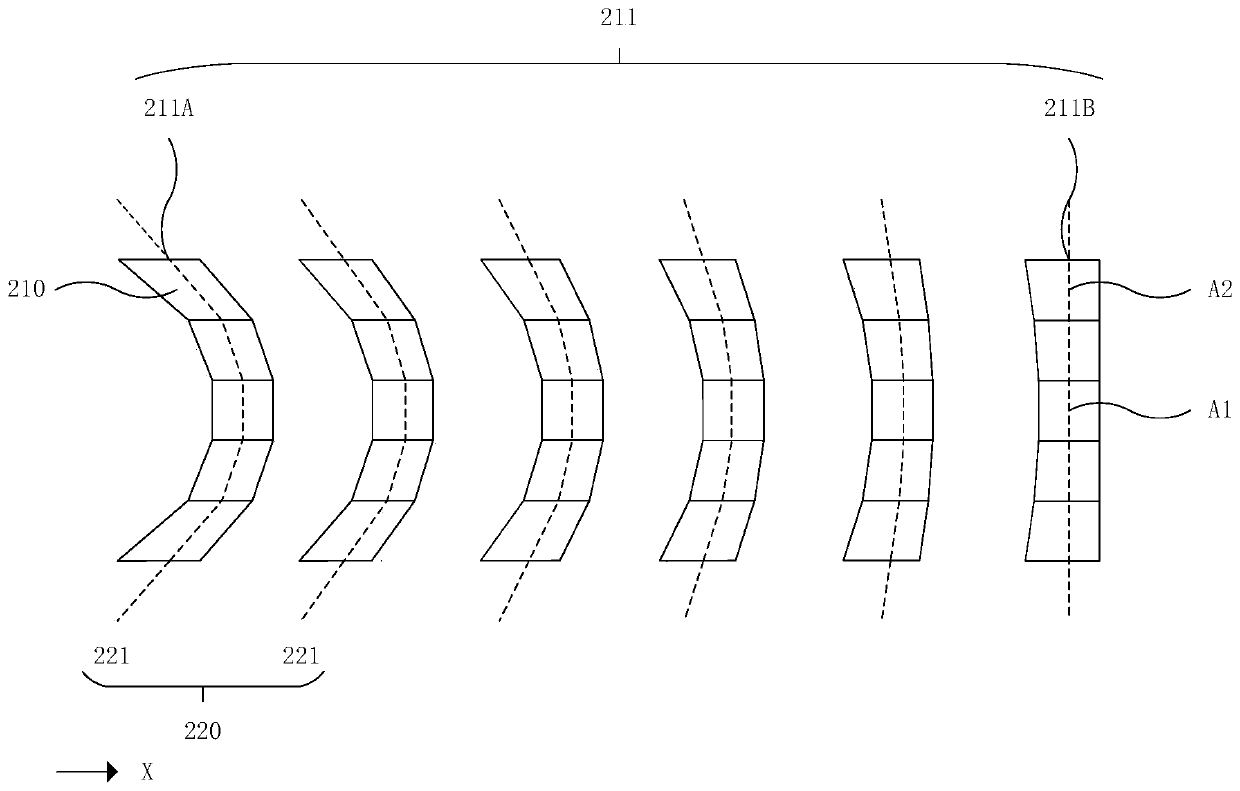

Touch display panel and a touch display device

ActiveCN109828690AExcellent touch uniformityTouch Uniformity ImpactInput/output processes for data processingDisplay deviceHuman–computer interaction

The invention provides a touch display panel and a touch display device. The touch display panel comprises a special-shaped edge and a plurality of touch units arranged in an array mode. Wherein eachtouch unit comprises at least one touch electrode; The plurality of touch units are respectively arranged along the plurality of bending lines to form a plurality of touch unit columns; The special-shaped edges of the touch unit columns are arranged in the first direction; And the touch unit columns are bent towards the special-shaped edges. The touch display device comprises a touch display panel. In the invention, the plurality of touch control unit columns realize self-capacitive touch control or mutual capacitive touch control; The touch control unit columns and the special-shaped edges are bent together, the distance between the special-shaped edges and the upper portions / the lower portions of the touch control unit columns on the adjacent sides enables a touch control blind area between the special-shaped edges and the upper portions / the lower portions of the touch control unit columns to be small, and the touch control uniformity of the touch control display panel is good. The distance between the special-shaped edge and the middle part of the touch control unit column on the adjacent side enables the special-shaped edge and the middle part of the touch control unit column to completely accommodate a wiring area, thereby avoiding static accumulation of multiple metal wires and avoiding static damage.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Anti-static high-viscosity acrylate adhesive and preparation process thereof

