Patents

Literature

86results about How to "To achieve the purpose of dust reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

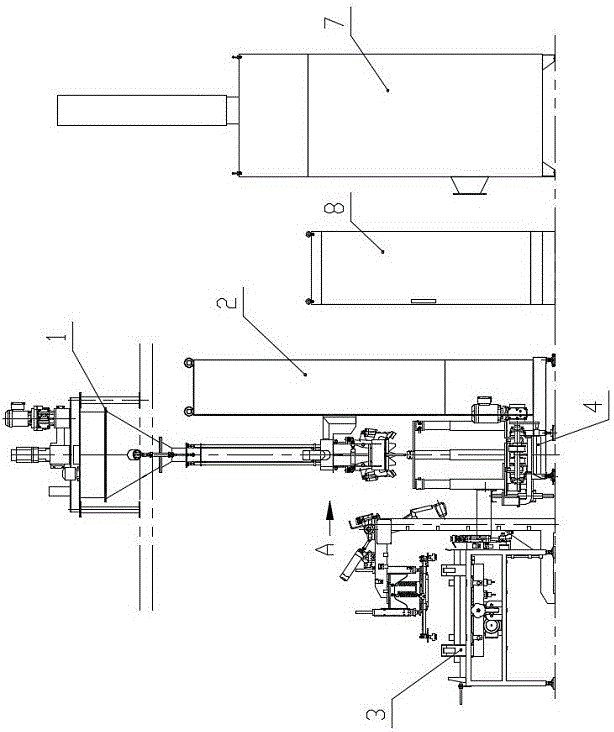

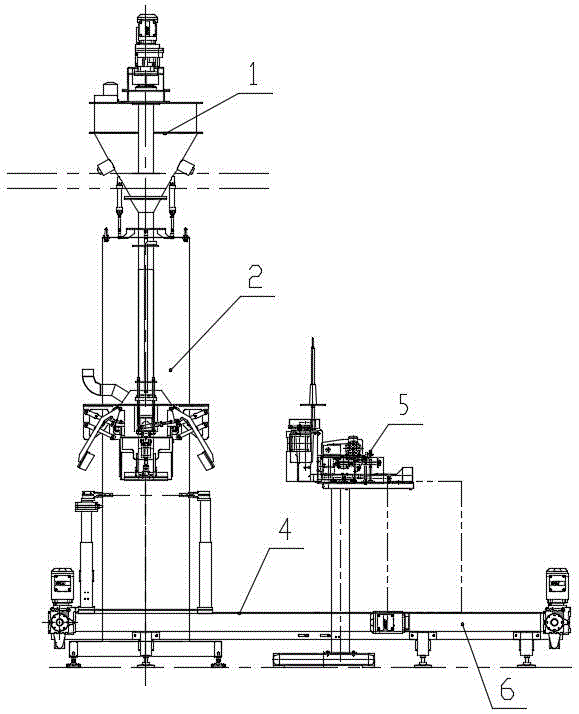

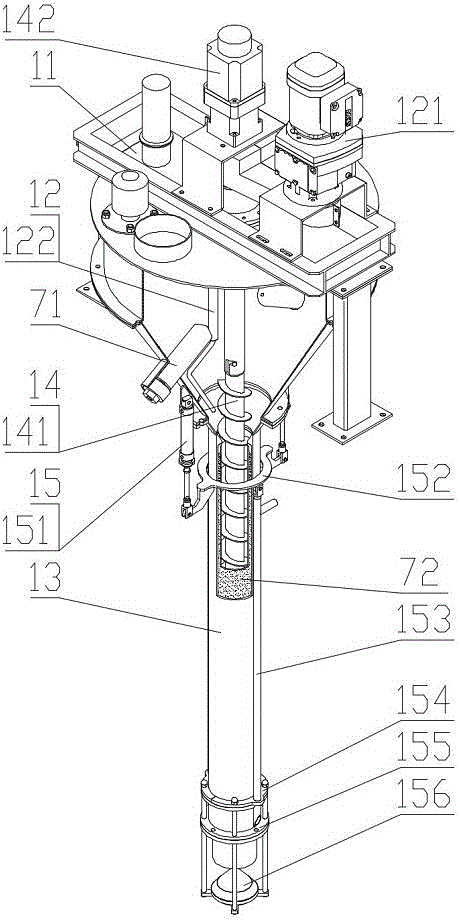

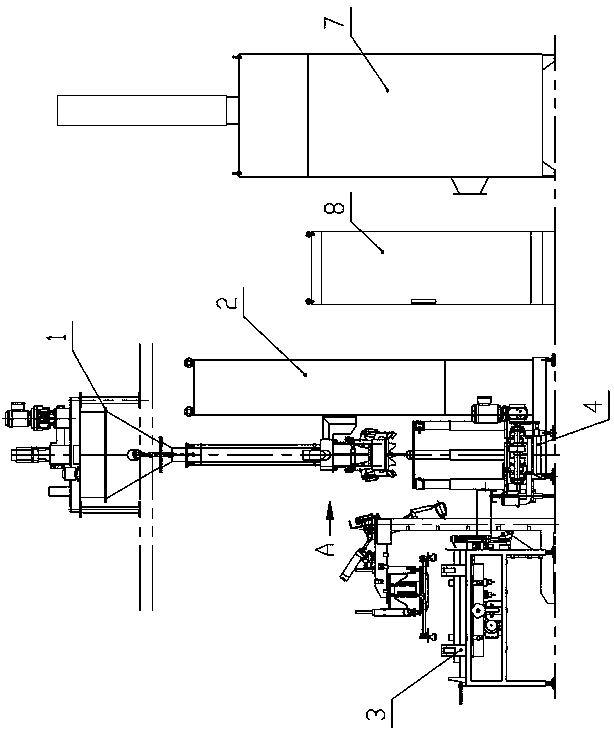

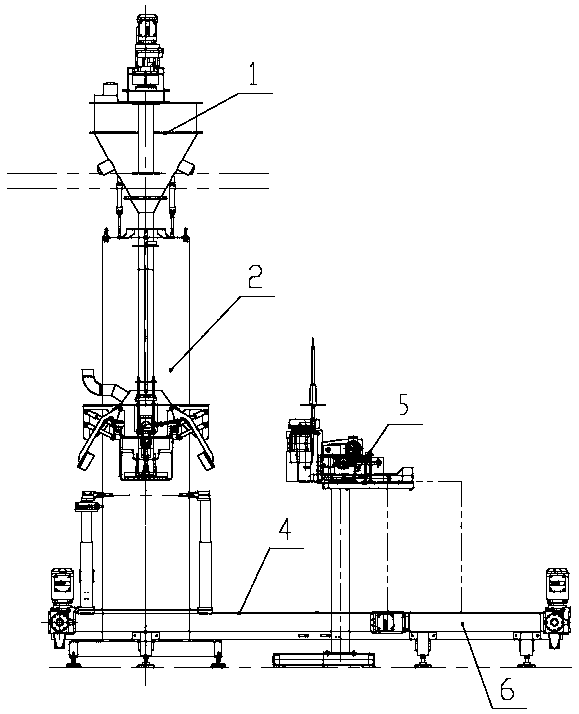

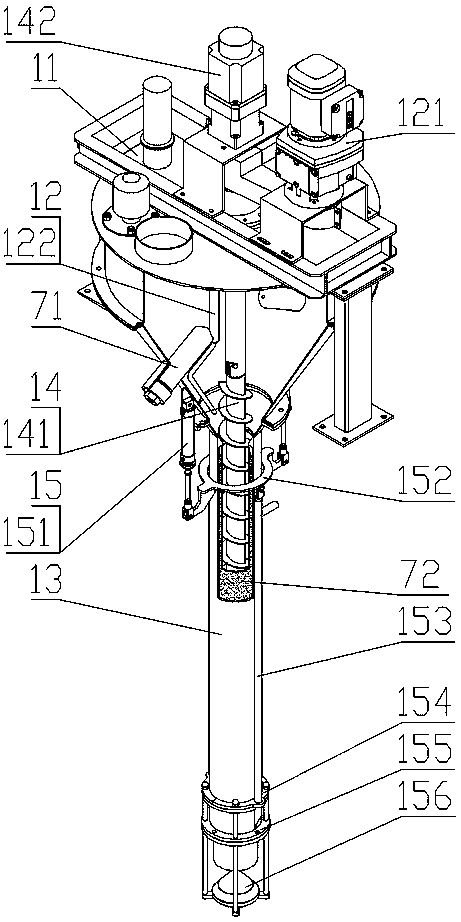

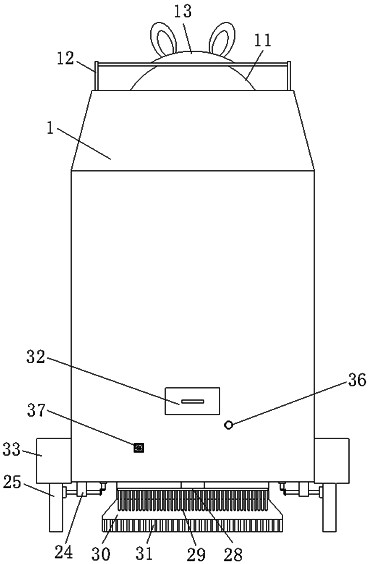

Full-automatic powder packaging system

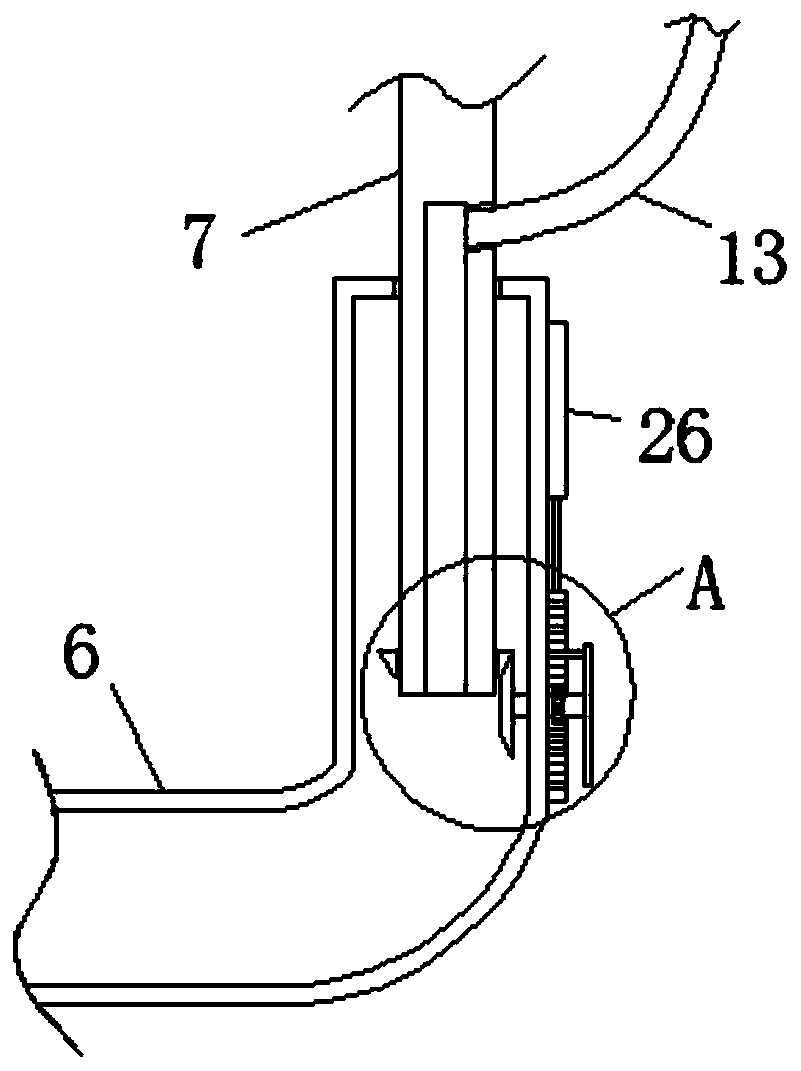

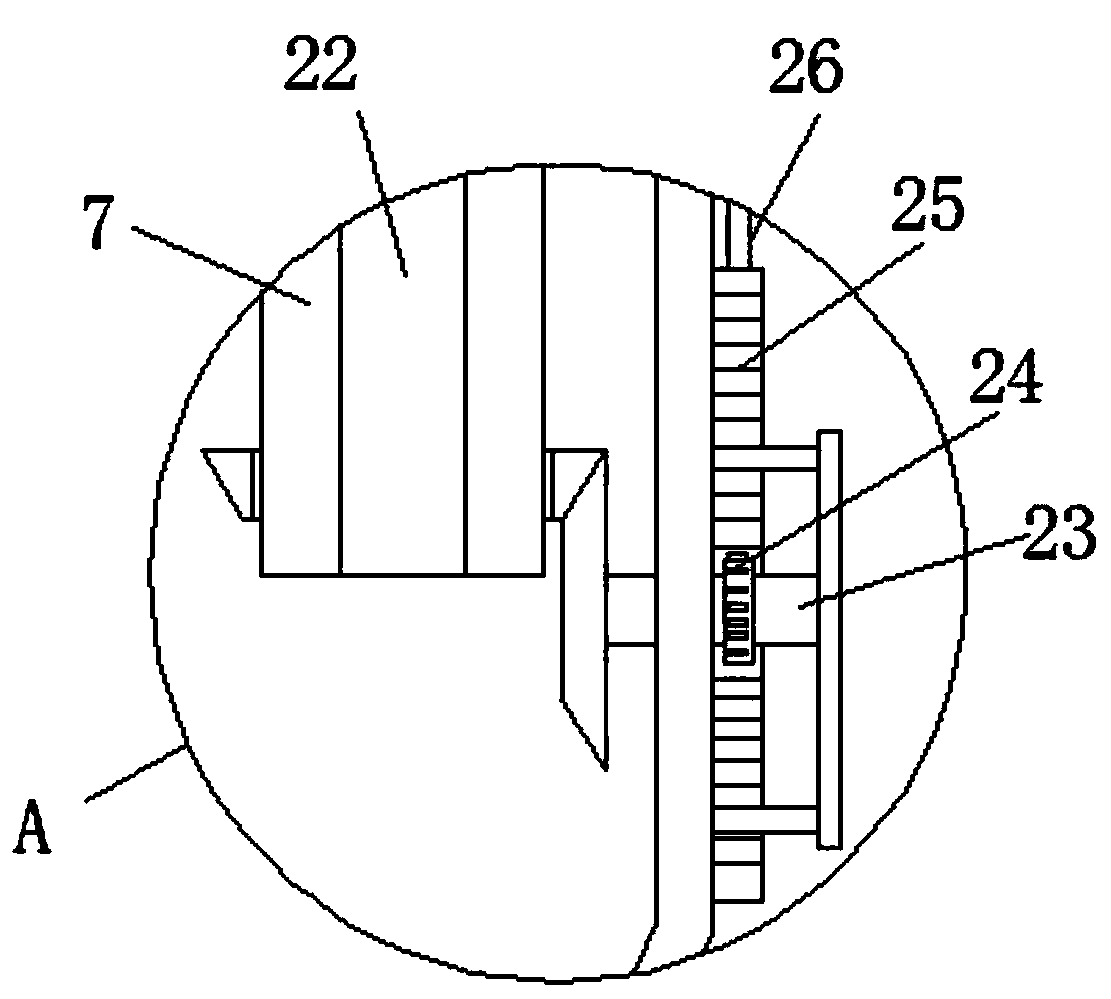

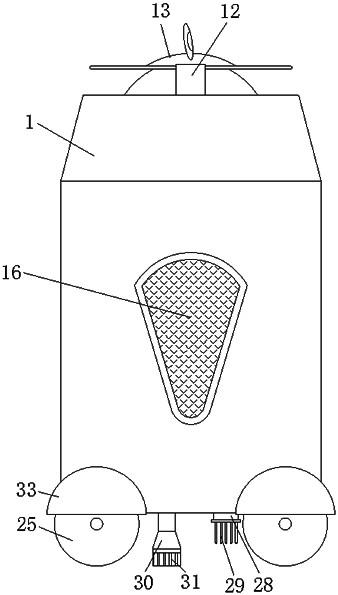

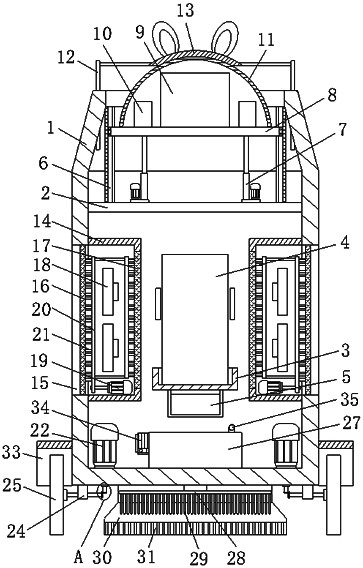

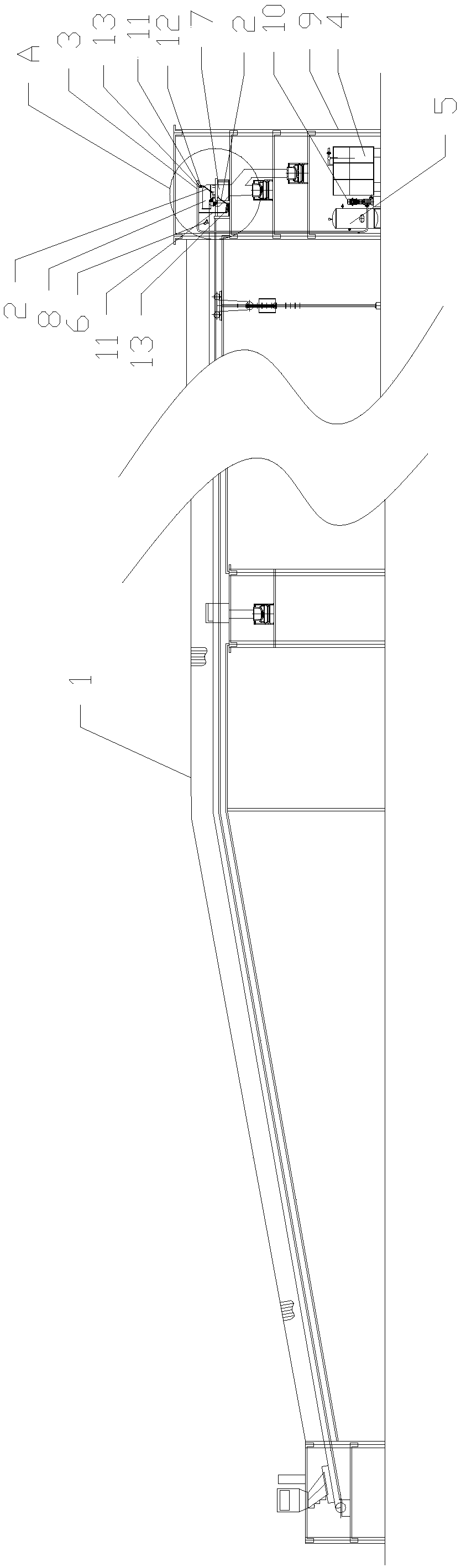

The invention discloses a full-automatic powder packaging system. The full-automatic powder packaging system comprises a screw filling device (1), a lifting bag clamping and weighing device (2), an automatic bagging device (3), a clamping, transferring and conveying device (4), a bag sewing device (5), a finished product transfer device (6), a powder recycling device (7) and an electronic control device (8). The lifting bag clamping and weighing device comprises a weighing mechanism (24) and a duckbill bag clamping mechanism (25) which can ascend and descend synchronously. A discharging cylinder (13) is sleeved with the duckbill bag clamping mechanism. The duckbill bag clamping mechanism clamps a packaging bag and ascends before filling operation so that a movable material door (156) can be located at the bottom in the packaging bag, the duckbill bag clamping mechanism gradually descends synchronous with ascending of the material level in the filling operation process, and the weighting mechanism conducts weighing at the same time. By the adoption of the full-automatic powder packaging system, powder materials can be weighed precisely, packaging bags are sealed and conveyed, and the full-automatic powder packaging system is especially suitable for premise metering and automatic packaging of extremely fine powder materials.

