Antistatic anti-aging plastic and preparation method thereof

An anti-aging and anti-static technology, applied in the field of polymer materials, can solve problems such as cracking, poor anti-aging performance, and easy aging, and achieve high notched impact strength, facilitate large-scale production, and good antistatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

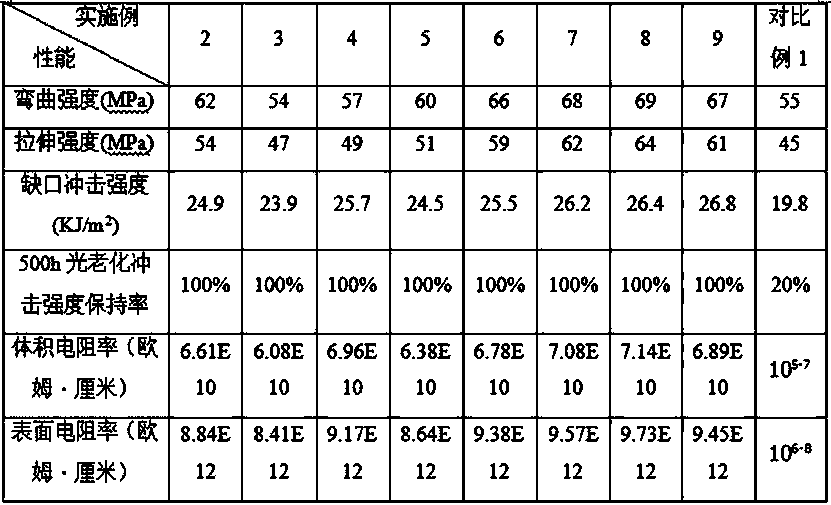

Examples

Embodiment 1

[0017] An antistatic and anti-aging plastic, which is mainly made of the following raw materials according to the ratio of parts by mass: 110-130 parts by mass of HDPE, 40-55 parts by mass of PVC, 30-40 parts by mass of PA6, 10-15 parts by mass of coupling Agent, 10-12 parts by mass of hydroxymethyl fatty amine, 10-20 parts by mass of impact modifier, 14-18 parts by mass of polyol, 5-10 parts by mass of antistatic agent, 10-20 parts by mass of carbon black, 5 parts by mass - 10 parts by mass of antioxidant, 10-20 parts by mass of DOP, 10-15 parts by mass of ultraviolet absorber, 5-10 parts by mass of epoxy octyl stearate and 1-5 parts by mass of barium stearate.

[0018] An antistatic and anti-aging plastic, which is made of the following raw materials according to the ratio of parts by mass: 110-130 parts by mass of HDPE, 40-55 parts by mass of PVC, 30-40 parts by mass of PA6, and 10-15 parts by mass of coupling agent , 10-12 parts by mass of hydroxymethyl fatty amine, 10-20 ...

Embodiment 2

[0028] An antistatic and anti-aging plastic, which is made of the following raw materials according to the ratio of parts by mass: 110 parts by mass of HDPE, 40-55 parts by mass of PVC, 30 parts by mass of PA6, 10 parts by mass of silane coupling agent KH-550, 10 parts by mass Parts by mass of hydroxymethyl aliphatic amine, 10 parts by mass of impact modifier CPE, 14 parts by mass of polycaprolactone polyol, 5 parts by mass of antistatic agent S-15, 10 parts by mass of carbon black with a particle size of 300-310 μm , 5 parts by mass of antioxidant 1010, 10 parts by mass of DOP, 10 parts by mass of ultraviolet absorber UV-327, 5 parts by mass of epoxy octyl stearate, and 1 part by mass of barium stearate.

[0029] The method for preparing the above-mentioned antistatic and anti-aging plastics comprises the following steps: firstly, after fully mixing the above-mentioned components uniformly, adding them into a twin-screw extruder to melt, plasticize and granulate at a temperatu...

Embodiment 3

[0031] An antistatic and anti-aging plastic, which is made of the following raw materials according to the ratio of parts by mass: 130 parts by mass of HDPE, 55 parts by mass of PVC, 40 parts by mass of PA6, 15 parts by mass of silane coupling agent KH-550, 12 parts by mass Methylol fatty amine, 20 parts by mass of impact modifier CPE, 18 parts by mass of polycaprolactone polyol, 10 parts by mass of antistatic agent SN, 20 parts by mass of carbon black with a particle size of 300-310 μm, 10 parts by mass Antioxidant 2246, 20 parts by mass of DOP, 15 parts by mass of ultraviolet absorber UV-327, 10 parts by mass of epoxy octyl stearate, 5 parts by mass of barium stearate and 10 parts by mass of dibutyl phthalate.

[0032] The method for preparing the above-mentioned antistatic and anti-aging plastics comprises the following steps: firstly, after fully mixing the above-mentioned components uniformly, adding them into a twin-screw extruder to melt, plasticize and granulate at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com