A preparation method of flax and tencel interwoven fabric

A linen and tencel technology, applied in auxiliary weaving equipment, textiles, fabrics, etc., can solve problems such as poor dimensional stability, thorny feeling, and easy wrinkling of linen, so as to avoid frictional breakage, increase specifications, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

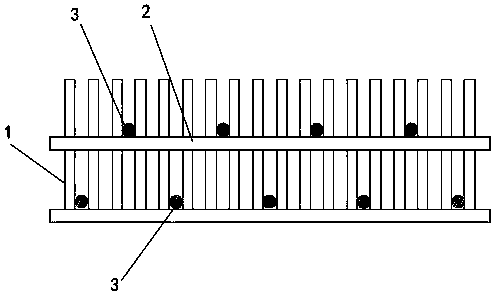

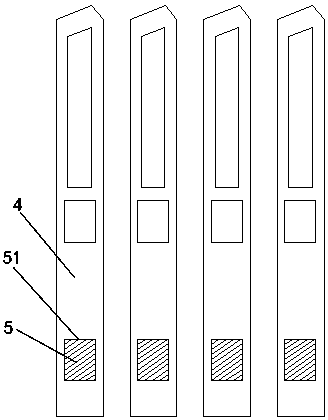

[0022] A method for preparing a linen and tencel interwoven fabric, the steps are as follows: (1) Winding process: the linen warp yarn is wound and formed by using an automatic winding machine, and specifically, a yarn guide winding machine can be used for forming. (2) Warping process: adopt the warping method in batches, adjust the number of warping heads of linen warp yarns, reduce the number of warping heads by half, place telescopic reeds one at a time, the number of warping heads is 5816, and the number of warping beams is 728×8. Generally, if the warping density is too high, the yarns will be easily broken due to mutual friction. The method of the present invention reduces the warping density and avoids the friction of the warp yarns. Such as figure 1 As shown, a parallel plate 2 is installed horizontally in the middle of the expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com