Owner:SAIMO ELECTRIC

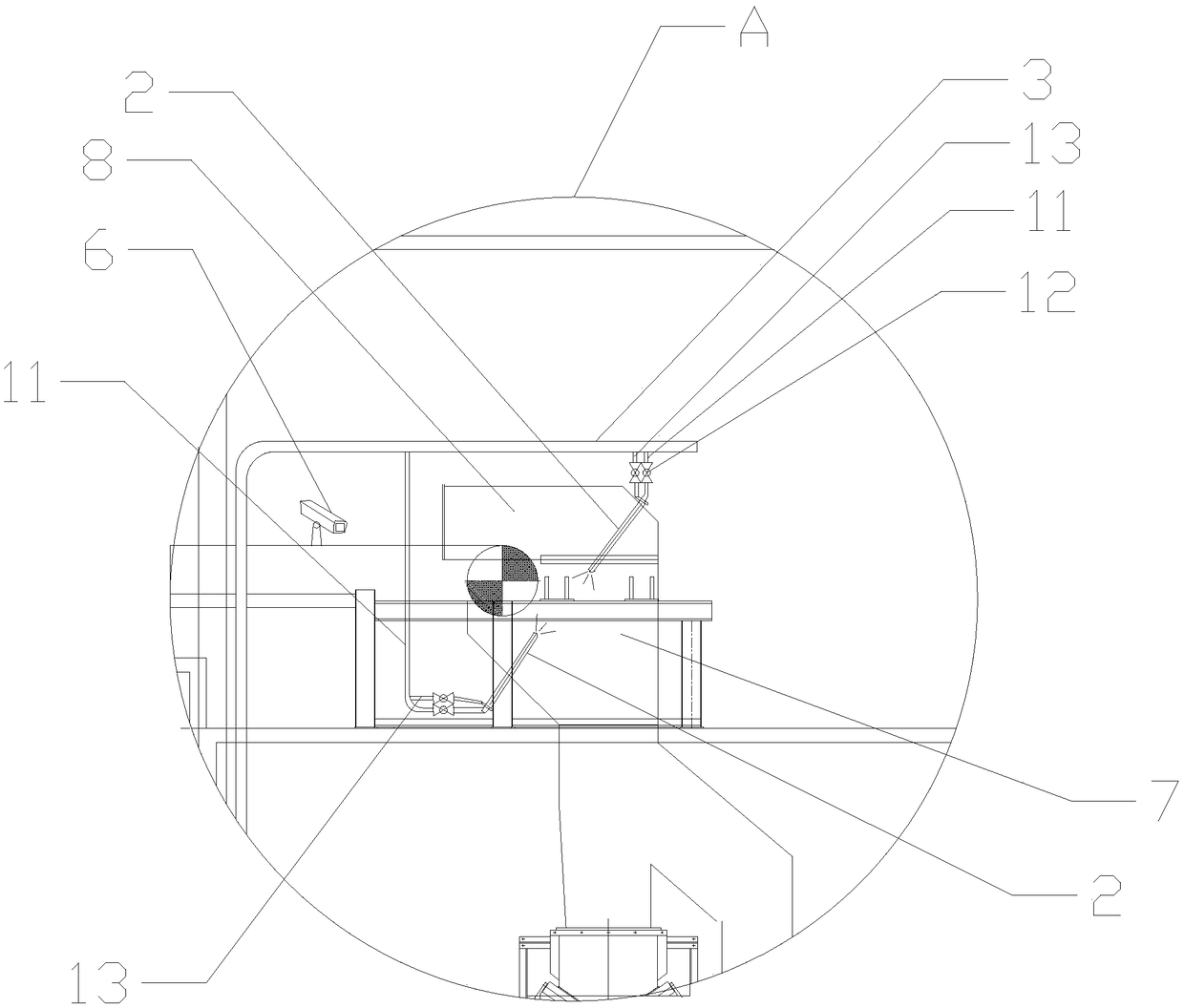

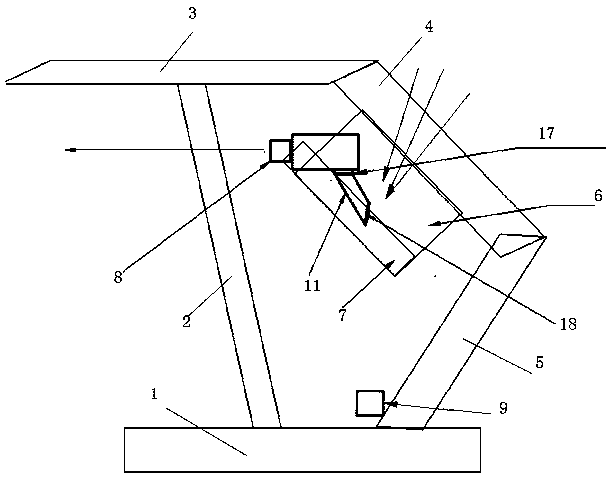

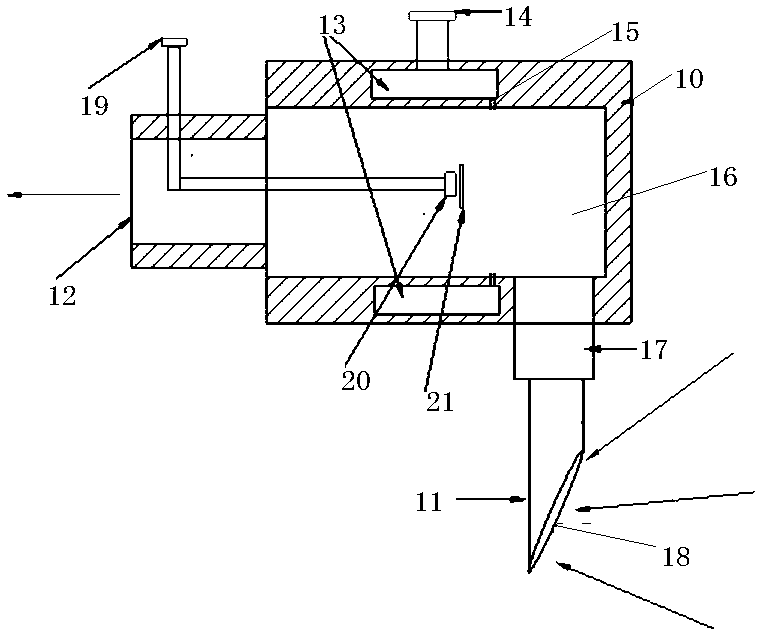

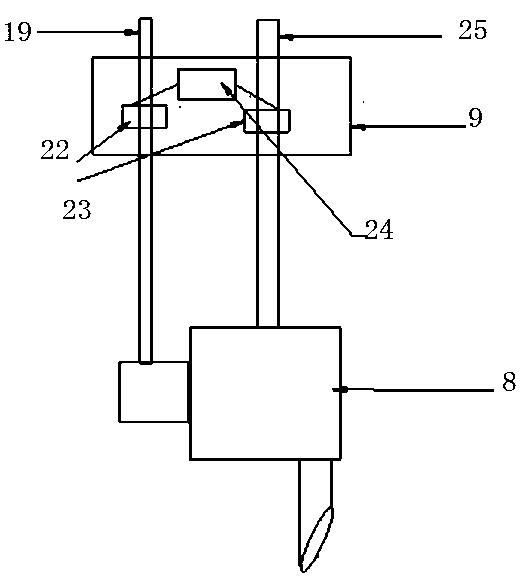

Mining air mist dust settling device in restricted space and application method of mining air mist dust settling device

ActiveCN104061012AReduce water consumptionLow water consumptionDust removalFire preventionCoalPetrochemistry

The invention discloses a mining air mist dust settling device in a restricted space and an application method of the mining air mist dust settling device, and belongs to the field of safety and environmental protection equipment during a mine production process. The mining air mist dust settling device in the restricted space is characterized in that during the coal production and transport process of working equipment taking pressure fluid as a power source under the control of a control unit, when coal dust pollution is generated at the time when the logistics direction of transported coal is changed, various actions or paces are realized through the device to achieve the goal of coal dust settling in the working field. The mining air mist dust settling device in the restricted space and the application method of the mining air mist dust settling device disclosed by the invention are widely suitable for various control executive devices in systems and industries of mining, petrochemistry, metallurgy, electric power, environmental protection and the like.

Owner:TAIYUAN UNIV OF TECH

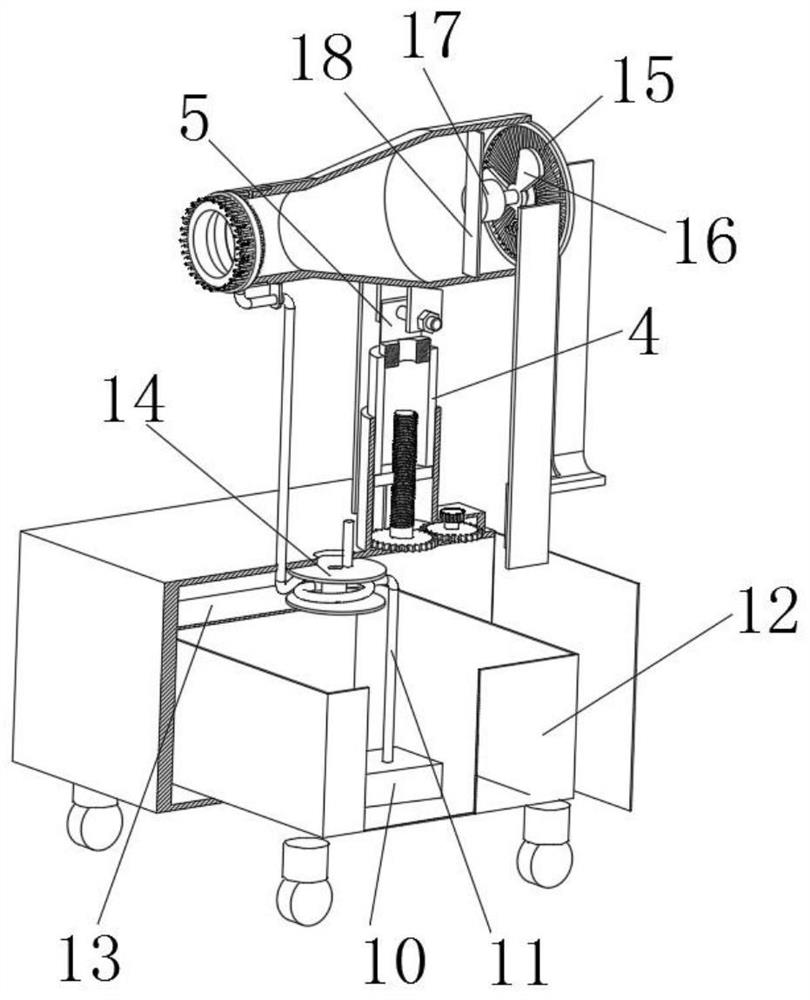

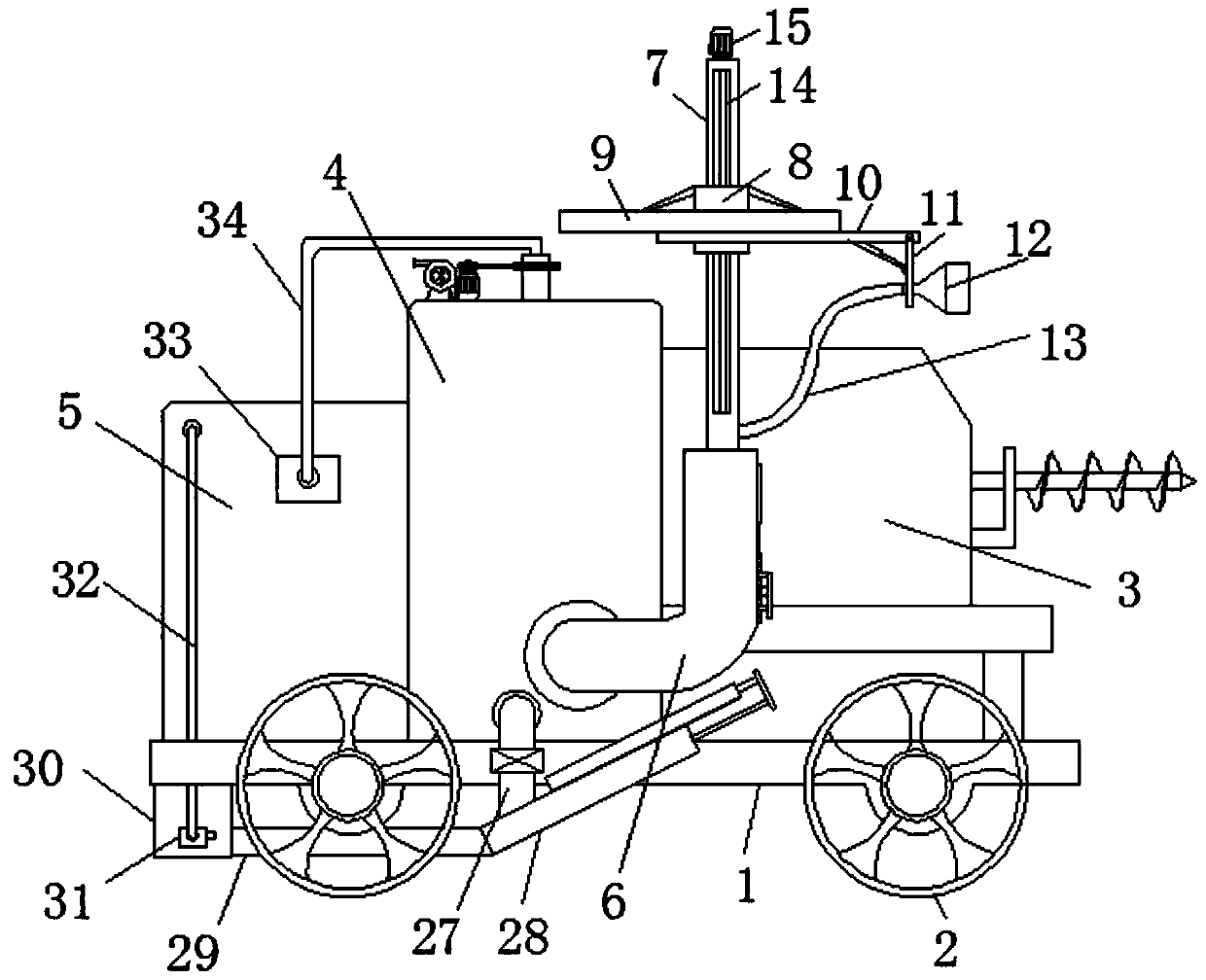

Earthwork dust settling device for building construction site

InactiveCN108221822AEffective dust suppression functionPrevent proliferationRoad cleaningWater storage tankArchitectural engineering

The invention discloses an earthwork dust settling device for a building construction site. The earthwork dust settling device comprises a water storage tank, wherein a bearing block is arranged on one side of the water storage tank; the bearing block pops up one side of the water storage tank; supporting columns are fixed at the lower end of the bearing block and the lower end of the water storage tank; fixing blocks are fixed at the lower ends of the two supporting columns; an adjusting device is arranged between the two fixing blocks; a supporting block is fixed at the upper end of the bearing block; a first lifting device is arranged at the upper end of the supporting block; the upper end of the first lifting device is rotationally connected with a first rotating disc; and a rotating device is arranged in the first rotating disc. According to the earthwork dust settling device disclosed by the invention, an effective dust settling function of building construction roads is realized, dust diffusion can be avoided, flying dust is eliminated, accidents are further decreased, the problems that low efficiency and poor dust settling effect are caused by manual dust settling and humanhealth is damaged due to inhalation of lots of dust in the dust settling process are solved. The earthwork dust settling device is simple to operate and suitable for popularization.

Owner:姚福泉

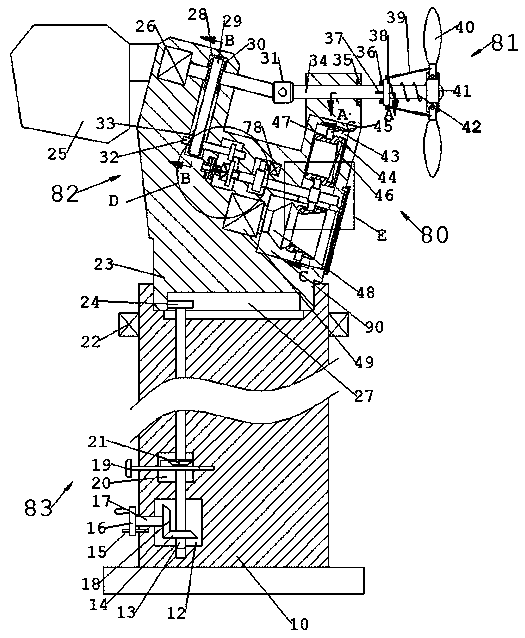

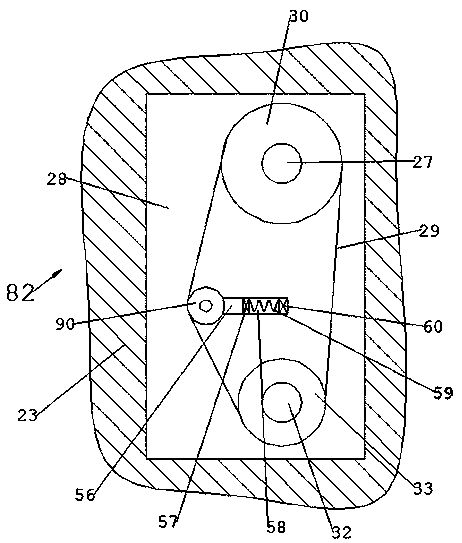

Wind water mixed atomizing method for down-hole coal cutter fully-mechanized coal winning machine

InactiveCN101307691AEfficient captureSolve slippageDust removalFire preventionWater sourceWater vapor

The invention belongs to a wind-water mixing spray technology which can be applied in underground comprehensive mining, comprehensive digging and in places requiring settling dust so as to improve safe production of a coal mine. The invention is characterized in that the technology is realized through the steps as follows: a wind source pipeline which is connected from a ground forcing fan to an extraction working surface with a selectable wind pressure of between 0.5 and 0.7MPa is in parallel connection with a water source pipeline which has certain pressure with a selectable hydraulic pressure of between 3 and 5MPa, and the volume ratio of the mixed wind and water is between 100-135 to 1; the wind source pipeline and the water source pipeline are both connected to nozzles of internal spraying and external spraying of a coal mining machine and a mechanical boring machine, so that wind-water mixing atomized water vapor is sprayed with a flow rate of between 15 and 20M<3> / minute; and the atomized water vapor captures coal dust, and disperses local gas generated during cutting a coal body. The invention aims to solve the problems caused by the local gas which is generated during settling dust and cutting coal and can not be dispersed in time, such as safety threat in production, water resource waste, affected coal quality, slipping belt, slipping goods, bin blockage or other problems.

Owner:李本学 +1

Environment-friendly wind energy searchlight for construction site

InactiveCN110553209AMeet environmental protection requirementsSelf-sufficient power supplyLighting support devicesUsing liquid separation agentArchitectural engineeringIrradiation

The invention discloses an environment-friendly wind energy searchlight for a construction site. The environment-friendly wind energy searchlight comprises a stand column which is fixedly arranged onthe ground, wherein an irradiation head is rotationally arranged on the top surface of the stand column, and an irradiation cavity is formed in the irradiation head; a bulb used for illumination is fixedly arranged in the inner wall of the right side of the irradiation cavity; after a buffer spring at the lower side moves to the bulb, the buffer spring pushes a lens frame and the bulb to be jackedtightly, the concave surface on the buffer spring can perform light condensation, and a concave mirror on a buffer spring at the upper side can be used for dispersing light, so that the irradiation range is larger, the wind power can be used for power generation, and the external environment can be sprayed with water on the installed construction site to achieve the purpose of dust reduction; andthe irradiation angle can be adjusted to fix the irradiation head at night, the irradiation condition can be adjusted, and the searchlight can adapt to different construction site environments.

Owner:ZHUJI PINGCUO LIGHTING TECH CO LTD

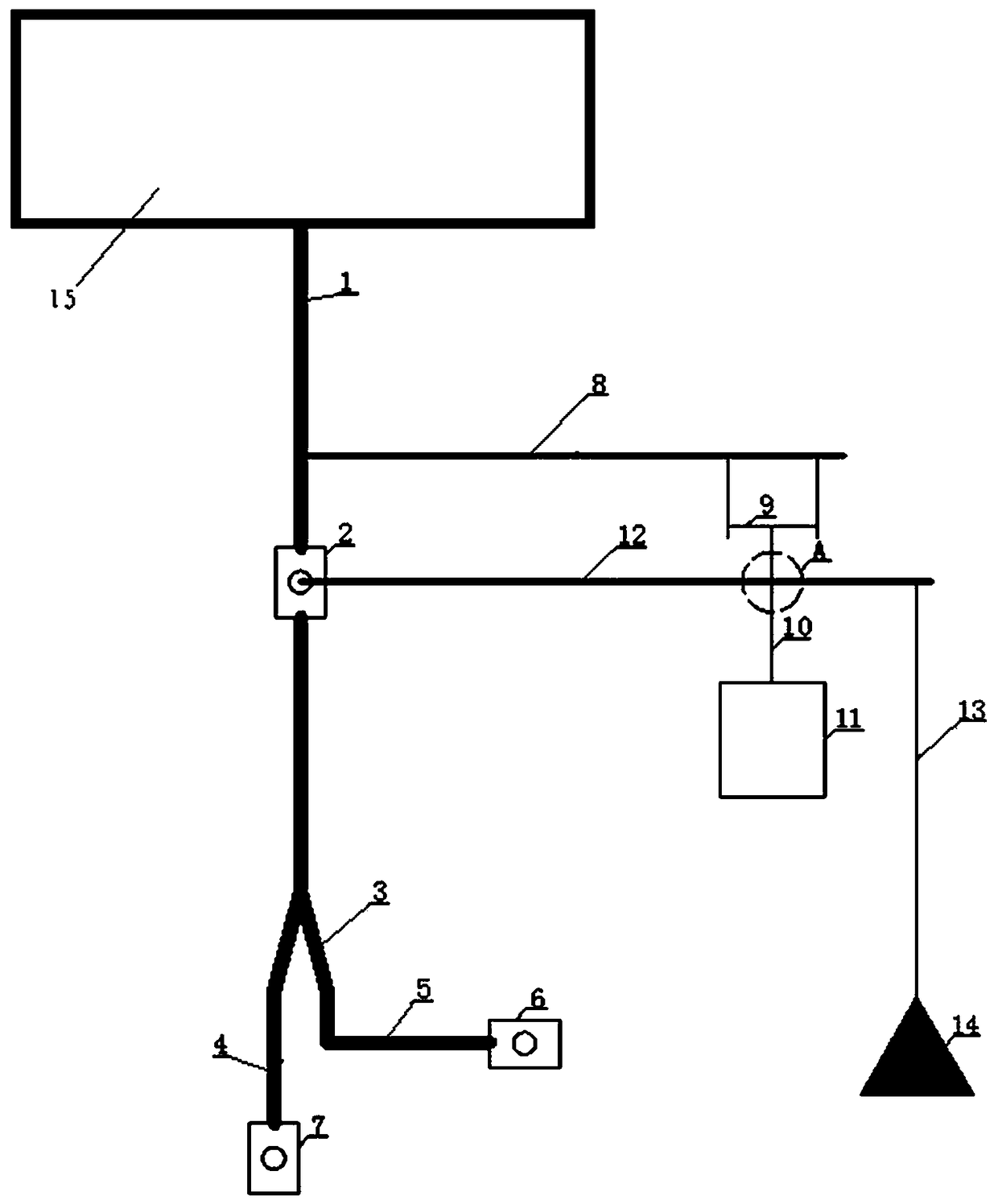

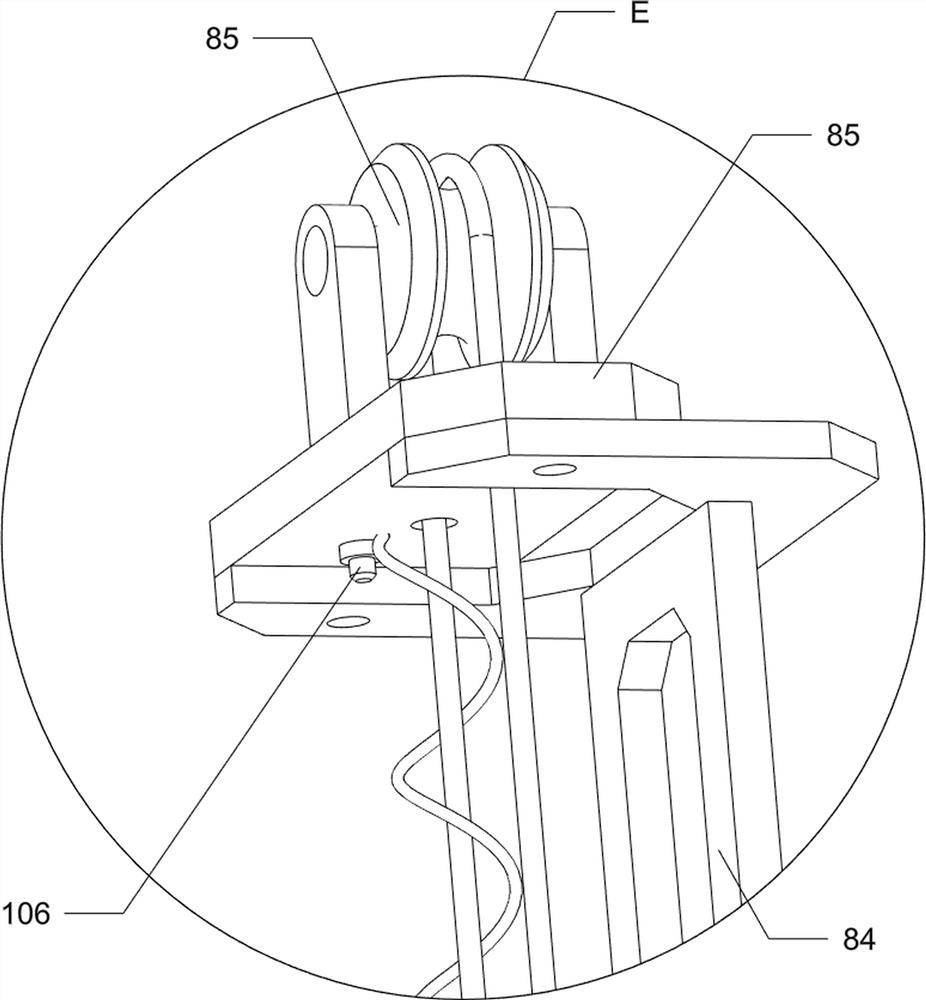

Pneumatic hydrodynamic linkage spray dust reduction device for blasting working face

