Movable armrest of passenger conveyer and armrest for passenger conveyer

A technology for passenger conveyors and handrails, applied in escalators, transportation and packaging, etc., can solve the problems of surrounding contamination and fluororesin fiber detachment, and achieve the effect of reducing resistance and preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

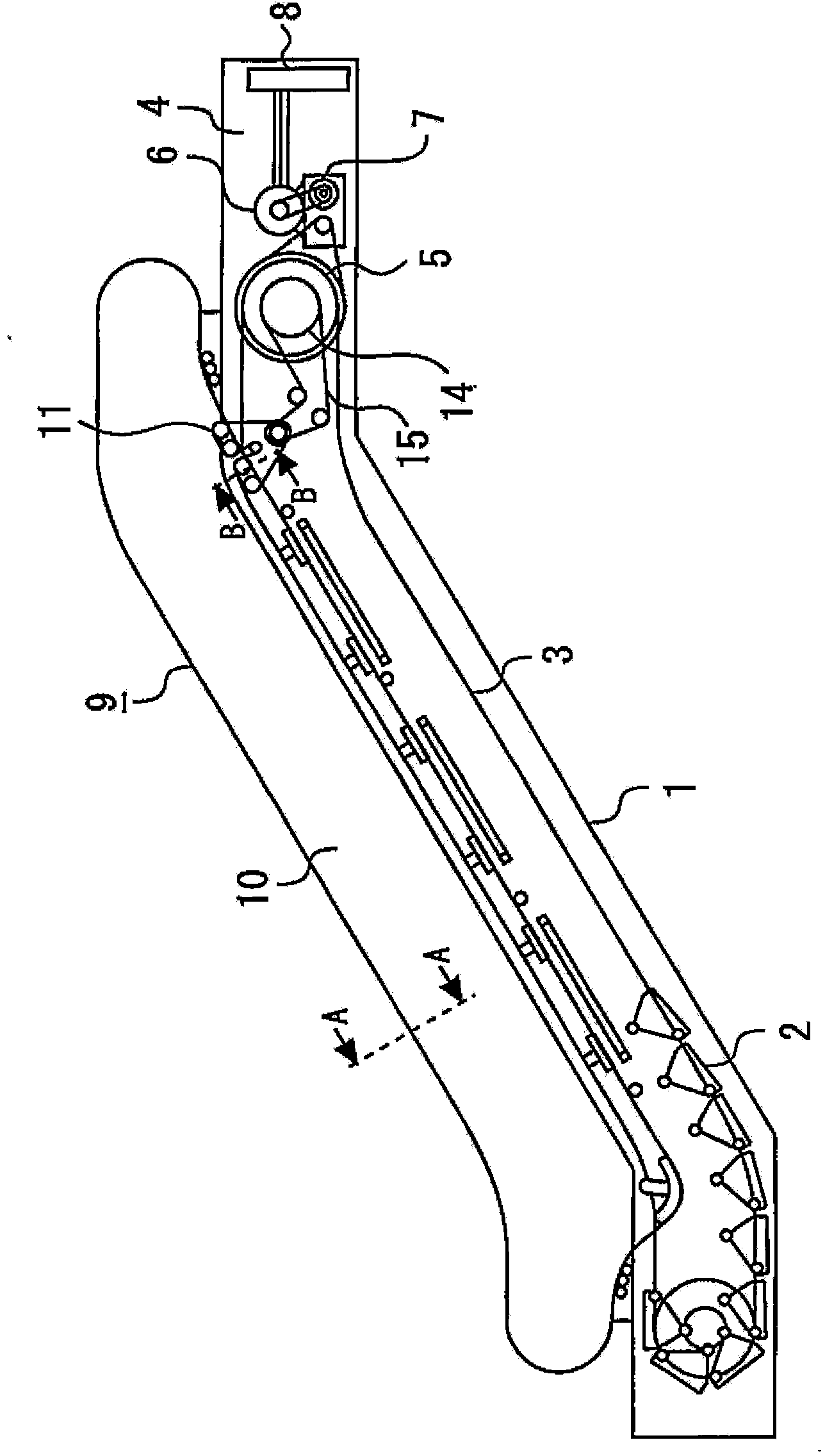

[0056] figure 1 It is a side view showing the overall structure of the passenger conveyor. Hereinafter, the structure of the escalator used when moving between upper and lower floors will be specifically explained. The description of other examples of the passenger conveyor, such as the structure of the moving sidewalk, is omitted.

[0057] in figure 1 Among them, number 1 is the truss of the escalator erected between the upper and lower floors. The truss 1 supports the dead weight and loading load of the escalator. Number 2 is the step used by passengers when they move between the upper and lower floors. The step 2 is connected to a ring-shaped step chain 3. In the machine room 4 installed on the upper part of the truss 1, the step chain 3 is wound around the step drive sprocket 5.

[0058] The number 6 is the drive motor, and the number 7 is the reducer. The drive motor 6 is used to drive the sprocket 5 for step drive and the like. The reducer 7 decelerates the output of th...

Embodiment approach 2

[0105] Figure 14 It is a figure which shows an example of the knitting method of the sliding cloth of the mobile handrail of Embodiment 2 of this invention.

[0106] in Figure 14 In the weaving method of the sliding cloth 21 shown, each lateral thread 23b passes through the back side of one longitudinal thread 24, and then continuously passes through the front side of the five longitudinal threads 24. The horizontal line 23b repeats this passage. For the vertical line 24, there are two passing methods relative to the horizontal line 23b. The first type longitudinal thread 24 passes through the front side of one transverse thread 23b, and then continuously passes through the back side of two transverse threads 23b. The first type longitudinal line 24 repeats this passage. The second type vertical thread 24 passes only the back side of the horizontal thread 23b. The first type longitudinal wires 24 and the second type longitudinal wires 24 are arranged alternately.

[0107] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com