ActiveCN106398602AReduced VOCEnvironmentally friendlyNon-macromolecular adhesive additivesMacromolecular adhesive additivesIsooctyl acrylateDispersity

The invention relates to the technical field of adhesives, in particular to an anti-static high-viscosity acrylate adhesive and a preparation process thereof. The anti-static high-viscosity acrylate adhesive comprises the following raw materials components in parts by weight: 800 parts of butyl acrylate, 80 parts of ethylhexyl acrylate, 70 parts of acrylic acid, 1,364 parts of ethyl acetate, 7 parts of acrylic acid-2- hydroxyethyl acrylate, 10 parts of AIBN, 230 parts of rosin resin and 1.3 parts of graphite powder. Downstream products of the product do not have volatilization of methylbenzene, and are environmentally friendly; and meanwhile, a method for adding materials in different steps is adopted in the preparation process of the product, implosion is prevented effectively, the product is high in dispersity, so that VOC amount of the downstream products is reduced obviously, more importantly, the viscosity is improved, and the product has anti-static performance.

Owner:YASUSA CHEM CO LTD

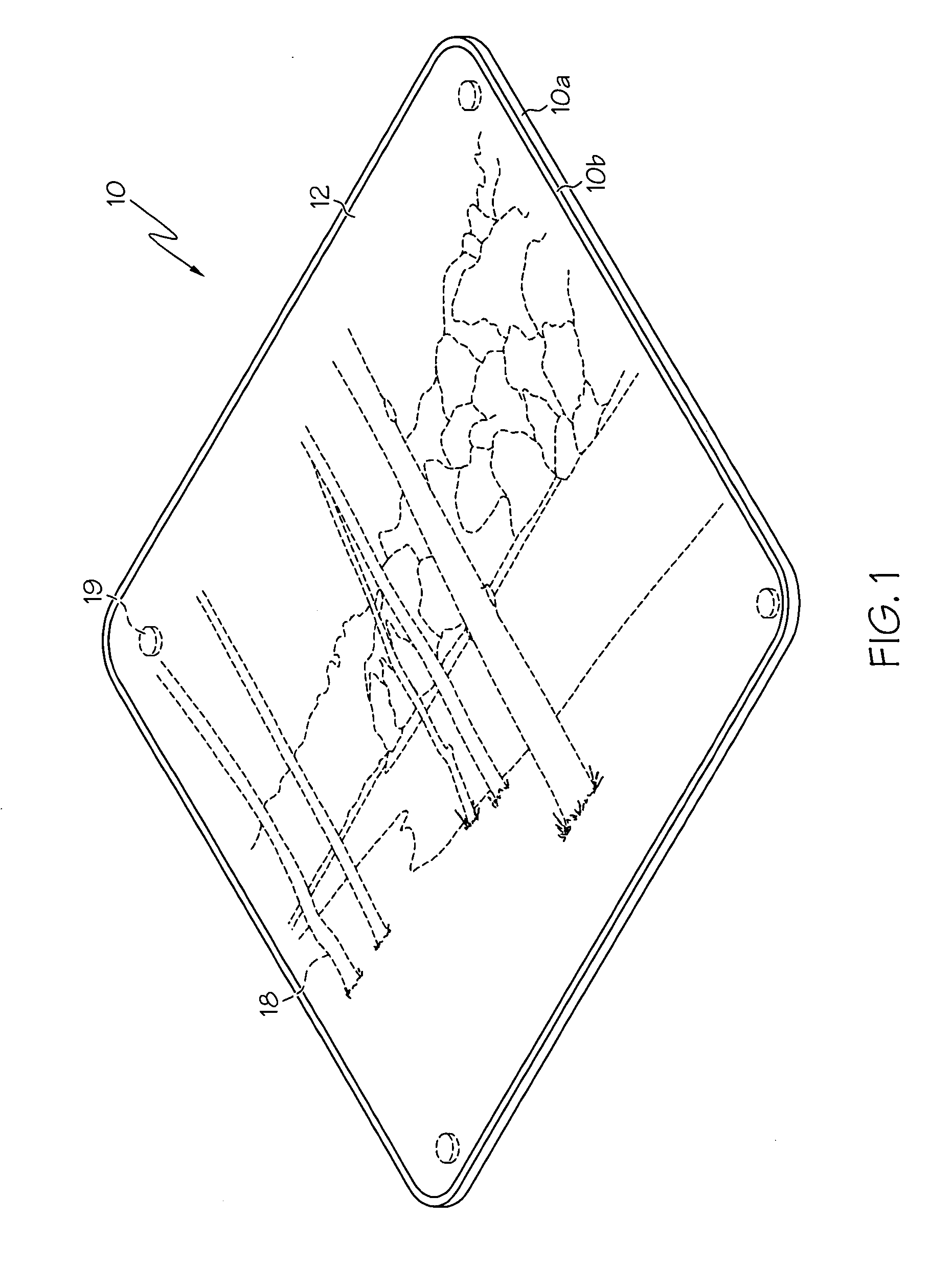

Graphic mat and method of producing the same

InactiveUS20060269726A1Improve securityPrevent static buildupLayered productsDecorative surface effectsVisibilityEngineering

The present invention is directed to a protective mat having a body portion with an upper and lower surface, and further having a graphic image printed on the lower surface of the body such that the image is visible through the upper surface of the mat. Another aspect of the present invention provides a backing to increase visibility of the graphic image when the protective mat is in use.

Owner:ROLITE PLASTICS

Display module and display device

PendingCN112736067APrevent static buildupAvoid failureSemiconductor/solid-state device detailsSolid-state devicesPhysicsPolarizer

The invention relates to a display module and a display device. The display device comprises a display panel, a barrier layer, a polarizer and an electrostatic protection structure. The display panel comprises a substrate, a light-emitting element layer and a thin film packaging layer. The substrate comprises a display area and a non-display area surrounding the display area. The thin film encapsulation layer covers the light emitting element layer. The blocking layer is located on the side, away from the substrate, of the thin film packaging layer and covers the display area. The polaroid is located on the side, deviating from the substrate, of the blocking layer. A first adhesive layer is located between the barrier layer and the polaroid, and the barrier layer is located in the first adhesive layer. The electrostatic protection structure is located between the polaroid and the thin film packaging layer and