PendingCN109057853AReduce dust concentrationImprove the effect of dust suppressionDust removalFire preventionEconomic benefitsWorking environment

The invention discloses a pneumatic hydrodynamic linkage spray dust reduction device for blasting a working face. The device comprises a water pipe connected with a purified water curtain device, a water pipe is transversely fixedly connected to a bracket, a vertically arranged connecting rod is hingedly connected with the lower portion of the free end of the bracket by a rotating shaft, the connecting rod is provided with a hook, and an iron plate is arranged at the lower end of the connecting rod; a quick valve is installed on the water pipe below the bracket, a valve stem of the quick valveand a transversely arranged rotating rod are linked, the rotating rod passes through the hook and is positioned by the hook, and a heavy hammer is hanged on the free end of the rotating rod; the lower end of the water pipe is connected with an air inlet pipe and a water inlet pipe through a Y-shaped triplet, and regulating valves are respectively arranged at the ends of the air inlet pipe and thewater inlet pipe. The device can greatly improve the on-site working environment, ensure the health of personnel, and have simple device manufacturing, easy material obtaining and good economic benefits.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

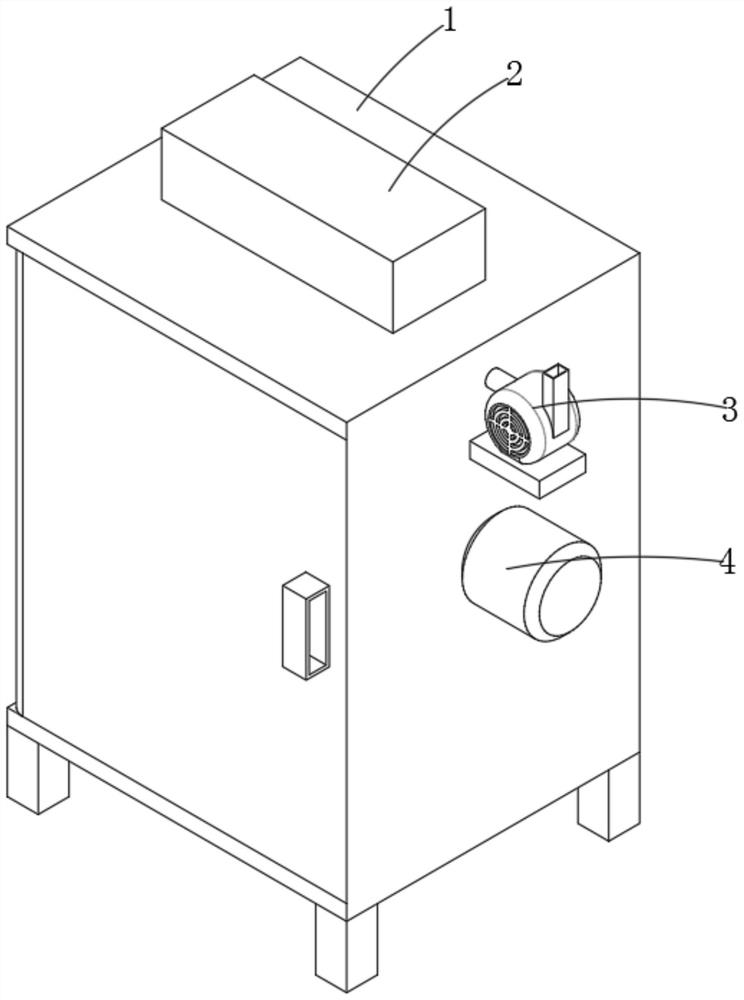

Environment-friendly rapid dust falling equipment for building construction and dust falling method

ActiveCN112704983AExpand the range of dust suppressionImprove the effect of dust suppressionUsing liquid separation agentBuilding material handlingEnvironmental geologyBellows

The invention discloses environment-friendly rapid dust falling equipment for building construction and a dust falling method, and relates to the technical field of building construction dust falling equipment. The environment-friendly rapid dust falling equipment comprises a box body, and an upper shell, a pair of side plates and a baffle are installed at the top of the box body; a height regulating mechanism is arranged in the shell; and a plurality of first spray heads and second spray heads which penetrate through through holes and are uniformly distributed are arranged on a spray head retainer. The invention further discloses a rapid dust falling method for environment-friendly building construction. Height adjustment can be carried out, higher flying dust can be covered, an air bellow can swing by arranging a cam, a baffle and a return spring, the dust falling range is increased, the dust falling effect is improved, the size of water spray mist particles can be adjusted according to the size of the flying dust by arranging the first spray head and the second spray head of different specifications, dust falling is effectively conducted on flying dust of different sizes, meanwhile, water is saved, and the environment-friendly effect is achieved.

Owner:广东雨泽科技发展有限公司

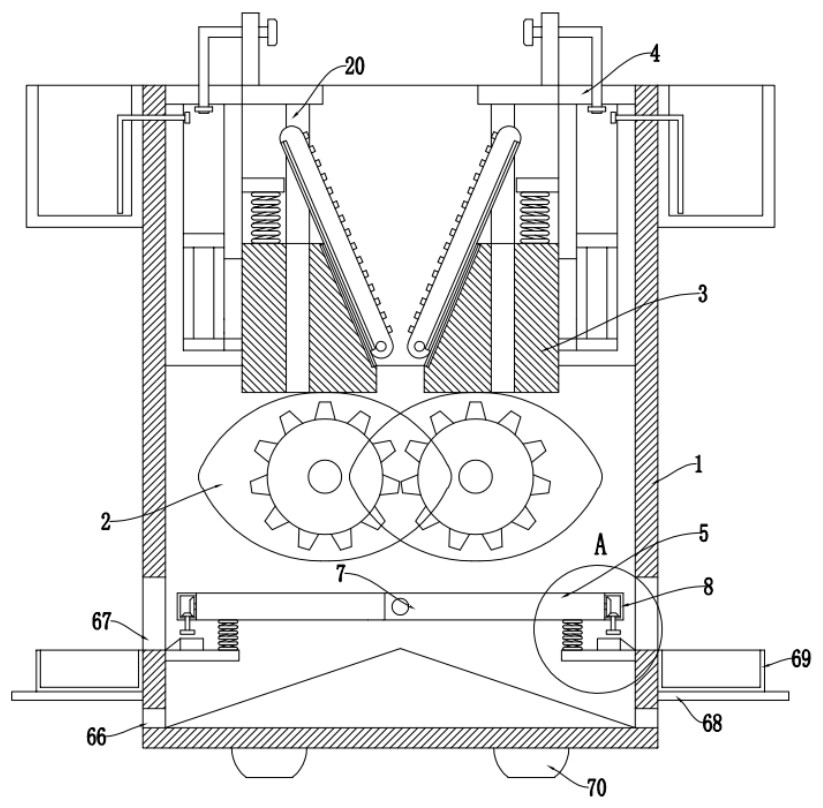

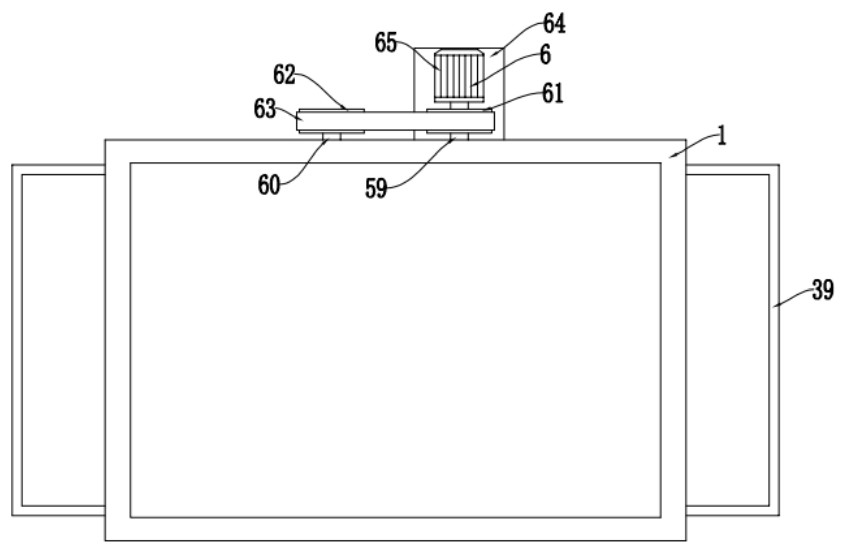

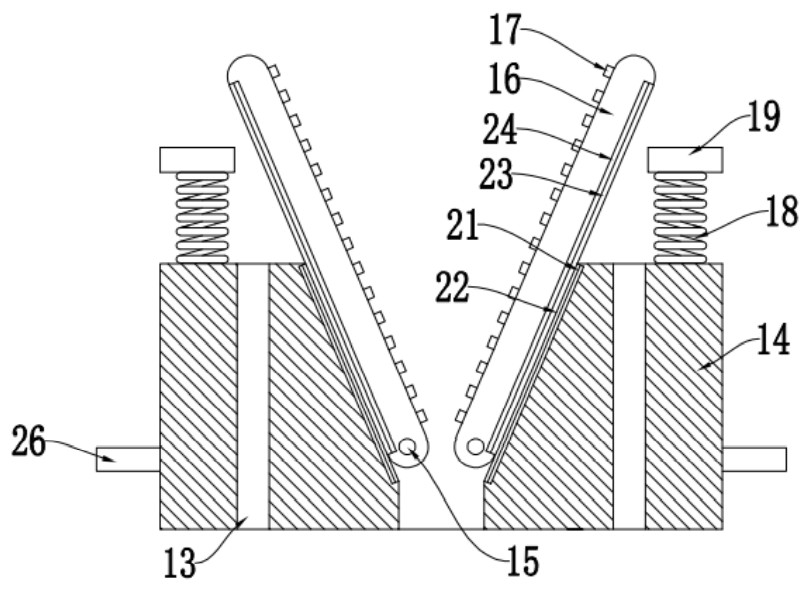

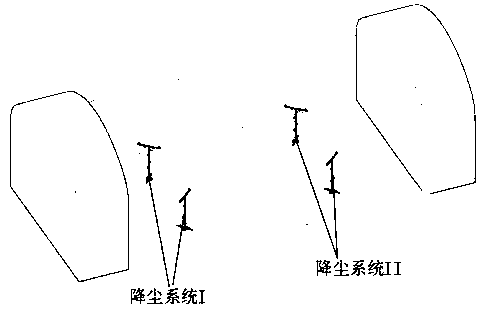

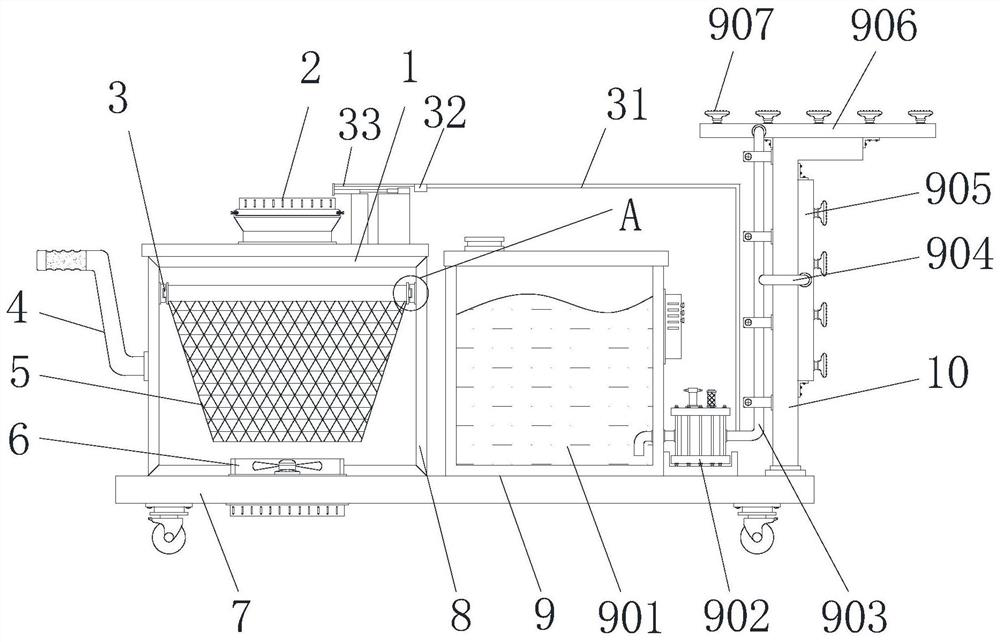

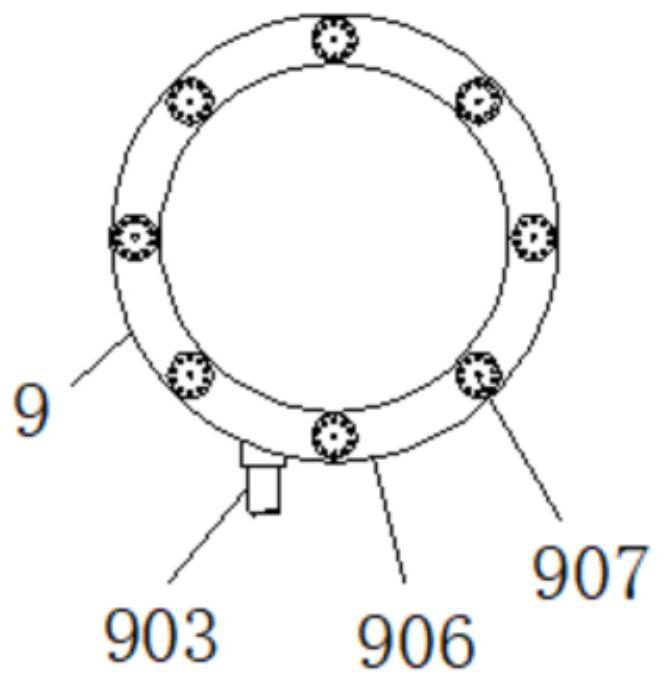

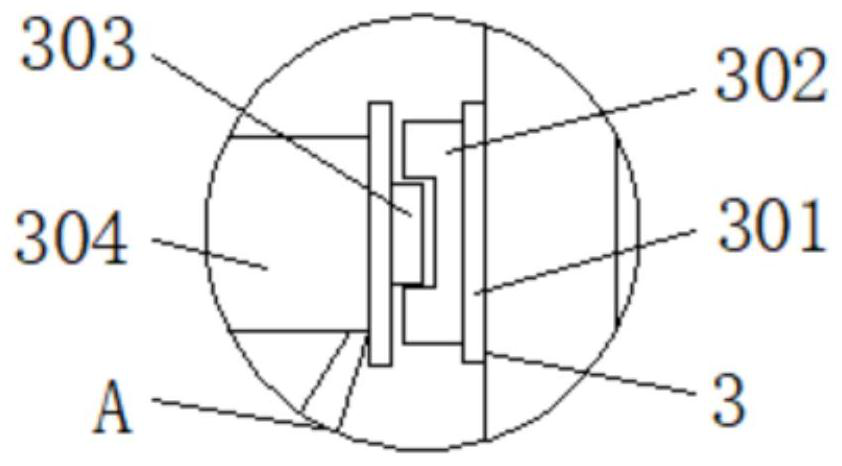

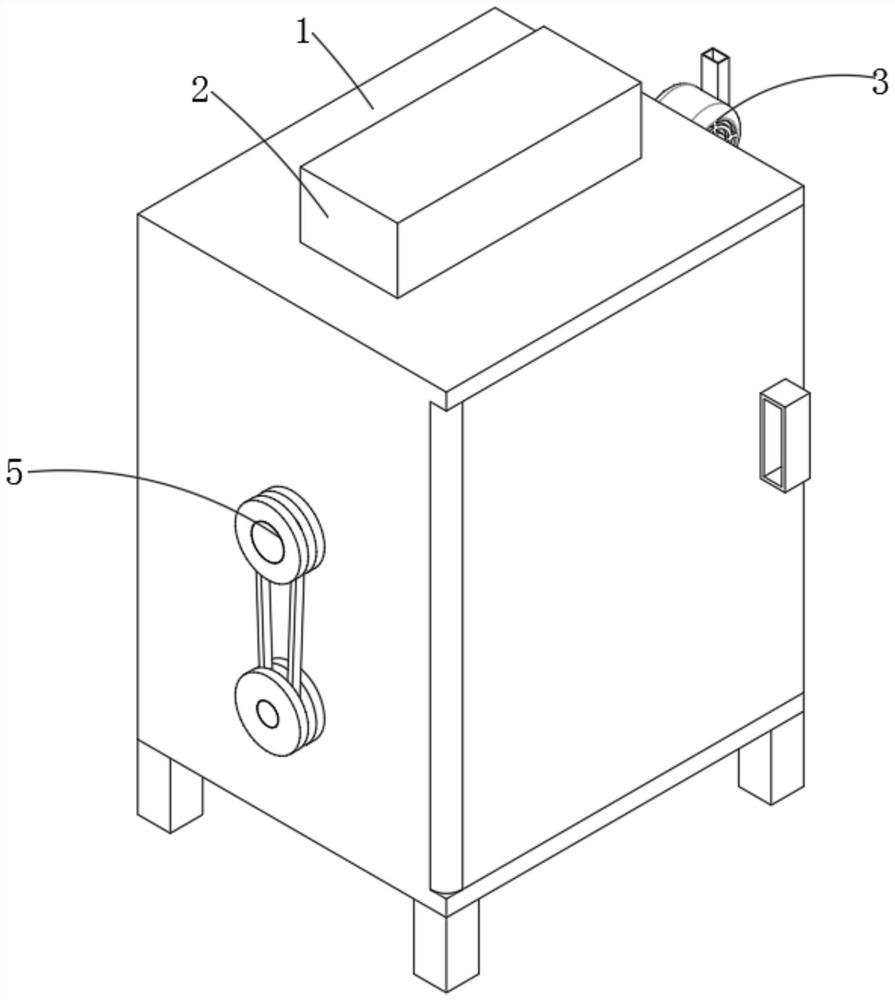

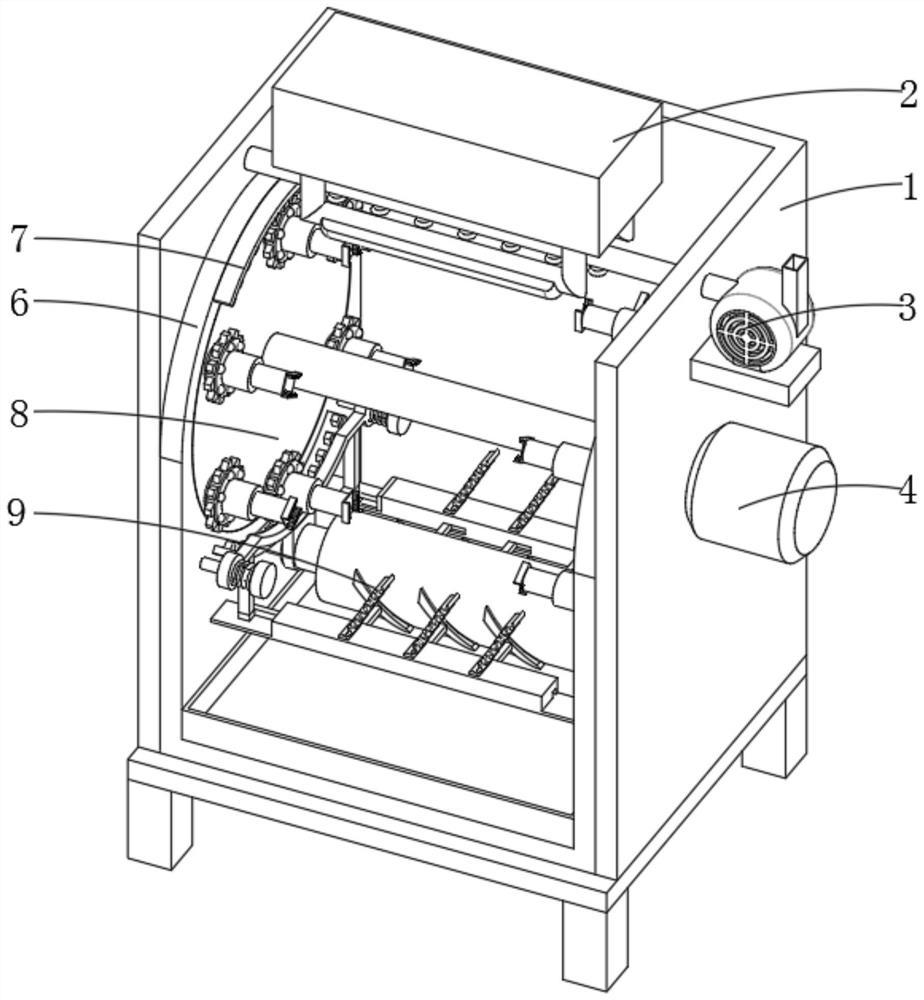

Passive periodic magnetic control type mine stone crushing and screening equipment

ActiveCN113560020AAchieve coarse crushingRealize functionUsing liquid separation agentGrain treatmentsStructural engineeringCrusher

The invention discloses passive periodic magnetic control type mine stone crushing and screening equipment. The equipment comprises a crushing and screening shell, an intermediary substance linkage fine crushing mechanism, a magnetic attraction sliding coarse crushing mechanism, self-suction and self-spraying dust falling mechanisms, a passive magnetic control self-cleaning screening mechanism and a power transmission mechanism. The intermediary substance linkage fine crushing mechanism is mounted in the middle of the interior of the crushing and screening shell. The magnetic attraction sliding coarse crushing mechanism is arranged at the upper portion of the intermediary substance linkage fine crushing mechanism, the self-suction and self-spraying dust falling mechanisms are symmetrically arranged at the two sides of the magnetic attraction sliding coarse crushing mechanism, the passive magnetic control self-cleaning screening mechanism is arranged at the lower portion of the intermediary substance linkage fine crushing mechanism, and the power transmission mechanism is arranged on the outer side wall of one side of the crushing and screening shell. The invention belongs to the field of welding machining, and particularly relates to the passive periodic magnetic control type mine stone crushing and screening equipment which is compact in structure, easy and convenient to operate, capable of combining coarse crushing and fine crushing, capable of preventing screening blockage and capable of automatically spraying and sucking dust.

