Featherproof fabric sizing size and sizing method

A technology of feather-proof fabric and sizing method, which is applied in the direction of wear-resistant fiber, plant fiber, fiber treatment, etc., and can solve problems such as unsatisfactory demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

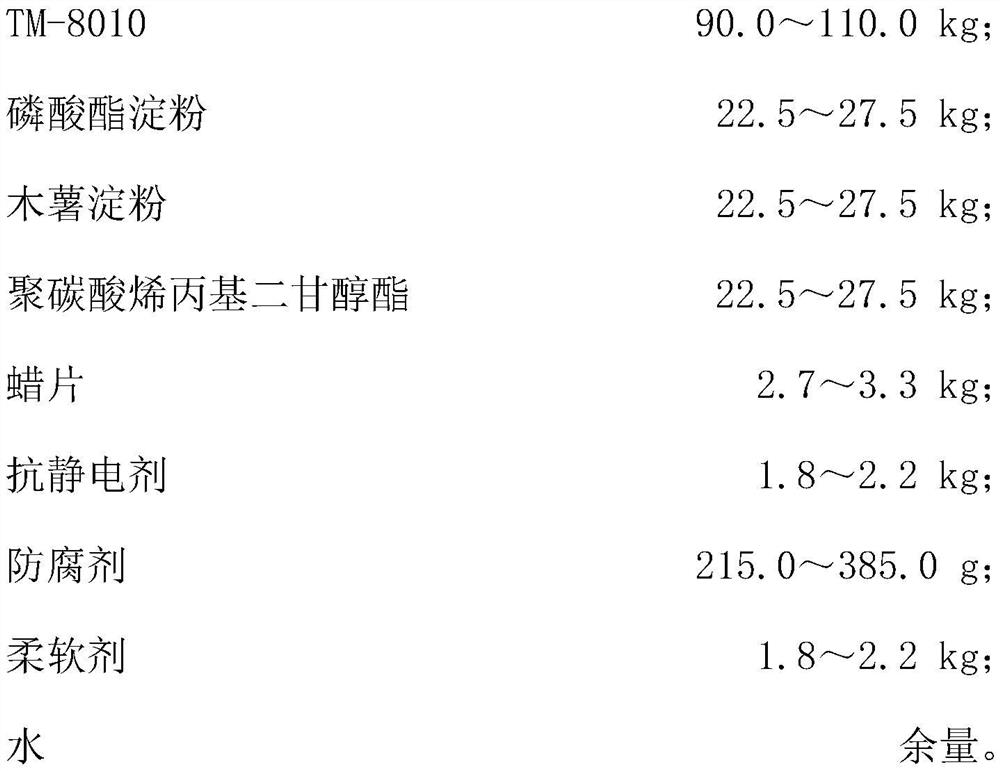

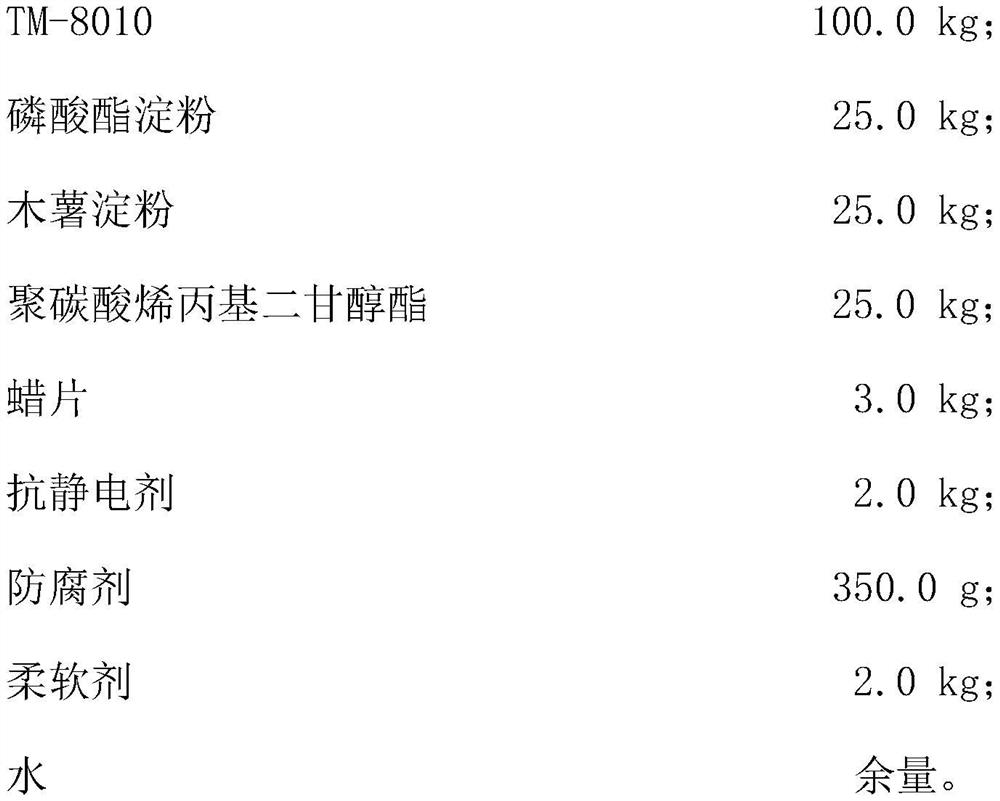

Method used

Image

Examples

Embodiment 1

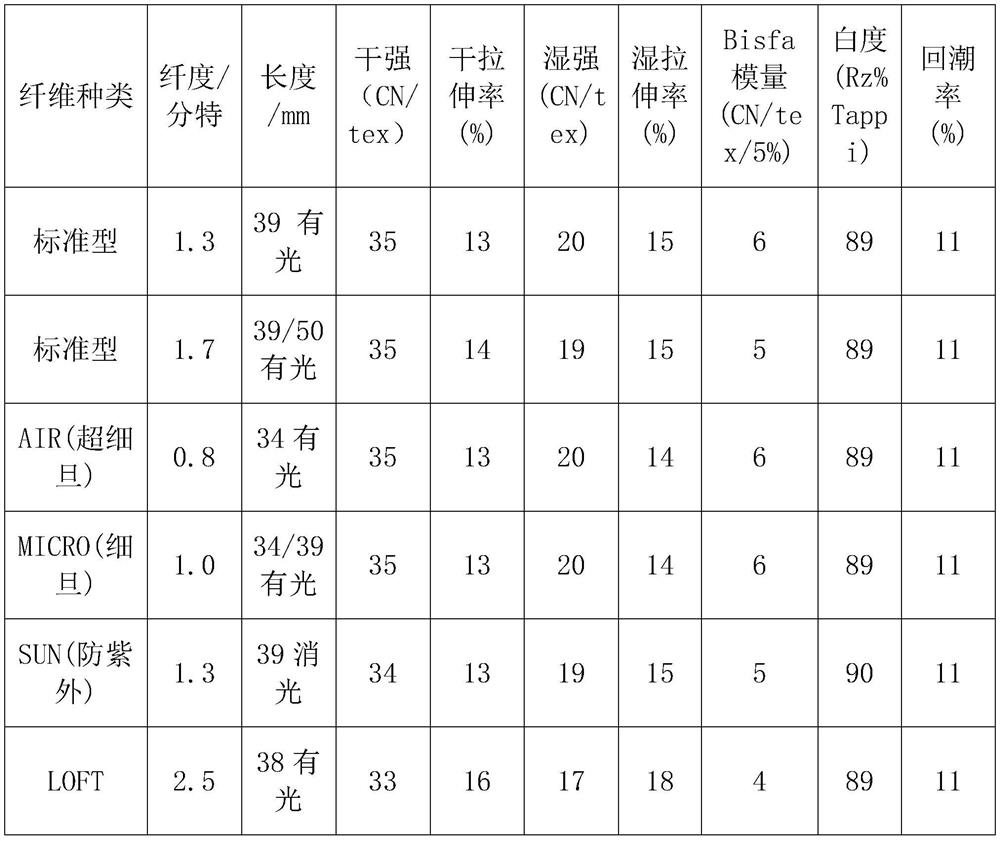

[0049] The specifications of raw materials and finished products of this embodiment are as follows:

[0050] Material: 60S high-count yarn (woven from superfine denier modal fiber)

[0051] Fabric specification: 105 ″ superfine denier modal 80* superfine denier modal 80 200*250 eight satin patterns

[0052] Finished product specifications: 98.5 "superfine denier modal 80* superfine denier modal 80 216*252 eight satin patterns

[0053] The production method includes warping process, sizing process, weaving process and dyeing and finishing process.

[0054] The whole process:

[0055] In order to reduce warp yarn breakage and weaving defects in the following process, it is necessary to ensure the uniformity of yarn tension. The tension of warp unwinding in the front, middle and back areas of the creel is inconsistent, with long yarn guiding distance in the back area, high yarn tension, short yarn guiding distance in the front area and low yarn tension. By adjusting the yarn channel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com