Preparation method of a three-dimensional in-plane quasi-isotropic stitched fabric

A quasi-isotropic, three-dimensional surface technology, used in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of low industrialization efficiency of three-dimensional in-plane quasi-isotropic fabrics, and achieve structural damage tolerance and use. Longer life, avoid friction breakage, reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

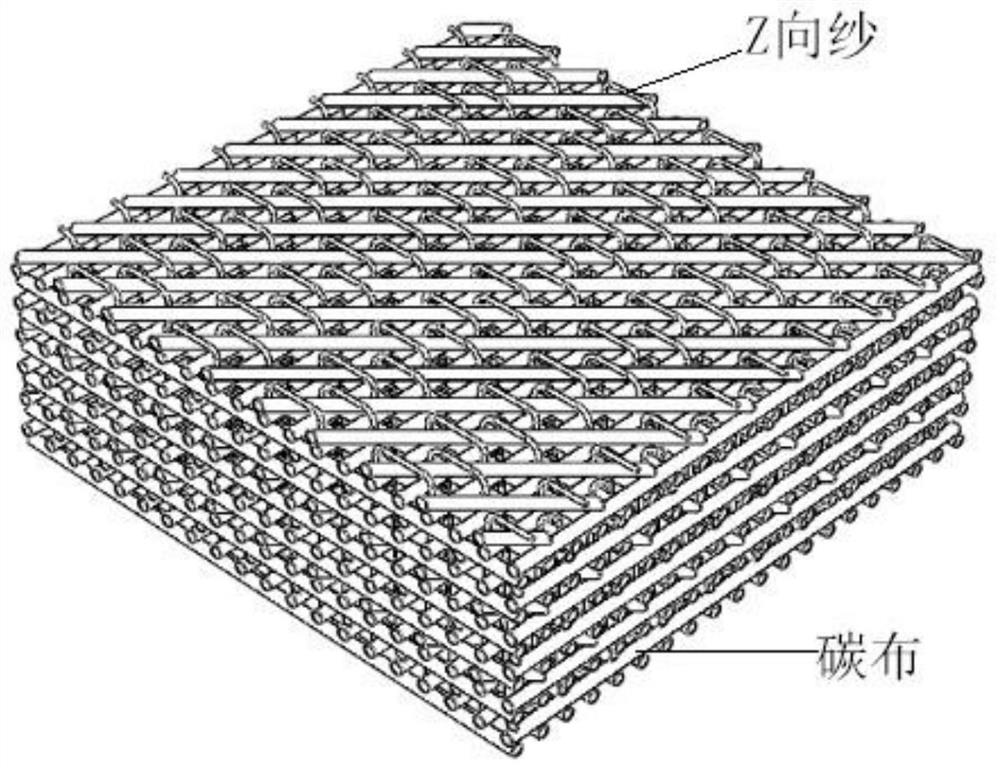

[0042] A method for preparing a quasi-isotropic stitched fabric in a three-dimensional plane, specifically according to the following steps:

[0043] The cloth chooses light material, high strength and fatigue resistance, wear-resistant and anti-aging carbon cloth, and its single layer thickness is 0.15mm-0.2mm, and the z-direction yarn chooses T800-6k carbon fiber. The size of the prefabricated part is 100mm×100mm, a total of 22 layers, 3.3 ~ 4.4mm thick, the arrangement sequence and ratio of carbon cloth are {C -45 C +45 C 0 C 90 C -45 C +45 C 0 C 90 C -45 C +45 C 0 C 90 C -45 C +45 C 0 C 90 C +45 C - 45 C 0 C 90 C +45 C -45}, where C indicates that the layer is carbon cloth, the subscript indicates the angle between the meridian of the layer of carbon cloth and the x-axis, and C -45 Indicates that the angle between the meridian of this layer of carbon cloth and the x-axis is -45°, C +45 Indicates that the included angle between the meridian of this la...

Embodiment 2

[0052] A method for preparing a quasi-isotropic stitched fabric in a three-dimensional plane, specifically according to the following steps:

[0053] Choose light material, high strength and anti-fatigue strength, wear-resistant and anti-aging carbon cloth and glass fiber cloth. Select 400tex S glass fiber which is superior to E glass fiber in terms of strength, modulus, dielectric constant, and high temperature resistance.

[0054] The size of the prefabricated part is 100mm×100mm, 22 layers, 3.66~4.4mm thick, and the order and proportion of the cloth are {G -45 G + 45 G -45 G +45 G -45 G +45 C 0 C 90 C 0 C 90 C 0 C 90 C 0 C 90 C 0 C 90 G -45 G +45 G +45 G -45 G +45 G -45}, where C indicates that the layer is carbon cloth, G indicates that the layer is glass fiber cloth, the subscript indicates the angle between the warp of the layer of carbon cloth or glass fiber cloth and the x-axis, and C -45 Indicates that the angle between the meridian of this laye...

Embodiment 3

[0063] A method for preparing a quasi-isotropic stitched fabric in a three-dimensional plane, specifically according to the following steps:

[0064] The cloth is made of light material, high strength and fatigue resistance, wear-resistant and anti-aging glass fiber cloth, the thickness of the single layer is 0.18mm-0.2mm, and the z-direction yarn is 400tex S glass fiber. The size of the prefabricated part is 200mm×200mm, a total of 20 layers, 3.6 ~ 4mm thick, the order and proportion of the carbon cloth {G -45 G +45 G 0 G 90 G -45 G 0 G 90 G -45 G +45 G 0 G 90 G -45 G +45 G 0 G +45 G - 45 G 0 G 90 G +45 G -45}, where G indicates that the layer is glass fiber cloth, the subscript indicates the angle between the warp of the layer of glass fiber cloth and the x-axis, G -45 Indicates that the angle between the warp of this layer of glass fiber cloth and the x-axis is -45°, G +45 Indicates that the included angle between the warp of this layer of glass fiber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com