Owner:徐州宏巨机械制造有限公司

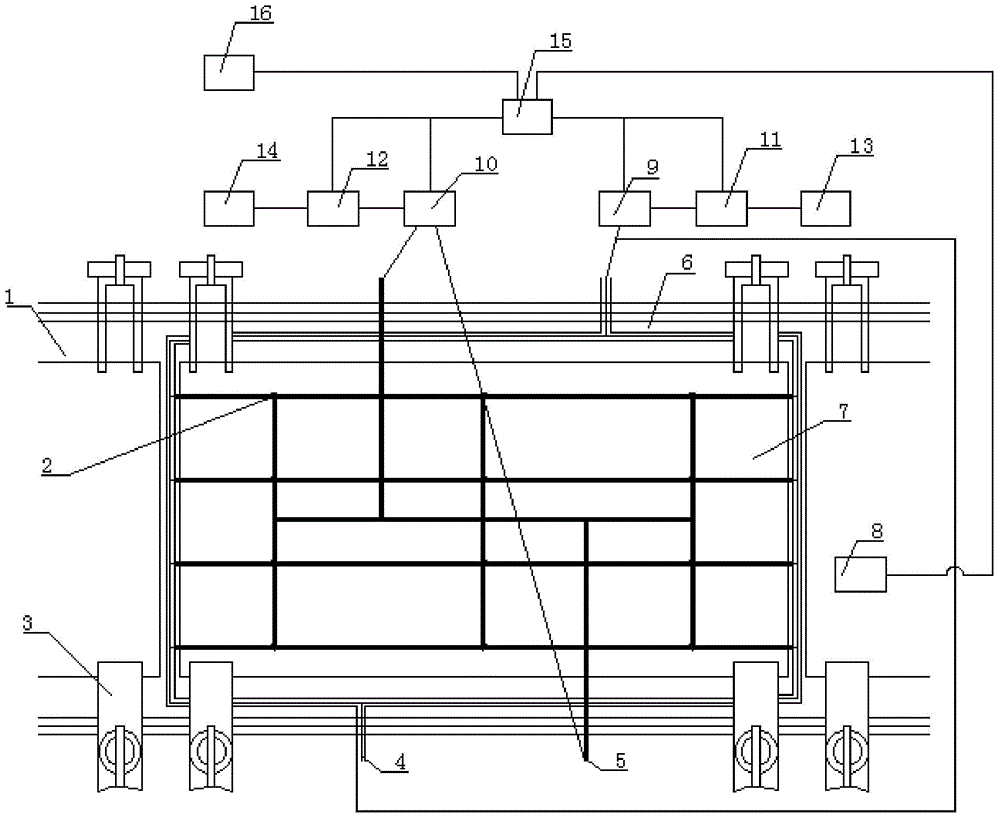

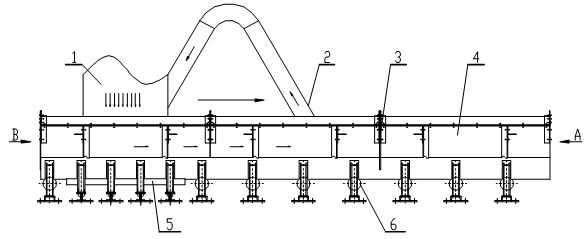

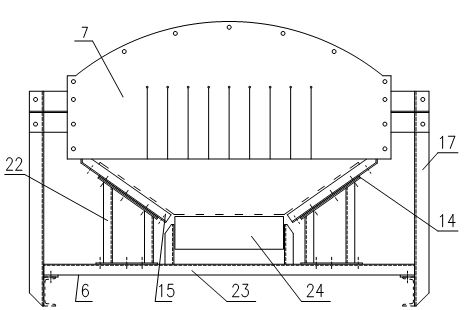

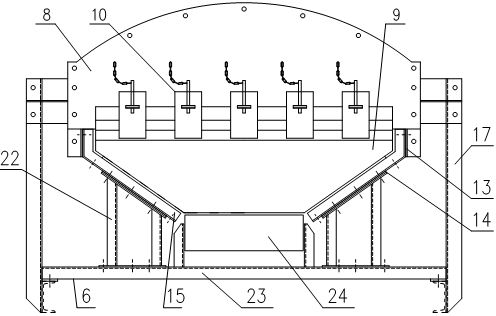

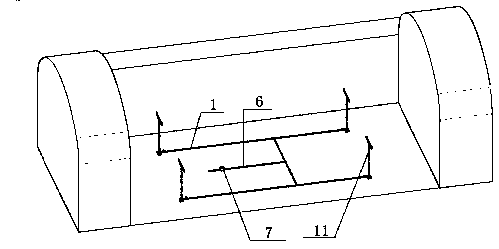

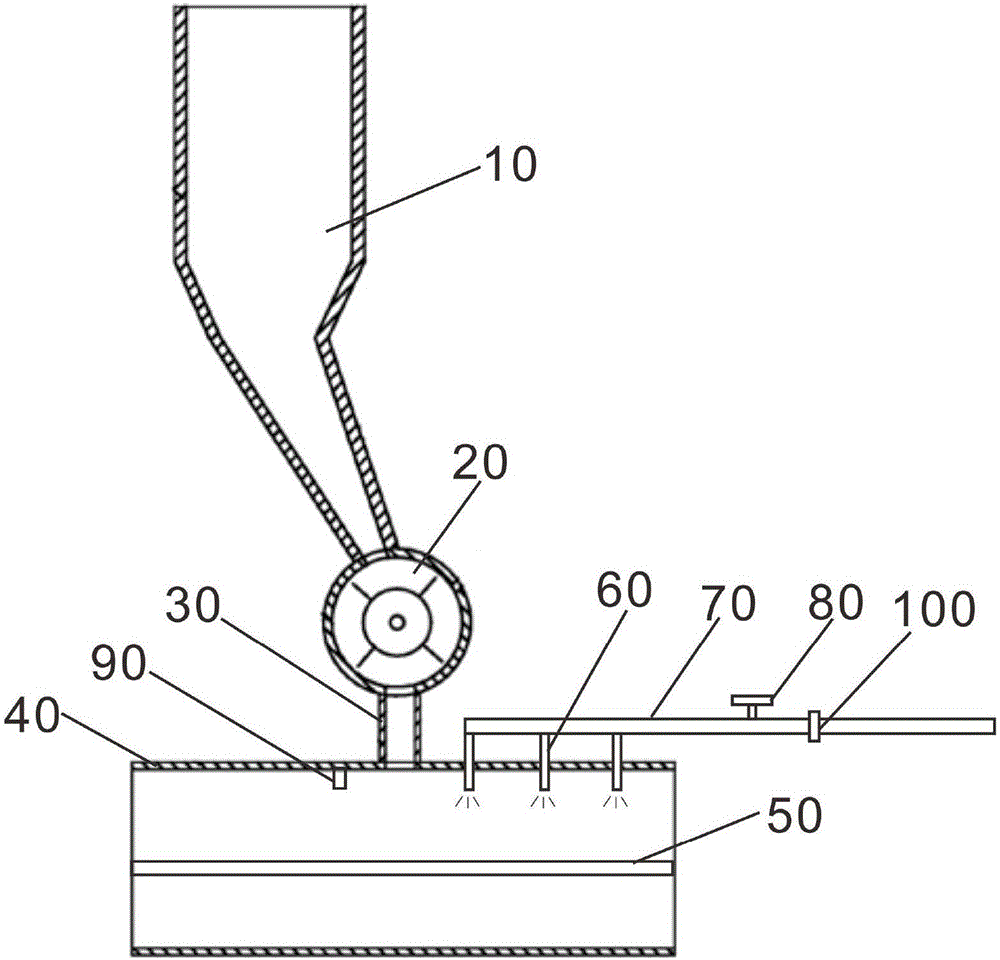

Totally-closed dust suppression material guiding device

The invention relates to a totally-closed dust suppression material guiding device, comprising a totally-closed guide chute, wherein the upper part of the guide chute is provided with an arc-shaped carrier plate which is provided with an opening thereon corresponding to a chute; an air return duct is connected with the side plate of the chute, and an air return duct curtain damper is installed at the front side of the opening of the air return duct, therefore, a closed circuit is formed by the chute, the totally-closed guide chute and the air return duct; an abnormal shaped buffering bed is arranged at the bottom of the chute of the totally-closed guide chute, the middle part of the chute of the totally-closed guide chute is provided with buffer strips, and the two sides of the chute of the totally-closed guide chute are provided with supporting plates; and the side plate brackets of the special-shaped buffering bed and the side plate brackets of a special-shaped roller set are provided with detachable double-flange side plates. The totally-closed dust suppression material guiding device has simple structure, reliable safety performance, convenient operation and obvious effects, can lower environment pollution caused by dust at the guide chute in field applications effectively, and realizes the purpose of dustfall.

Owner:TIANJIN CHENGKE MECHANICAL & ELECTRICAL TRANSMISSION TECH

Bridge drainage structure

ActiveCN109914238ASolve the problem of insufficient aestheticsSolve the problem of uneven drainageBridge structural detailsStructural engineeringRoad surface

Owner:齐齐哈尔市政工程设计研究院有限责任公司

Dust separation ventilation equipment for roadway

PendingCN113599950APrevent backAvoid flyingCombination devicesDispersed particle filtrationActivated carbonElectric machinery

The invention relates to ventilation equipment, and in particular, relates to dust separation ventilation equipment for a roadway. The invention provides the dust separation ventilation equipment for the roadway, wherein the dust separation ventilation equipment is high in purification efficiency, and an activated carbon column is convenient to replace. The dust separation ventilation equipment for the roadway comprises a base, a working hollow column, an air inlet fan, an air outlet fan, a starting switch, a reset switch, a filter plate, an activated carbon adsorption net, a connecting assembly and a scraping assembly; the working hollow column is arranged at the top of the base, the air inlet fan is arranged on one side of the working hollow column, and the air outlet fan is arranged on one side of the working hollow column; and the starting switch is arranged on one side of the air inlet fan, and the reset switch is arranged on one side of the air inlet fan. A vibrating motor drives a vibrating plate to vibrate, so that the filter plate vibrates, and dust on the filter plate can be shaken off.

Owner:袁晶晶

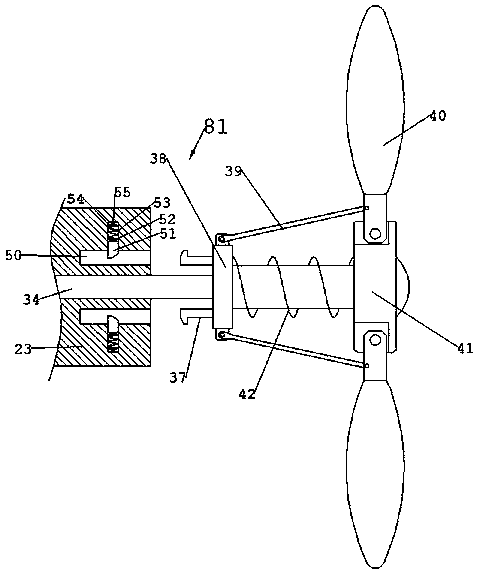

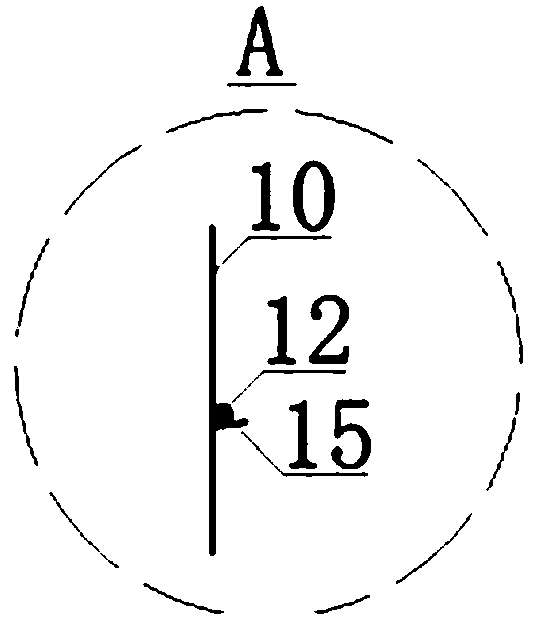

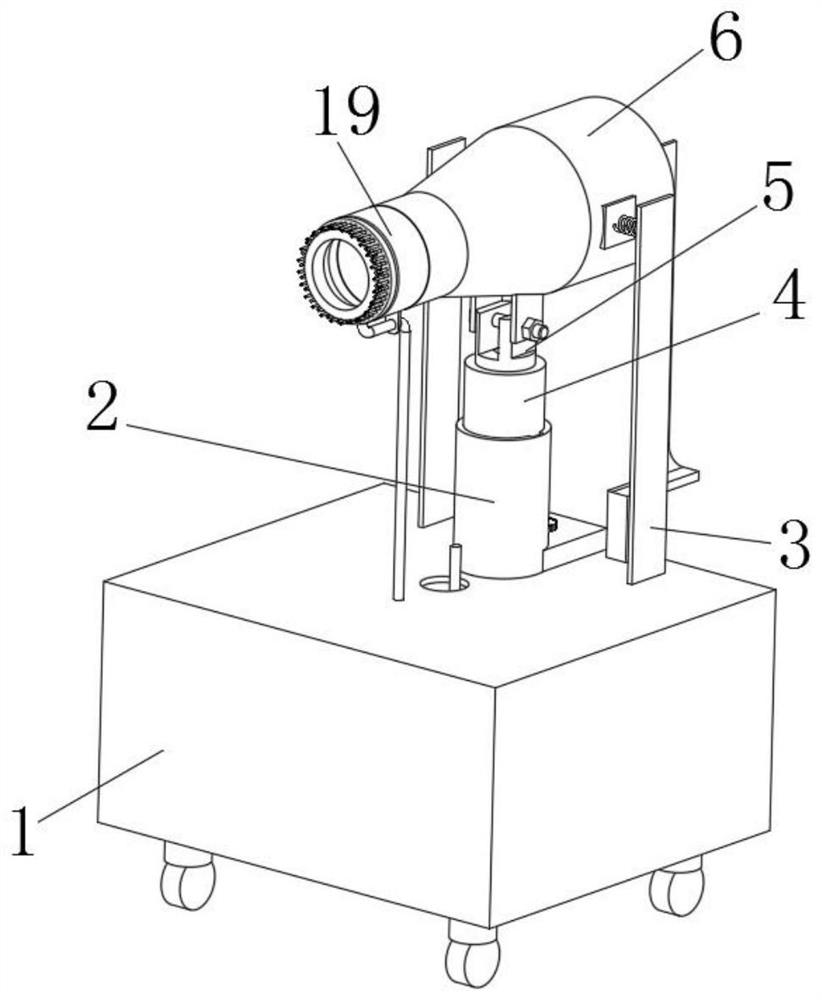

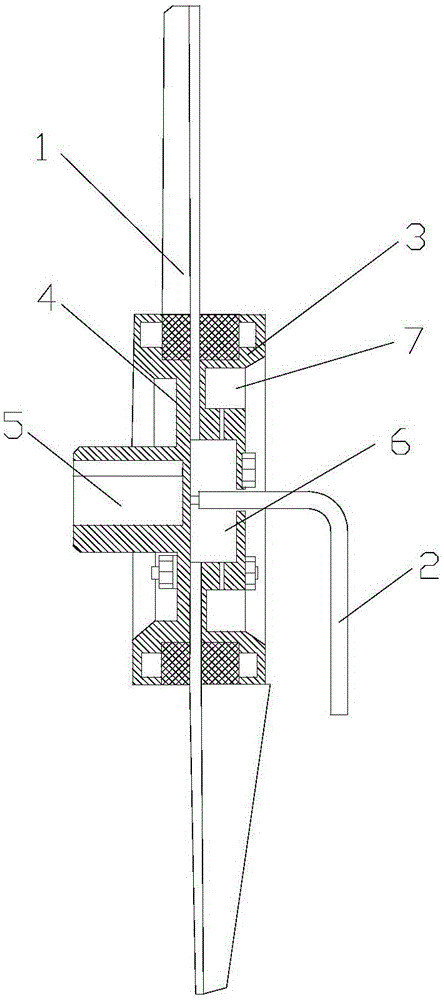

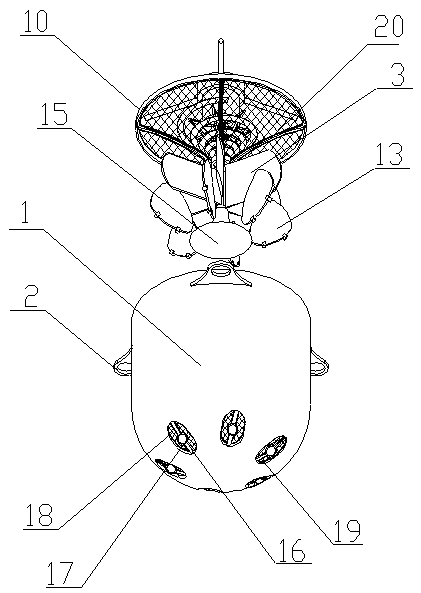

Wind-water atomizing aspirating device for mines

InactiveCN105134282AImprove atomization efficiencyTo achieve the purpose of dust reductionPump componentsDust removalDrive wheelStructural engineering

The invention discloses a wind-water atomizing aspirating device for mines. The wind-water atomizing aspirating device for the mines comprises an atomizer, a blade and a water pipe, the atomizer comprises a front hub and a rear hub which are fixedly connected through a bolt, a drive axle which is connected with power equipment is arranged on the rear hub, a water inlet inner cavity and an atomizing inner cavity which are communicated with each other through an aqueduct are formed in the front hub, the atomizing inner cavity is arranged on the outer side of the water inlet inner cavity and is of an annular structure, a water outlet end of the water pipe is introduced into the water inlet inner cavity, and an installation end of the blade is installed between the front hub and the rear hub through a bolt. According to the wind-water atomizing aspirating device for the mines, a hydraulic motor or an explosion-proof electric machine can be adopted to drive the wind-water atomizing aspirating device, spray is blown out through wind power produced by a wind wheel, dense fogdrops collect dust, and the purpose of aspirating is achieved; due to the fact that the atomizing device is made of special steel, more corrosive gas exists in mining areas, the corrosive gas is dissolved in water to form acid, and equipment which is used in the mining areas for a long time is prone to corrosion through acidic materials; by means of titanium alloy hubs, the defect that the corrosion is produced due to long-time soaking in the water can be effectively overcome; by means of the improvement of material components, the atomizing efficiency of the aspirating device is improved.

