Patents

Literature

104 results about "Co composting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

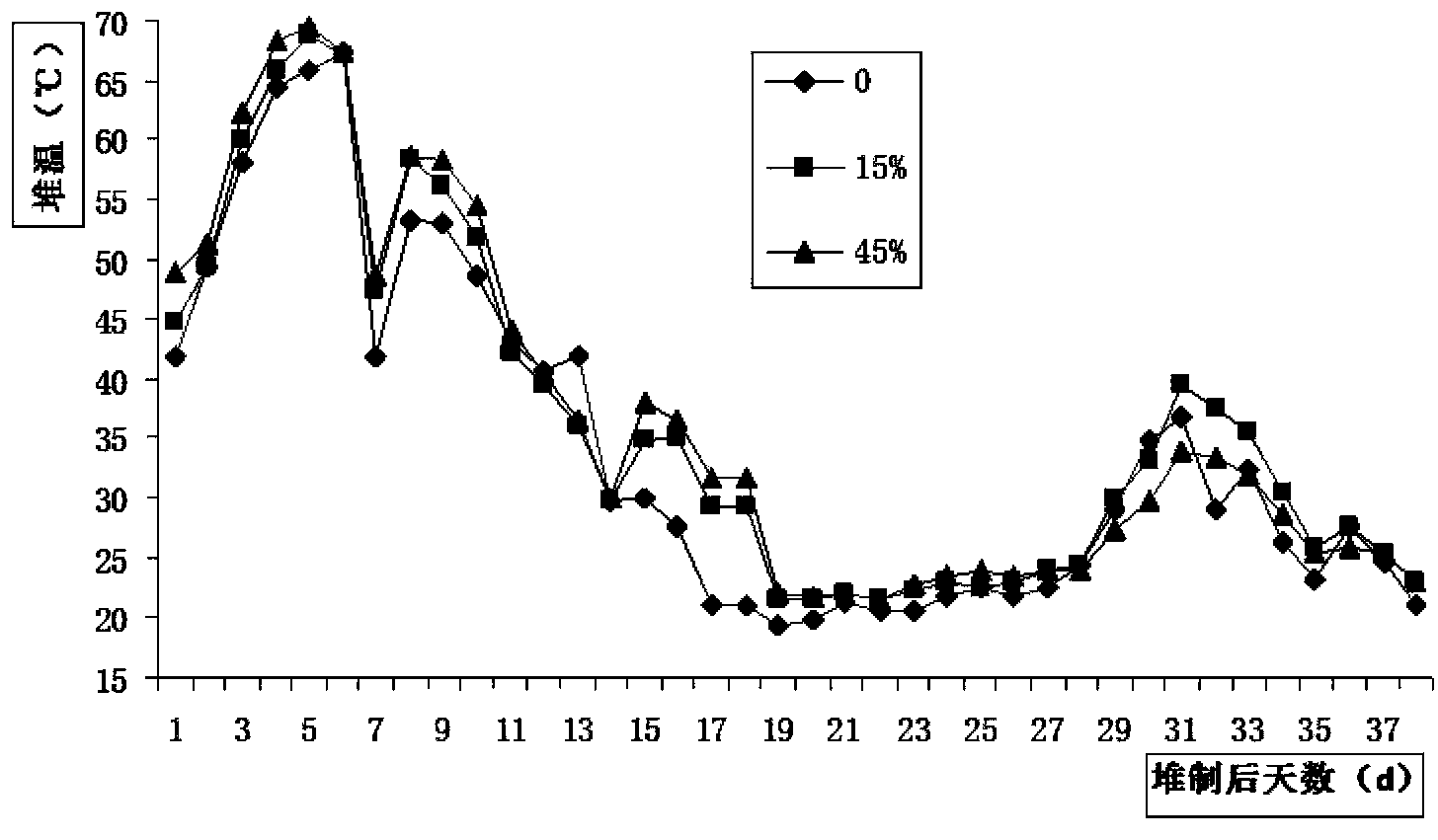

Co-composting is the controlled aerobic degradation of organics, using more than one feedstock (faecal sludge and organic solid waste). Faecal sludge has a high moisture and nitrogen content, while biodegradable solid waste is high in organic carbon and has good bulking properties (i.e., it allows air to flow and circulate).

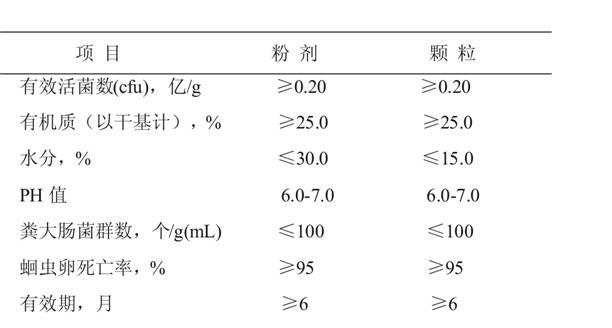

Bio-organic fertilizer produced by using livestock manure

ActiveCN102219570ASimple structureImprove conversion rateBio-organic fraction processingFungiLivestock manureAgricultural science

The invention provides an efficient active bio-organic fertilizer produced by using livestock manure and a preparation method thereof. The preparation method comprises the following steps: pre-treating the livestock manure, straw and peat; mixing the livestock manure, straw and peat at a weight ratio of (3-5):(1-2):(1-2); adding a composite ageing bactericide based on the condition that the weight ratio of the mixture to the high-concentrated organic material ageing bactericide is (5000-10000):(1-2), evenly mixing, and then carrying out composting fermentation for 7-10 days, wherein during the composting fermentation, the material needs to be stirred 1-2 times each day; and mixing the material decayed by fermentation with a functional composite bactericide which is generated by single fermentation at a weight ratio of (5000-1000):(1-2), granulating and drying at low temperature so as to obtain the high-efficiency and active bio-organic fertilizer. The process is relatively simple, is easy to operate, and can be used for lowering the product cost is low, saving energy and turning wastes into wealth, thereby being beneficial to promotion of benign ecological circulation and environment conservation; and by utilizing the fertilizer, the quality of the product is good, thereby obviously improving the yield and quality of agricultural products.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

Biological fermentation compost technique

InactiveCN103145465AAvoid pollutionIncrease production capacityBio-organic fraction processingOrganic fertiliser preparationBiotechnologyFermentation

The invention relates to a biological fermentation compost technique, comprising the following steps of 1, preparing a material and a tool for preparing biological fermentation compost; 2, carrying out aerobic fermentation of the biological fermentation compost; and 3, carrying out anaerobic fermentation of the biological fermentation compost. The biological fermentation compost technique has the beneficial effects that 1, environmental pollution control is achieved; 2, the soil is improved; and the land capacity is improved; 3, the technical bottleneck problem of the traditional agricultural production can be changed; and 4, the biological fermentation compost technique is wide in application range, economic and practical.

Owner:吴忠市萌源生物科技推广有限公司

Animal carrion and static compost hazard-free treatment method of products thereof

InactiveCN101838166AEnvironmental degradationEconomic degradationBio-organic fraction processingAnimal corpse fertilisersFecesPlant disease

The invention relates to an animal and a static compost hazard-free treatment method of products thereof, belonging to the field of environment protection. The method is characterized by comprising the step of simultaneously mixing carbon source accessories such as dry hay and the like and nitrogen source accessories such as animal wastes and the like with animal carrion and products thereof for composting. Based on the compost construction method, a single-layer or multi-layer construction method is adopted according to animal weight. After compost is constructed, the temperature of the compost is increased to 55 DEG C and maintained for more than 3 days or is increased to 45 DEG C and maintained for 7 days, so that disease microorganisms are inactivated basically. After the compost is constructed, the compost is statically treated and turned after a certain period of time, and the process is repeated until the compost is fermented so that the compost becomes thoroughly decomposed and can be applied. The invention is safe, environmental friendly and economical, and cheap compost accessories easily obtained in villages, such as dry hay, straw, animal wastes and on the like, are used for decomposing the animal carrion; the animal carrion and the products thereof can be thoroughly decomposed and converted into a beneficial green organic plant fertilizer; and a feasible method is provided for an application in animal epidemic outbreaks.

Owner:DALIAN UNIV OF TECH

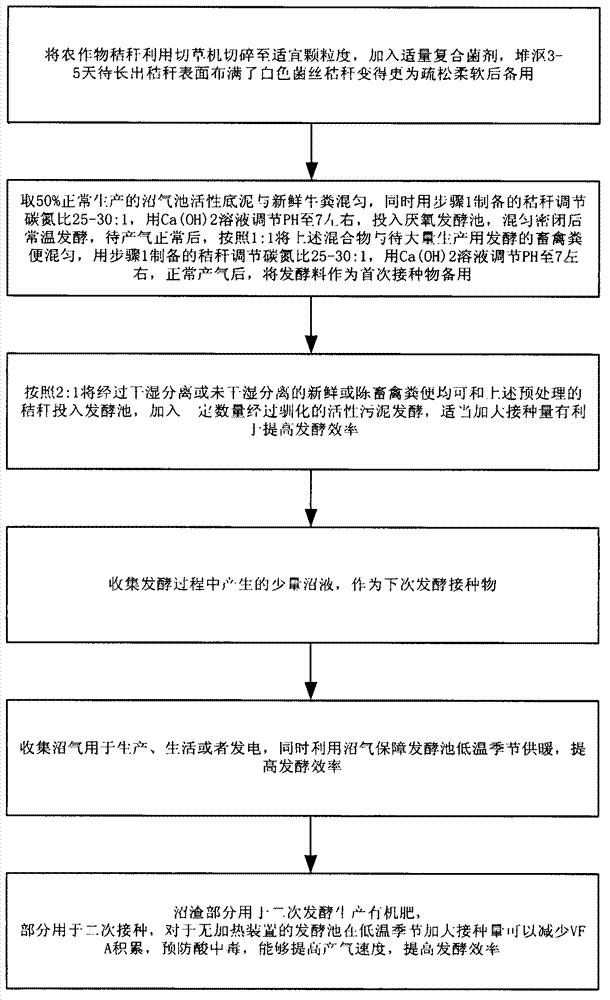

Method for producing methane by dry fermentation of beast and bird wastes and crop straws

InactiveCN102925494ANo ammonia poisoningReduce lossesBio-organic fraction processingClimate change adaptationFecesSlurry

The invention discloses a method for producing methane by dry fermentation of beast and bird wastes and crop straws. According to the method, solid beast and bird excrements with the dry material concentration of higher than 15% and crop straws which is subjected to pre-treatment are mixed according to a certain ratio and introduced to an anaerobic dry fermenting device together with naturalized active mud; a small deal of biogas slurry is recovered as inoculums, and fermentation residues are subjected to secondary compost to produce organic fertilizer. The method has the following advantages of high gas generation speed and high fermentation efficiency; the methane content is up to 50-65% which can meet the using demands of power generation and diary gas appliances; the produced organic fertilizer is unlikely to cause ammonia poison; eggs are killed completely; and the nitrogen fertilizer loss is low.

