Pure cotton heavy bath mat weaving process

A pure cotton and bath mat technology, applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of poor durability, poor elasticity, and easy deformation, and achieve the effect of good durability, good elasticity, and not easy to generate static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

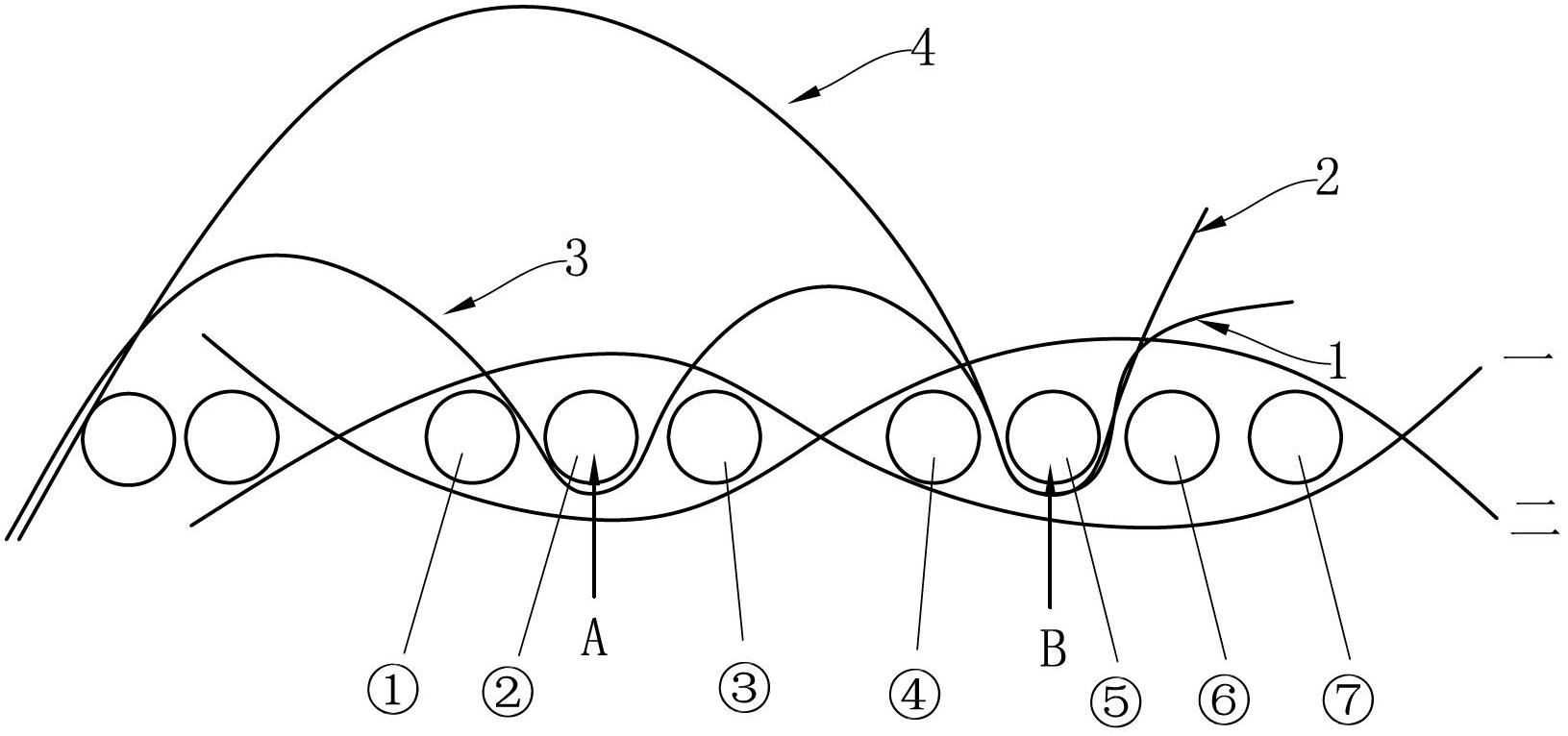

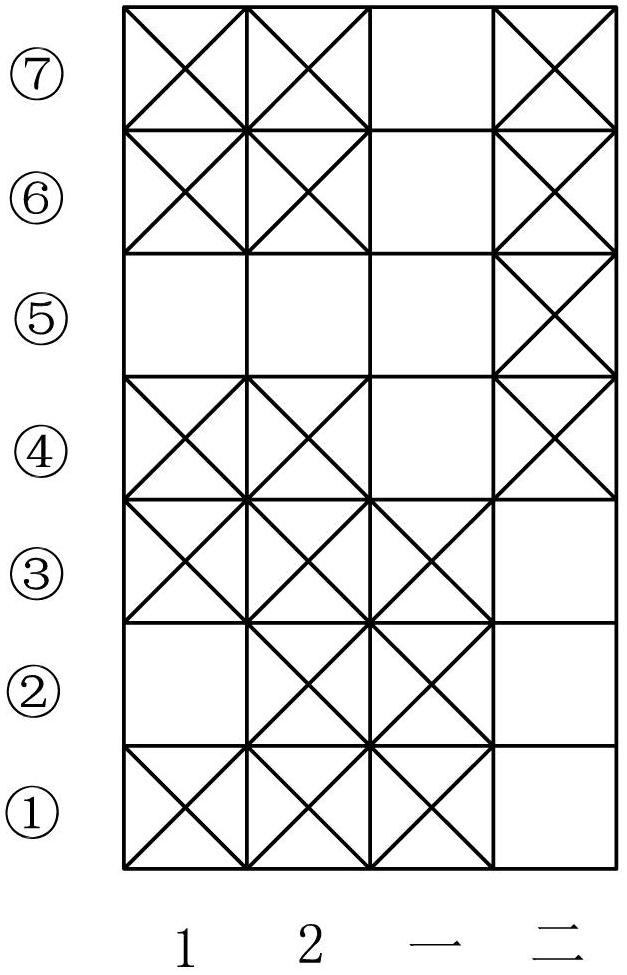

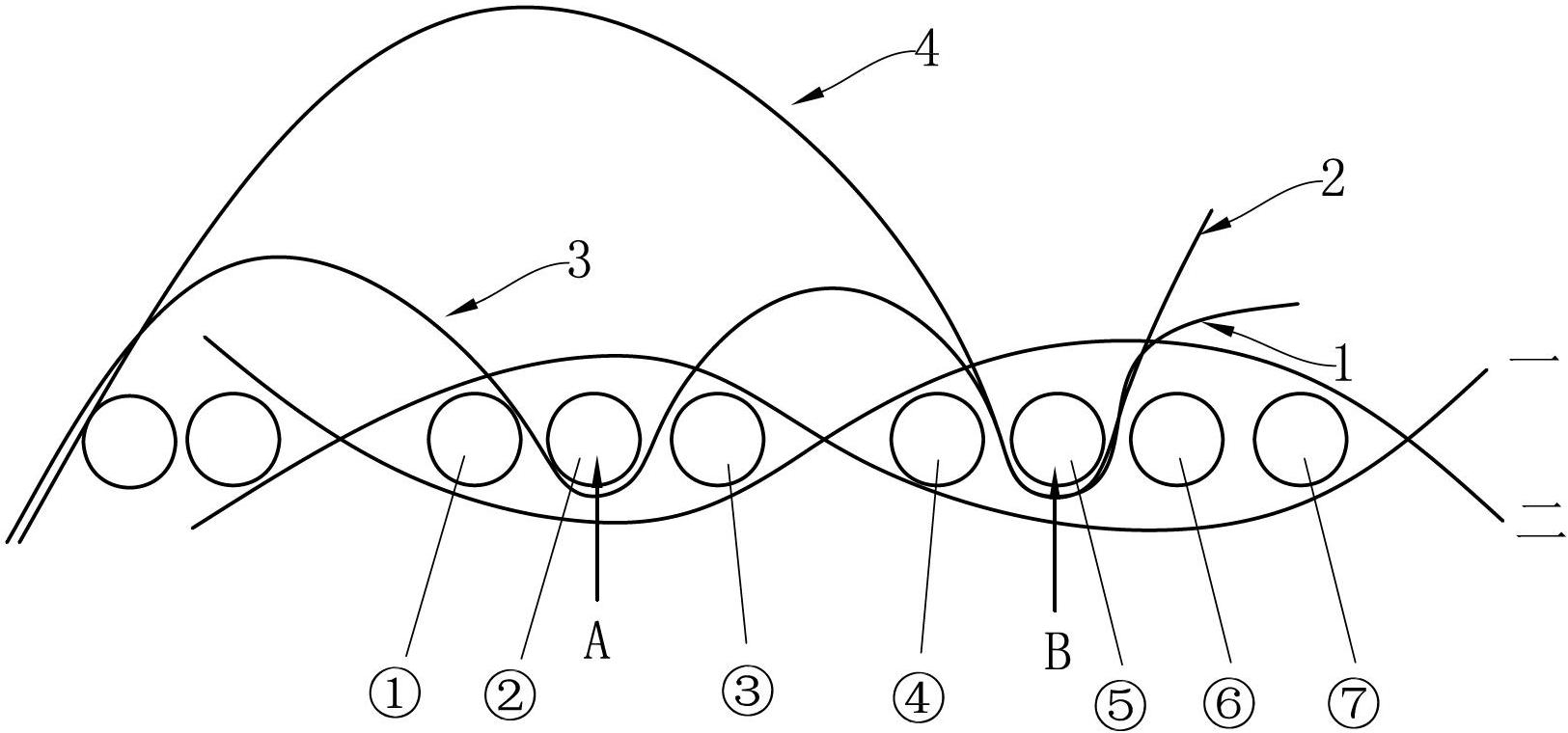

[0037] The weaving process of pure cotton low-count bath mat includes the following weaving steps:

[0038] S1. Spin the fine-staple cotton into a single yarn with a twist of 72.9 tex and a twist of 40 twists / 10 cm, and then combine the single yarns into 4 strands to make a weakly twisted bobbin yarn with a twist of 18 twists / 10 cm.

[0039] This step includes the following steps: 1. Opening and cleaning process. The mixed fine-staple cotton is opened and impurity-removed with a cotton opener, and the raw cotton is further opened and impurity-removed with a cotton cleaner, and the raw cotton is made into a certain specification of cotton. lap or cotton layer; ② Carding process, the finished cotton lap