A lubricating type pre-coated thread locking sealant and preparation method thereof

A technology of sealant and thread, which is applied in the field of lubricating pre-coated thread-locking sealant and its preparation, can solve the problem of not being able to improve the lubricity of pre-coated thread-locking sealant and affecting the adhesion of pre-coated thread-locking sealant film. Force and torque strength, no mention of lubricity of pre-applied threadlocker sealant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The embodiment of the present invention also provides a preparation method of the lubricating type pre-coated thread locking sealant, comprising the following steps:

[0062] Prepare component A and component B, the order of preparing component A and component B is not limited, component A can be prepared first, component B can be prepared first, or component A and component B can be prepared at the same time;

[0063] The preparation process of A component is as follows:

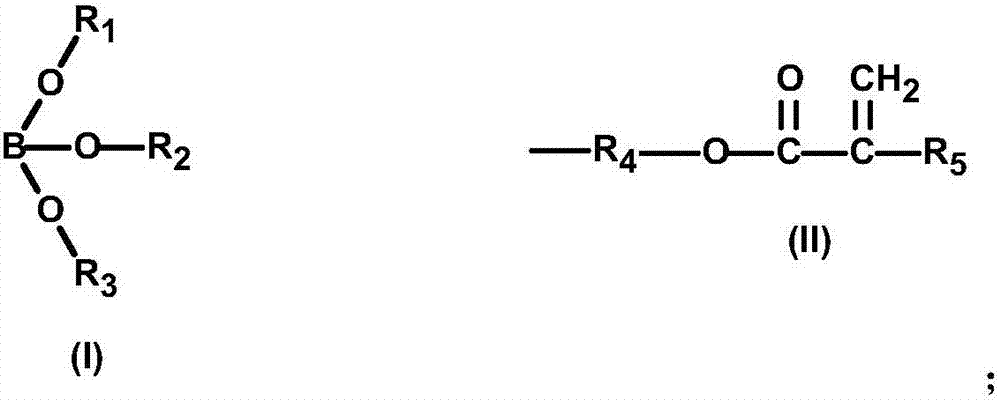

[0064] Prepare the self-lubricating monomer first: the reaction vessel is connected in series with a water separator, a condenser, and a vacuum system; according to the different structural formulas of the self-lubricating monomer to be prepared, two methods can be used to prepare the self-lubricating monomer:

[0065] Method 1: Prepare basic raw materials: boric acid and hydroxyacrylate, wherein the molar ratio of boric acid to hydroxyacrylate is 1:3; put in boric acid and hydroxyacrylate, and then ...

