Dust falling device for mine downhole fully-mechanized coal mining face shifting frame falling coal fog gun

A technology of fully mechanized mining face and dust suppression device, which is applied in mining devices, safety devices, dust prevention and other directions, can solve the problems of pollution of the working environment, endanger the health of operators, and affect the operation of operators, so as to improve the working environment and protect the The effect of good health and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

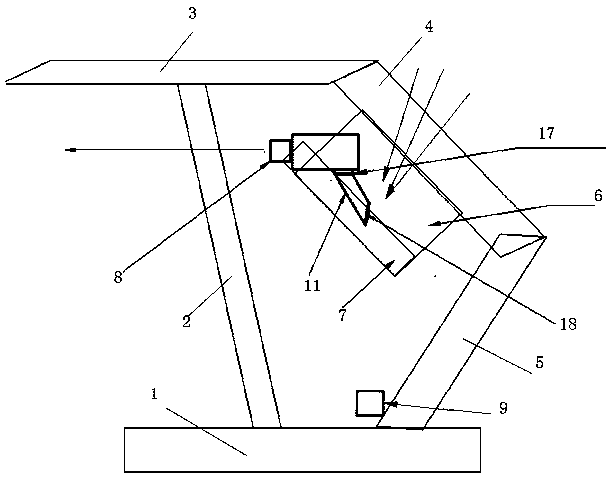

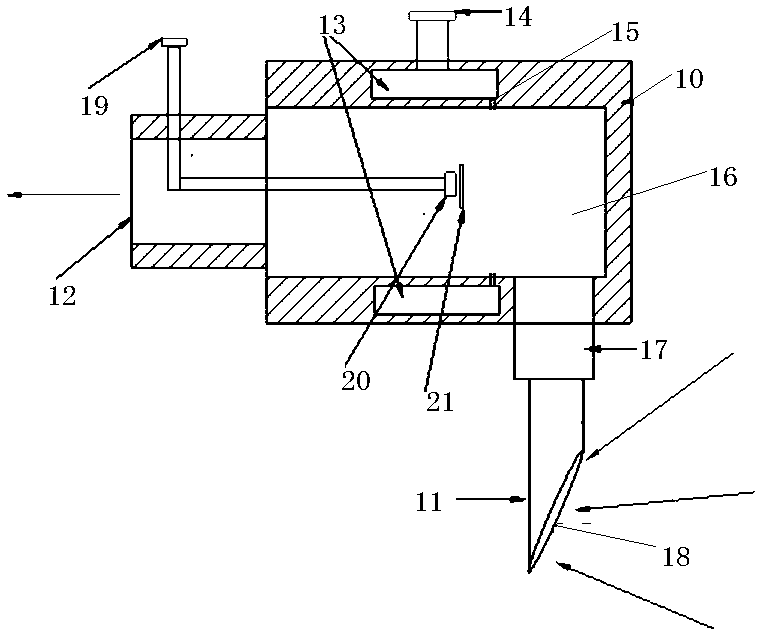

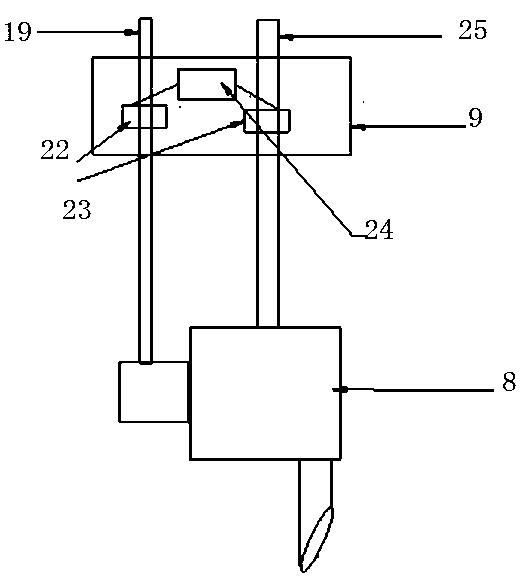

[0030] Such as figure 1 As shown, the present invention discloses a coal-spray cannon and dust suppression device for underground fully mechanized mining, which is installed on a hydraulic support. The hydraulic support includes a base 1 and a top beam 3 connected to the base through a telescopic hydraulic prop 2 , a cover beam 4 and a connecting rod 5 are arranged between the base and the top beam, the upper end of the cover beam is hinged with the top beam, the lower end is hinged with the upper end of the connecting rod, and the lower end of the connecting rod is hinged with the base, and one side of the cover b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com