Totally-closed dust suppression material guiding device

A fully enclosed and material-guiding technology, applied in the field of material-guiding systems, can solve problems affecting the health of workers in safe production, dust pollution in material-guiding troughs, poor sealing effects, etc., achieving remarkable practical effects, safe and reliable performance, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

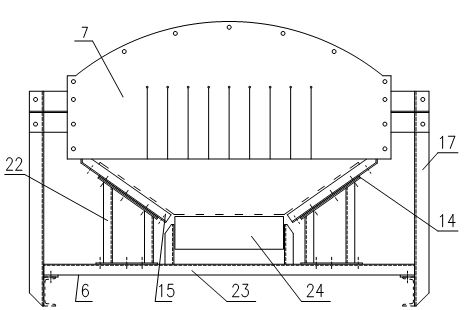

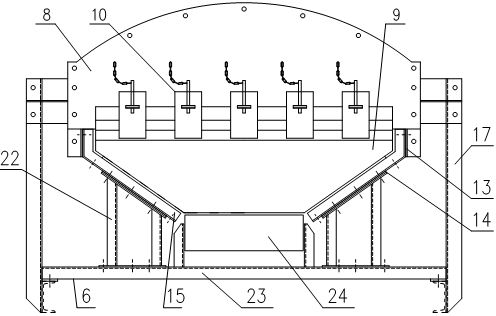

[0012] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, structural diagrams, and features provided according to the present invention are described in detail as follows:

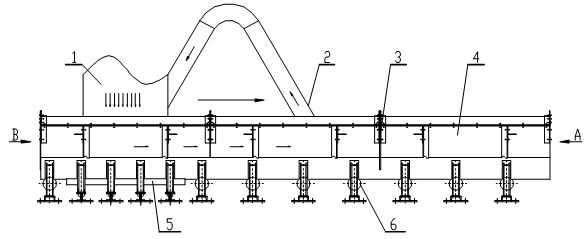

[0013] Such as Figure 1-Figure 5 As shown, a fully enclosed material guide system for dust suppression, the system includes a fully enclosed material guide trough 4, a special-shaped buffer bed 5, a special-shaped idler roller group 6, a return air duct 2 and a return air duct curtain 3.

[0014] The upper part of the fully enclosed material guide trough 4 is provided with an arc-shaped top plate 11, the opening provided on it corresponds to the feed chute 1, the return air pipe 2 is connected with the side plate of the chute 1, and a Establish the air return pipe retaining curtain 3, so form a closed circuit between the chute 1, the fully enclosed material guide chute 4 and the air return pipe 2 three.

[0015] The fully-enclosed material-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com