Embodiment 1

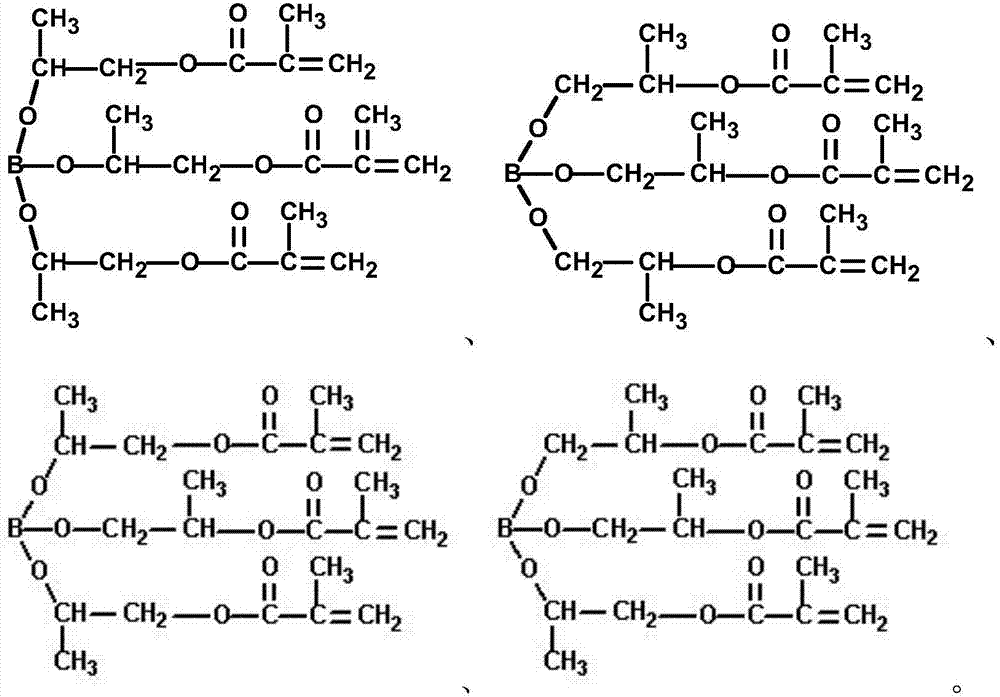

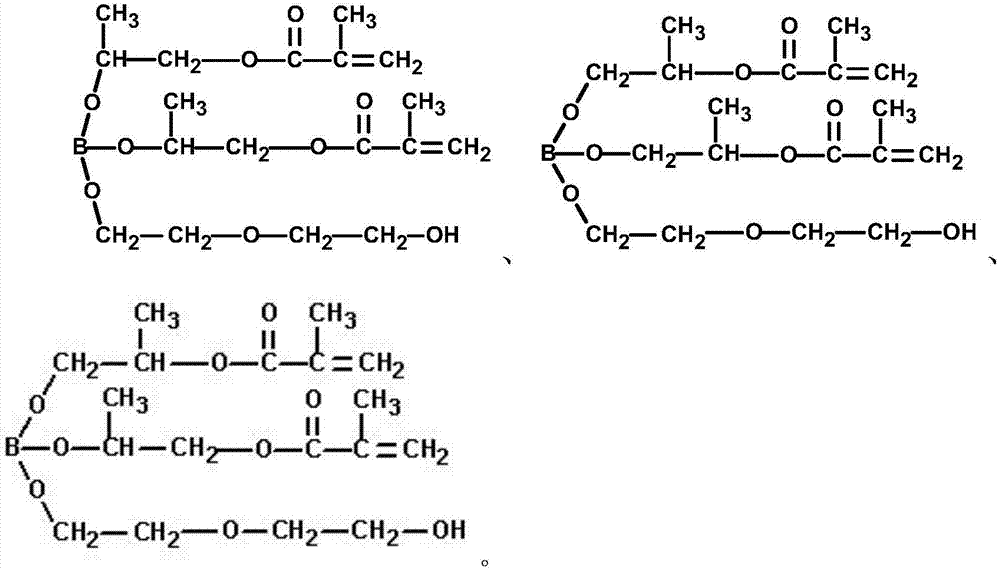

[0076] The lubricated pre-coated thread locking sealant provided in this embodiment includes component A and component B, and component A and component B are mixed in a mass ratio of 28:1; in terms of mass percentage Wt, component A includes 46% deionized water, 6% polyurethane thickening emulsion (thickening emulsifier), 0.5% propyl ferrocene (polymerization accelerator), 5% calcium carbonate (filler), 10% auto Lubricating type monomer, 31% polyethylene glycol 200 dimethacrylate, 0.5% pigment, wherein, the structural formula of self-lubricating type monomer is:

[0077]

[0078] Component B is microcapsule initiator.

[0079] The preparation process of the above lubricated pre-coated thread locking sealant is as follows:

[0080] Prepare Part A:

[0081] Prepare the self-lubricating monomer first: the reaction vessel is connected in series with a water separator, a condenser, and a vacuum system, and the basic raw materials are prepared: boric acid, hydroxyethyl methacry...

Embodiment 2

[0086] The lubricated pre-coated thread locking sealant provided in this embodiment includes component A and component B, and component A and component B are mixed in a mass ratio of 23:1; in terms of mass percentage Wt, component A includes 46% of deionized water, 6% of high molecular weight cellulose (thickening emulsifier), 0.5% of ferrocene (polymerization accelerator), 5% of silica powder (filler), 30% of self-lubricating single Body, 11% ethoxylated bisphenol A dimethacrylate, 1.5% solvent yellow (pigment), wherein, the self-lubricating monomer structural formula is the same as the self-lubricating monomer structural formula in Example 1; Group B Divided into microcapsule initiators.

[0087] The preparation process of the above lubricated pre-coated thread locking sealant is as follows:

[0088] Preparation of component B: The preparation process is the same as in Example 1.

[0089] Prepare Part A:

[0090] Prepare the self-lubricating monomer first: the reaction ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com