Owner:苏州市吴江区农业环境监测站

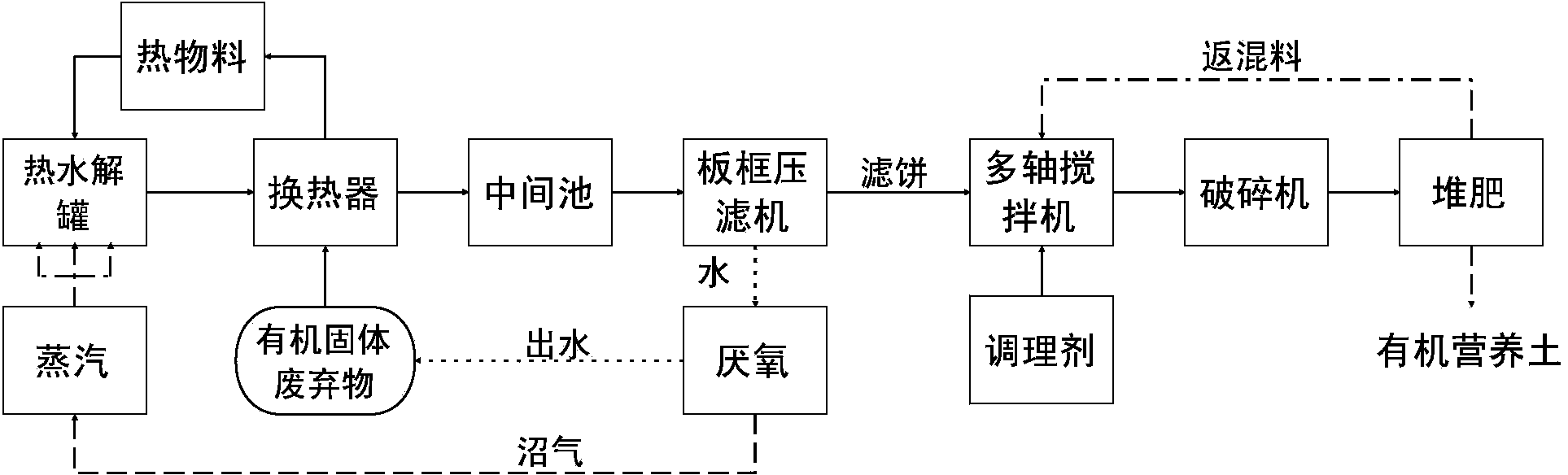

Thermal hydrolysis and high-temperature aerobic composting treatment process of organic solid wastes

ActiveCN104177145ASpeed up fermentationImprove dehydration effectBio-organic fraction processingClimate change adaptationOxygenFilter press

The invention discloses a thermal hydrolysis and high-temperature aerobic composting treatment process of organic solid wastes. The process comprises the following steps: preheating the organic solid wastes with the solid content of 10%-15% by virtue of a heat exchanger, performing thermal hydrolysis on hot steam with pressure of 0.4-1.0MPa and temperature of 150-190 DEG C, dehydrating the treated materials in a plate-and-frame filter press to form filter cakes with the water content of 35%-50%, adding proper conditioners and back-mixing materials into the filter cakes, and finally performing high-temperature aerobic composting treatment in a composting system to form organic nutritional soil. Compared with a conventional composting system, the process has the characteristics that the conditioner consumption is greatly reduced, the composting speed is relatively high, the composting effect is relatively good, and the treating capacity of the composting system is increased by 2-3 times.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

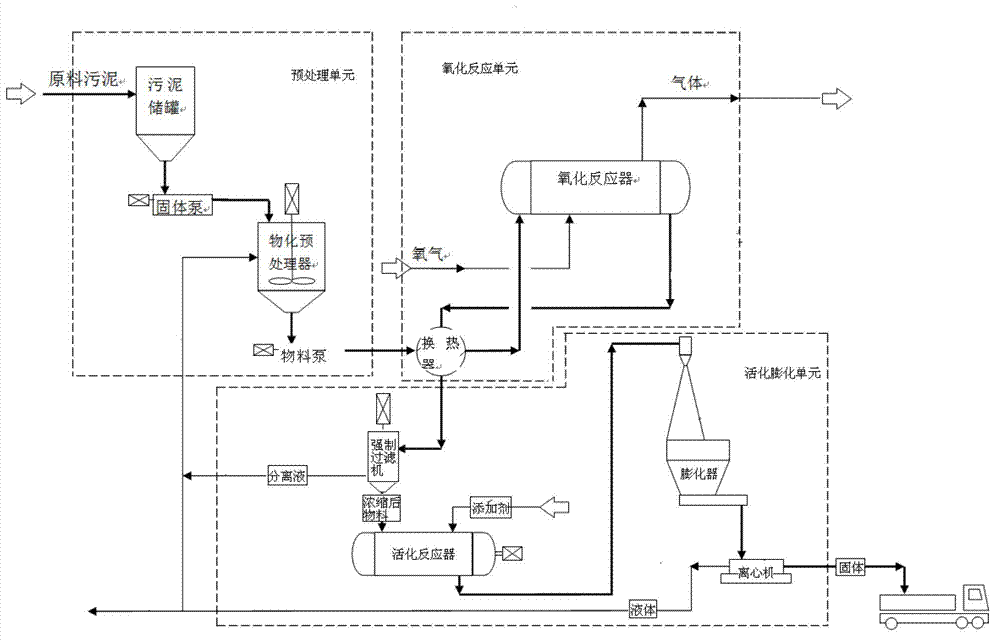

Method for rapid recycling of sludge

ActiveCN102786190AFacilitate solid-liquid separationSmall filter specific resistanceSludge treatmentFiltrationLandscaping

The invention discloses a method for rapid recycling of sludge. The method comprises the following steps that: (1) raw material sludge is conveyed into a physicochemical preprocessor to prepare with water; (2) the prepared sludge is conveyed to an oxidation reactor through a heat exchanger, simultaneously oxygen is feed into the oxidation reactor, and the sludge and the oxygen are subjected to a part wet oxidation reaction in the oxidation reactor; (3) high-temperature materials and gas are obtained from the part wet oxidation reaction, with the gas being discharge and the high-temperature materials being inputted to the heat exchanger; (4) the high-temperature materials enter into a forced filter after passing through the heat exchanger, and concentrated materials obtained from the forced filter enter into an activating reactor to take an activation reaction; and (5) the activated materials enter into a puffing device to puff, and the puffed materials enter into a centrifuge to separate solid and liquid, thereby realizing the rapid recycling of the sludge. According to the method provided by the invention, the processed products is relatively easy to separate solid and liquid, specific filtration resistance is relatively small, and the product is free of toxicity and stink, and can be used as soil amendment and landscaping fertilizer or compost raw materials, etc.

Owner:北京绿创生态科技有限公司

Method for producing organic fertilizer by mixing and composting microbial inoculum fermentation fungi residue and pig manure

InactiveCN103613419AIncrease productionSimple structureBio-organic fraction processingOrganic fertiliser preparationBiotechnologyDecomposition

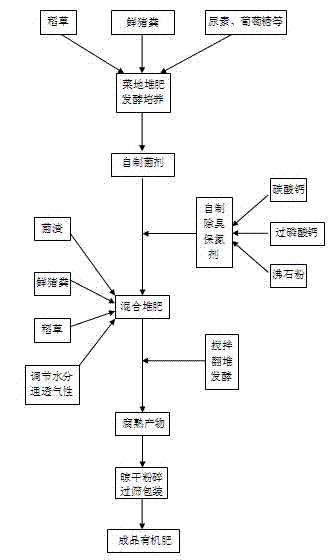

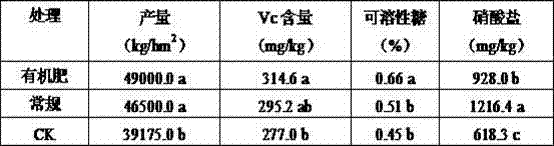

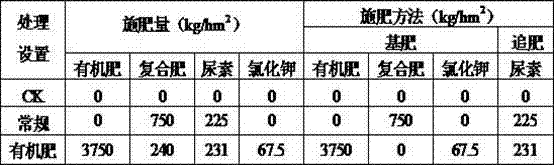

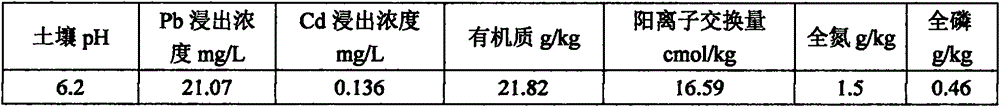

The invention relates to a method for producing an organic fertilizer by mixing and composting microbial inoculum fermentation fungi residues and pig manure. The method is realized through a series of steps of preparing a self-made microbial inoculum and a self-made deodorizer, mixing and composting the treatment fungi residues and the pig manure to produce the organic fertilizer, and the like. The method disclosed by the invention has the advantages of fast starting, high fermentation temperature, long high temperature duration time, thoroughness in composting decomposition, thoroughness in pathogenic bacteria and harmful worm egg killing, few nutrient loss, high organic fertilizer quality, small investment, simple process, easiness and convenience in operation and short treatment period, is favorable to generalization and popularization, can achieve the dual purposes of alleviating the pollution of wastes on the environment and realizing the recycling of the wastes.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

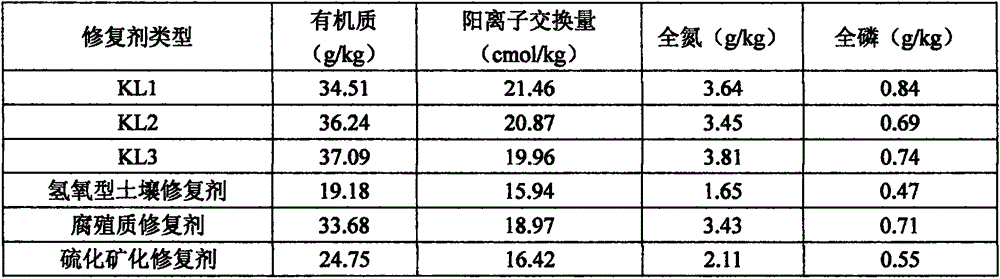

Preparation method of sulfurized modified charcoal soil restoration conditioner

ActiveCN105860986AEnvironmental changes (such as pH) have little effectReduce the impactOrganic fertilisersSoil conditioning compositionsClay mineralsLivestock manure

The invention provides a preparation method of a sulfurized modified charcoal soil restoration conditioner. The method comprises the following technological steps that 1, biomass is placed under the temperature of 400-600 DEG C for pyrolysis carbonization for 1-2 h, and charcoal is obtained; 2, clay minerals are smashed and screened by a 120-mesh screen for use; 3, a sulfurizing agent and the screened clay minerals are mixed according to the mass ratio being (1-10):100 and placed under the temperature of 100-150 DEG C for 60-70 min, sulfurized modified clay is formed; 4, the sulfurized modified clay, livestock manure and charcoal are mixed according to the mass ratio of (0.5-5):(35-45):55 for composting, the carbon nitrogen ratio is controlled to be (30-35):1, the composting time is 20-30 d, the water content is controlled to be 50-60%, and the soil restoration conditioner is formed. Heavy metal in soil can be efficiently stabilized and slightly affected by environmental changes such as pH; organic matters, nitrogen and other soil nutrient elements in restored soil can be improved and soil fertility can be effectively improved while heavy metal in the soil can be stabilized and the soil structure is not damaged.

