High-temperature kiln product sorting and tracing method and system based on two-dimensional code nameplates

A traceability system and two-dimensional code technology, which is applied in the field of traceability system and batch sorting based on two-dimensional code nameplates, can solve the problems of low recording efficiency, error-prone, poor versatility, etc., and achieve long service life, cost saving, Easy to Scan Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below, but the present invention is not limited to the following examples.

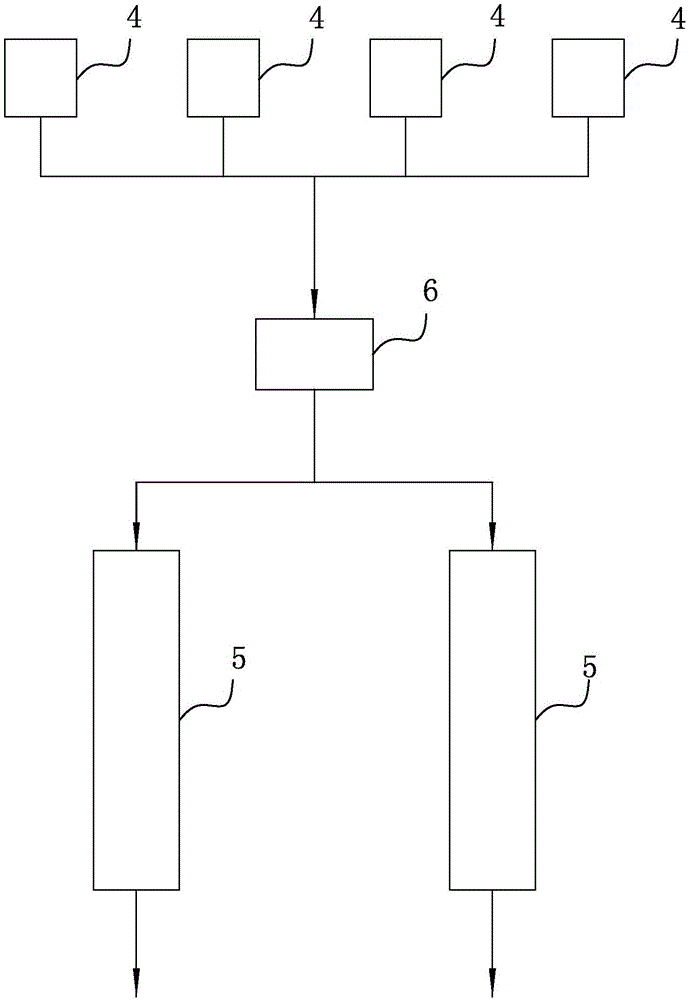

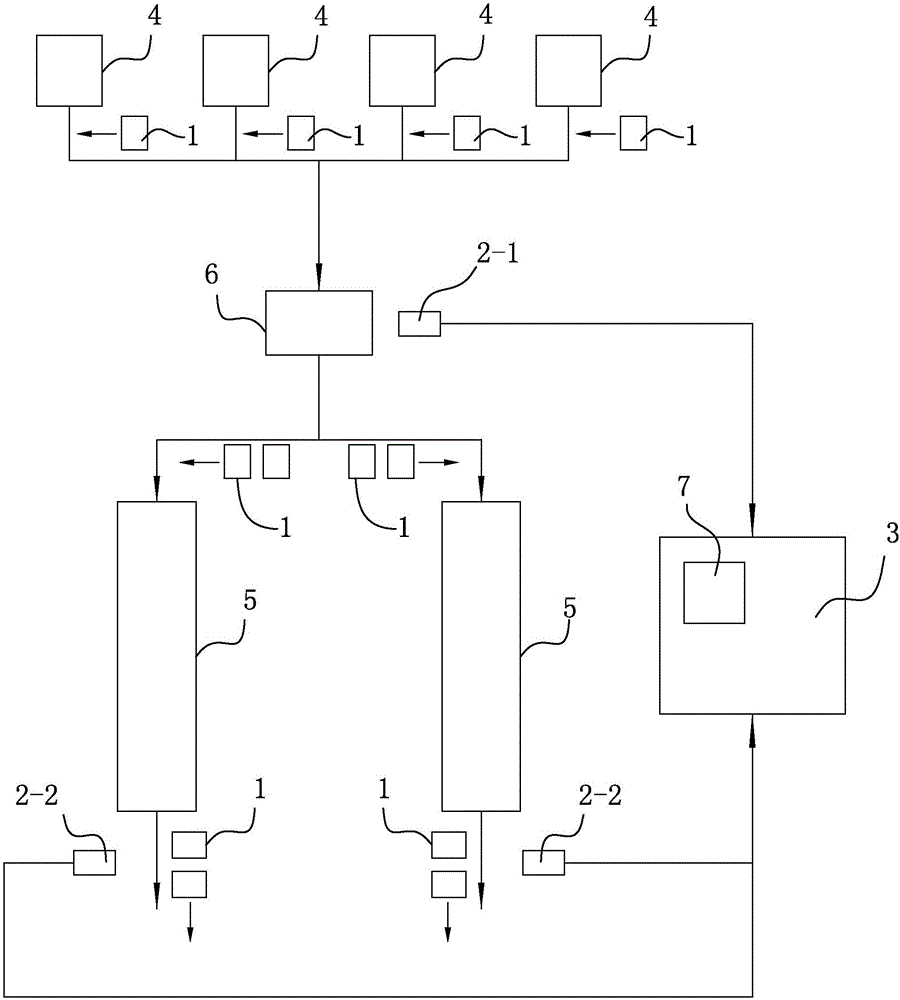

[0034] Such as figure 2 As shown, the high-temperature kiln product sorting and traceability method based on the two-dimensional code nameplate of the present invention comprises the following steps:

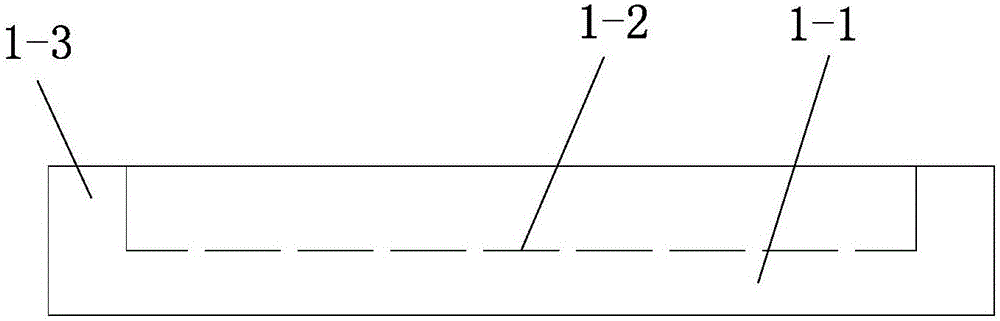

[0035] 1) Manually operate the computer, and associate each product batch information with the corresponding two-dimensional code nameplate 1 in the database module of the computer 3; product batch information generally includes the batch-kiln relationship and people, machines, materials, methods, Ring and other information can be determined according to the production needs of the enterprise;

[0036] 2) At the exit of the machine, the two-dimensional code nameplate is placed on the product manually or by a robot, and advances along the assembly line along with the product; generally, a batch of products is placed on a pallet or bracket, and adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com