Owner:WUXI HUAHONG INFORMATION TECH

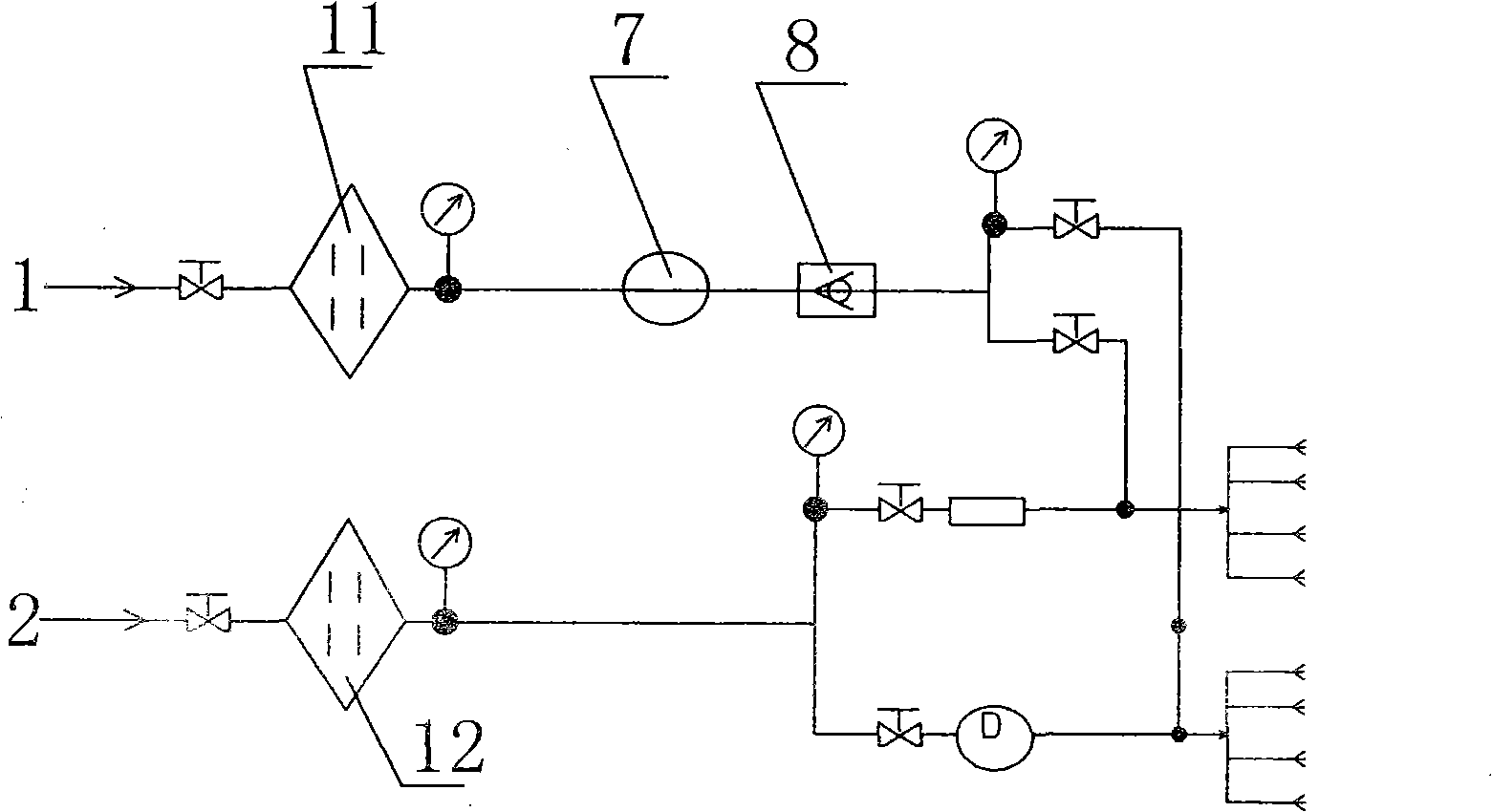

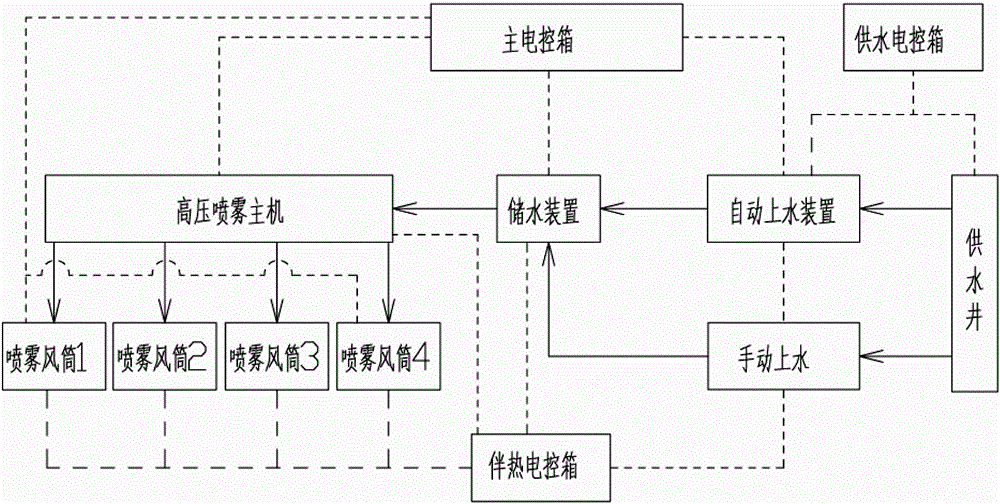

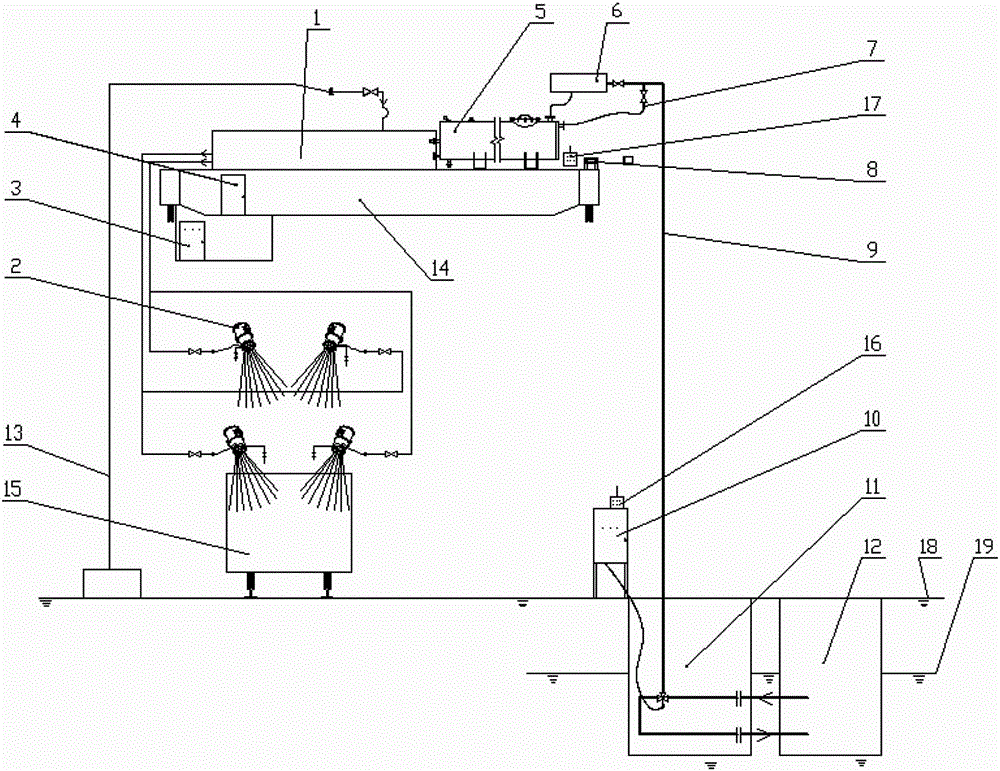

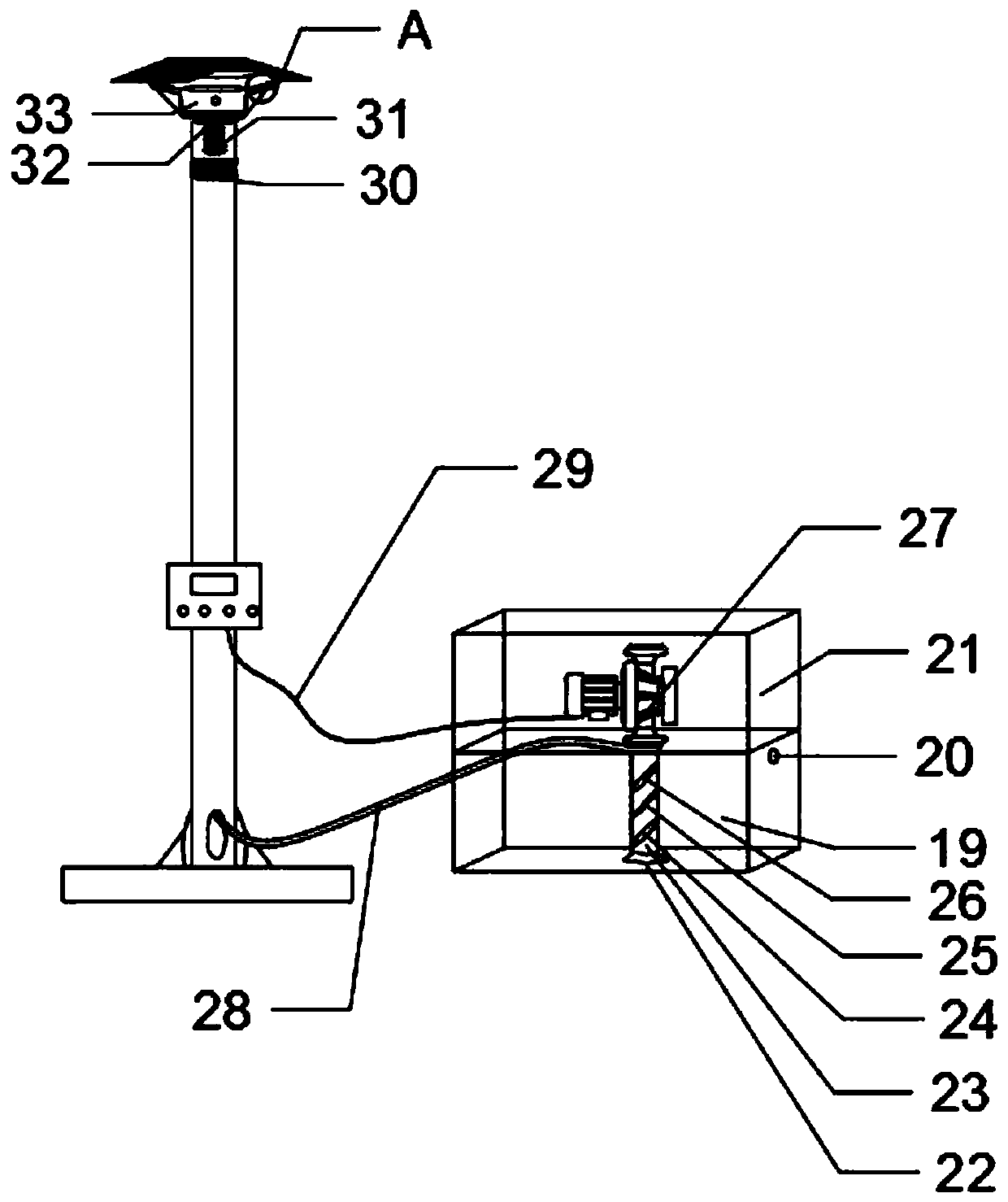

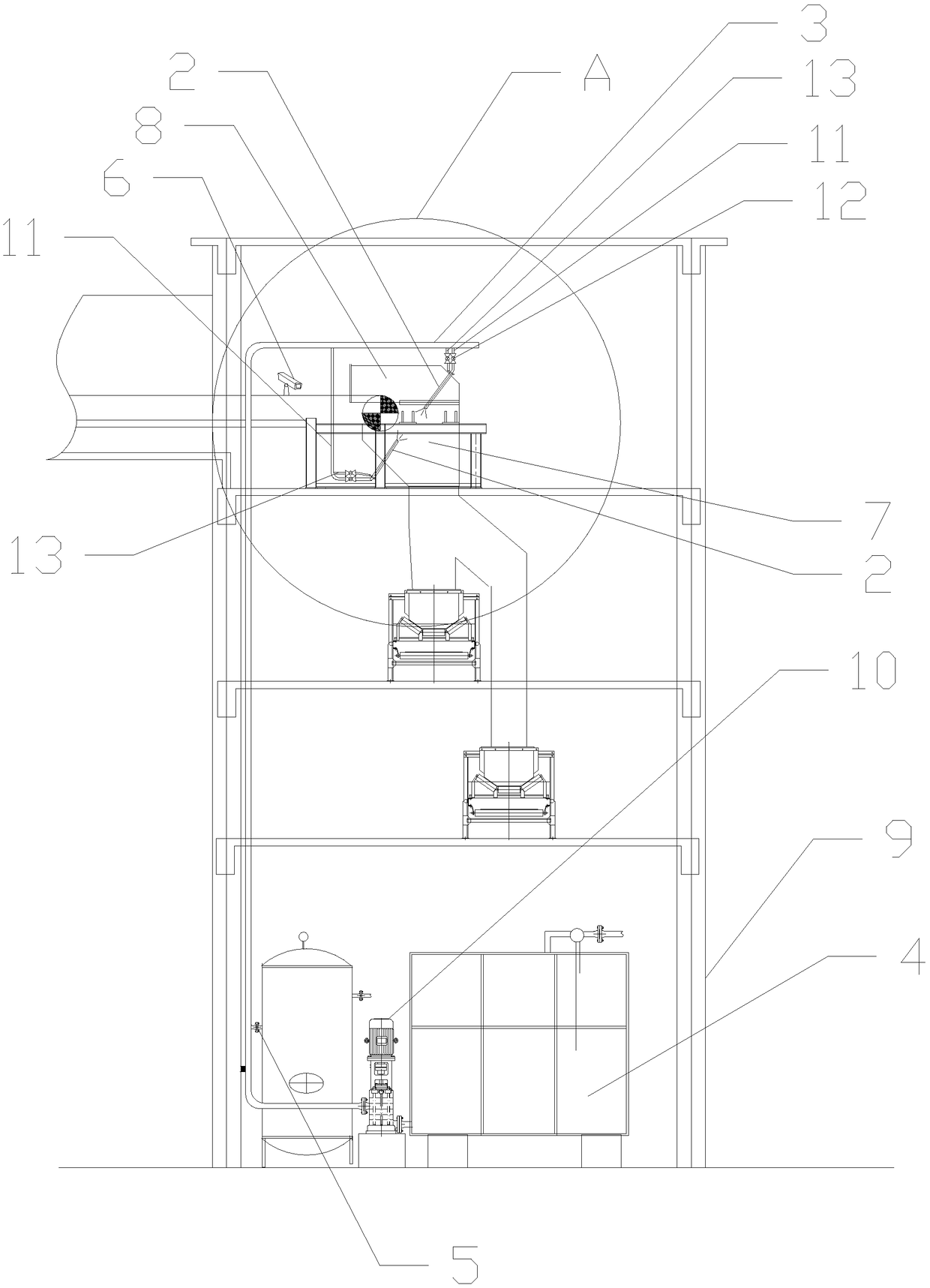

Low-temperature-resistant dust suppression system for unloading of grab bucket of traveling crane

ActiveCN105214418ATo achieve the purpose of dust reductionGuaranteed to workUsing liquid separation agentWater storageElectricity

The invention discloses a low-temperature-resistant dust suppression system for unloading of a grab bucket of a traveling crane. The low-temperature-resistant dust suppression system comprises a main high-pressure spray machine, a spray air cylinder, a main electric cabinet, a water storage device, a heat tracing device, a water inflow device, a water feed and water return pipeline, a water feed electric cabinet, a water supply dry well, a water supply wet well, a back blow device, a water supply remote control receiver and a water supply remote control emitter. After being pressurized and filtered by the main high-pressure spray machine, water in the water storage device is sprayed by the spray air cylinder. Water in the water supply wet well is controlled by the water feed electric cabinet to pass through the water supply dry well, the water feed and water return pipeline and the water inflow device sequentially to be injected into the water storage device. The water supply remote control emitter is electrically connected with the water storage device, and a signal emitted by the water supply remote control emitter is received by the water supply remote control receiver and then transmitted to the water feed electric cabinet. The back blow device is connected with the main high-pressure spray machine. The main electric cabinet is electrically connected with the main high-pressure spray machine, the spray air cylinder, the water storage device and the water inflow device. The purposes of dust suppression and dust fall are achieved.

Owner:QINHUANGDAO CAPITAL STARLIGHT ENVIRONMENTAL TECH CO LTD

Drilling device for machining fan shell

InactiveCN112108681AMeet regulatory needsAchieve the purpose of drillingLarge fixed membersPositioning apparatusElectric machineryDrill hole

The invention discloses a drilling device for machining a fan shell. The drilling device comprises a workbench and a first electric telescopic rod; a water storage tank is fixedly connected to the middle end of the bottom of the workbench; and a pump with the output end communicating with a spray head through a pipeline is fixedly installed at the left end of the bottom of an inner cavity of the water storage tank. The drilling device is provided with a first support, a first motor bracket, a first motor, a first conveying shaft and a first threaded sleeve, so that the vertical position of a drill rod can be adjusted; a second support, a second motor bracket, a second motor, a second conveying shaft and a second threaded sleeve are arranged, so that the horizontal position of the drill rodcan be adjusted; a third motor and the drill rod are arranged, so that the purpose of drilling the fan shell is realized; a fourth motor, a clamping platform, a fixed clamping plate, a supporting plate, a third electric telescopic rod and a movable clamping plate, so that the purpose of continuous drilling operation can be achieved; and the water storage tank, the pump, the pipeline and the sprayhead are arranged, so that the purpose of dust falling of dust can be achieved.

