Polyamide composite material and preparation method thereof

A composite material and polyamide technology, applied in the field of polyamide composite materials and its preparation, can solve the problems of low friction coefficient, high dry friction coefficient, low surface hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

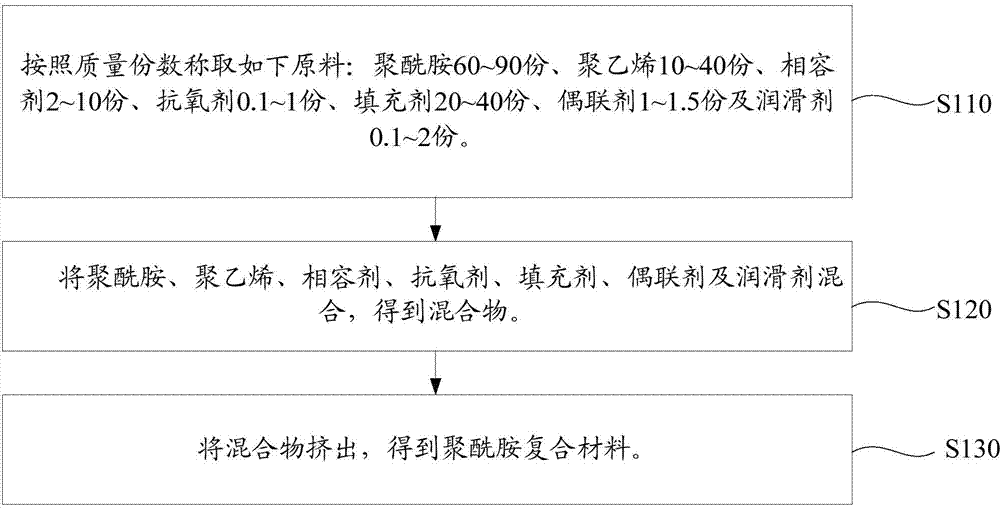

[0037] Such as figure 1 As shown, the preparation method of the polyamide composite material in one embodiment can be used to prepare the above-mentioned polyamide composite material. The preparation method of above-mentioned polyamide composite material comprises the steps:

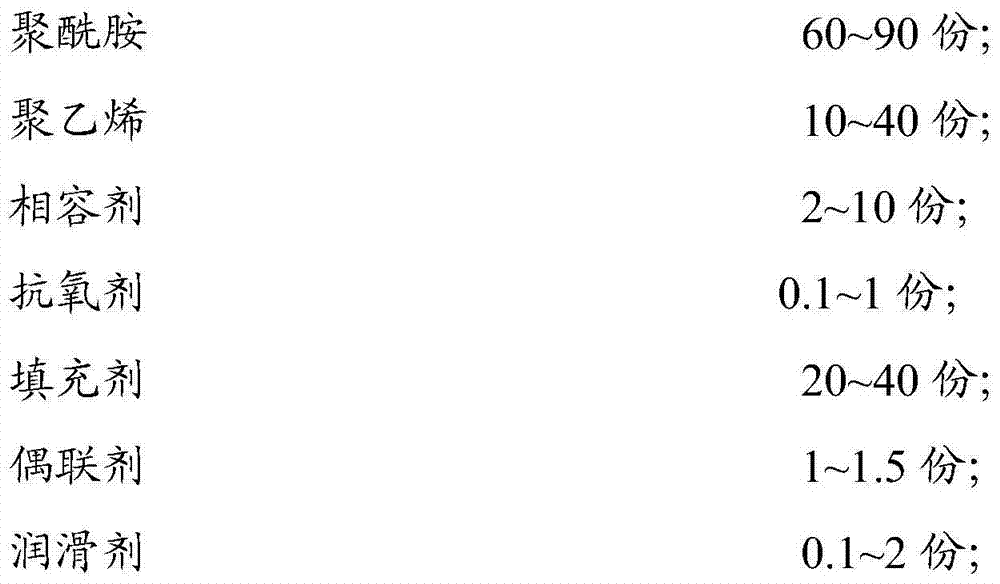

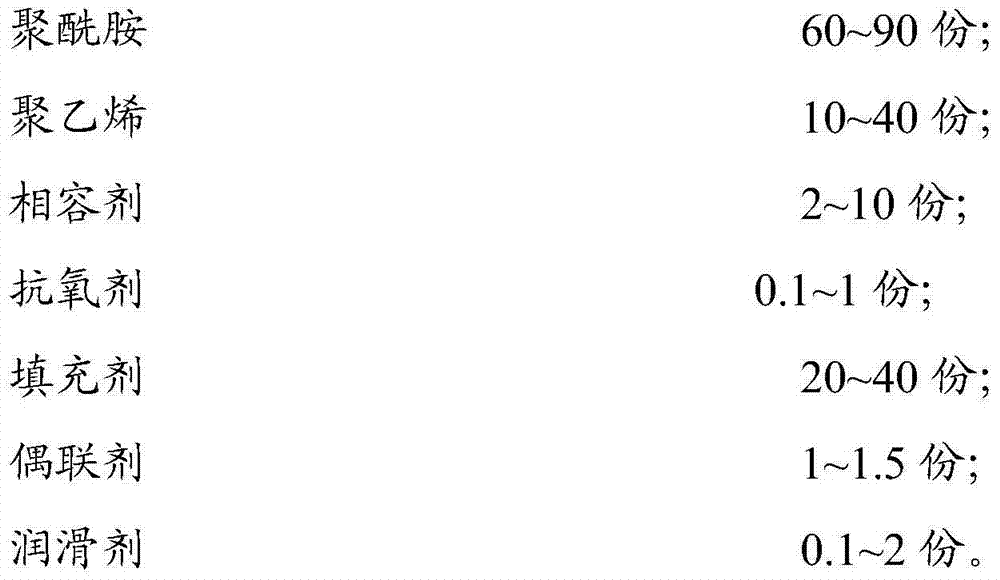

[0038] Step S110: Weigh the following raw materials in parts by mass: 60-90 parts of polyamide, 10-40 parts of polyethylene, 2-10 parts of compatibilizer, 0.1-1 part of antioxidant, 20-40 parts of filler, 1-1.5 parts of joint agent and 0.1-2 parts of lubricant.

[0039] Among them, polyamide (PA), also known as nylon. Preferably, the polyamide is polyamide 6.

[0040] Preferably, the relative viscosity of the polyamide is 2.4-2.8.

[0041] Among them, the number average molecular weight of polyethylene is 2 to 5 million; the density is 0.936 to 0.946g / cm 3 ; The particle size of polyethylene is 50-100 mesh.

[0042] The compatibilizer is maleic anhydride grafted high-density polyethylene, for examp...

Embodiment 1

[0058] The preparation steps of the polyamide composite material of the present embodiment are as follows:

[0059] (1) Take the following raw materials according to the parts by mass:

[0060]

[0061] (2) Stir and mix the alkali-free glass fiber and glass microspheres with the silane coupling agent KH-550 in a high-speed mixer with a rotation speed of 1800 rpm at 65°C to obtain a premix; mix the premix with polyamide 6. Polyethylene, maleic anhydride grafted high-density polyethylene, antioxidant 1098 and ethylene bisstearamide were mixed in a high-speed mixer for 12 minutes to obtain a mixture; wherein, the diameter of the alkali-free glass fiber was 8 to 15 Micron, the aspect ratio is 5-10, the particle size of glass beads is 2 microns; the relative viscosity of polyamide 6 is 2.4; the number average molecular weight of polyethylene is 200, and the density is 0.936g / cm 3 , The particle size of polyethylene is 50 mesh.

[0062] (3) Put the mixture in the twin-screw ext...

Embodiment 2

[0066] The preparation steps of the polyamide composite material of the present embodiment are as follows:

[0067] (1) Take the following raw materials according to the parts by mass:

[0068]

[0069] (2) Stir and mix the alkali-free glass fiber and glass microspheres with the silane coupling agent KH-550 in a high-speed mixer with a rotation speed of 2800 rpm at 85°C to obtain a premix; mix the premix with polyamide 6. Mix polyethylene, maleic anhydride grafted high-density polyethylene, antioxidant 1098 and ethylene bisstearamide in a high-speed mixer for 10 to 12 minutes to obtain a mixture; wherein, the diameter of the alkali-free glass fiber is 8 ~15 microns, aspect ratio 5~10, particle size of glass beads is 2 microns; relative viscosity of polyamide 6 is 2.8; number average molecular weight of polyethylene is 500, density is 0.946g / cm 3 , The particle size of polyethylene is 100 mesh.

[0070] (3) Put the mixture in the twin-screw extruder, and set the screw spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com