Owner:HUNAN JINLV ENVIRONMENTAL PROTECTION CO LTD

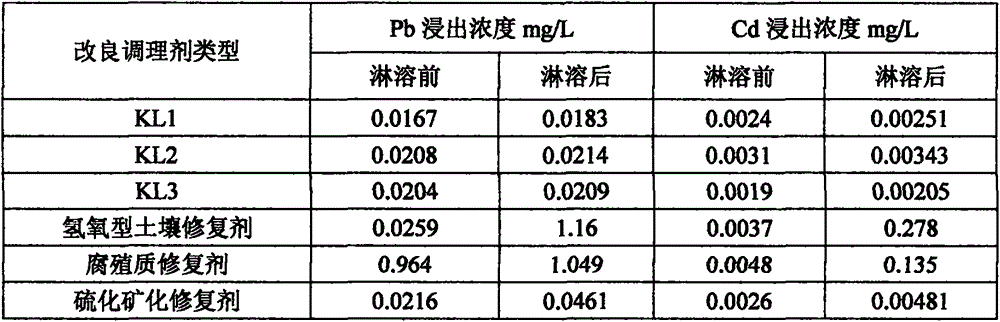

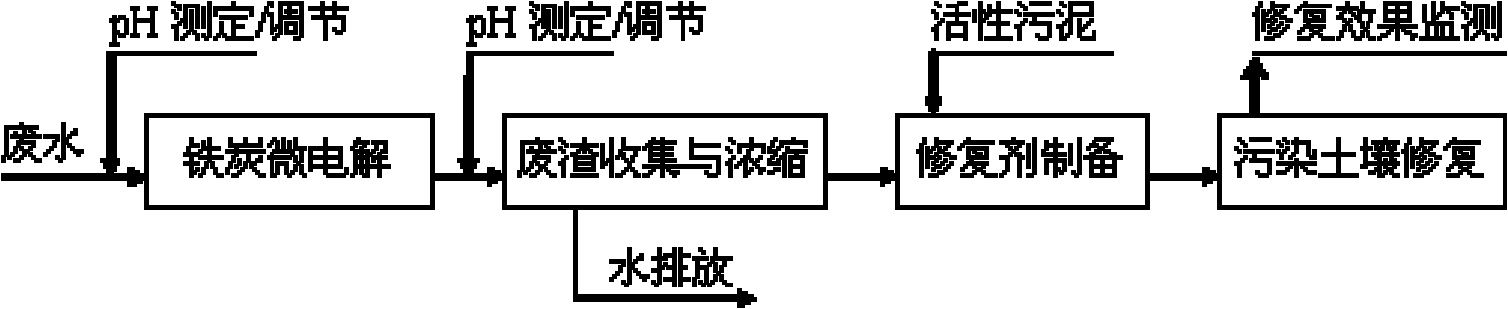

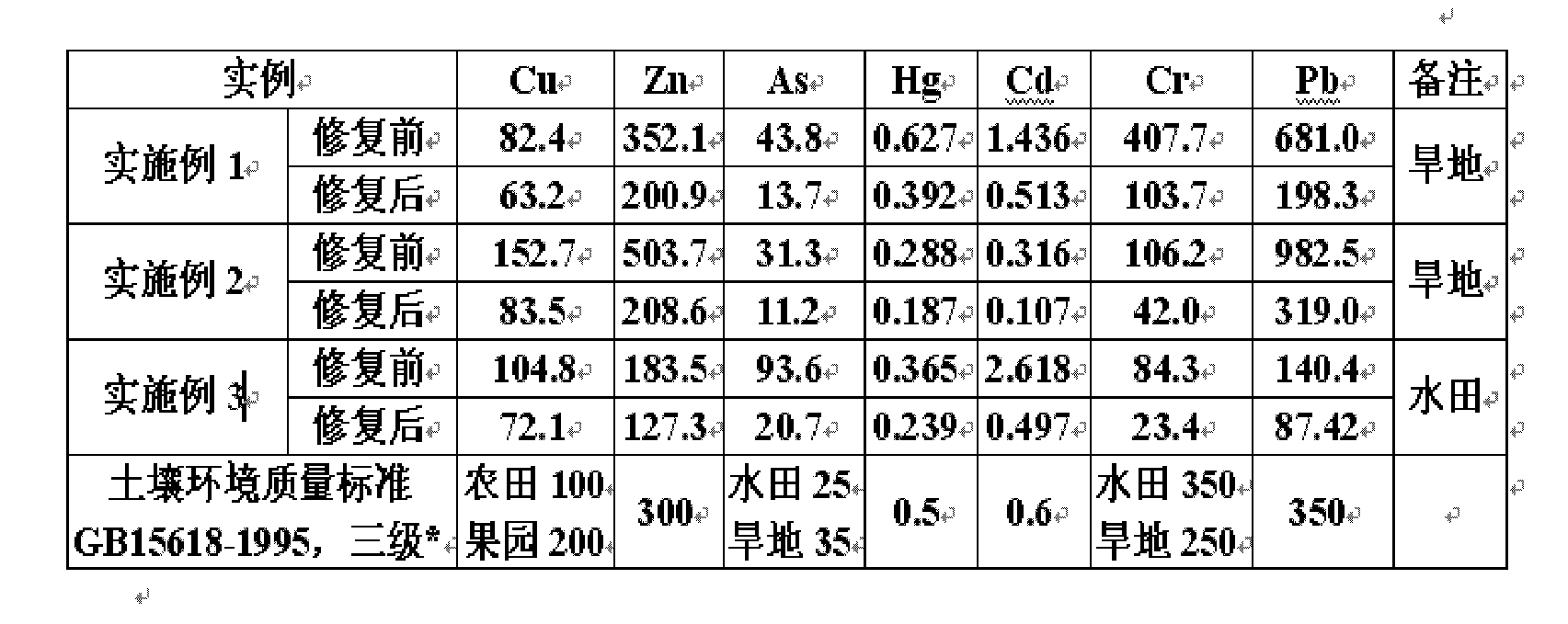

Method for utilizing and disposing micro-electrolyzed waste residue of organic waste water and method for immobilizing arsenic and heavy metal in soil

InactiveCN101791624AEfficient disposalEnhance agricultural securityContaminated soil reclamationWater/sewage treatmentActivated sludgeElectrolysis

The invention relates to a method for utilizing and disposing micro-electrolyzed waste residue of organic waste water, a method for immobilizing arsenic and heavy metal in soil and a method for utilizing and disposing micro-electrolyzed waste residue and activated sludge of organic waste water. The invention is characterized in that iron carbon is used as main filler for the micro electrolysis of the organic waste water, the waste residue (solids) produced after the micro electrolysis of the iron carbon is collected, concentrated and mixed with the activated sludge, inorganic / organic mixed restoration agent is prepared after 10-50 days of composting treatment are conducted, the weight of the iron in the restoration agent accounts for (0.5-20) percent of the total weight of the solids, finally deep tillage is conducted to restore the pollution soil after the restoration agent is evenly dispersed in soil, and the weight ratio of the restoration agent to the polluted soil is (0.1-5.0):100.

Owner:CENT SOUTH UNIV

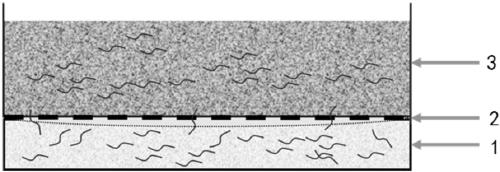

Biomass-charcoal-containing composting system and composting method

ActiveCN105175044AIncreased nitrate nitrogen contentPromote rapid reproductionBio-organic fraction processingOrganic fertiliser preparationMicroorganismFermentation

The invention discloses a biomass-charcoal-containing composting system and composting method. The biomass-charcoal-containing composting system mainly comprises the following raw materials in parts by weight: 92-110 parts of basic composting material, 0.3-0.5 part of microbial inoculant and 0.9-1.8 parts of biomass charcoal. The basic composting material comprises sludge and straws, wherein the sludge and straws are mixed, so that the carbon-nitrogen ratio of the basic composting material is 20-30, and the water content of the basic composting material is 50-70%. The method comprises the following steps: mixing the raw materials for constituting the basic composting material, adding the microbial inoculant and biomass charcoal into the basic composting material, and uniformly mixing to obtain the composting system. A three-step fermentation process is utilized to perform composting fermentation on the composting system for 28-32 days, thereby obtaining the biological compost.

Owner:HEBEI UNIVERSITY

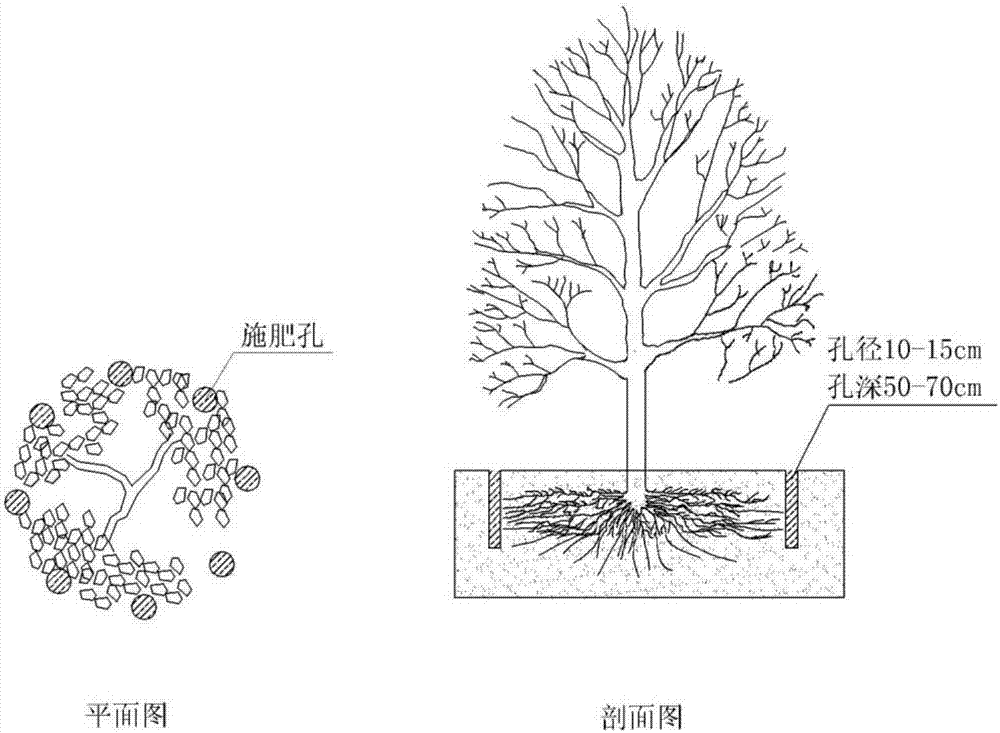

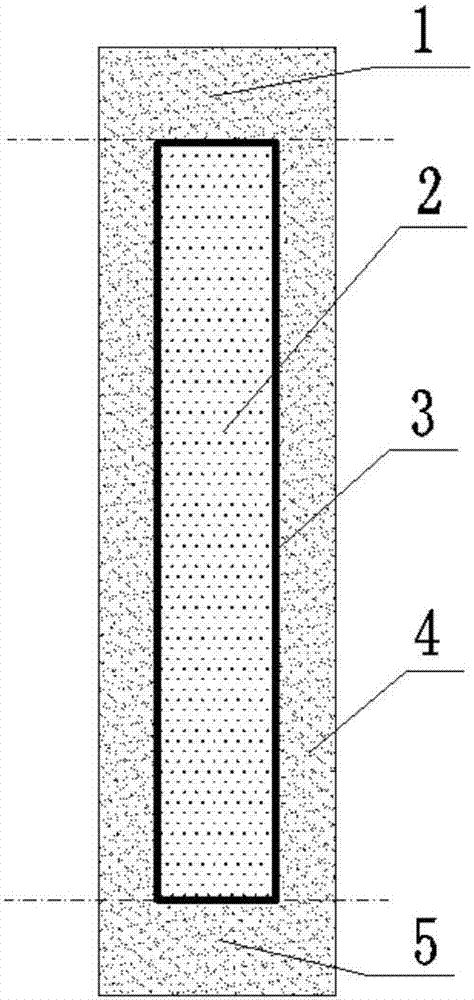

Preparation and application methods of stick fertilizer with synergy of reduced application of chemical fertilizers and increased application of organic fertilizers