Owner:江西艾斯欧匹精密智造科技有限公司

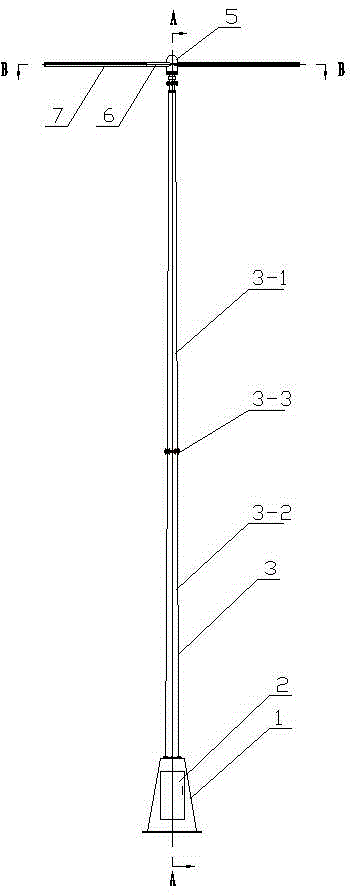

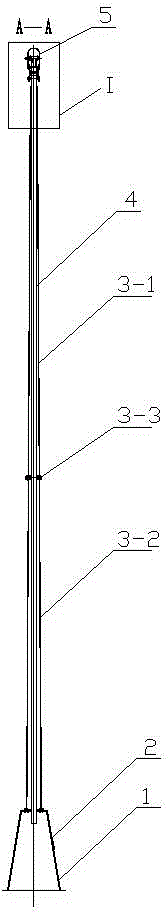

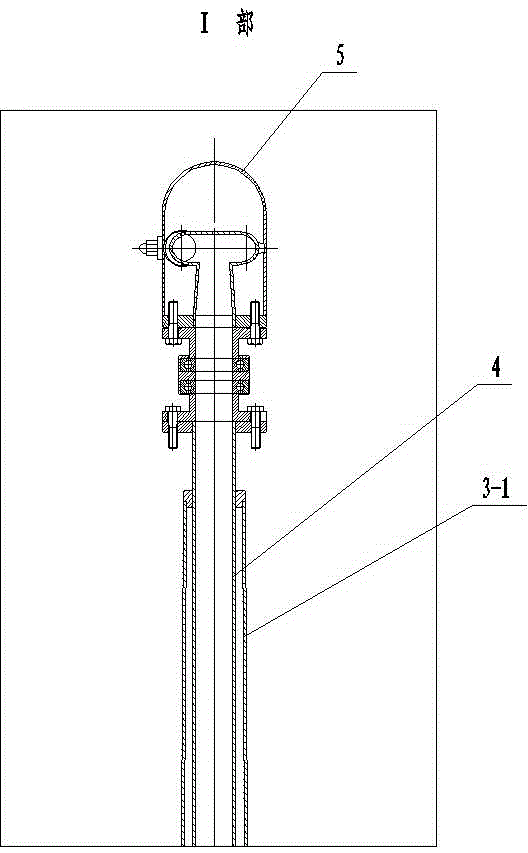

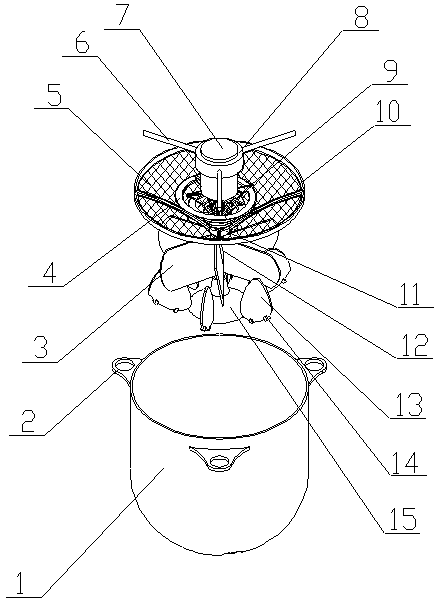

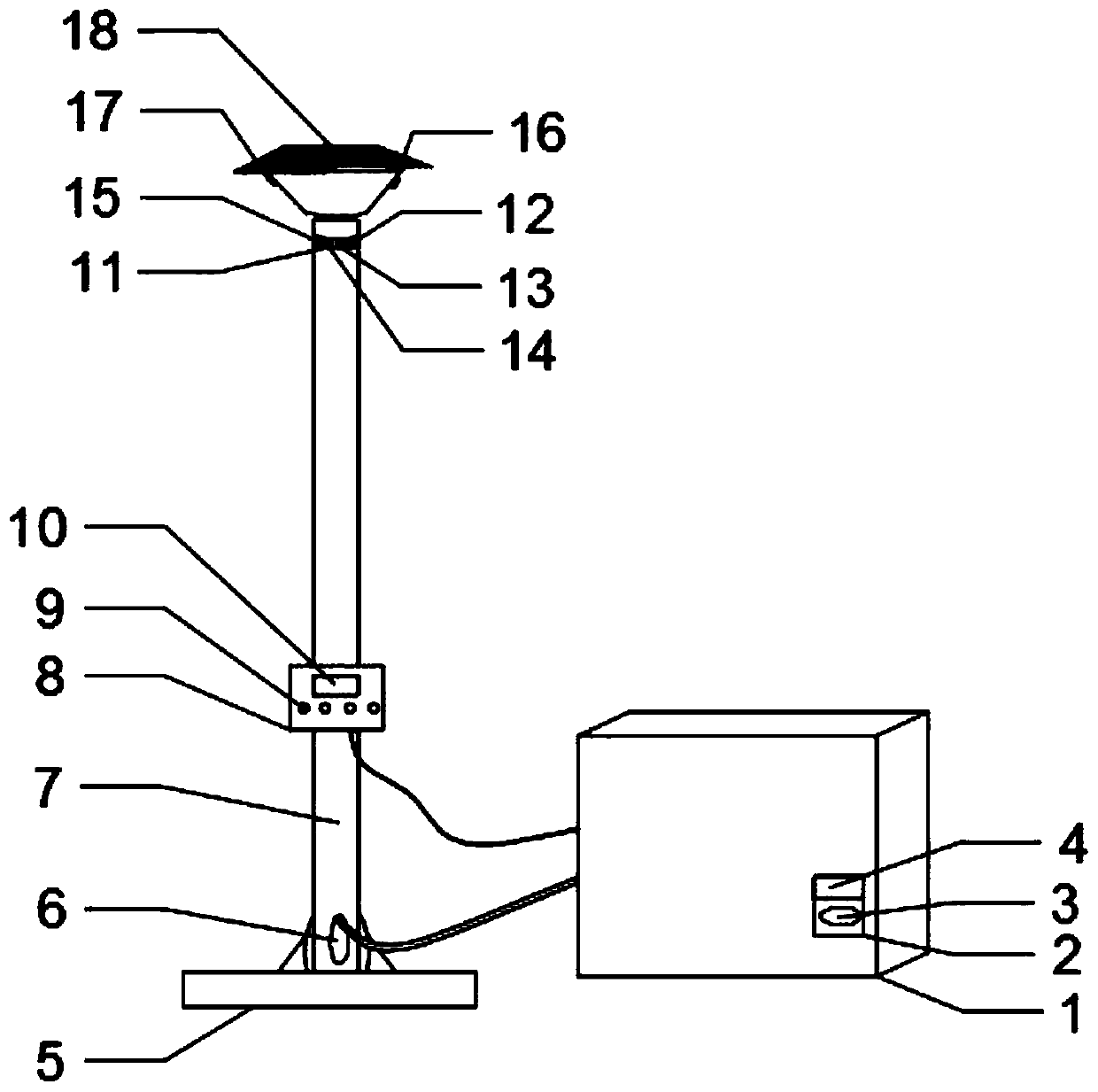

High rod power-free rotary sprayer

InactiveCN104056739ATo achieve the purpose of dust reductionThe purpose of dust suppression hasUsing liquid separation agentMovable spraying apparatusBulk cargoSpray nozzle

The invention discloses a high rod power-free rotary sprayer, and relates to dust control equipment used in outdoor coal yards and bulk cargo storage yards in ports. The high rod power-free rotary sprayer comprises a base; the middle part of the upper part of the base is connected with an outer tube which is vertically arranged; the diameter of the upper end of the outer tube is small while the diameter of the lower end is large; a vertical water pipe penetrates into the outer tube; the upper end of the vertical water pipe penetrates through the outer tube and is then connected with a swivel joint; the inner cavity of the swivel joint is communicated with the vertical water pipe; the swivel joint is connected with two first transverse water pipes; the water inlet ends of the two first transverse water pipes are respectively communicated with the inner cavity of the swivel joint; the water outlet ends of the two first transverse water pipes are respectively connected with an atomizing nozzle; the atomizing nozzle on one first transverse water pipe and the atomizing nozzle on the other first transverse water pipe are symmetrically arranged. The high rod power-free rotary sprayer is arranged in the center of a section zone of a storage yard or a coal yard; the rotary sprayer sprays water from the center to the outside, 0-360-degree covering can be realized, and covering radii are overlapped.

Owner:YANGZHOU YINJIANG MINING EQUIP

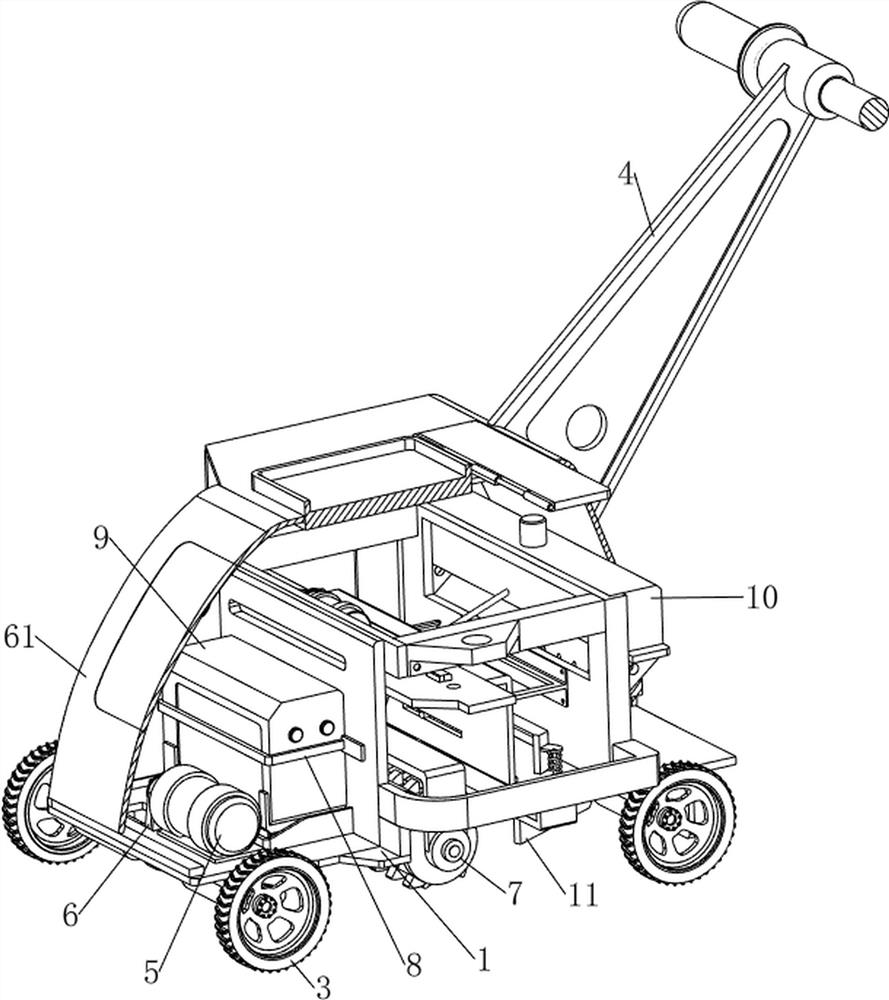

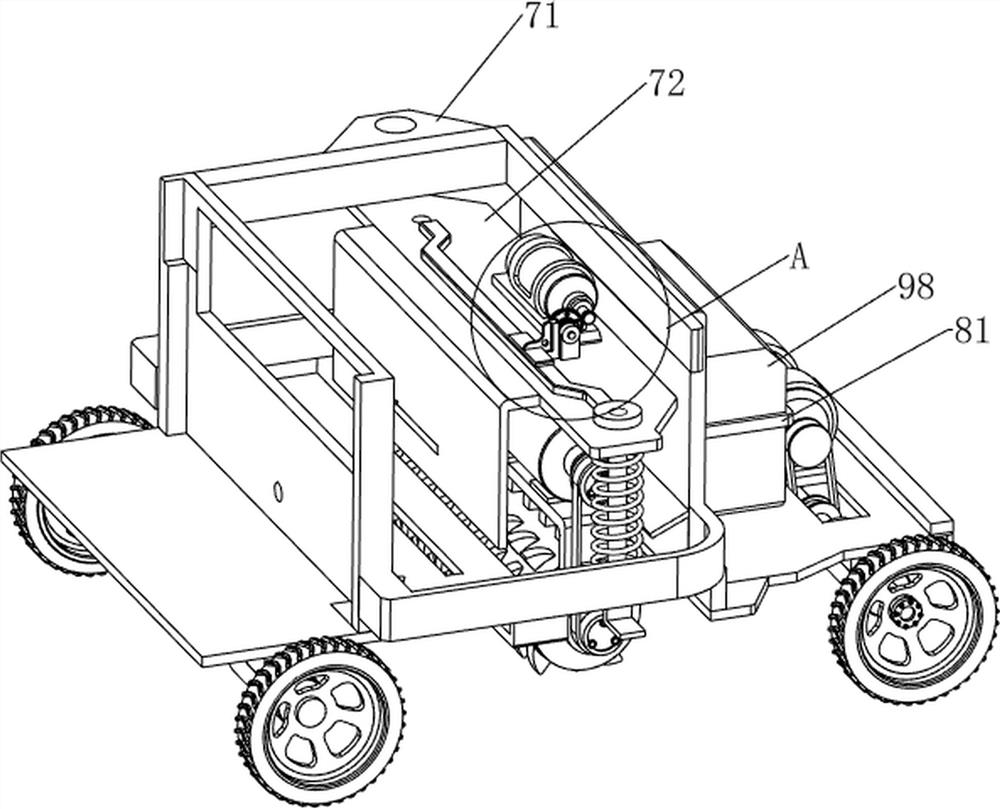

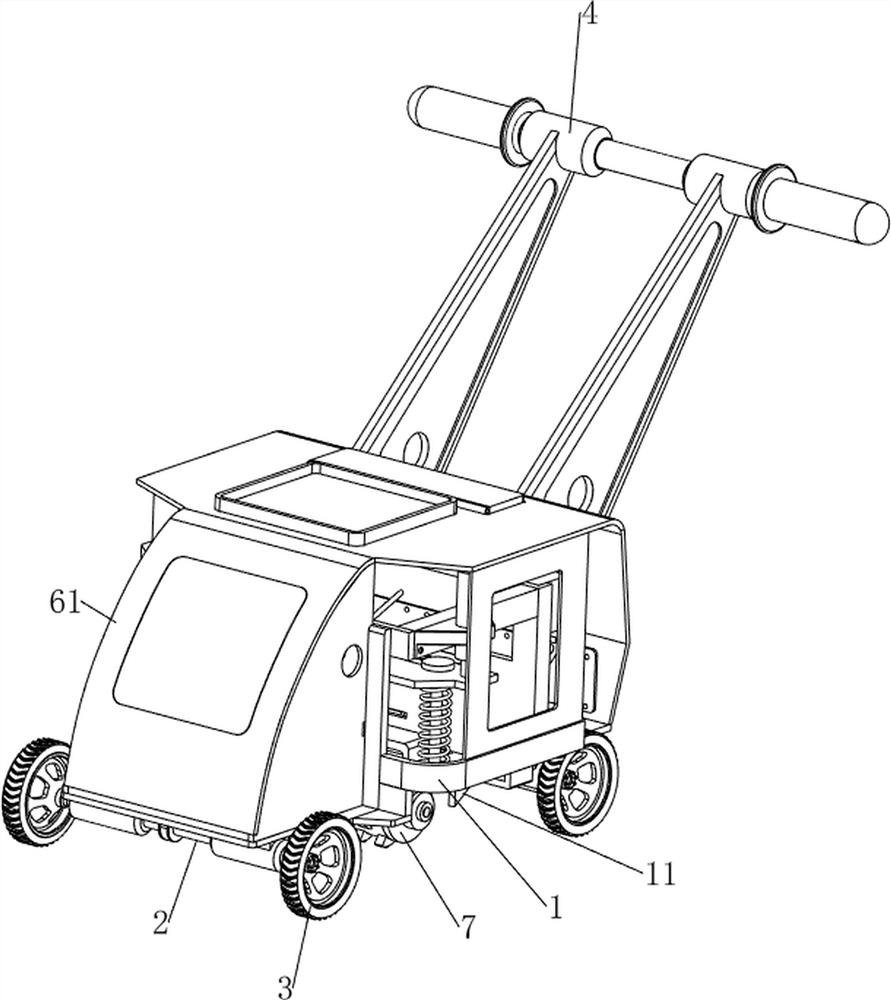

Energy-saving and environment-friendly milling machine for concrete pavement maintenance

PendingCN114508027AAvoid pollutionSave electricityBatteries circuit arrangementsDirt cleaningPavement maintenanceGear drive

The invention relates to an energy-saving and environment-friendly milling machine, in particular to an energy-saving and environment-friendly milling machine for concrete pavement maintenance. The invention provides the energy-saving and environment-friendly milling machine for concrete pavement maintenance, which does not pollute air and is relatively low in cost. The invention discloses an energy-saving and environment-friendly milling machine for concrete pavement maintenance. The milling machine comprises a frame, the first rotating shafts are rotationally connected to the lower part of the frame in a front-back symmetrical manner; the tires are connected to the left and right sides of the two first rotating shafts; the top of the frame is connected with the shell. The rack moves to drive the one-way gear and the second rotating shaft to rotate, so that the second rotating shaft drives the second full gear to rotate through the first full gear, the second full gear drives the rotating shaft of the generator to rotate, then the generator generates electricity, and the generator converts mechanical energy into electric energy and stores the electric energy into the storage battery. In addition, oil burning is not needed, and air pollution caused by tail gas can be avoided.

Owner:黄海珍

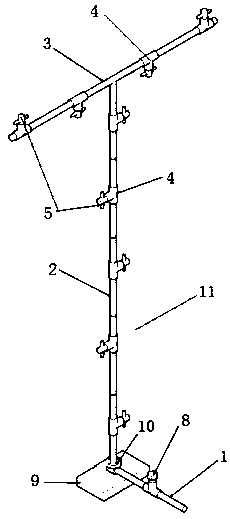

Three-section multistage spraying dust reducing system for tunnel dust

PendingCN110410136ASolve the problem of rapid concentration riseAdsorptiveDust removalFire preventionSlagEngineering

The invention discloses a three-section multistage spraying dust reducing system for tunnel dust. The dust reducing system is composed of multiple spraying devices identical in structure. Each spraying device comprises a water conveying pipeline, and the water conveying pipelines of the multiple spraying devices are connected with a main water conveying pipe. The main water conveying pipe is connected with a vertical galvanization water pipe, and the top of the vertical galvanization water pipe is connected with a horizontal galvanization water pipe. Multiple tee joints are arranged on the vertical galvanization water pipe and the horizontal galvanization water pipe at intervals. A rotary spray head is arranged on each tee joint. According to the device, running of a slag transporting truck is not influenced in the dust reducing process, the device is light and can be randomly moved in a tunnel, the spraying covering range is far wider than that of a currently taken dust reducing measure, and a better dust reducing effect can be achieved.

