Preparation method of silicane functionalized graphene, antistatic organic silicon pressure sensitive adhesive and preparation method thereof

A silicone pressure-sensitive adhesive, antistatic technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of no antistatic properties of silicone pressure-sensitive adhesives and uneven dispersion of graphene , to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

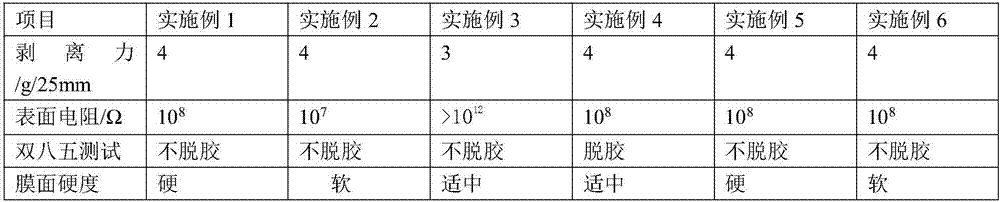

Examples

Synthetic example 1

[0027] Add 100 parts by mass of 98% concentrated sulfuric acid to the three-necked flask, stabilize the temperature at 0°C with an ice-water bath, slowly add a mixture of 1 part by mass of powdery flake graphite and 5 parts by mass of sodium nitrate under mechanical stirring, and stir vigorously to make the reaction uniform , then add 10 parts by mass of potassium permanganate in batches, control the temperature at 5°C, control the temperature at 25°C after the rubber material is completed, stir for 20 minutes, then add 300 parts by mass of distilled water, control the temperature at 80°C for 10 minutes, and then use warm water Dilute to 1000 parts by mass, add hydrogen peroxide until the solution is golden yellow. Then dilute hydrochloric acid and deionized water are fully washed to no SO42-ions, and the filter cake after suction filtration and washing can be vacuum-dried for 12 hours to obtain graphene oxide; get 0.1 mass parts of graphene oxide and ultrasonically disperse it...

Synthetic example 2

[0029] Add 200 parts by mass of 98% concentrated sulfuric acid to the three-necked flask, stabilize the temperature at 5°C with an ice-water bath, slowly add a mixture of 10 parts by mass of powdery flake graphite and 5 parts by mass of sodium nitrate under mechanical stirring, and stir vigorously to make the reaction uniform , then add 30 parts by mass of potassium permanganate in batches, control the temperature at 10°C, control the temperature at 40°C after the rubber compound is completed, stir for 60 minutes, then add 500 parts by mass of distilled water, control the temperature at 100°C for 50 minutes at high temperature, and then use warm water Dilute to 2000 parts by mass, add hydrogen peroxide until the solution is golden yellow. Then dilute hydrochloric acid and deionized water are fully washed to no SO42- ions, and the filter cake after suction filtration and washing can be vacuum-dried for 24 hours to obtain graphene oxide; get 0.5 parts by mass of graphene oxide an...

Synthetic example 3

[0031]Add 100 parts by mass of water glass and 100 parts by mass of water in a four-necked flask, add 80 ml of hydrochloric acid under rapid stirring, then add 6 parts by mass of dimethylvinylethoxysilane, 6 parts by mass Parts by mass of hexamethyldisiloxane and 90 parts by mass of ethanol were stirred and reacted at 50-60° C. for 30 minutes, and then 100 parts by mass of hexamethyldisiloxane was added and stirred for 1 hour. Stand to separate layers, remove the lower layer of dilute hydrochloric acid ethanol solution. Add 15 parts of concentrated hydrochloric acid to the resin solution in the upper layer under stirring, and stir and react at room temperature for 2 h. Then stand to separate the sulfuric acid, wash with water until neutral, and after drying with calcium chloride, distill the hexamethyldisiloxane to obtain a vinyl MQ silicone resin with an M / Q of 0.7 and a vinyl mass fraction of 3.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com