InactiveCN106883066AIncrease motivationEffectively deal with major bottlenecks that are difficult to comprehensively reduce application and increase efficiencyExcrement fertilisersBioloigcal waste fertilisersLivestock manureSludge

The invention provides a stick fertilizer with synergy of reduced application of chemical fertilizers and increased application of organic fertilizers. The stick fertilizer is prepared from organic materials, inorganic materials and auxiliary additive materials, wherein the organic materials are prepared from a finished product obtained by decomposing after composting mushroom residue, a finished product obtained by decomposing after composting straws, a finished product obtained by decomposing after composting livestock manure, a finished product obtained by decomposing after mixing and composting biogas residue and mushroom residue, a finished product obtained by decomposing after mixing and composting sludge and mushroom residue and a finished product obtained after decomposing peat and oil cakes; the inorganic materials are prepared from slow-release compound fertilizers and / or slow-release elemental chemical fertilizers; the auxiliary additive materials are prepared from copper sulfate, zinc sulfate, ferrous sulfate, molybdenum sulfate, ammonium molybdate, manganese sulfate, calcium chloride, fulvic acid or humic acid. Through the stick fertilizer, the organic fertilizers and the inorganic fertilizers are collaboratively applied; the stick fertilizer has the advantages that the application quantity of the chemical fertilizer is reduced, the application efficiency of the chemical fertilizers is improved, and the application quantity of the organic fertilizers is increased; the stick fertilizer is prepared by mixed pressing or separately pressing; the preparation method is simple; the stick fertilizer is deeply applied by drilling holes; the application frequency is low; the labor and the effort of operation are reduced; after the stick fertilizer is applied to fruit trees, the fruit trees are high in yield and high in quality.

Owner:CHONGQING LANDSCAPE & GARDENING RES INST

Rapid composting method of water plant by utilization of biomass charcoal

ActiveCN103396179AFast compostingReduce moisture contentBio-organic fraction processingOrganic fertiliser preparationMixed materialsHigh water content

A rapid composting method of a water plant by utilization of biomass charcoal is characterized by successively comprising the following steps: the first step, weighing raw materials: the raw materials comprises a base composting material and the biomass charcoal, the base composting material comprises a fresh water plant and air-dried straw, the ratio of the fresh water plant to the air-dried straw is configured based on that the range of the dry-basis carbon nitrogen ratio of the base composting material being 22-28, according to the actual water content, natural weight is obtained by conversion, an input amount of the biomass charcoal is 40%-50% of the dry-basis weight of the base composting material, and the water content after mixing of the three raw materials is controlled between 60% and 75%; the second step, evenly mixing the weighted three raw materials to produce a mixed material, and putting the mixed material to a composting place; and the third step, carrying out composting treatment of the mixed material until the mixed material forms a humic substance, namely a organic fertilizer product. Through use of the rapid composting method, a conventional dewatering volume-reduction pretreatment process of the high-water-content fresh water plant is omitted, and two-way synergy of rapid composting and ammonia emission reduction of the fresh water plant can be realized.

Owner:江苏太湖地区农业科学研究所

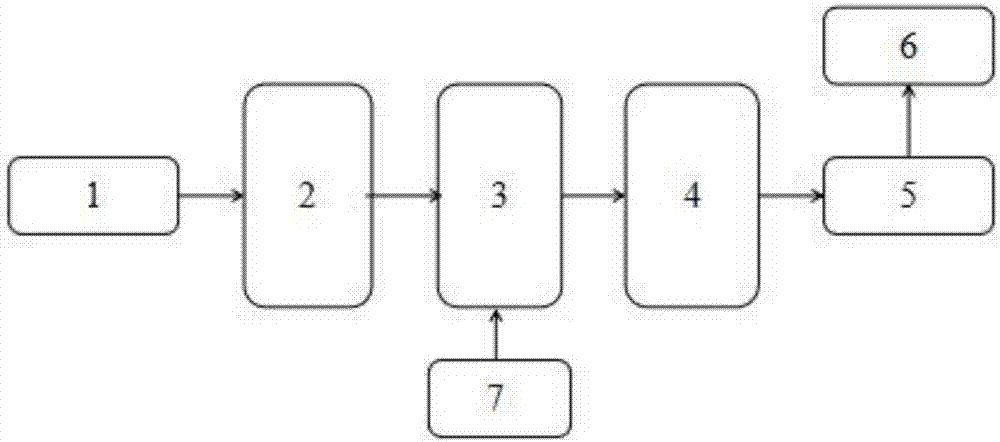

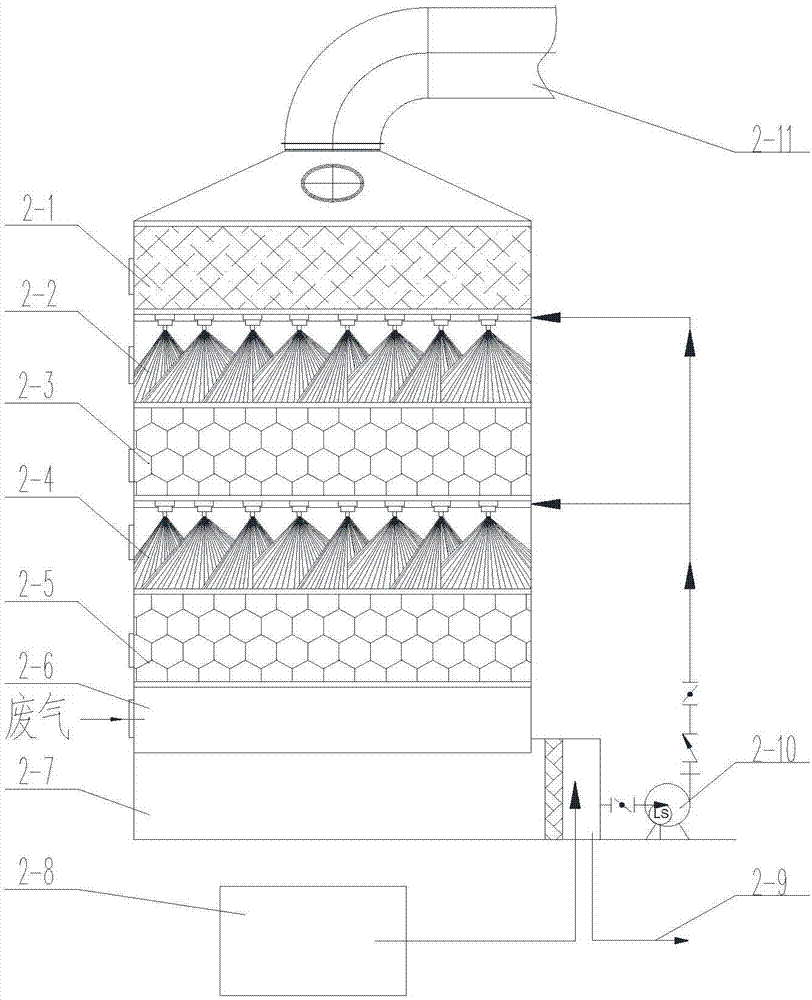

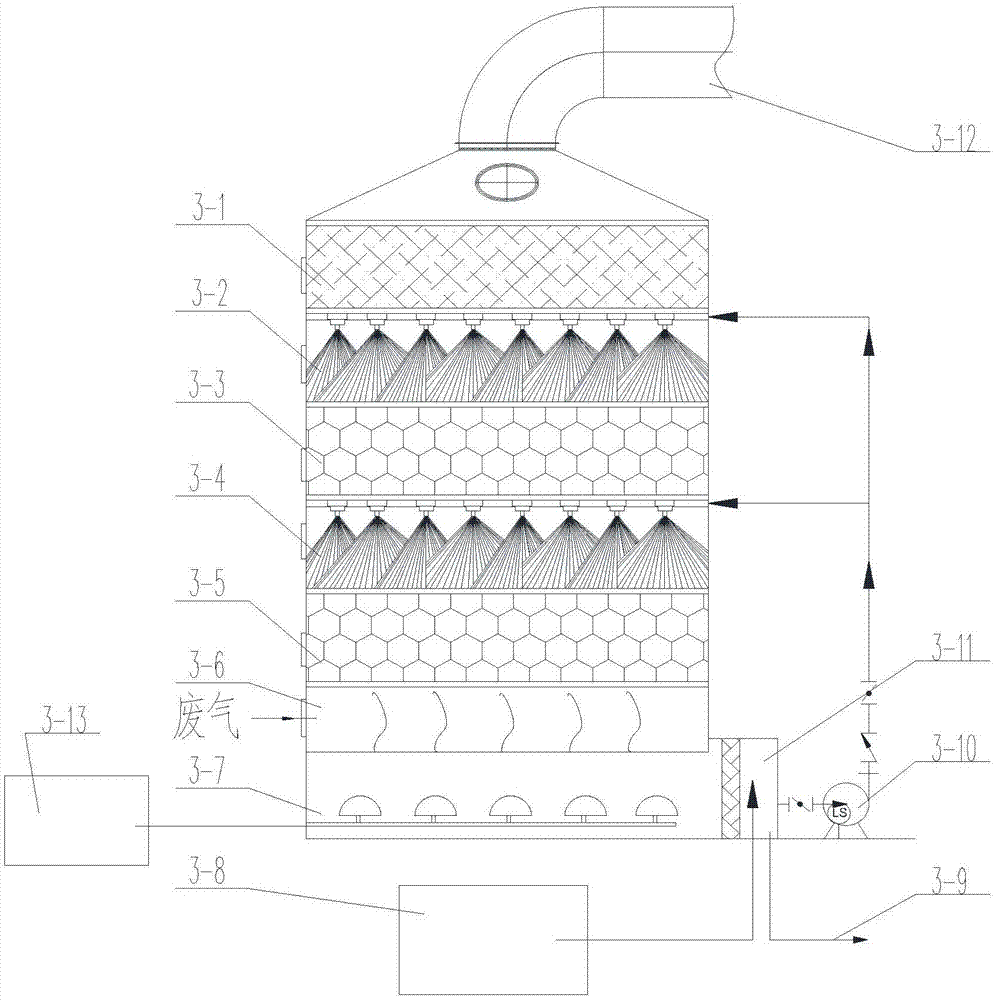

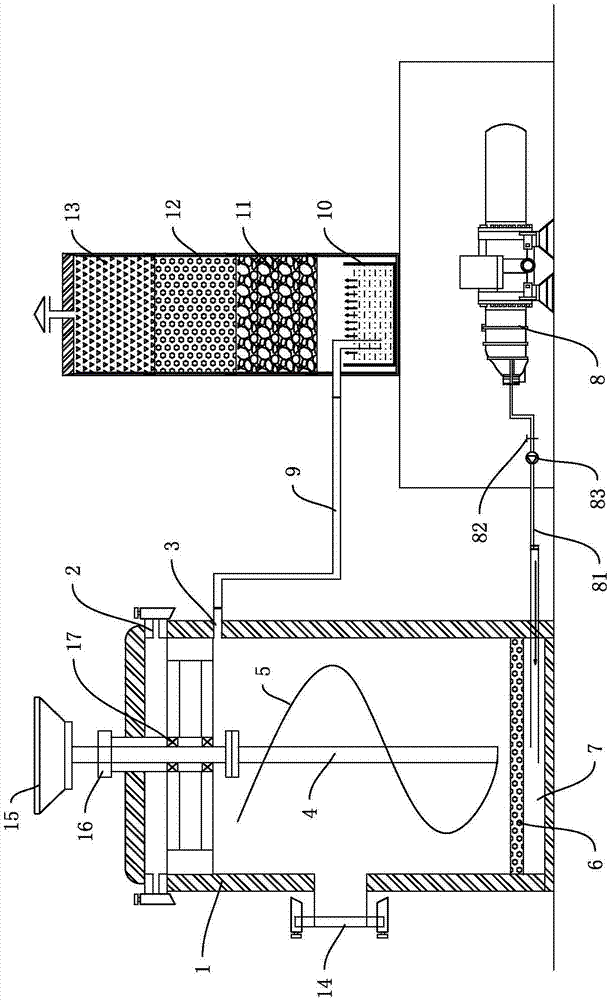

Oxidation treatment system for waste gas produced during innocent treatment of animal manure