Owner:GUIZHOU UNIV

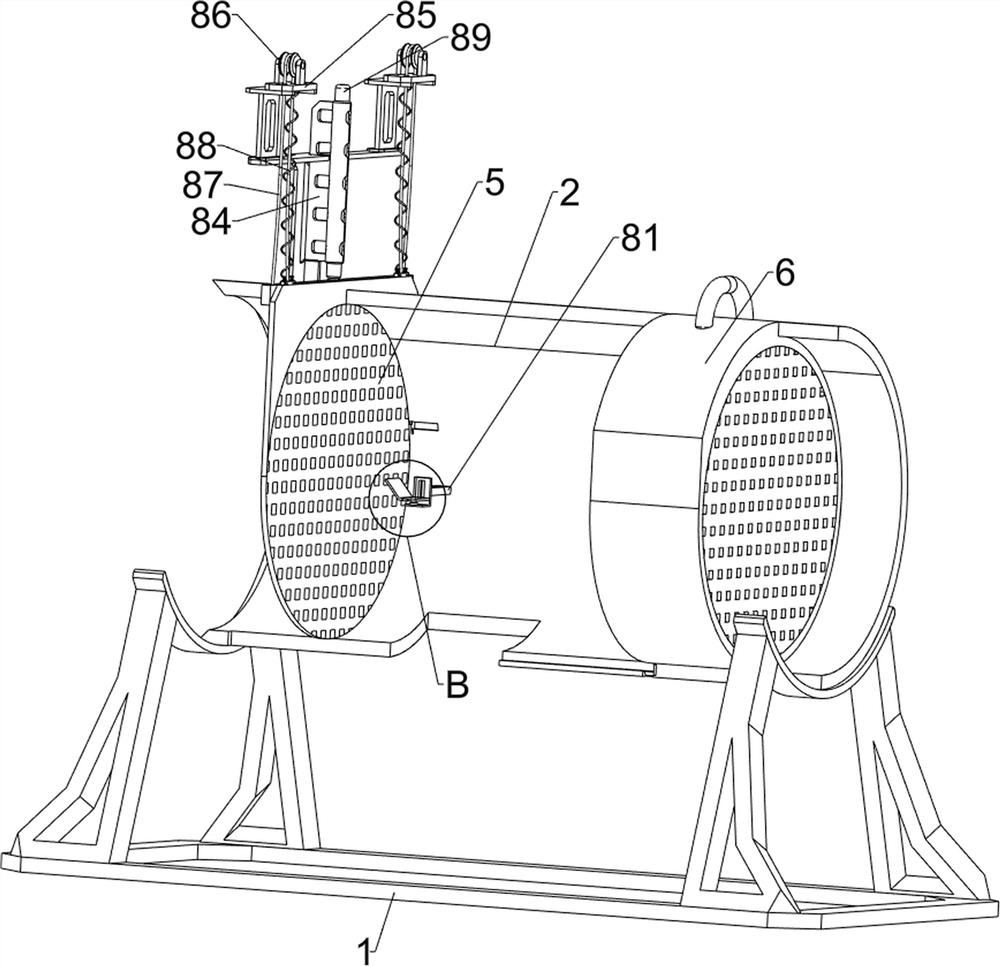

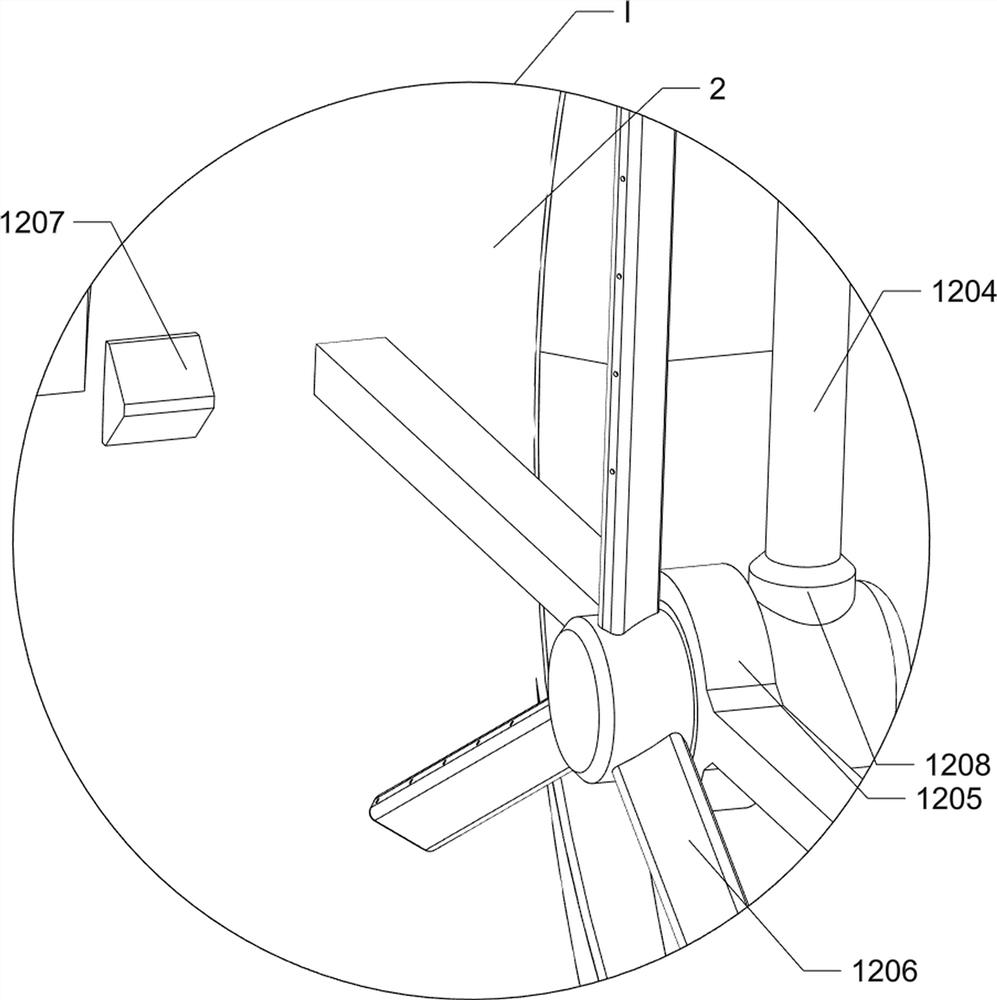

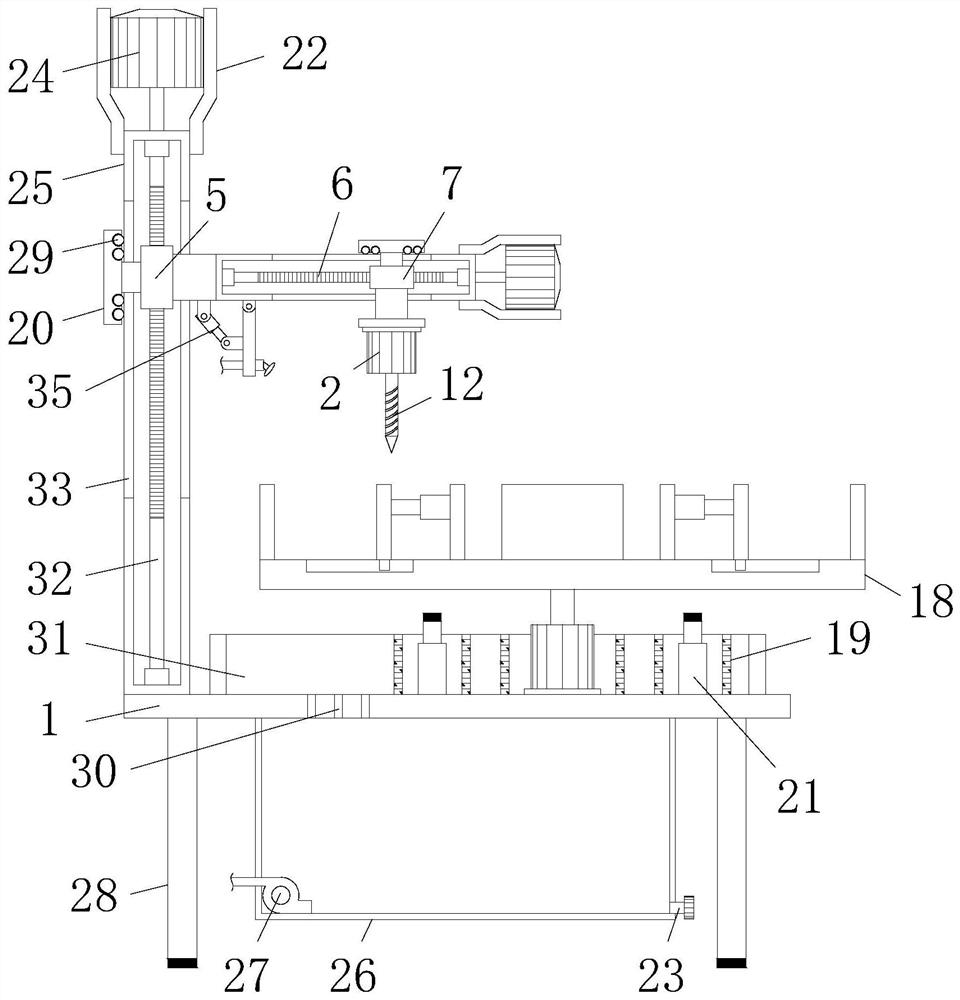

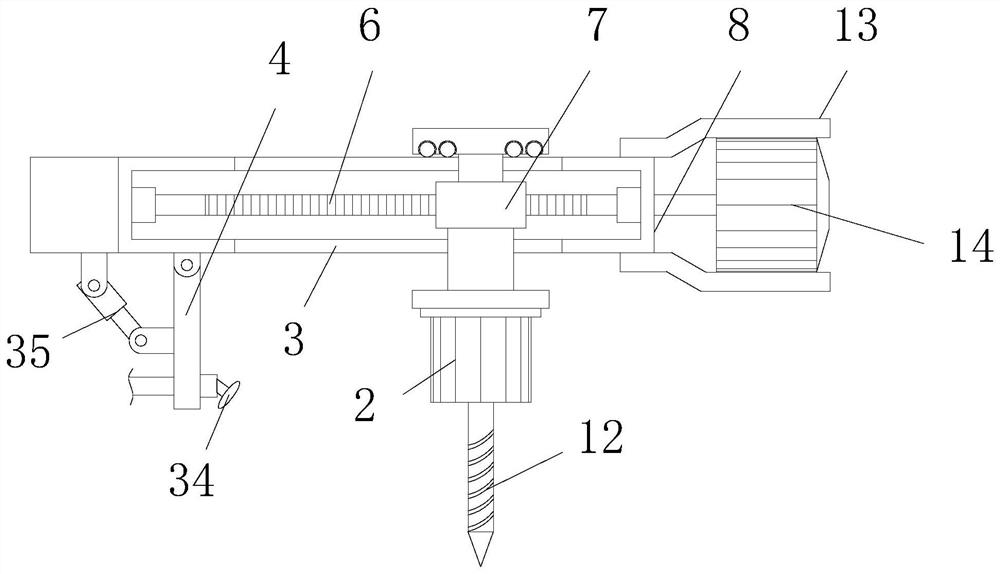

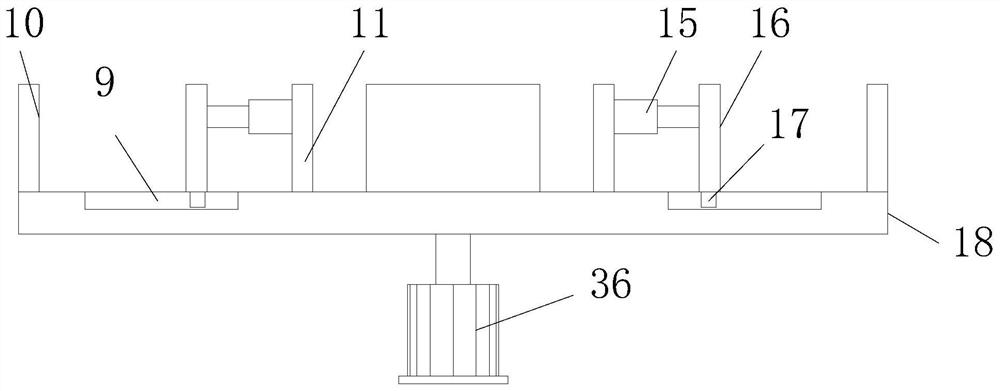

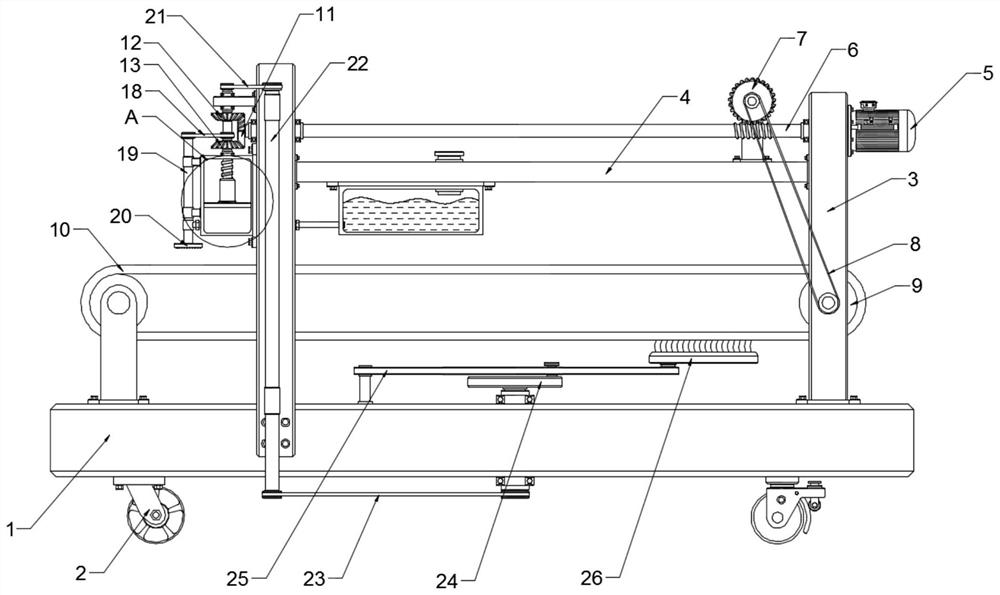

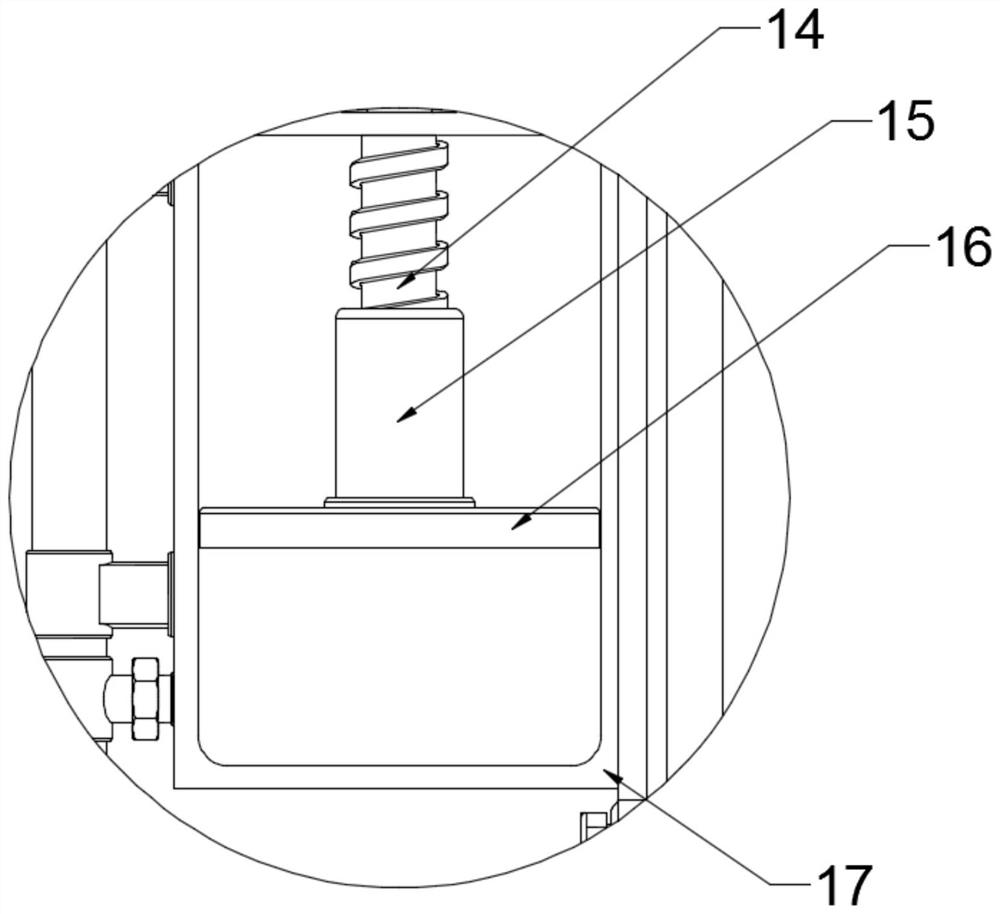

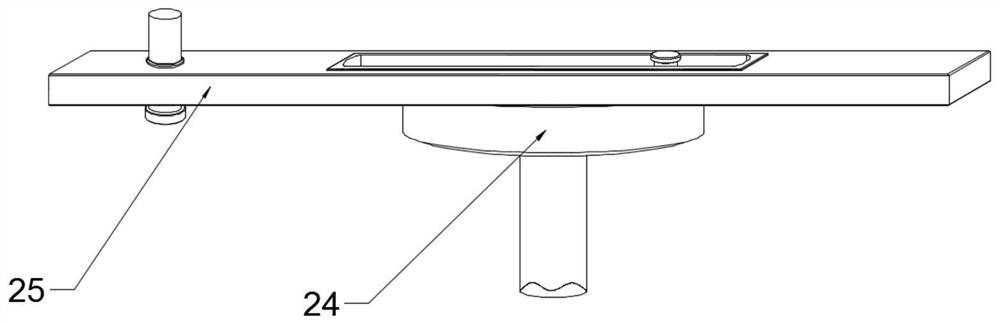

A fully automatic powder packaging system

The invention discloses a full-automatic powder packaging system. The full-automatic powder packaging system comprises a screw filling device (1), a lifting bag clamping and weighing device (2), an automatic bagging device (3), a clamping, transferring and conveying device (4), a bag sewing device (5), a finished product transfer device (6), a powder recycling device (7) and an electronic control device (8). The lifting bag clamping and weighing device comprises a weighing mechanism (24) and a duckbill bag clamping mechanism (25) which can ascend and descend synchronously. A discharging cylinder (13) is sleeved with the duckbill bag clamping mechanism. The duckbill bag clamping mechanism clamps a packaging bag and ascends before filling operation so that a movable material door (156) can be located at the bottom in the packaging bag, the duckbill bag clamping mechanism gradually descends synchronous with ascending of the material level in the filling operation process, and the weighting mechanism conducts weighing at the same time. By the adoption of the full-automatic powder packaging system, powder materials can be weighed precisely, packaging bags are sealed and conveyed, and the full-automatic powder packaging system is especially suitable for premise metering and automatic packaging of extremely fine powder materials.

Owner:SAIMO ELECTRIC

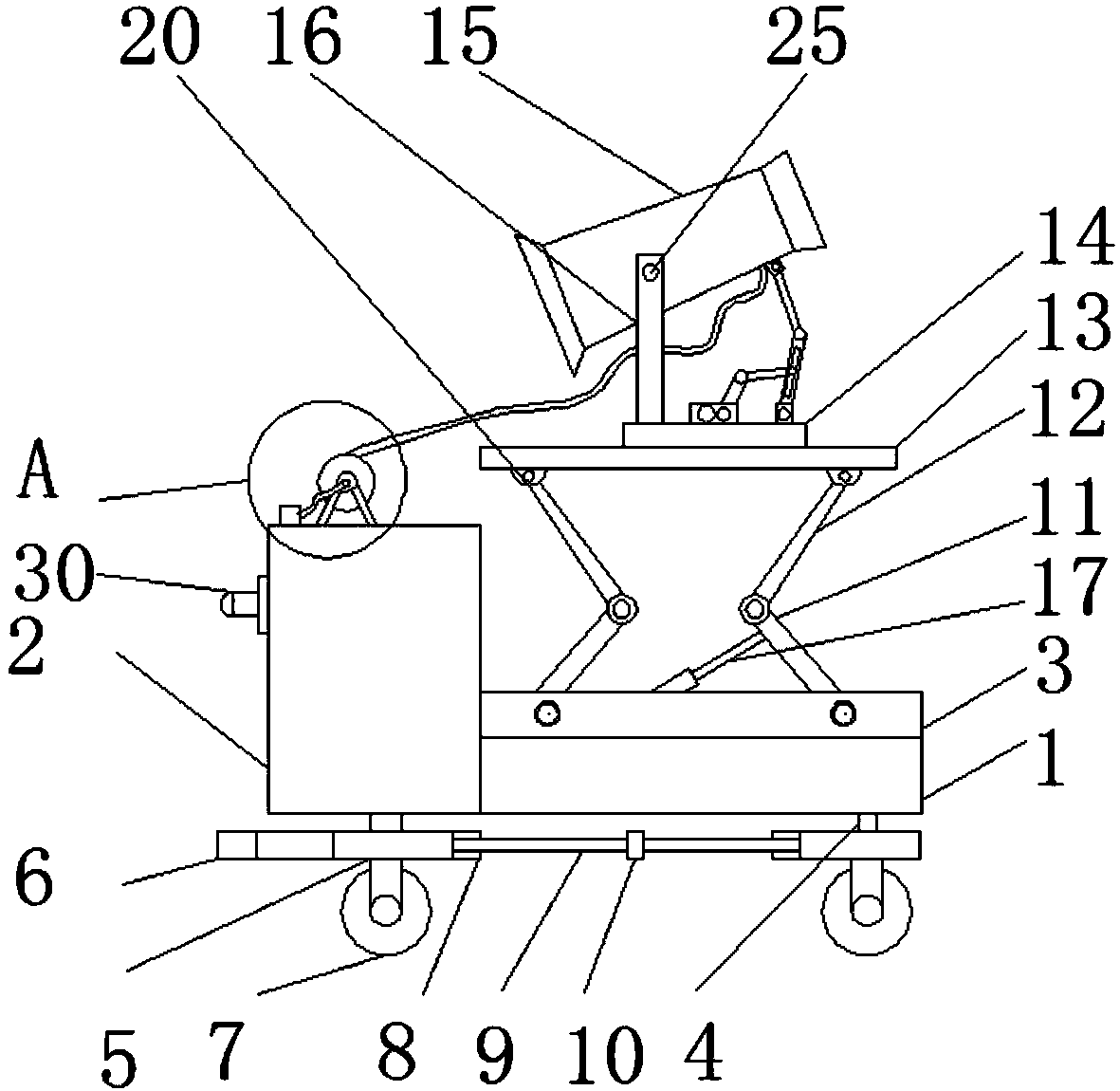

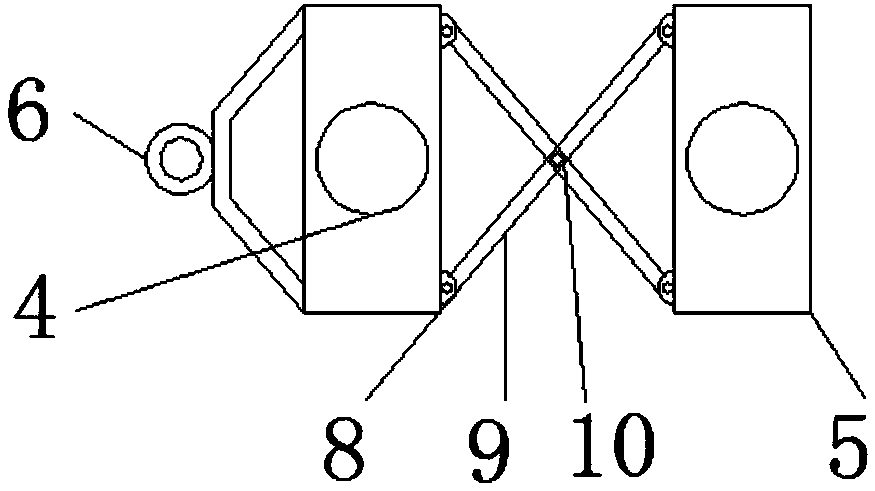

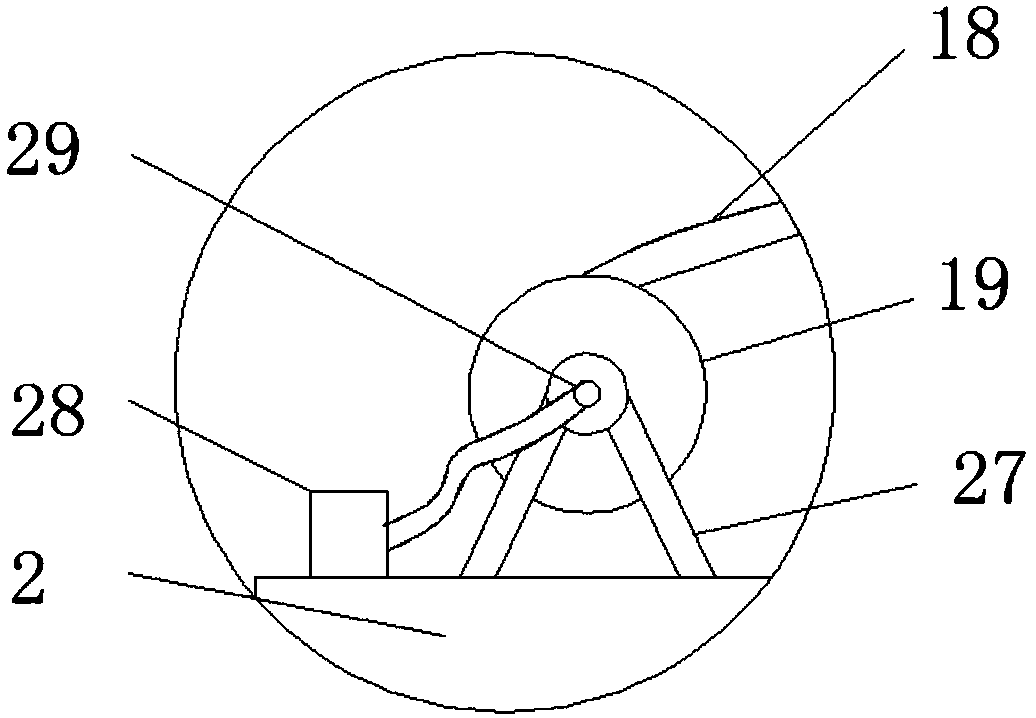

Ore mining equipment with dust fall function

PendingCN111075447ALarge adjustment rangeRealize all-round adjustmentDust removalFire preventionMining engineeringDust control

The invention discloses ore mining equipment with a dust fall function, and belongs to the technical field of ore mining. The ore mining equipment comprises an assembling plate, wherein the assemblingplate is provided with idler wheels and is provided with a mining component, a sprinkling chamber and a water tank; the sprinkling chamber is provided with a driving pipe; the top of the driving pipeis rotatably provided with a cylinder; the cylinder is provided with a lifting and lowering block in a sliding way; the lifting and lowering block is provided with a horizontal rail plate; the rail plate is provided with a horizontal cross bar in a sliding way; an oscillating bar is hinged to the cross bar and is provided with a dust collection hopper; the dust collection hopper is connected witha flexible pipe; and the bottom of the cylinder is provided with a groove. By use of the ore mining equipment, the omnibearing regulation of the dust collection hopper on a spatial position is realized, so that omnibearing dust collection can be realized, and a regulation range is wide. The dust collection is carried out through ejection, so that a dust collection effect is good, sprinkling wateris filtered, water is reused, and water resources are saved. Meanwhile, filter residues can be conveniently discharged, and use quality is good.

