Blowing and vacuuming machine

A blower and drive motor technology, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of no place for static electricity to be released, damage to the internal electronic components of the blower, electric shock to users, etc., to achieve easy implementation and avoid static electricity Gather and configure simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

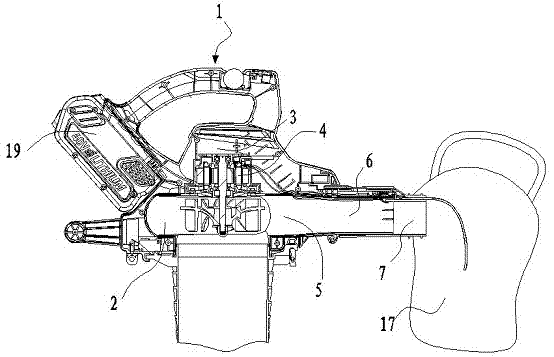

[0025] Such as figure 1 , figure 2 The shown air blower comprises: a main housing 2, the main housing 2 has an air outlet 6; a driving motor 4 arranged in the main housing 2; a DC power supply, specifically as figure 1 Shown is a lithium battery 19, which is electrically connected to the driving motor 4; a collecting device, specifically a cloth bag 17 connected to the air outlet 6; and an electrostatic discharge unit electrically connected to the driving motor 4, and the electrostatic discharge unit extends to air outlet 6. Wherein, the electrostatic discharge unit is an element with conductive properties. In this embodiment it is a discharge wire 16 . One end of the discharge wire 16 is connected to the metal casing of the drive motor 4 , and the other end extends inside the air outlet 6 . Used to better discharge static electricity.

no. 2 example

[0027] Such as figure 1 As shown, the blower can also be, which includes: a main housing 2, the main housing 2 has an air outlet 6; a driving motor 4, arranged in the main housing 2; a DC power supply, specifically as figure 1 Shown is a lithium battery 19, which is electrically connected to the drive motor 4; a collection device, specifically a cloth bag 17 connected to the air outlet 6; an electrostatic discharge unit, which is electrically connected to the drive motor 4, and extends to collection device.

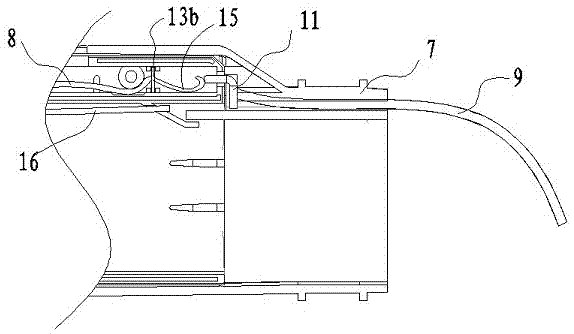

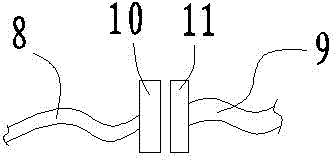

[0028] Wherein the electrostatic discharge unit specifically includes: a first wire 8 and a second wire 9, one end of the first wire 8 is electrically connected to the drive motor 4, the other end is set as a first contact 10, and one end of the second wire 9 Extending to the collecting device, the other end is set as a second contact 11 , and the first contact 10 is electrically connected to the second contact 11 .

[0029] The reason for using two sections of wires fo...

no. 3 example

[0033] The way to replace the elastic element in the second embodiment is as figure 2 As shown: the elastic element can also be: the elastic element includes a bent reed 15 and a terminal 13b connecting the reed 15, the terminal 13b is connected to the first wire 8, and the second contact 11 is connected by the contact spring The sheet 15 is electrically connected to the first wire 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com