Protection film components containing vessel and manufacturing method thereof

A technology of protective film and storage container, which can be used in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., and can solve problems such as difficulty in cleaning photomasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Hereinafter, examples of the present invention will be described, but the present invention is not limited thereto.

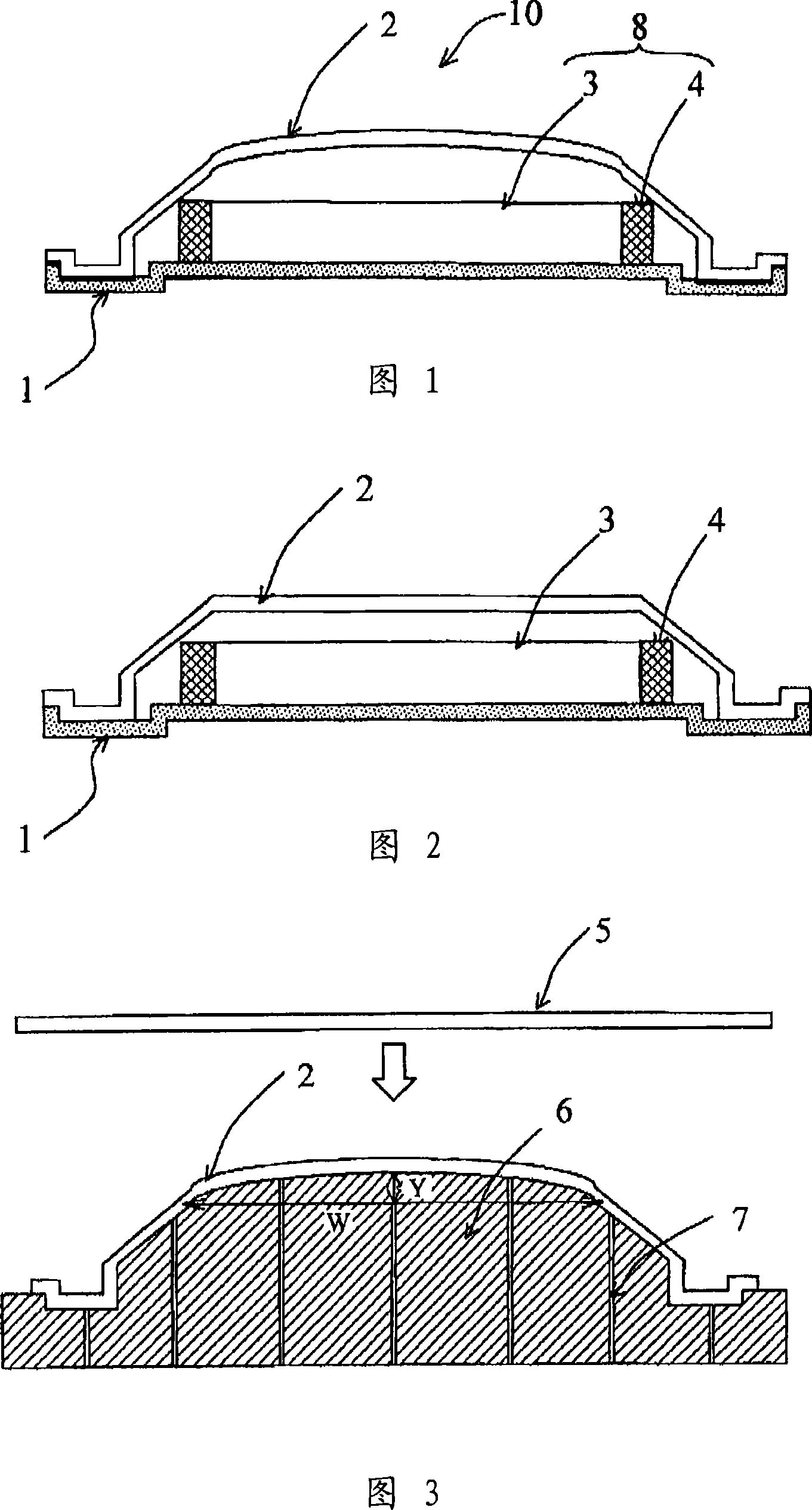

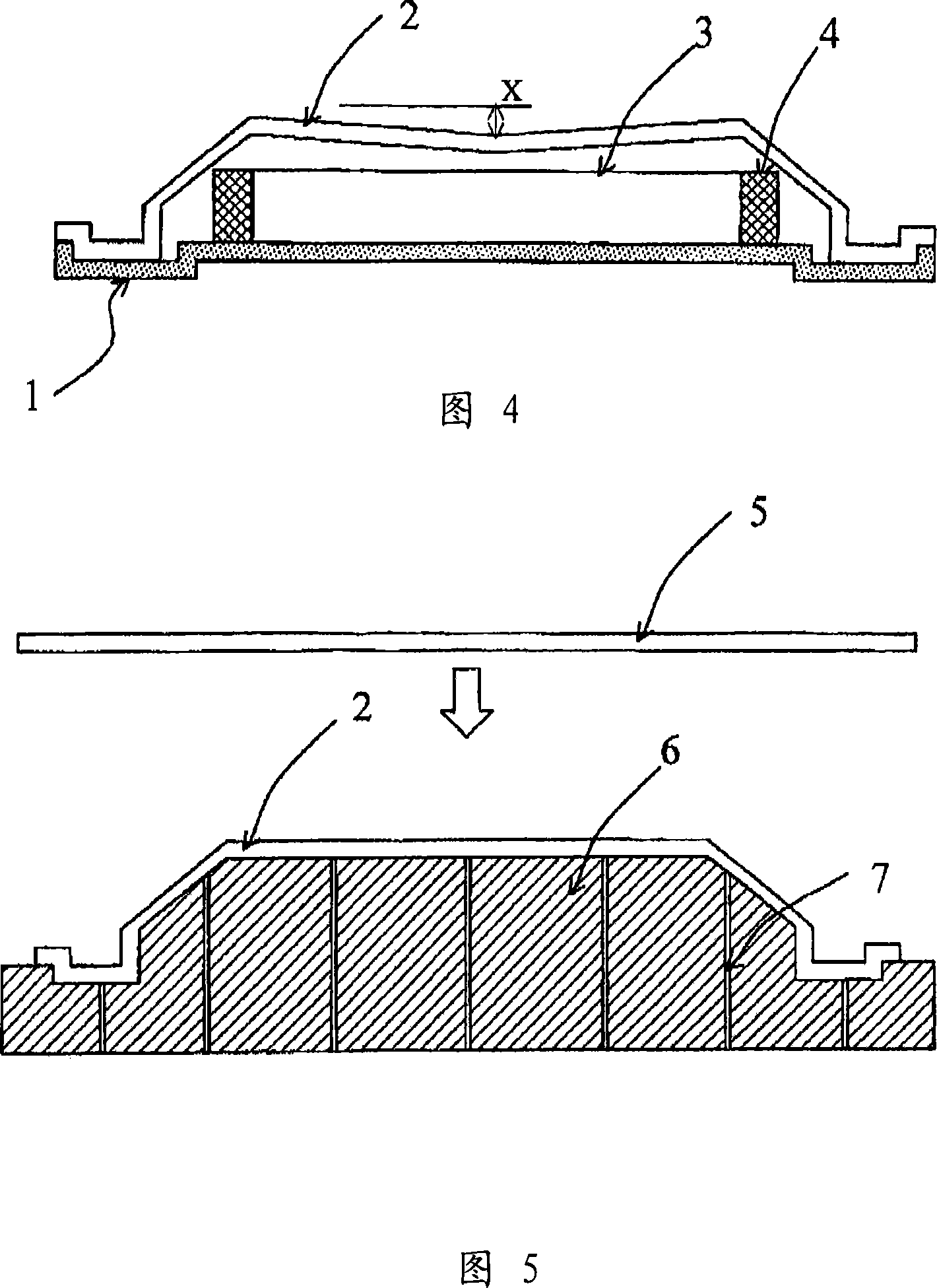

[0067] The pellicle storage container 10 shown in FIGS. 1 and 2 was produced. The structure of the pellicle assembly storage container 10 is mainly composed of a container body 1 and a container cover 2, both of which are antistatic ABS resin (surface resistance value 5×10 11 Ω / □) formed by molding.

[0068] In the pellicle assembly storage container 10 of FIG. 1 , the top surface of the cover body 2 is designed to form a convex shape even if bent due to its own weight, so that the top surface will not adhere to the pellicle 3 .

[0069] In the pellicle assembly storage container 10 of FIG. 2 , the top surface of the cover body 2 is designed to be in a gentle convex shape, so as to counteract the bending amount caused by the weight of the top surface itself and make it horizontal.

[0070] Fig. 3 is a diagram showing a vacuum forming mold used to manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com