InactiveCN106861395AThorough treatmentImprove securityGas treatmentWaste water treatment from animal husbandryEnvironmental resistanceEngineering

The invention relates to an oxidation treatment system for waste gas produced during innocent treatment of animal manure. The system comprises a waste gas collection area (1), an acid pickling spray tower (2), an oxidation spray tower (3), an acid-base neutralization tower (4), an exhaust fan (5), a chimney (6), a positive charge ozone generator (7) and the like. The waste gas oxidation system can specifically remove waste ammonia gas, hydrogen sulfide, volatile organic compounds and the like produced in the composting fermentation engineering, and has the advantages of thorough waste gas treatment, good effect, low cost, stable process, high safety and high cost performance; and the ammonium sulfate rich waste liquid produced by the waste gas oxidation treatment system is not discharged to the outside but serves as a nitrogen element and water supplement liquid in the biological organic fertilizer granulation process, so that the system does not produce secondary pollution, realizes reuse of waste resources and is beneficial to environment protection.

Owner:秦皇岛领先康地农业技术有限公司

Composting method

InactiveCN101973794AReduce waste of resourcesEasy to operateClimate change adaptationOrganic fertilisersFertilizerDecomposition

The invention discloses a composting method, comprising the following steps of: (1) mixing a composting raw material and a microbial inoculum to obtain a compost body; (2) fermenting the compost body at high temperature to obtain a primary composting product; and (3) continuing fermenting the primary compost product to obtain a fertilizer. Experiments prove that in the invention, based on the concepts that the activity and the diversity of microorganisms are promoted by high temperature in the composting process and large amount of heat energy is generated from the high-temperature decomposition of organic matters by microorganisms, the heat energy from high-temperature fermentation is also recycled in the composting process at the same time of adding the microorganism microbial inoculum in the composting process.

Owner:CHINA AGRI UNIV

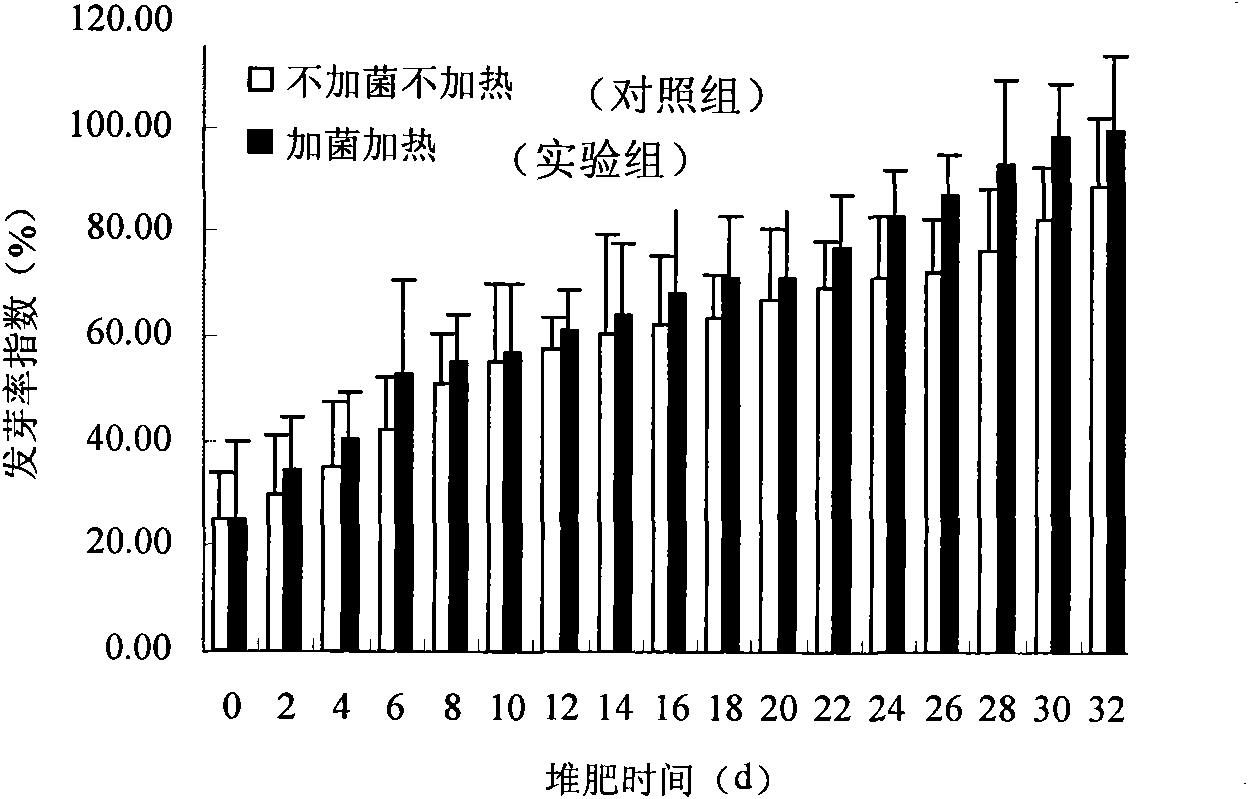

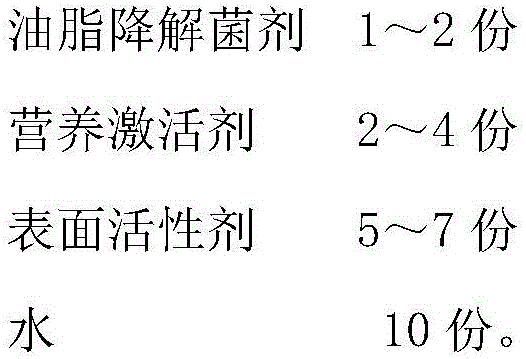

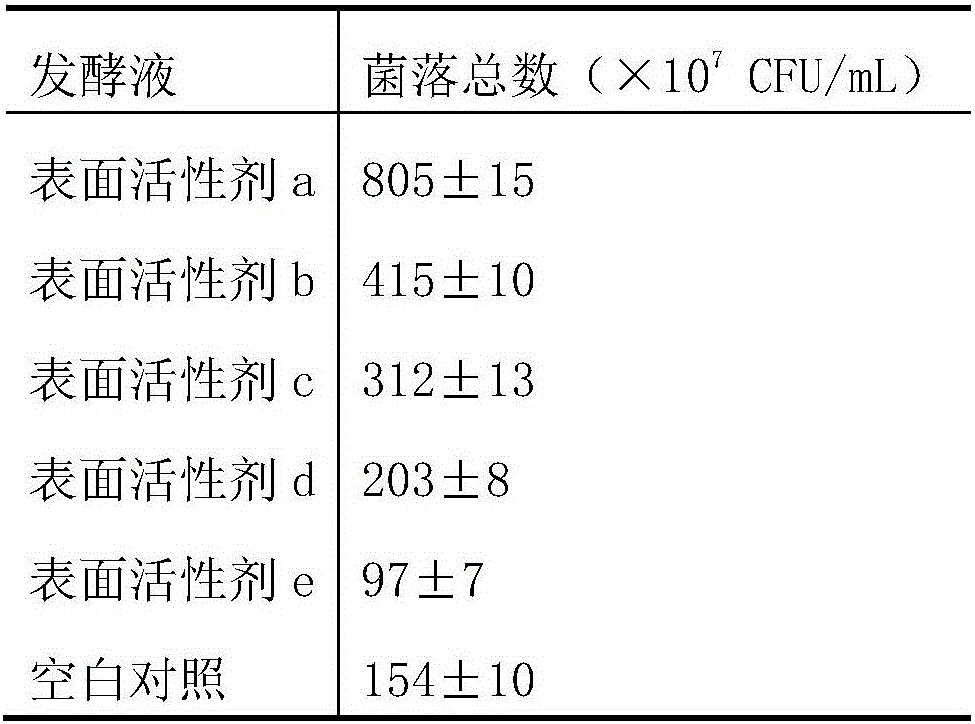

Efficient aerobic composting oil removing preparation for kitchen waste and method for preparing efficient aerobic composting oil removing preparation

ActiveCN106187335AImprove composting efficiencyFast degradationClimate change adaptationOrganic fertilisersBacillus licheniformisRoom temperature

The invention discloses an efficient aerobic composting oil removing preparation for kitchen waste. The efficient aerobic composting oil removing preparation comprises grease degradation bacteria, nutrition activators and surfactants. The grease degradation bacteria include bacillus subtilis, bacillus coagulans or / and bacillus licheniformis; the surfactants are neutral surfactants without disinfection effects. The invention further provides a method for preparing the efficient aerobic composting oil removing preparation. The method includes steps of (1), weighing the grease degradation bacteria and the nutrition activators according to a weight ratio, stirring the grease degradation bacteria, the nutrition activators and water, mixing the grease degradation bacteria, the nutrition activators and the water with one another to obtain mixed liquid and then allowing the mixed liquid to stand still at the room temperature for 2-4 hours; (2), adding the surfactants into the mixed liquid obtained at the step (1), mixing the surfactants and the mixed liquid with one another and dissolving the surfactants in the mixed liquid to obtain the efficient aerobic composting oil removing preparation. The efficient aerobic composting oil removing preparation and the method have the advantages that grease can be emulsified, the microbial grease degradation speeds can be increased, in other words, the composting efficiency of the kitchen waste can be improved, and the grease content can be reduced and reaches 5%-7% from the original 25%-28% within 48 hours.