Owner:招金矿业股份有限公司蚕庄金矿

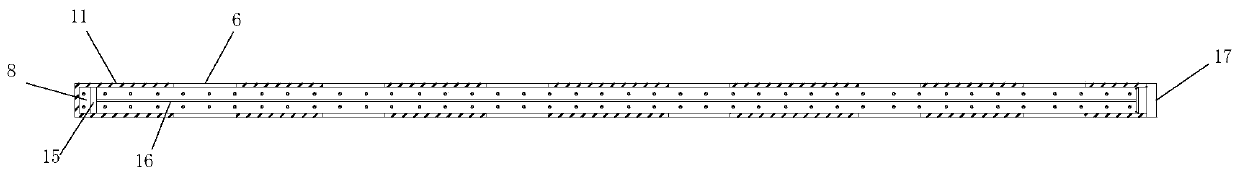

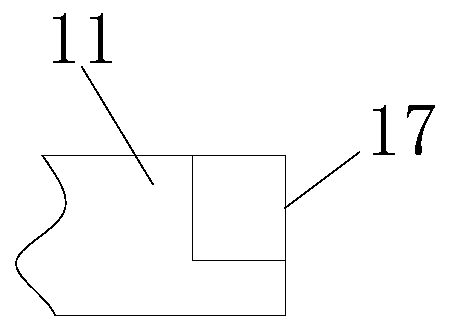

Micro powder conveying device

InactiveCN106044298AGuaranteed to workAvoid wastingConveyorsLoading/unloadingEngineeringControl valves

The invention relates to a micropowder conveying device, which includes a feed hopper, a solenoid valve, a feed pipe and a conveying pipe. The conveying pipe is provided with a filter screen for filtering dust, and the filter screen is detachably installed on the side wall of the conveying pipe. , the top of the delivery pipeline is provided with an atomizing nozzle, a water supply pipeline and a control valve, one end of the water supply pipeline is connected to the atomization nozzle, the other end is connected to the water supply tank, and the control valve is set on the water supply pipeline to control the opening and closing of the water supply pipeline Closed, the control valve is connected with the solenoid valve at the same time, when the solenoid valve is opened, the control valve is triggered to open at the same time. The invention sprays atomized water vapor through the atomizing nozzle, so that the dust falls together with the water vapor to achieve the purpose of dust reduction. At the same time, the filter screen can filter out a part of the dust, so that the dust will not fly and float into the external environment, thereby avoiding dust. Harmful to the health of the staff, it can also avoid the waste of raw materials, reduce the labor intensity of workers, and ensure the normal operation of the conveying device.

Owner:扬州锦盛微粉有限公司

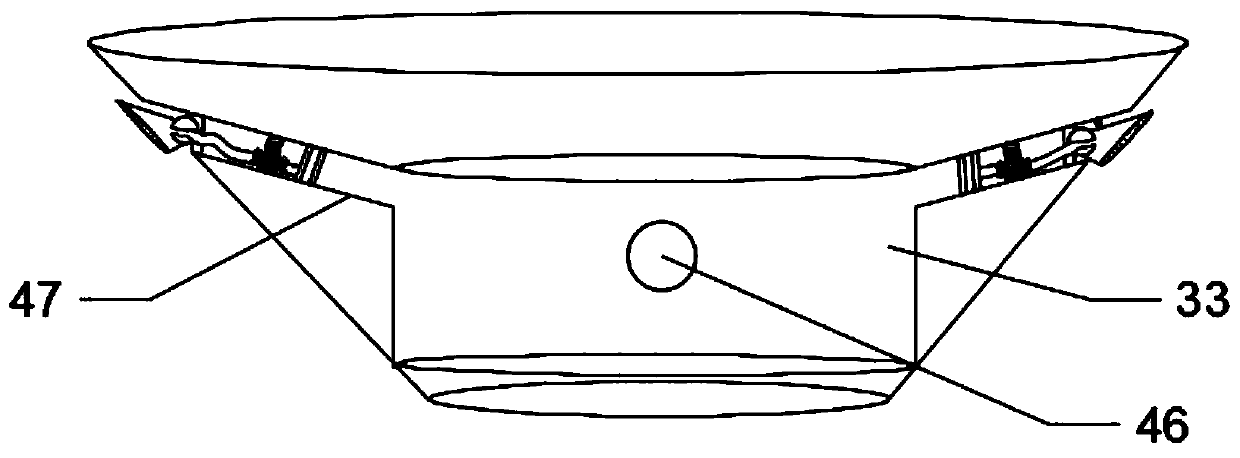

Underground intermittent foam dust-falling spraying nozzle for coal mine construction

ActiveCN107866337ASimple structureImprove the effect of dust suppressionDust removalFire preventionRound tableEngineering

The invention relates to an underground intermittent foam dust-falling spraying nozzle for coal mine construction, and discloses a spraying nozzle which can spray foam intermittently to make the foambe in full contact with dust for improving dust-falling effect. The underground intermittent foam dust-falling spraying nozzle is characterized in that three fixed lugs are arranged on the outer sideof a main body cylinder at equal intervals, and fixed holes are formed in each fixed lug; a plurality of spraying slots are formed in the bottom of the main body cylinder at equal angles, and each spraying groove is of an elliptical structure; each spraying slots is internally provided with a split net, each split net is made of steel wires, the surface of each split net is coated with a coating layer, and spraying rings are placed in the spraying grooves and connected with the main body cylinder through two connecting plates, and a supporting ring is arranged in the main body cylinder and connected with the inner wall of the main body cylinder through a plurality of fixing rods; and a driving motor is placed in the inner ring of the support ring, one end of a rotating rod is connected with one end of a motor shaft of the driving motor through a connecting ring, a fixed table is arranged at the other end of the rotating rod through a bearing and connected with the middle of the bottomend of the main body cylinder, and the fixed table is in a round table shape.

Owner:徐州新南湖科技有限公司

Automatic spraying device and spraying system thereof

ActiveCN110860419AReduced service lifeAvoid the impact of product qualityUsing liquid separation agentSpraying apparatusWater storage tankEngineering

The invention discloses an automatic spraying device and a spraying system thereof, and belongs to the technical field of dust suppression equipment. The automatic spraying device comprises a sprayingdevice and a water storage tank arranged in the spraying device, wherein a pressure detector is fixedly installed in the water storage tank, a plurality of water delivery channels are arranged on thepressure detector, a second water pump is fixedly installed in the water delivery channels, a fourth filtering plate and a fifth filtering plate are fixedly arranged at one side of the second water pump, the other side of the second water pump is connected with a rotary positioning ball through a water delivery pipe, an electromagnet is arranged on the outer side of the rotary positioning ball, and a nozzle is fixedly installed at one end of the rotary positioning ball. According to the invention, by arranging a filter, the fourth filtering plate and the fifth filtering plate, and arranging afirst filtering plate, a second filtering plate and a third filtering plate in the filter, each layer of filtering plate can filter out different impurities according to different densities, so thatthe water sprayed by the nozzle is purer, and blockage is avoided.

Owner:安徽众品机械科技有限公司

Environment-friendly dust removal device for building construction

ActiveCN111643995AReduce noiseEasy to disassemble and replaceCombination devicesDispersed particle filtrationArchitectural engineeringMechanical engineering

The invention discloses an environment-friendly dust removal device for building construction. The device comprises a dust suction box, a dust suction port, a push handle and a bottom plate, wherein adust suction port is fixedly connected to the top end of the dust suction box, a dust suction fan is fixedly connected to the bottom end of the interior of the dust suction box, a bottom plate is fixedly connected to the bottom end of the dust suction box, a noise reduction structure is fixedly connected to the inner side wall of the dust suction box, and a first dust falling mechanism is fixedlyconnected to one side of the top end of the noise reduction structure. Dust is removed through the arrangement of the dust suction fan and the first dust falling mechanism, so that the dual dust removal function is achieved, and the dust removal efficiency is improved.

Owner:深圳市卓越装饰工程有限公司

Intelligent robot for financial consultation

The invention relates to the technical field of financial consultation equipment, in particular to an intelligent robot for financial consultation. The invention aims to solve the technical problems that an existing device has a lower attraction force and an easily-blocked filter screen and cannot clean the ground. In order to solve the above technical problem, the invention provides an intelligent robot for financial consultation. The intelligent robot for financial consultation consists of a robot shell, a mounting plate, a display mechanism, a heat dissipation mechanism and a cleaning mechanism; by arranging a ventilating fan, a cleaning frame and cleaning brushes, when the intelligent robot works, air in the robot shell can be circulated through the ventilating fan; when an output shaft of a rotary motor rotates, the cleaning frame can swing leftwards and rightwards, the cleaning brushes on the two sides of the cleaning frame can clean a first filter screen and a second filter screen, and cleaned dust can be discharged under the action of the ventilating fan; and in this way, the first filter screen and the second filter screen are cleaned while the interior of the robot shell is cooled.

Owner:济宁新程万创信息技术有限公司

Belt conveyor dust suppression device

InactiveCN109019083AApplicableGood dust suppression effectControl devices for conveyorsLoading/unloadingLine tubingSpray nozzle

The invention relates to a belt conveyor dust suppression device which comprises a belt conveyor, a high-pressure water spray nozzle, a line penetrating pipe, a water tank, a gas storage tank and a camera. Two high-pressure water spray guns are symmetrically installed on the two sides of a feeding hopper at the right end of the belt conveyor through flange bolts, two high-pressure water spray gunsare symmetrically installed on the two sides of a belt conveyor head cover on the belt conveyor through flange bolts, a transit frame is arranged at the right end of the belt conveyor, and the watertank, the gas storage tank and a multi-stage pressurized water pump motor are arranged on the bottom of the transit frame. The water tank is connected with the multi-stage pressurized water pump motor, the multi-stage pressurized water pump motor is connected with the high-pressure water spray guns through water pipelines, the gas storage tank is connected with the high-pressure water spray guns through air pipelines, and valves are arranged at the front ends of the water pipelines and the air pipelines. The belt conveyor dust suppression device fully utilizes an aerodynamic principle and a fluid mechanics principle, and has applicability and good dust suppression effect.

Owner:青州中联水泥有限公司

Dust reduction structure for excavation of narrow river valley

PendingCN108104041ASimple structureEasy to implementData processing applicationsRoad cleaningPipeflowSlag

The invention provides a dust reduction structure for excavation of a narrow river valley. The structure includes a high-altitude water pool, water introducing pipes and multiple rainfall-type water spraying PVC pipes; the rainfall-type water spraying PVC pipes stretch across the two sides of the river valley aloft and are arranged along downward sliding routes of overturned slag. The rainfall-type dust reduction structure for excavation of the narrow river valley aims at solving the problem that it is difficult to carry out excavation and dust reduction on high slopes, simple and few pipelines are adopted for comprehensively covering excavation surfaces and the downward sliding routes of the overturned slag, and the structure is simple, convenient to implement and great in effect. By carrying out artificial rainfall on the excavation surfaces of the slopes and the downward sliding routes of the overturned slag, the purpose of reducing dust is achieved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

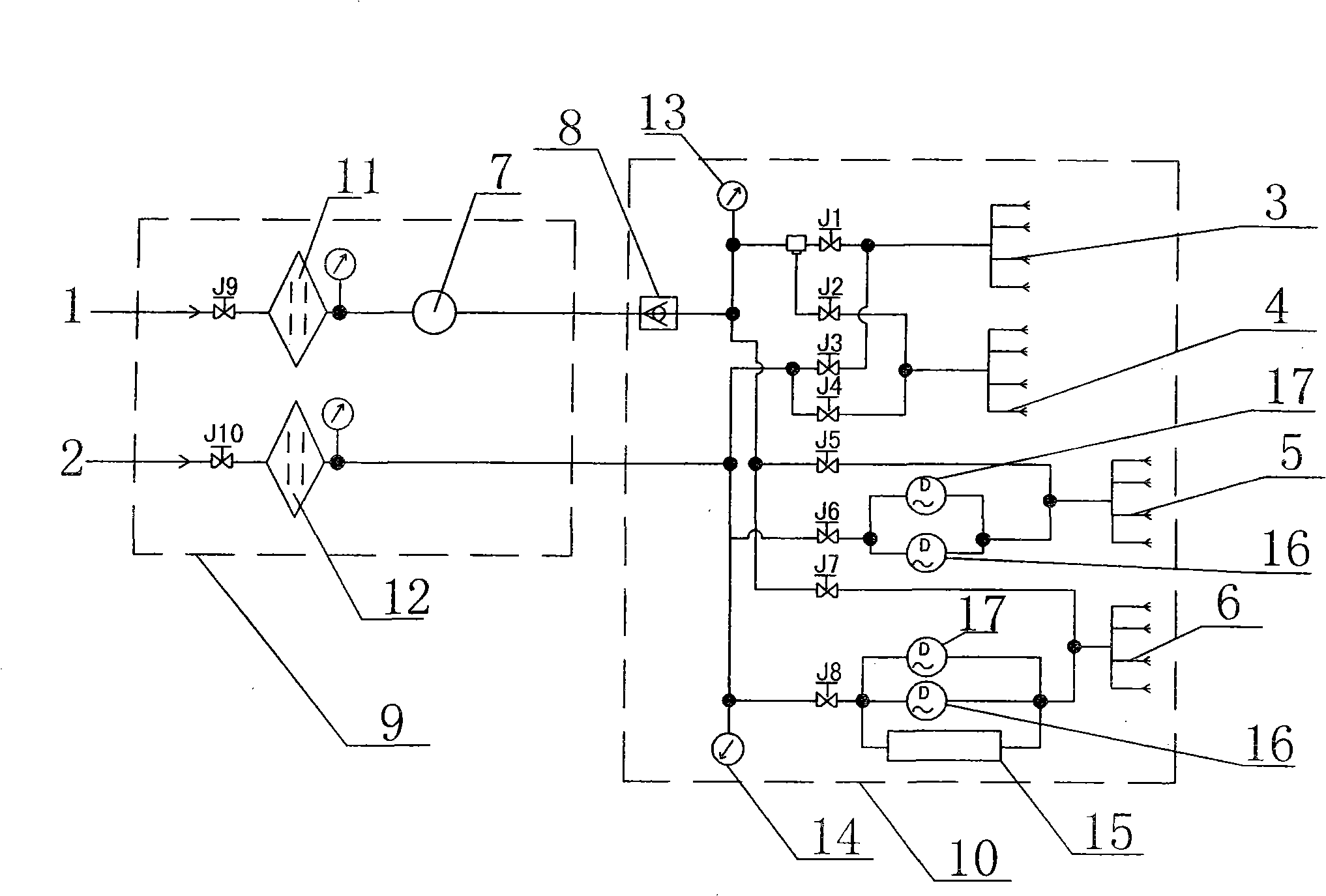

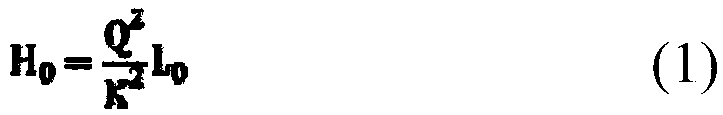

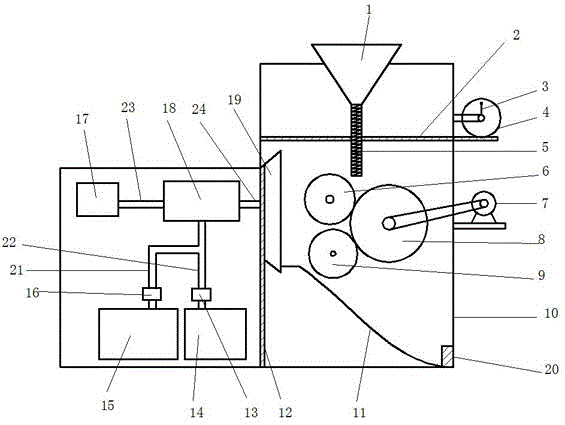

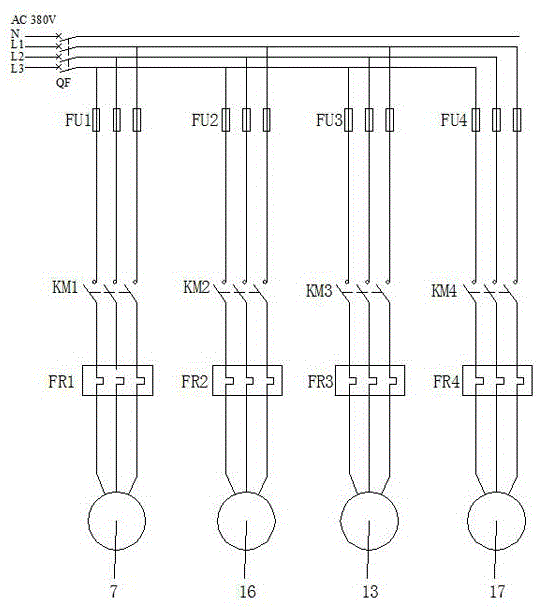

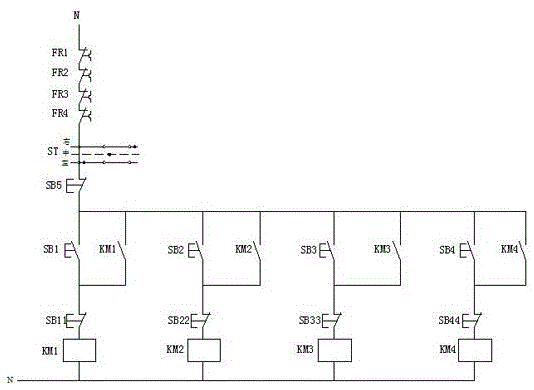

Dust suppression crusher and control system thereof

The invention discloses a dust-reducing crusher and its control system, comprising a first crushing gear, a second crushing gear and a third crushing gear all located inside the machine body, the first crushing gear meshes with the second crushing gear, the first crushing gear and the The third crushing gear meshes, the second crushing gear is located on the upper part of the third crushing gear, there is a partition inside the box, all the devices on the left side of the partition constitute the dust suppression system, and all the devices on the right side of the partition constitute the crushing system. The control system of the dust reduction crusher consists of three parts: the main circuit, the manual control system and the automatic control system. The crusher can improve the crushing degree of materials and reduce the influence of dust on the service life of the crusher.

Owner:CHENGDU DESHANNENG TECH CO LTD

Conveying device for mine

InactiveCN113044472ARealize transmissionInnovative designConveyorsUsing liquid separation agentElectric machineryBrush

The invention relates to a conveying device for a mine. The conveying device for the mine comprises a working table and two mounting plates arranged on the working table; a transverse plate is arranged on the mounting plates; a motor is further arranged on the mounting plates; the motor is connected with two rollers arranged on the working table through a first transmission assembly; a conveying belt is arranged on the rollers; the first transmission assembly is connected with a forward and reverse rotation assembly; the forward and reverse rotation assembly is connected with a lead screw; the lead screw is in threaded fit with a threaded sleeve; one end of the threaded sleeve is connected with a hydraulic assembly arranged on the mounting plate; one side of the hydraulic assembly is connected with a water tank fixedly arranged on the transverse plate through a one-way valve; the other side of the hydraulic assembly is connected with a rotary spraying assembly, which is connected with the lead screw through a second belt and arranged on the hydraulic assembly, through the one-way valve; the lead screw is connected with a swing assembly; and a brush plate used for cleaning the conveying belt is arranged on the swing assembly. The conveying device for the mine disclosed by the invention is novel in design, simple in structure and high in practicability.

Owner:彭伟平

Dust falling device for mine downhole fully-mechanized coal mining face shifting frame falling coal fog gun

PendingCN110107341AProtect your healthSimple structureMining devicesDust removalEngineeringHigh pressure water

The invention discloses a dust falling device for a mine downhole fully-mechanized coal mining face shifting frame falling coal fog gun. The dust falling device includes a negative-pressure generator,an atomizing mechanism and a dust suction tube, the negative-pressure generator is fixed to the upper end of a gangue sliding groove, the gun muzzle end of the negative-pressure generator directly faces the coal wall, an airflow expansion cavity is formed in the side wall of the negative-pressure generator, an air inlet is formed in the corresponding outer side wall of the air flow expansion cavity, an annular nozzle is arranged on the corresponding inner wall, a dust suction mouth is formed in the side wall of the end, away from the gun muzzle, of the negative-pressure generator to be connected with the dust suction tube, the free end of the dust suction tube is located in the gangue sliding groove, and compressed air is ejected from the annular nozzle and forms a negative -pressure cavity in the rear end to suck dust in the gangue sliding groove; and the atomizing mechanism includes a high-pressure water pipe extending into the negative-pressure generator, an atomizing spraying headinstalled at the end of the high-pressure water pipe and a diffusion plate located on the front part of the atomizing spraying head, atomized water ejected by the atomizing spraying head touches thediffusion plate and then bounces and diffuses and is mixed with sucked dust to form dust-containing water mists to eject to the gun muzzle, and high-efficiency dust falling is achieved.

Owner:陈业武

Cleaning and dust removing device for engineering surveying and mapping

ActiveCN113894079AAvoid the problem of low cleaning efficiencyImprove cleaning efficiencyHuman health protectionUsing liquid separation agentGear driveGear wheel

The invention discloses a cleaning and dust removing device for engineering surveying and mapping, and relates to the technical field of engineering surveying and mapping. The cleaning and dust removing device comprises a cleaning box, a spraying device is fixed to the top of the cleaning box, the output end of the spraying device extends into the cleaning box, an air injection fan and a motor are sequentially fixed to the right side of the cleaning box from top to bottom, the output end of the air injection fan extends into the cleaning box, an output shaft of the motor is rotationally installed on the right side of the cleaning box in a penetrating mode, a U-shaped frame is fixed to the bottom of the inner wall of the cleaning box, and a clamping device is arranged inside the U-shaped frame. According to the cleaning and dust removing device for engineering surveying and mapping, an arc-shaped rack on the upper side is matched with a gear, when the gear rotates to the arc-shaped rack, the arc-shaped rack drives the gear to rotate, so that the gear drives a telemeter rod to rotate along with the gear through an elastic telescopic rod, the air injection fan conducts dust removal and cleaning on the telemeter rod in all directions, and the telemeter rod cleaning efficiency is improved.

Owner:海南优力检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com