Phenol aldehyde resin and preparation method thereof, and automobile filter paper

A technology of phenolic resin and phenolic compound, which is applied in the field of resin, can solve the problems of poor electrical conductivity, etc., and achieve the effects of good electrical conductivity, good burst resistance and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

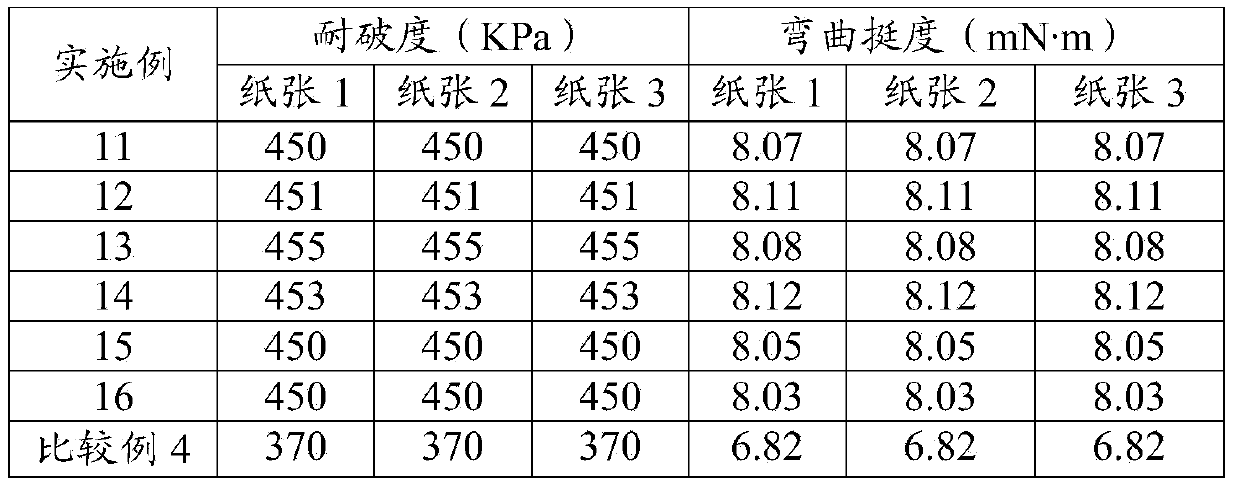

Examples

preparation example Construction

[0038] In the present invention, the particle size of the graphene is preferably 0.335 nm to 33.5 nm, more preferably 1 nm to 10 nm. In the present invention, the preparation method of described graphene preferably comprises the following steps:

[0039] 1), under the action of a catalyst, the biomass carbon source is subjected to catalytic treatment to obtain a first intermediate product, and the catalyst includes one or more of manganese chloride salts, iron compounds, cobalt compounds and nickel compounds Several;

[0040] 2) In the presence of a protective gas, the first intermediate product is heated from a first temperature to a second temperature and then kept warm to obtain a second intermediate product. The first temperature is 20°C to 40°C, and the The second temperature is 300°C-400°C;

[0041] 3) In the presence of a protective gas, heating the second intermediate product from the second temperature to a third temperature and then keeping it warm to obtain a thir...

Embodiment 1

[0086] At 90° C., hydrolyzing corncobs in sulfuric acid for 10 minutes to obtain lignocellulose, the mass of the sulfuric acid being 3% of the mass of the corncobs;

[0087] At 70°C, the lignocellulose was subjected to acidic sulfite treatment for 1 hour to obtain porous cellulose, the pH value in the acidic sulfite treatment process was 1, the acid was sulfuric acid, and sulfite It is magnesium sulfite, the quality of the sulfuric acid is 4% of the quality of the lignocellulose, and the liquid-solid ratio is 2:1.

[0088] The obtained porous cellulose is bleached with hydrogen peroxide, the mass of the hydrogen peroxide is 5% of the mass of the porous cellulose, the bleaching temperature of the hydrogen peroxide bleaching is 100° C., and the bleaching time is 5 hours.

[0089] Stir the porous cellulose and manganese chloride at 20°C for 2 hours for catalytic treatment, the mass ratio of the manganese chloride and porous cellulose is 0.01:1; Drying at a low temperature to obt...

Embodiment 2

[0093] At 180°C, hydrolyzing corncobs in nitric acid for 10 hours to obtain lignocellulose, the mass of the nitric acid being 20% of the mass of the corncobs;

[0094] At 180°C, the lignocellulose was subjected to acidic sulfite treatment for 6 hours to obtain porous cellulose, the pH value during the acidic sulfite treatment process was 7, the acid was sulfuric acid, and sulfite It is sodium sulfite, the quality of the sulfuric acid is 30% of the quality of the lignocellulose, and the liquid-solid ratio is 20:1.

[0095] The porous cellulose is bleached with hydrogen peroxide, the mass of the hydrogen peroxide is 5% of the mass of the porous cellulose, the bleaching temperature of the hydrogen peroxide bleach is 100° C., and the bleaching time is 5 hours.

[0096] Stir the porous cellulose and ferric nitrate at 180°C for 10 hours for catalytic treatment, the mass ratio of ferric nitrate and porous cellulose is 2:1; dry the obtained catalytically treated product at 120°C , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Burst resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com