Energy-saving and environment-friendly milling machine for concrete pavement maintenance

A concrete pavement, energy saving and environmental protection technology, applied in the field of milling machines, can solve the problems of high cost and easy air pollution, and achieve the effects of saving electric energy, improving safety performance, and avoiding air pollution by exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

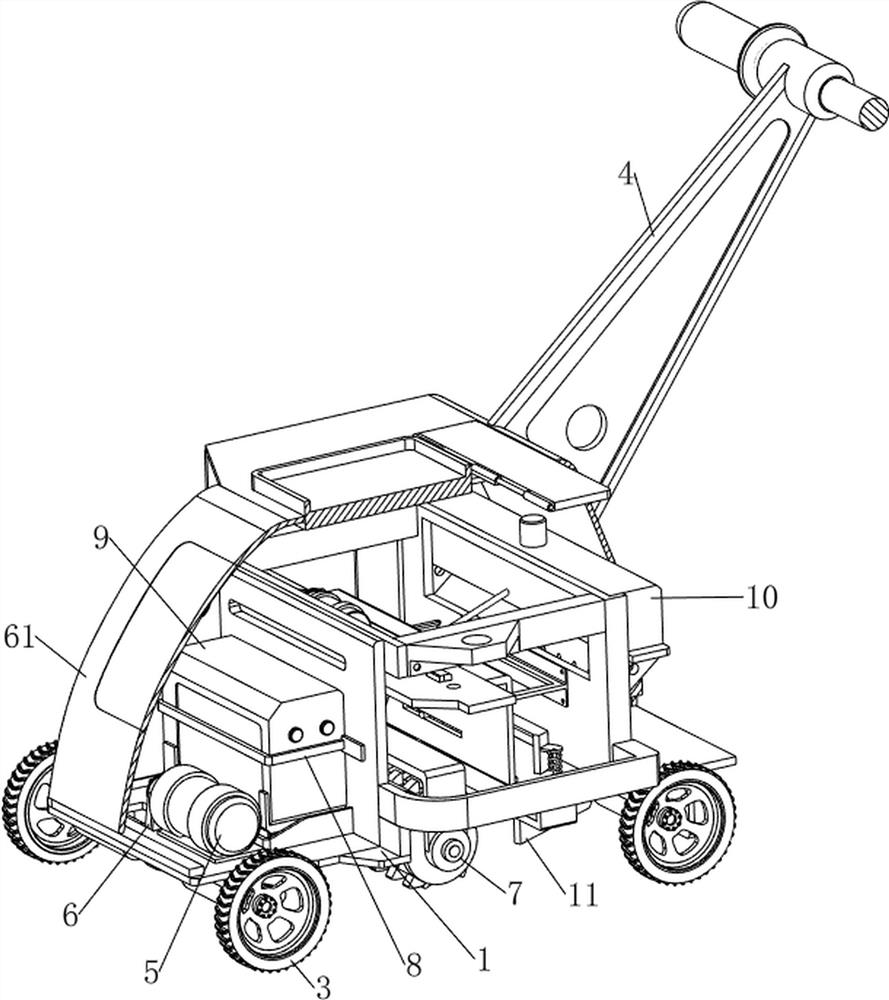

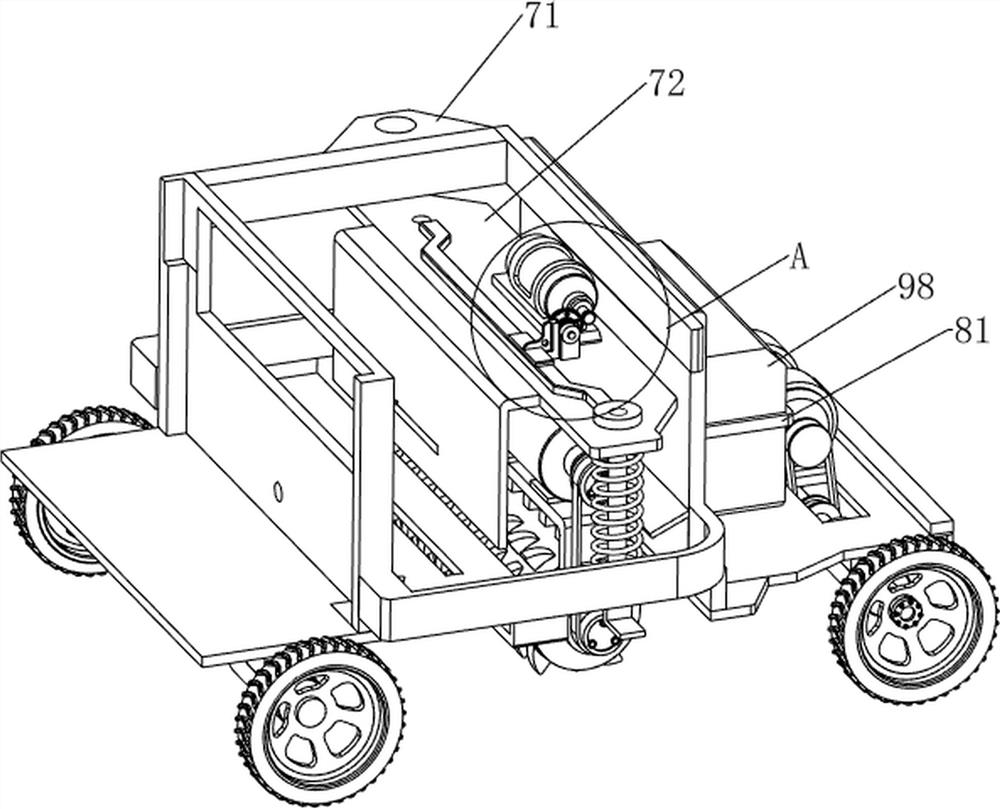

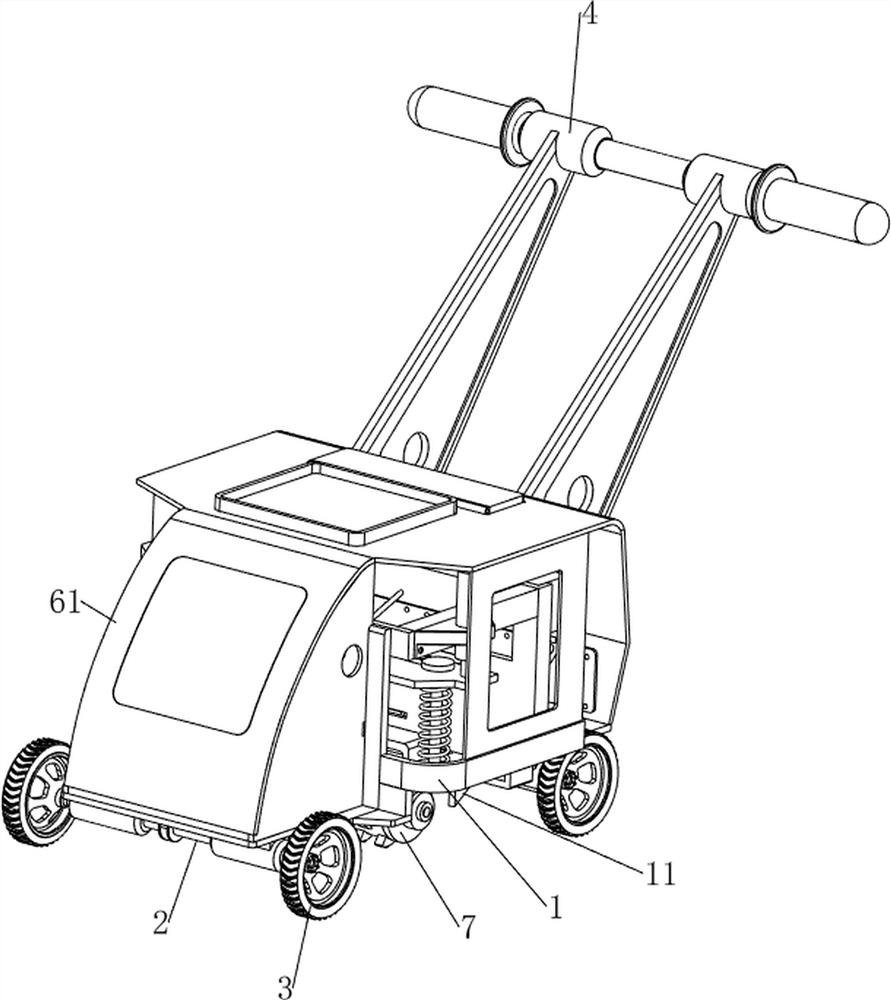

[0081] see figure 1 , figure 2 and image 3 , an energy-saving and environment-friendly milling machine for concrete pavement maintenance, comprising a frame 1, a first rotating shaft 2, a tire 3, a handle 4, a first motor 5, a first belt 6, a casing 61, a milling mechanism 7, and a buffer mechanism 8 and the power supply mechanism 9, the lower part of the frame 1 is symmetrically connected with the first rotating shaft 2 through bearings, and the left and right sides of the two first rotating shafts 2 are connected with tires 3, and the tires 3 are used to realize energy-saving and environment-friendly milling for the maintenance of the concrete pavement The machine moves, the top of the frame 1 is welded with a casing 61, the rear upper side of the casing 61 is welded with a handle 4, the front side of the inner bottom of the frame 1 is fixed with a first motor 5 by bolts, and the first motor 5 is connected to the left side of the output shaft of the first motor 5 and the ...

Embodiment 2

[0087] On the basis of Example 1, please refer to figure 2 , Figure 9 , Figure 10 and Figure 11 , also includes a dust-reducing mechanism 10, the dust-reducing mechanism 10 is used for dust-reducing the dust generated when chiseling, and the dust-reducing mechanism 10 includes a fourth support 101, a water storage tank 102, a fifth support 103, a first water pipe 104, a second Water pipe 105, sliding plug 106, second telescopic spring 107 and case cover 108, frame 1 upper right side is welded with fourth support 101, and the top of fourth support 101 is provided with water storage tank 102, and water storage tank 102 is used for storing water, storage The middle part of the water tank 102 is equipped with a detachable case cover 108, the case cover 108 is used to close the water storage tank 102, the upper right side of the frame 1 is fixedly connected with the fifth support 103 by bolts, the fifth support 103 is located on the left side of the fourth support 101, A fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com