Hair Brush

a brush and hair technology, applied in the field of hair brushes, can solve the problems of accumulating calories, transmitting heat with less speed and effectiveness, and brush types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

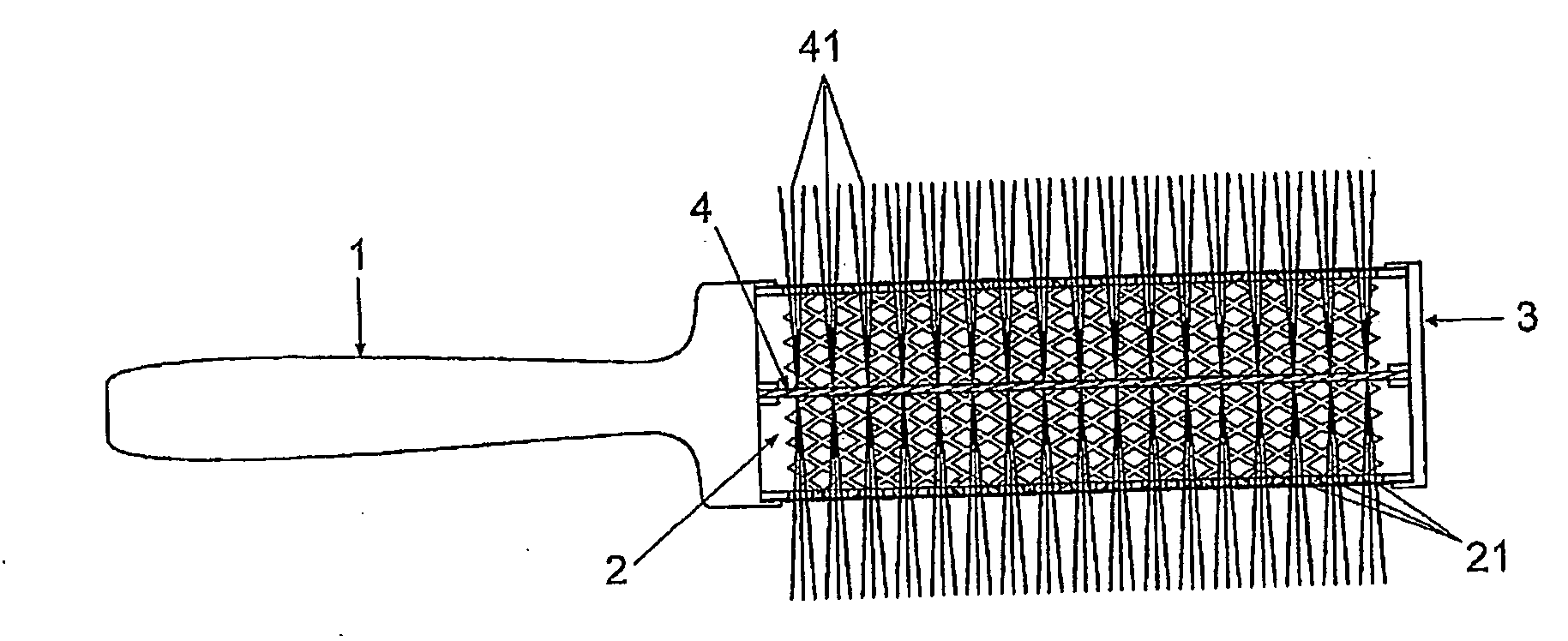

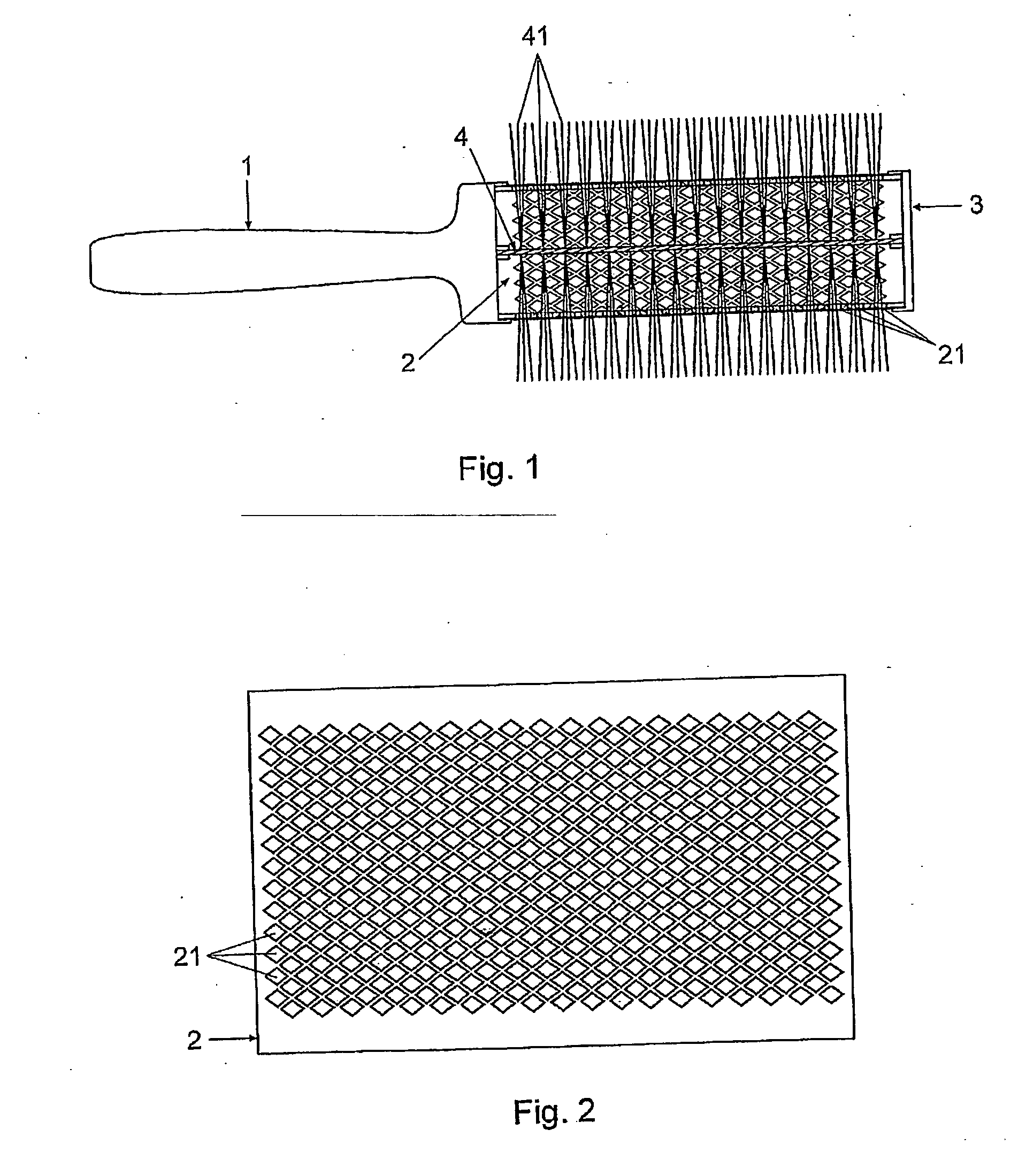

[0009]The brush of this invention presents a series of technical features that allow a more effective and optimized use of it providing also a longer durability.

