A continuous feeding equipment for petroleum coke calcination that can reduce dust pollution

A technology of dust pollution and petroleum coke, applied in lighting and heating equipment, using liquid separating agent, furnace, etc., can solve the problems of low safety and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

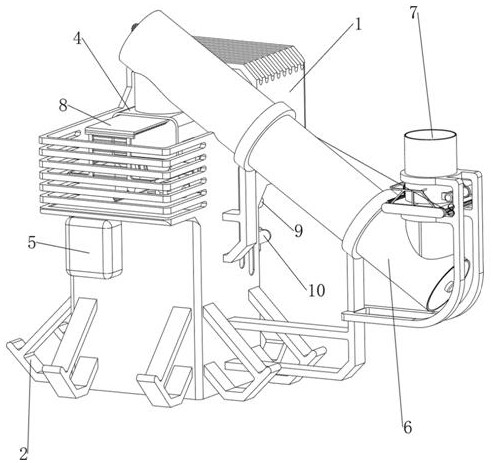

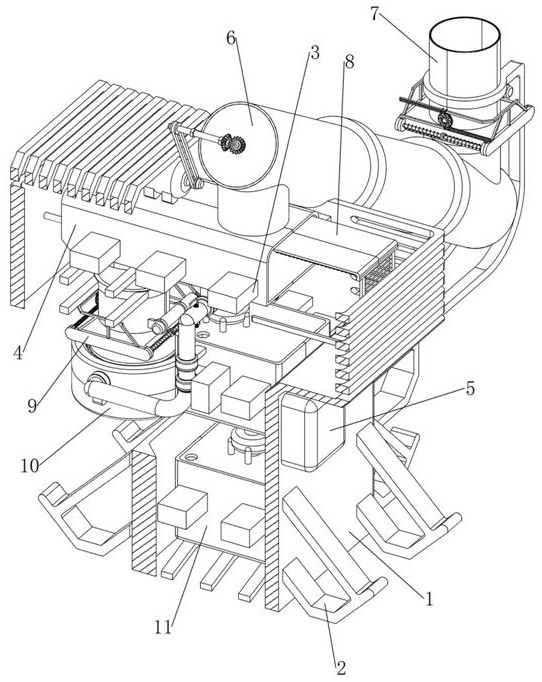

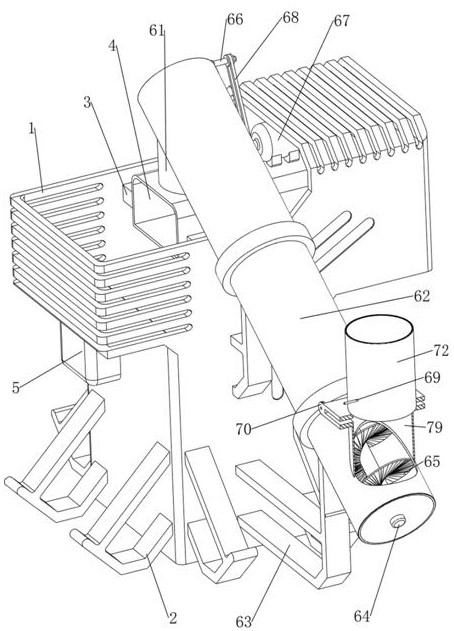

[0038] A continuous feeding equipment for petroleum coke calcination that can reduce dust pollution, such as Figure 1-18 As shown, it includes an outer casing 1, a supporting foot 2, a connecting block 3, a petroleum coke temporary storage box 4, a screw feeder 6, a packing mechanism 7, a pushing mechanism 8 and a continuous feeding control mechanism 9. The outer casing 1 The lower part of the side is connected with eight supporting feet 2 evenly spaced along the circumferential direction, and the upper part of the inner wall on the left and right sides of the outer casing 1 is symmetrically connected with six connecting blocks 3, and the inner surfaces of the six connecting blocks 3 are connected with a petroleum coke temporary storage box 4. Petroleum coke temporary storage box 4 is used to store petroleum coke, and a screw feeder 6 is connected between the top of petroleum coke temporary storage box 4 and the right side of outer casing 1, and screw feeder 6 is used to trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com