Owner:HANYU GRP CO LTD

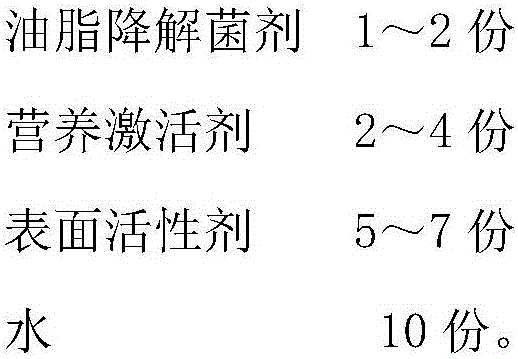

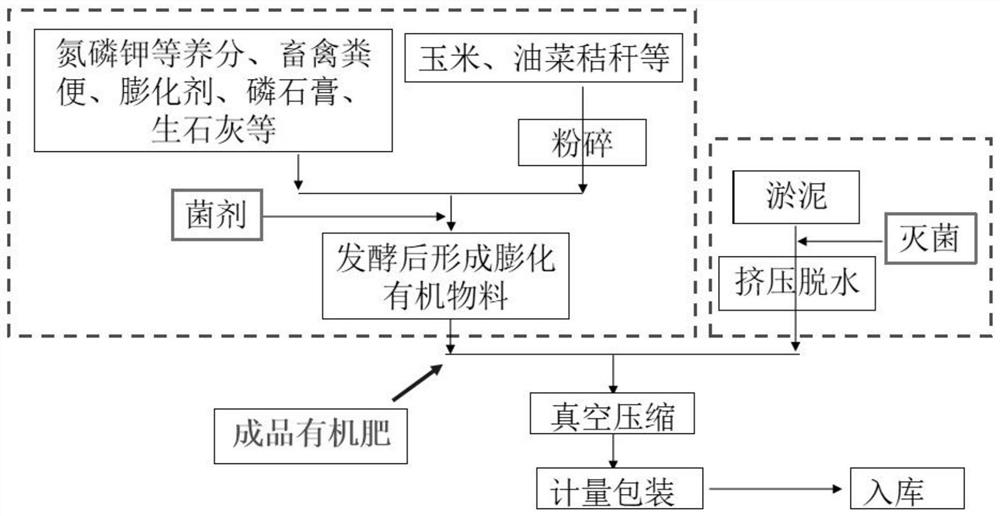

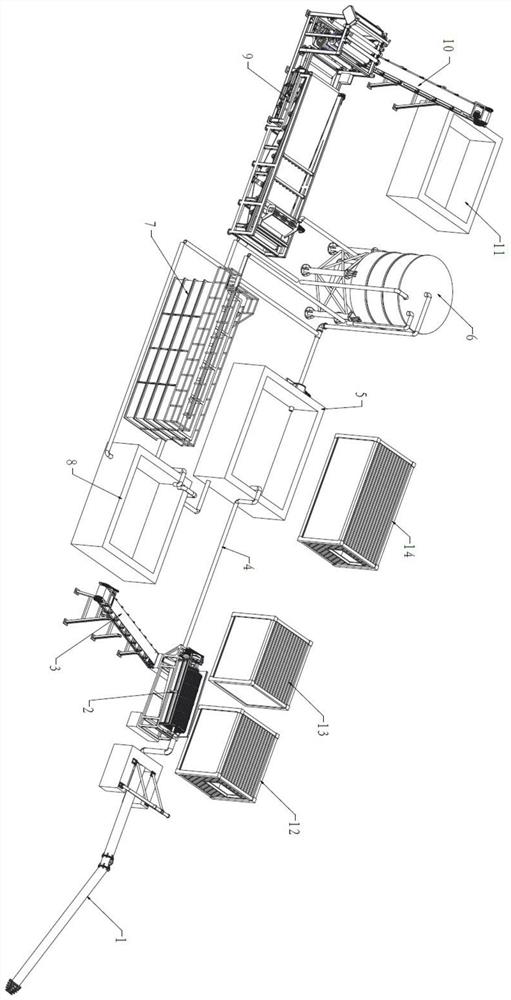

Method and equipment for preparing organic fertilizer from river and lake bottom mud and livestock and poultry manure

PendingCN113336596AAdjust moisture contentSimple preparation processCalcareous fertilisersBio-organic fraction processingAgricultural engineeringPoultry manure

The invention discloses a method and equipment for preparing an organic fertilizer from river and lake bottom mud and livestock and poultry manure, and belongs to the technical field of resource utilization of river and lake bottom mud. The invention relates to a method for preparing an organic fertilizer from river and lake bottom mud and livestock and poultry manure. The method comprises the following steps: conveying bottom mud to a ship for filter-pressing dehydration; settling and flocculating the sludge and performing material property improvement; performing innocent treatment on supernate, and dehydrating and innocent treatment on sludge; mixing the sludge with the straw; pressing the sludge into a mud cake; decomposing livestock and poultry manure in a storage yard; mixing the mud cake with the puffed organic material; composting finished organic fertilizer; and weighing, packaging and outputting finished products. According to the method, the sediment and the livestock and poultry manure are organically combined, a certain amount of straw or reed is added, and utilization of the sediment can be achieved while desilting is conducted; therefore, the occupied area of the whole bottom mud pretreatment system is reduced, and the bottom mud treatment period is shortened. Raw materials such as composted livestock and poultry manure and straw are mixed with sludge, an industrial assembly line can be directly formed on site, the production efficiency is high, the investment cost is low, and the applicability is high.

Owner:湖南凯迪工程科技有限公司

Decomposition device for treating rural domestic waste composting waste gas with biomass

InactiveCN102180719AReduce investmentEfficient purificationOther chemical processesDispersed particle separationDecompositionExhaust pipe

The invention discloses a decomposition device for treating rural domestic waste composting waste gas with biomass, which belongs to the technical field of agricultural waste utilization. The decomposition device comprises: a composting barn in which a leachate collecting pipe is disposed, and on which a biomass processing exhaust pipe is disposed; a leachate collecting pool which is communicated with the leachate collecting pipe. The decomposition device of the invention performs aerobic composting of rural solid waste; the composting temperature is easy to insulate and control; and the waste gas generated during the composting process is processed by using biomass corn cores and straw cores as special gas adsorption materials. The leachate is collected and sprayed back during the composting process, which can not only ensure the water content of the compost, but also realize zero discharge of waste water; the device can perform positive or negative pressure adjustment of the gas in the barn at any time, makes full use of the existing rural biomass resources, and can effectively purify peculiar smell generated by the compost.

Owner:CHINA AGRI UNIV

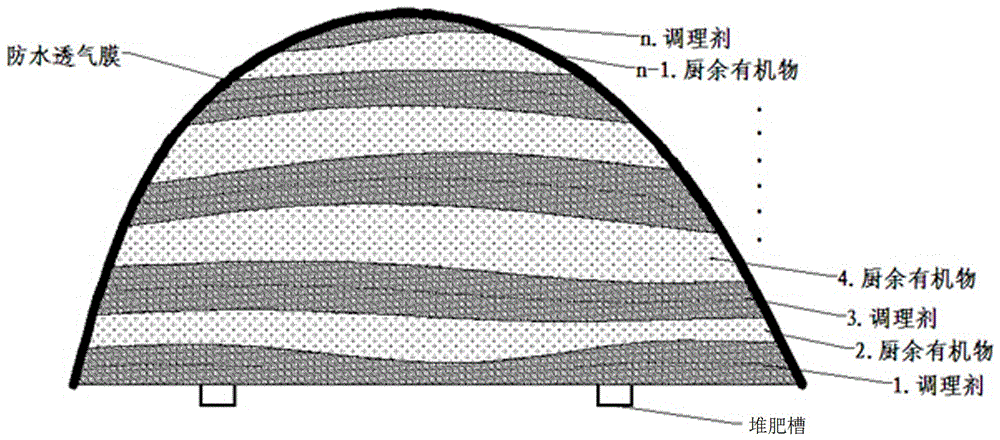

Compost building method for food waste organic matter aerobic composting

InactiveCN106187336ALess investmentReduce pollutionClimate change adaptationBioloigcal waste fertilisersPorosityMixed materials

The invention discloses a compost building method for food waste organic matter aerobic composting. The method comprises the steps that 1, a layer of conditioner is laid inside a composting groove; 2, a food waste organic matter is laid on the conditioner; 3, a layer of conditioner is laid on the food waste organic matter; 4, the steps 2 and 3 are executed again to obtain a mixed material; 5, the obtained mixture is stacked into strip-shaped composts; 6, after the whole composting groove is filled with the material composts, a waterproof ventilation membrane is spread; 7, a sensor is inserted, ventilation is enabled, and fermentation residues are obtained 20-40 days after one-time aerobic fermentation; 8, the fermentation residues are transferred to another groove, the steps 5 and 6 are executed again, and the composts are obtained 7-20 days after second-time aerobic fermentation. According to the composting method, the conditioners are laid inside the composting groove, mixed composting is performed on the conditioners and the food waste organic matter, the composts have the better porosity, and air circulation is promoted, so that the aerobic composting process is uniform in fermentation, the composting quality is improved, and the composting period is shortened.