surrounds the blocking layer. In the display module, the blocking layer is located between the polaroid and the thin film packaging layer to prevent the problem that the polaroid fails; besides, the electrostatic protection structure surrounds the barrier layer to prevent electrostatic charges from entering the barrier layer or dispersing the electrostatic charges in the barrier layer or exporting the electrostatic charges, so that the problem of electrostatic accumulation of the display device is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Blowing and vacuuming machine

The invention discloses a direct-current blower-vacuum. The blower-vacuum comprises a main case, a drive motor, a direct-current power supply, a collecting device and an electrostatic discharge unit, wherein the main case is provided with an air outlet, the drive motor is disposed in the main case, the direct-current power supply is electrically connected with the drive motor, the collecting device is connected with the air outlet, and the electrostatic discharge unit is electrically connected with the drive motor and extends to the air outlet or the inside of the collecting device. According to the blower-vacuum, the electrostatic discharge unit is arranged in the blower, so that gathering of static electricity in the direct-current blower-vacuum can be avoided, electrostatic shocks to users or damage to electronic components inside the blower-vacuum can be further prevented.

Owner:CHANGZHOU GLOBE CO LTD

Moisture-wicking, antibacterial and antistatic multifunctional fabric and production method thereof

ActiveCN104389076BImprove wearing comfortGuaranteed antistatic functionWoven fabricsYarnYarnMoisture absorption

The invention discloses a multifunctional fabric with moisture absorption and perspiration, antibacterial and antistatic properties and a production method thereof. The multi-functional fabric is made of 95-99% multi-functional blended yarn and 1-5% stainless steel anti-static yarn or conductive anti-static yarn; the multi-functional blended yarn is made of moisture-wicking fiber 50-80%, cotton Fiber 15-45% and silver fiber 5-10% are blended; stainless steel antistatic yarn is made of moisture-wicking fiber 35-45%, cotton fiber 10-30%, silver fiber 3-7% and stainless steel fiber 25-40% % blended; conductive yarn antistatic yarn is twisted from 3-5% organic conductive yarn and 95-97% multifunctional blended yarn. The multifunctional fabric produced by the invention has antistatic function, moisture absorption and perspiration function and antibacterial function, which can not only ensure the antistatic function of the fabric, but also greatly improve the air permeability of the fabric, improve the wearing comfort of the fabric, and have good antibacterial function.

Owner:ZHENGZHOU NO 4 COTTON TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com