Calculation method of on-machine sizing rate in sizing process

A technology of sizing and sizing, applied in the field of immediate reflection of sizing rate on the machine, can solve the problems of blindness and randomness, cumbersome sampling and analysis process, time lag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] Now take the calculation method of on-machine sizing rate in the sizing process of 67″C32s*C32s 133*78 twill variety as an example to illustrate, and it also has a guiding effect on the calculation method of on-machine sizing rate in the sizing process of other varieties.

[0120] 67〃C32s*C32s 133*78 twill varieties; total warp number: 8904; yarn count number: 18.2; length of each piece: 42.7 meters; number of pieces per package: 48 pieces; Total elongation: 1.6%; yarn count is pure cotton, metric moisture regain: 8.5%; process standard sizing rate: 14±1%

[0121] The slurry formula is as follows: 25 kilograms of PVA (the moisture content of the slurry is 7%)

[0122] 75 kg of starch (the moisture content of the slurry is 14%)

[0123] 5 kg of propylene slurry (the moisture content of the slurry is 14%)

[0124] The pulping process limits the volume after stewing: 77 cm

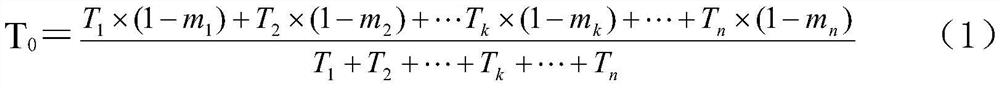

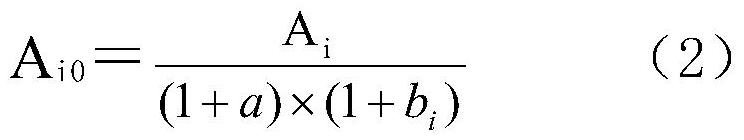

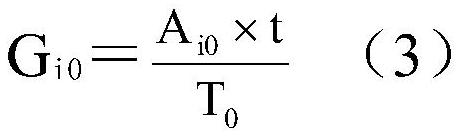

[0125] Step 1: Calculate the average dry weight ratio of the size used for sizing in the sizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com