Owner:KINGFA SCI & TECH CO LTD

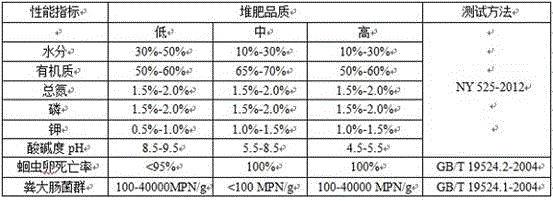

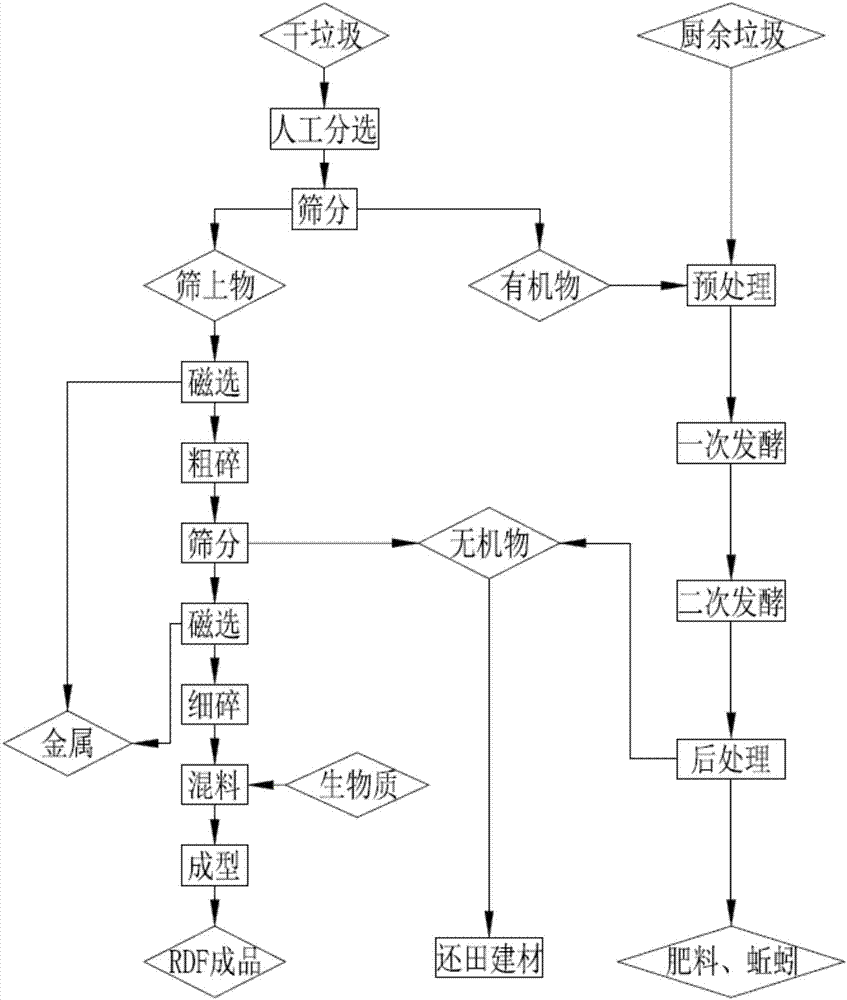

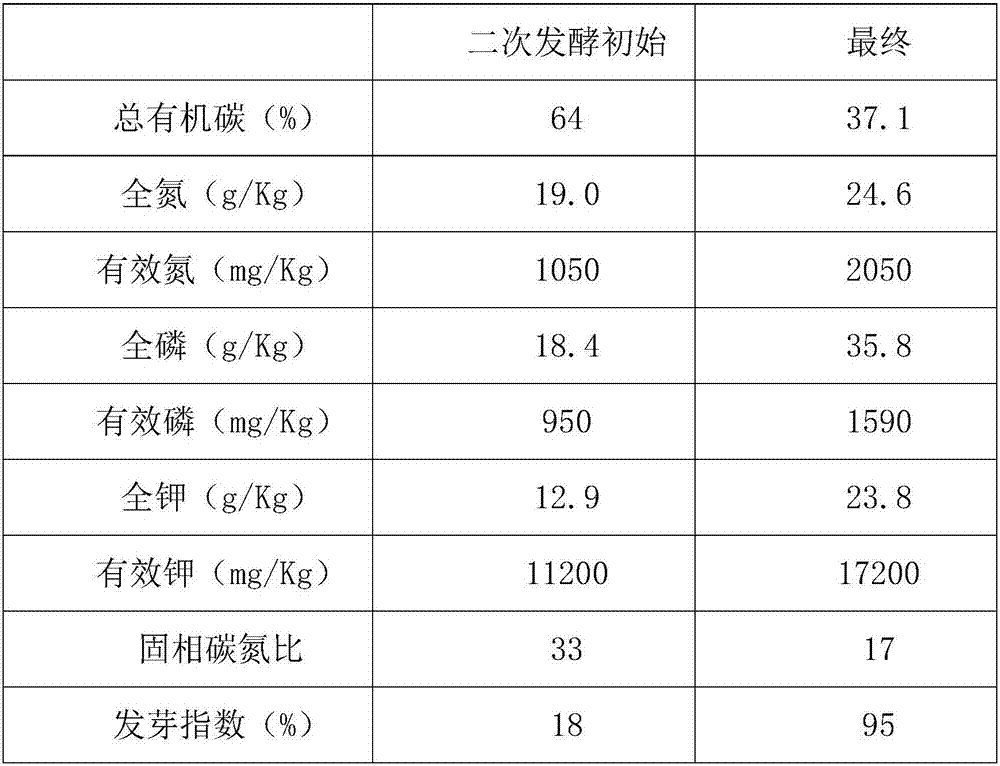

Food waste composting method and rural waste classification method using same

ActiveCN107417313AResolution timeSolve the low mortality rate of pathogenic bacteriaCalcareous fertilisersBio-organic fraction processingClassification methodsCo composting

The invention provides a food waste composting method and a rural waste classification method using the same. The classification method comprises the steps of dividing rural waste into food waste and fuel waste, and according to the characteristics of the waste, using the food waste for preparing fertilizer and preparing the combustible waste into RDF fuel, wherein the preparation of the food waste into fertilizer comprises the steps that aerobic primary fermentation is performed on the waste, then a primary fermentation product is adjusted, and secondary fermentation is performed by implanting earthworms in the primary fermentation product; after the secondary fermentation, food waste is quickly decayed; in the RDF fuel production process, dry and wet separation, natural air drying, and mixing with dry biomass methods are adopted to deal with the waste, thereby reducing energy consumption. Compared with the current waste disposal methods, the food waste composting method and the rural waste classification method using the same, provided by the invention, make full use of the waste, turn the waste into useful fertilizer, and have the advantages of short period of waste composting, good fertilizer effect, low consumption in preparing fuel from the waste.