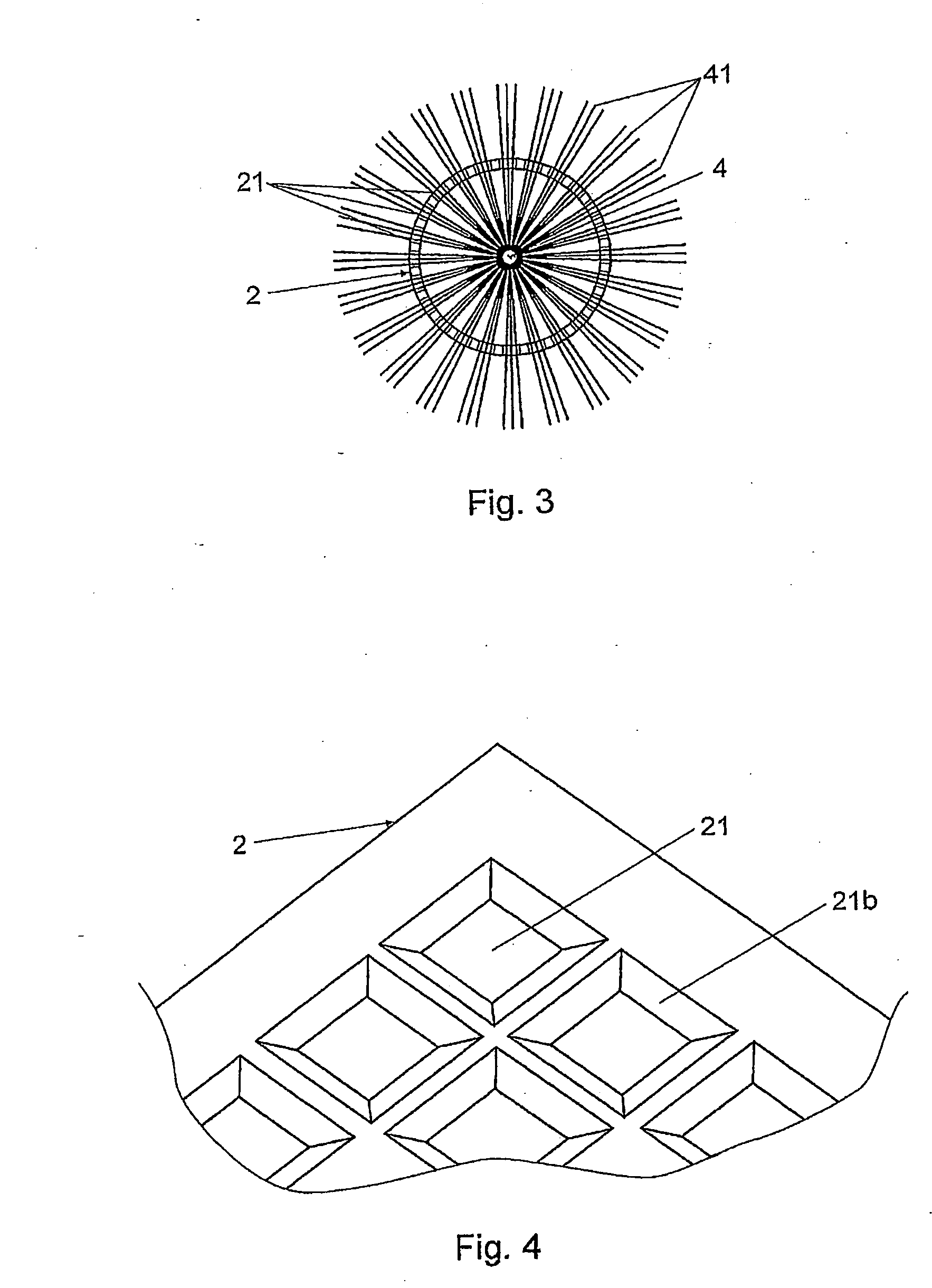

[0010]According to the invention, the brush features an aluminium tubular body holed and coated externally with an artificial plastic material with non-stick properties, with a high capacity of heat transmission and resistant to chemical and physical agents, being this material polytetrafluorethylene, also known as Teflon®.

[0011]Given that the aluminium is a good conductive material for heat, a homogeneous distribution of heat applied by means of a hair drier or similar can be achieved.

[0012]Furthermore, the coating of polytetrafluorethylene makes the time of heat transfer to be prolonged and provides a proper protection against the damage of the brush caused by the action of components in products applied on the hair, giving thus a longer useful life to the brush. Additionally, due to the non-stick properties of this coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com