or cotton layer is fed into the carding machine for careful and thorough carding, so that the bundle fibers are separated into single fibers, and the fibers are partially straightened to make a certain Uniform oval carded sliver of density. And the regular circles are placed in ...

Embodiment 2

[0047] The weaving process of pure cotton low-count bath mat includes the following weaving steps:

[0048] S1. Spin the fine-staple cotton into a single yarn of 72.9 tex and a twist of 30 twists / 10 cm through the opening and cleaning process, the carding process, and the rotor spinning process, and then the single yarn is combined through the yarn combining process. The strands were made into a weakly twisted bobbin yarn with a twist of 15 twists / 10 cm.

[0049] S2. The bobbin yarn is warped and sizing, relying on a G6300 rapier loom, using No. 50 reed, ground warp 1 into the reed, wool warp 0.5 into the reed, the weft density is 50 picks / 2.54 cm, and the vehicle speed is 300 Rotation / min, and 35tex×2 ground warp and 57tex weft yarn are used for weaving. The weft and 3 wefts are made of short loops respectively, and finally woven into grey fabrics.

[0050] S3. utilize the caustic soda that contains 30L / 450kg concentration, 20L / 450kg concentration hydrogen peroxide stabiliz...

Embodiment 3

[0053] The weaving process of pure cotton low-count bath mat includes the following weaving steps:

[0054] S1. Spin the fine-staple cotton into a single yarn of 72.9 tex and a twist of 60 twists / 10 cm through the opening and cleaning process, the carding process, and the rotor spinning process, and then the single yarn is combined through the yarn combining process. The strands were made into a weakly twisted bobbin yarn with a twist of 25 twists / 10 cm.

[0055] S2. The bobbin yarn is warped and sizing, relying on Sulzer G6200 rapier loom, using No. 50 reed, ground warp 1 into the reed, wool warp 0.5 into the reed, the weft density is 70 picks / 2.54 cm, and the vehicle speed It is 380 rpm, and the ground warp of 37tex×2 and the weft of 60tex are used for weaving. The warp 3, 3 and 4 wefts are made of short loops respectively, and finally woven into grey fabrics.

[0056] S3. utilize the caustic soda that contains 30L / 450kg concentration, 20L / 450kg concentration hydrogen pero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com