Semi-wet mixing and dust-suppressing technology for automobile friction material

A friction material and semi-wet technology, which is applied in the field of automobile friction material semi-wet mixing and dust reduction technology, can solve the problems of large production dust, low production capacity, and affecting the health of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

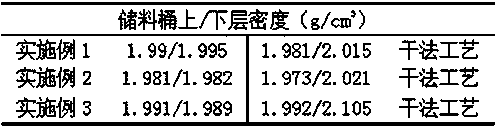

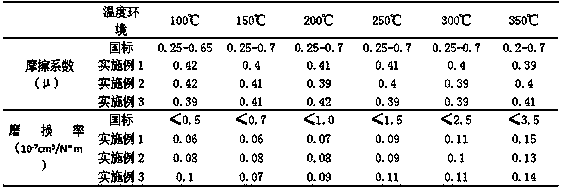

Embodiment 1

[0024] a) Mixing: After the raw materials are weighed according to the proportion, they are transferred to the mixer, stirred and mixed evenly at high speed under three sets of rake paddles and four sets of high-speed flying knives to obtain a first-level mixture; the raw materials and their proportions are: 10% phenolic resin, 10% zircon, 15% phosphorus flake graphite, 15% barium sulfate, 15% talcum powder, 35% glass fiber;

[0025] b) Dust reduction: Add low molecular weight phenolic resin with a molecular weight of 375 to the primary mixture through the three liquid injection holes of the mixer, and the addition method is high-pressure mist spraying, and the spraying angle is 60°, without dripping , after spraying, the material is discharged quickly to obtain a secondary mixture, and the water content of the secondary mixture is measured to be less than 1.2%;

[0026] c) Aging: Transfer the secondary mixture to the dehumidification room and lay it open for dehumidification ...

Embodiment 2

[0029] a) Mixing: After the raw materials are weighed according to the proportion, they are transferred to the mixer, stirred and mixed evenly at high speed under three sets of rake paddles and four sets of high-speed flying knives to obtain a first-level mixture; the raw materials and their proportions are: 5% phenolic resin, 5% nitrile powder, 5% zircon, 5% alumina, 10% phosphorus flake graphite, 5% granular graphite, 15% barium sulfate, 15% talcum powder, 20% mineral fiber, ceramic fiber 15%;

[0030] b) Dust reduction: Add low molecular weight phenolic resin, with a molecular weight of 527, into the first-stage mixture through the three liquid injection holes of the mixer, and the addition method is high-pressure mist spraying, and the spraying angle is 70°, without dripping , after spraying, the material is discharged quickly to obtain a secondary mixture, and the water content of the secondary mixture is measured to be less than 1.2%;

[0031] c) Awakening: transfer the...

Embodiment 3

[0034] a) Mixing: After the raw materials are weighed according to the proportion, they are transferred to the mixer, stirred and mixed evenly at high speed under three sets of rake paddles and four sets of high-speed flying knives to obtain a first-level mixture; the raw materials and their proportions are: 5% phenolic resin, 5% nitrile powder, 5% iron ore, 5% alumina, 10% zircon, 15% coke, 10% barium sulfate, 10% talcum powder, 10% barite powder, mineral fiber 5%, glass fiber 15%, carbon fiber 5%.

[0035] b) Dust reduction: Add low molecular weight phenolic resin with a molecular weight of 769 to the primary mixture through the three liquid injection holes of the mixer, and the addition method is high-pressure mist spraying, and the spraying angle is 50°, without dripping , after spraying, the material is discharged quickly to obtain a secondary mixture, and the water content of the secondary mixture is measured to be less than 1.2%;

[0036] c) Aging: transfer the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com