Method for utilizing and disposing micro-electrolyzed waste residue of organic waste water and method for immobilizing arsenic and heavy metal in soil

A technology of organic wastewater and micro-electrolysis, applied in the environmental field, can solve the problems of surface water and marine environmental pollution, environmental damage, air pollution, etc., and achieve effective repair, good effect, and short treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

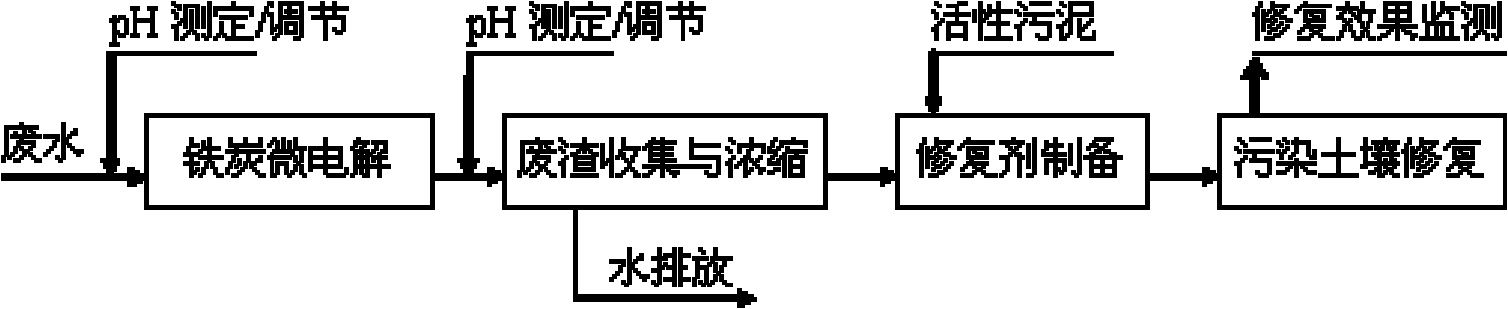

Method used

Image

Examples

Embodiment 1

[0030] Laboratory preparation of soil sample restoration implementation steps.

[0031] ①Organic wastewater, iron-carbon micro-electrolysis waste: if there is wastewater, use concentrated sulfuric acid to adjust the pH=3.0, and treat it with a catalytic iron-carbon micro-electrolysis column with a ratio of iron to carbon of 2:1, with a residence time of 1.0h, and the iron-carbon micro-electrolysis column uses 10 After adjusting the pH to 9.0, the% lime milk enters the advection sedimentation tank, and the retention time of the sedimentation tank is 1.5h. The waste residue is concentrated by suction filtration.

[0032] ②Preparation of repairing agent: The remaining activated sludge produced by the treatment of domestic sewage is mixed with the organic wastewater iron-carbon micro-electrolysis waste at a mass ratio of 3:1, and the composting process is performed for 28 days to obtain the repairing agent.

[0033] ③Remediation of soil pollution: Take dry land soil, analyze the water c...

Embodiment 2

[0035] Implementation steps for remediation of soil contaminated by percolation water in a lead-zinc mine tailing pond.

[0036] Laboratory preparation of soil sample restoration implementation steps.

[0037] ①Organic wastewater, iron-carbon micro-electrolysis waste residue: If there is wastewater, use 5% sulfuric acid solution to adjust the pH of the wastewater to 4.0, and treat it with a catalytic iron-carbon micro-electrolysis column with a ratio of iron: carbon: catalyst of 2:1:0.02, with a residence time of 1.5h, The effluent of the iron-carbon micro-electrolysis column adopts 5% lime milk to adjust the pH to 10.0 and then microflocculates. The waste residue is concentrated by a plate and frame filter press.

[0038] ②Preparation of repairing agent: The remaining activated sludge produced by the anoxic and aerobic (A / O) biochemical treatment of organic wastewater is mixed with the organic wastewater iron-carbon micro-electrolysis waste at a mass ratio of 2:1, and then composted...

