Three-section multistage spraying dust reducing system for tunnel dust

A spray dust reduction and tunnel technology, which is applied in dust prevention, safety devices, mining equipment, etc., can solve problems such as increased energy consumption, narrow roads, and blockage of slag trucks, and achieve the effect of light mobility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

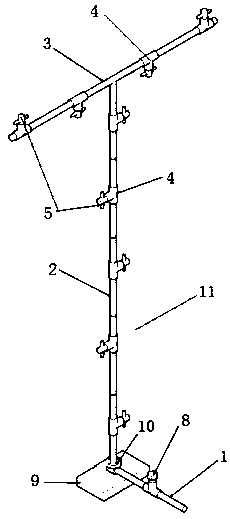

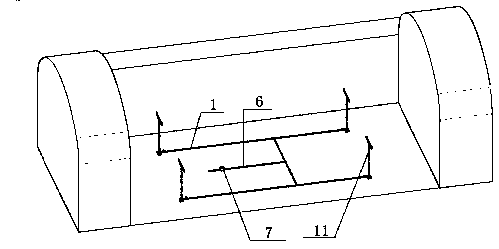

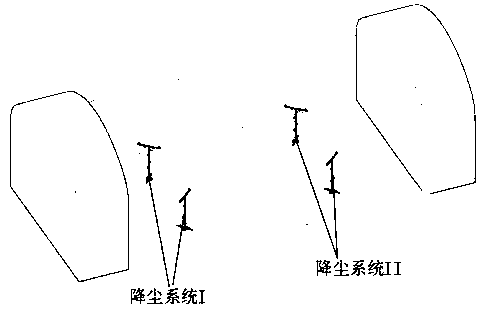

[0023] Embodiment of the present invention: a tunnel dust three-section multi-stage spray dust suppression system, as attached Figure 1-3 As shown, the dust suppression system is composed of multiple sets of spraying devices 11 with the same structure, and each set of spraying devices 11 includes a water delivery pipeline 1, and the water delivery pipelines 1 of multiple sets of spraying devices 11 are all connected with the water delivery main pipe 6, and The water main pipe 6 is connected to the water source outside the tunnel, the conveying main pipe 1 is fixedly connected with the vertical galvanized water pipe 2, the top of the vertical galvanized water pipe 2 is connected with the horizontal galvanized water pipe 3, and the vertical galvanized water pipe 2 and the horizontal galvanized water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com