Embodiment 3

[0041] Implementation steps of soil restoration in a certain paddy field by the Xiangjiang River in Huangchaling, Hengyang.

[0042] ①Organic wastewater, iron-carbon micro-electrolysis waste residue: same as Example 1.

[0043] ② Preparation of repair agent: same as in Example 1.

[0044] ③Remediation of soil pollution: Take 40kg of paddy soil, add 0.30kg of remediation agent to 20kg of soil and mix well, and add no remediation agent to the other 20kg of soil. Both are saturated with water; other extraction and analysis steps are the same as in Example 1.

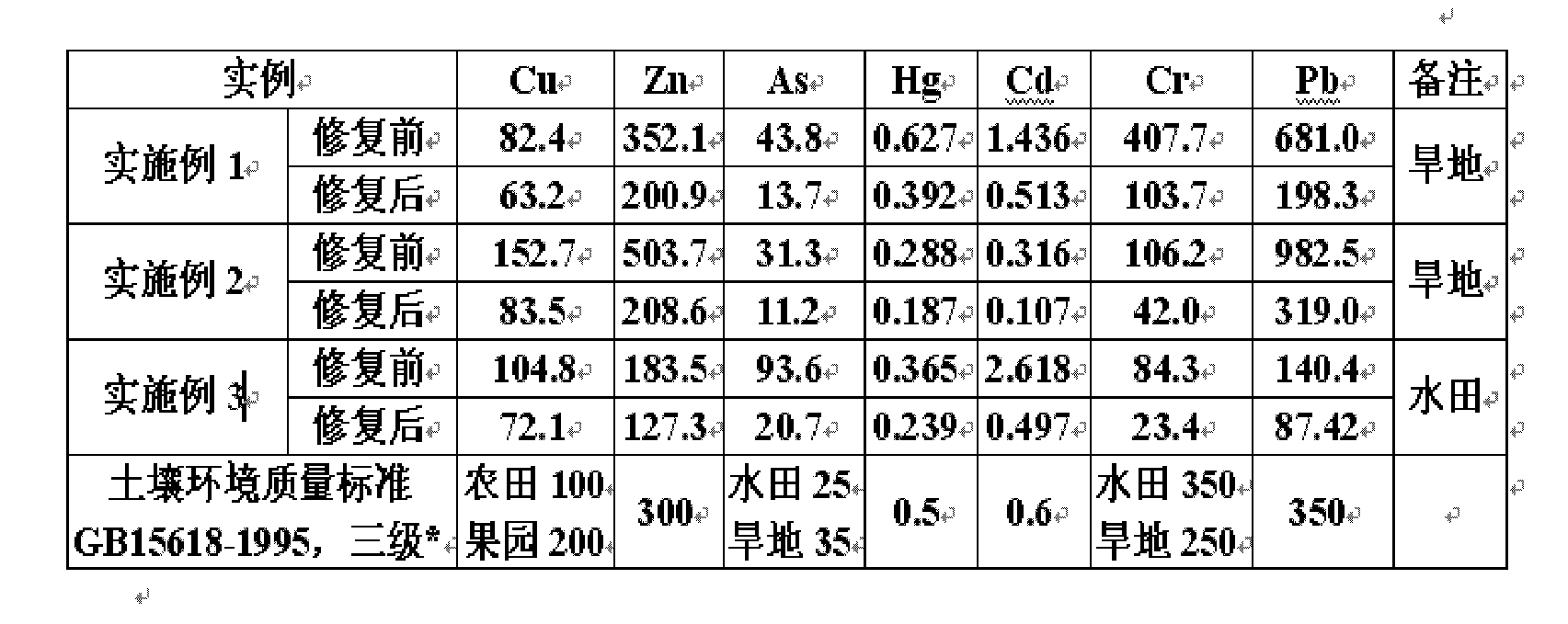

[0045] Table 1 shows the analysis results before and after soil restoration in Examples 1 to 3.

[0046] Table 1 Effect before and after soil restoration mg / kg

[0047]

[0048] *pH=6.5-7.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com