Owner:CHONGQING SAGE RENEWABLE RESOURCES UTILIZATION CO LTD

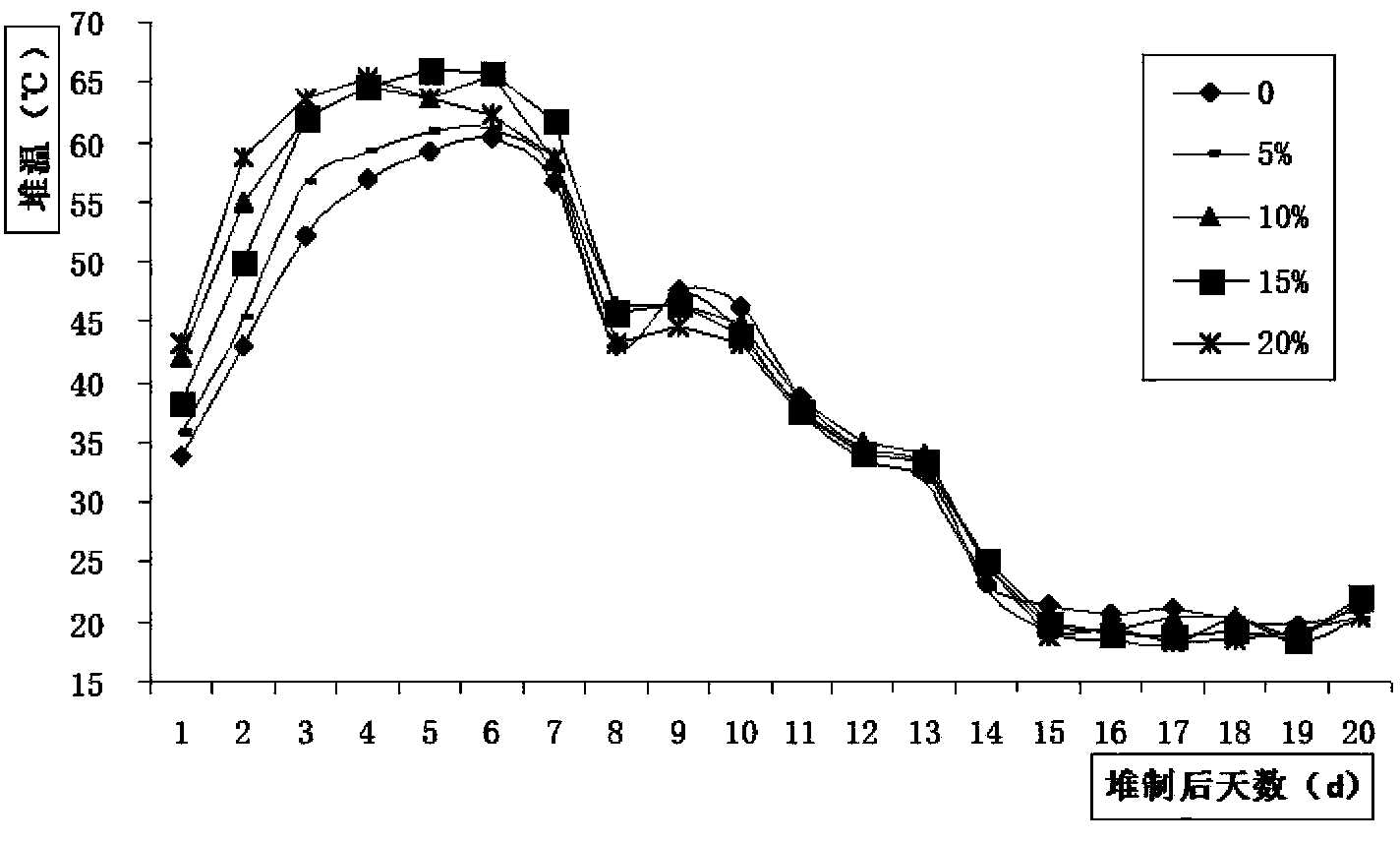

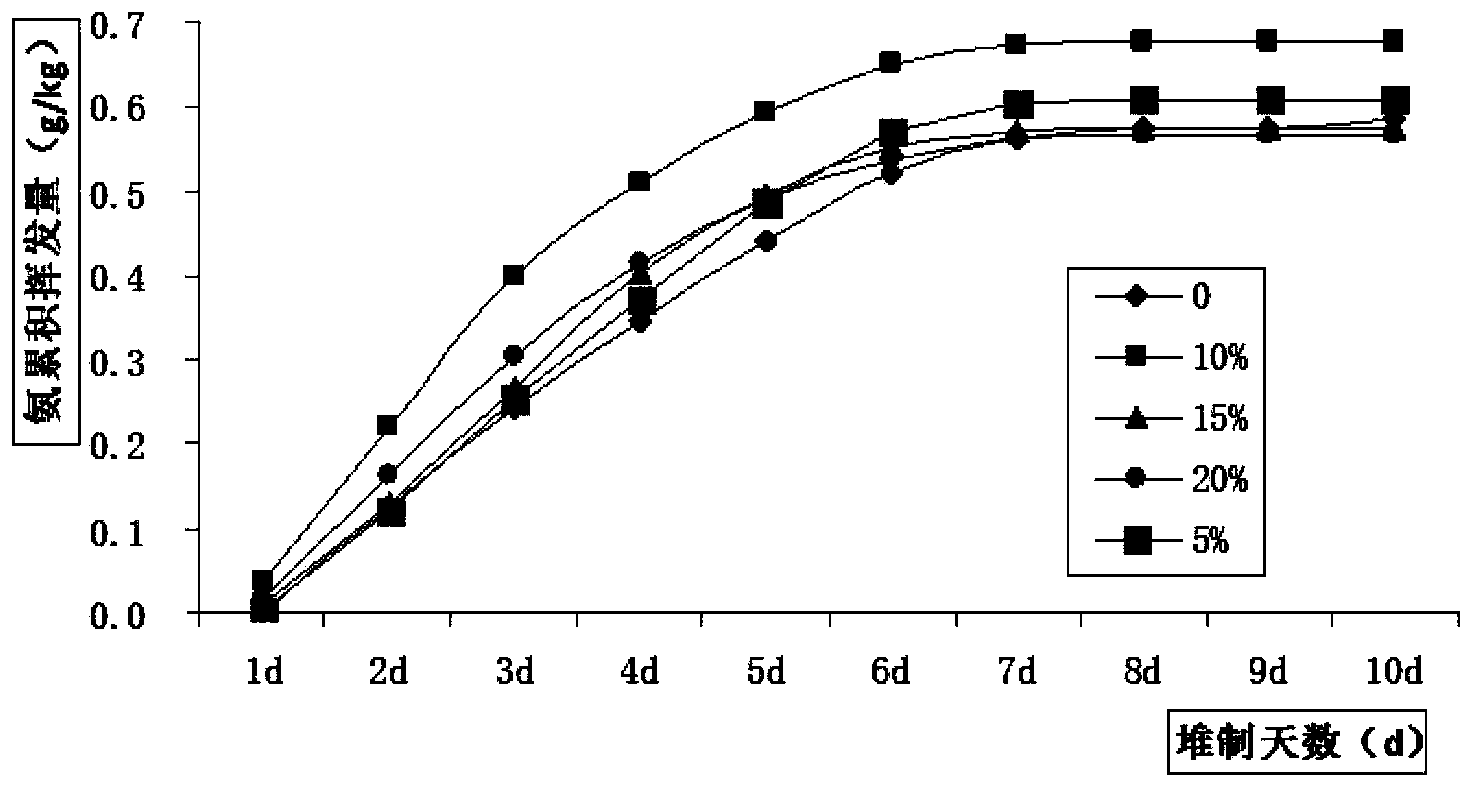

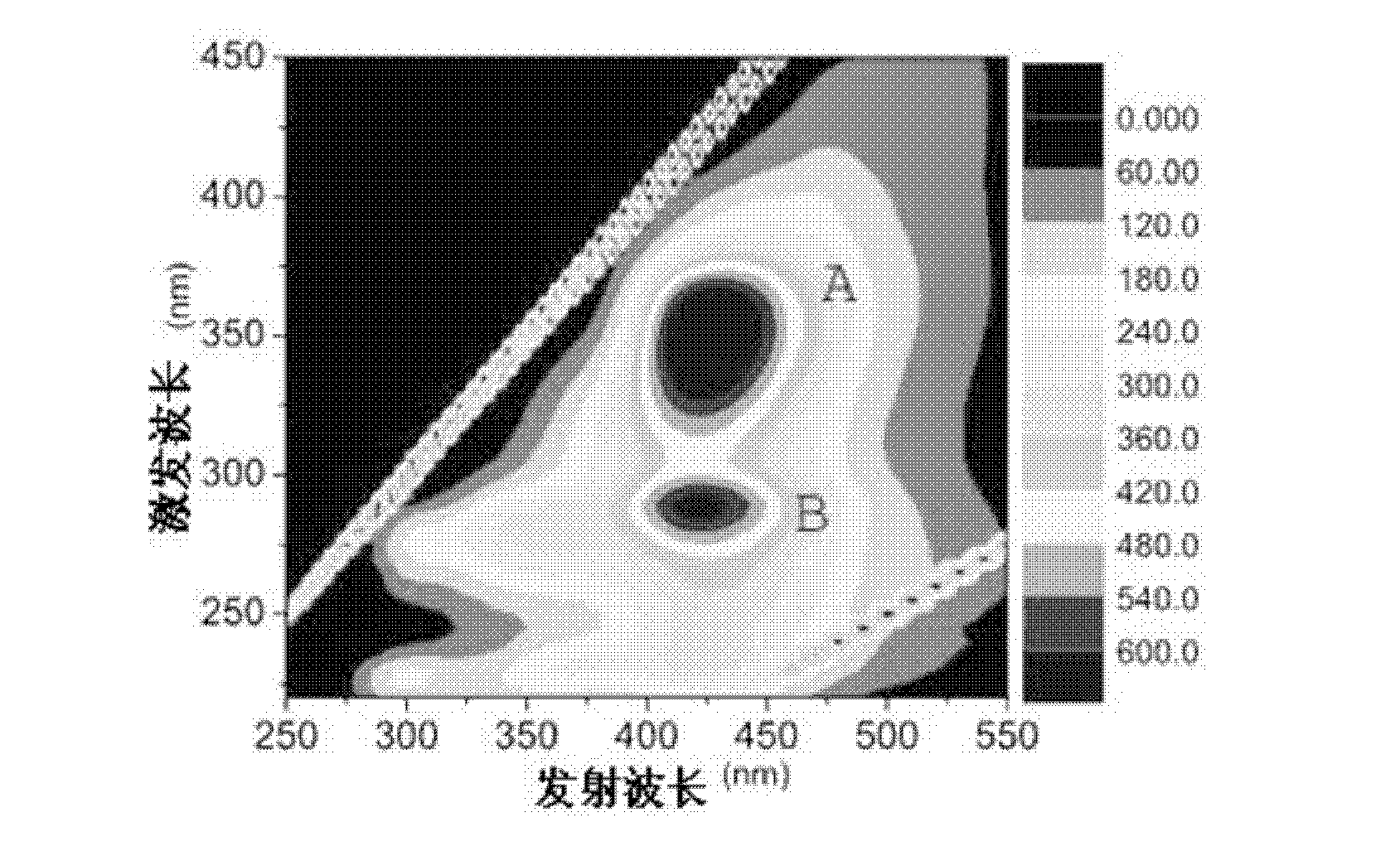

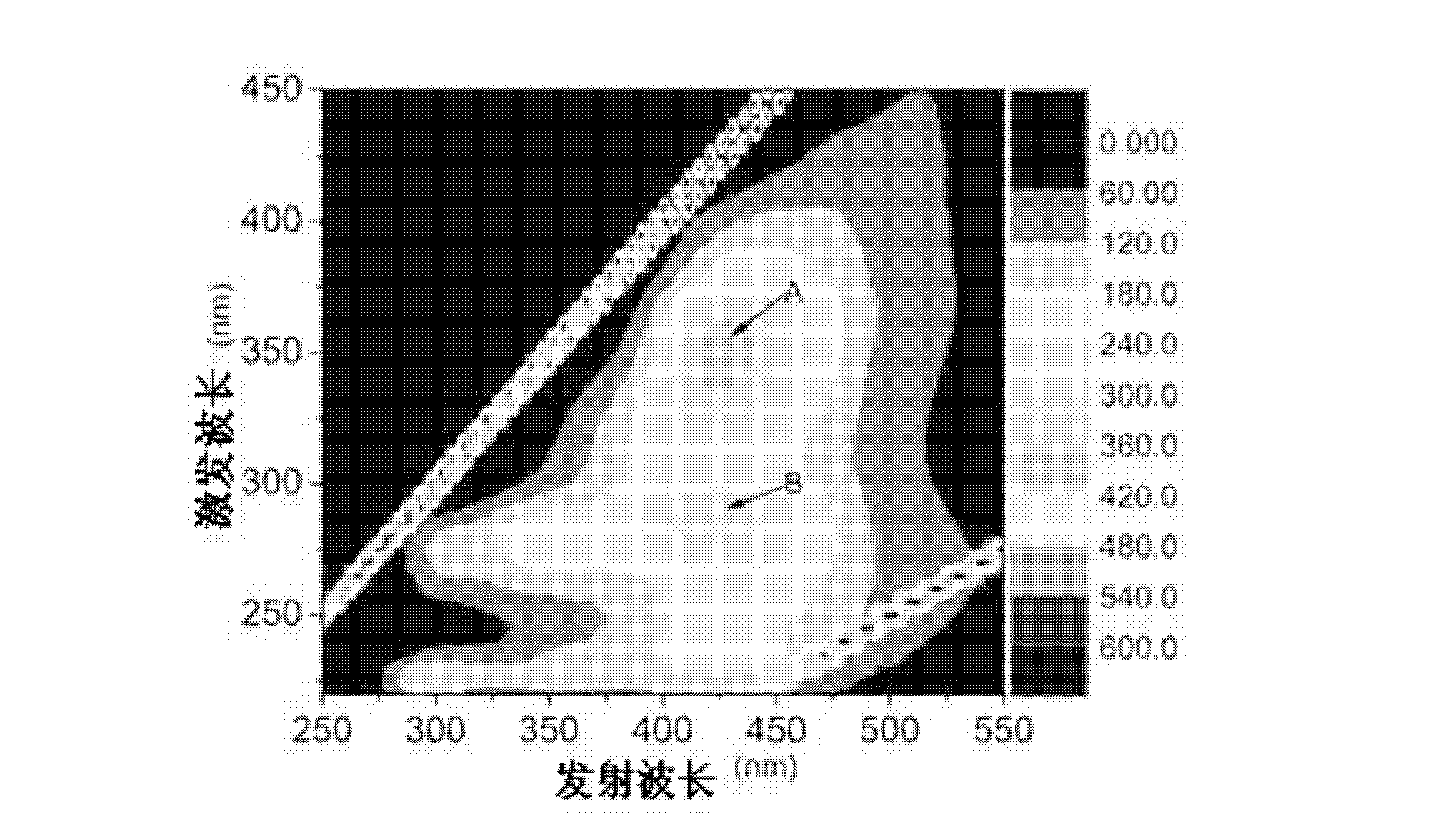

Method for carrying out sludge aerobic composting by using cane sugar and straws as carbon source conditioning agents

InactiveCN102643122AReduce volatilityReduce lossesBio-organic fraction processingOrganic fertiliser preparationSucroseSludge compost

A method for carrying out sludge aerobic composting by using cane sugar and straws as carbon source conditioning agents aims to solve the problem of high nitrogen loss during sludge aerobic composting, and includes the steps: firstly, uniformly mixing the cane sugar with the straws to be used as the carbon source conditioning agents; secondly, uniformly mixing the conditioning agents with dewatered sludge so that a mixture is obtained; and thirdly, subjecting the mixture of the conditioning agents and the dewatered sludge in the step two to high-temperature composting, monitoring the temperature of a compost during composting, adding the carbon source conditioning agents in the step one after a high-temperature period is achieved for 18-24h, composting in a mixed manner until the temperature of the compost achieves the ambient temperature, and stopping ventilation so that high-temperature compositing is completed. The method can reduce volatilization of ammonia gas, can lower nitrogenloss, can increase the humus content of compost products, and is used for the field of aerobic sludge composting.

Owner:HARBIN INST OF TECH

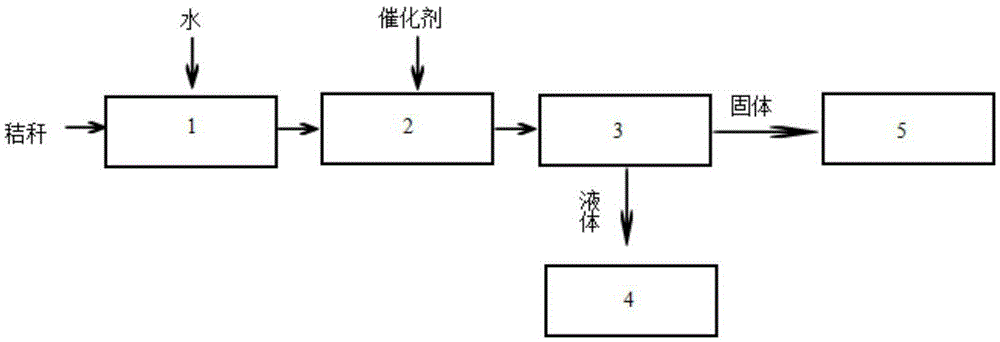

Method for efficient production of biogas from straw

InactiveCN105420281AIncrease gas production rateIncrease profitWaste based fuelFermentationSlurryOrganic matter

The invention relates to a method for efficient production of biogas from straw. The method comprises the following steps: soaking straw with a water solution which contains a metal salt catalyst by a certain concentration so that one part of soluble and diffluent organic matters in the straw are transferred to a liquid phase from a solid phase, pressing a solid-liquid mixture in a solid-liquid separator or a plate-and-frame filter press, so that solid and liquid are separated, fermenting the obtained liquid in an anaerobic environment to produce biogas and composting or drying and incinerating solid residues as required. The method disclosed by the invention can avoid the problems of low fermentation efficiency, low biogas residue and biogas slurry utilization rate and the like in fermentation by direct utilization of the straw. According to the method, most components, for fermentation, in the straw, are dissolved in the liquid for direct fermentation, and the solid residues obtained from pressing, instead of being wasted, are composted or incinerated to release heat energy. The utilization rate of the straw is improved, the biogas yield is increased and environmental pollution caused by burning of the straw is solved as well.

Owner:TIANJIN UNIV

Method for co-composting waste edible fungi bags and urban sludge

InactiveCN103864484AHigh P, K contentPromote growthBio-organic fraction processingOrganic fertiliser preparationBiotechnologyEvening

The invention discloses a method for co-composting waste edible fungi bags and urban sludge. The method comprises the following steps of (1) uniformly mixing squeezed and smashed waste fungi bags, chicken dung and urban sludge, adding water, and adjusting the moisture content to obtain a mixture; (2) respectively activating high-efficiency composting zymophyte, and inoculating the high-efficiency composting zymophyte into a liquid culture medium for cultivation for 3-5 days to respectively prepare high-efficiency composting fermentation bacteria agents; (3) respectively spraying the high-efficiency composting fermentation bacteria agents into the mixture for stacking and fermentation, turning the stacks once every morning and evening, supplementing the water at any time to guarantee the moisture content, and fermenting for 8-12 days to obtain high-efficiency organic fertilizers. The method disclosed by the invention has the advantages of simple technology, easiness in operation and small investment; the prepared fertilizers are high in N, P and K content; solid waste is recycled and is turned into treasures for improving the soil and promoting growth of crops; due to the recycling of the waste edible fungi bags, environmental and economical benefits are achieved.

Owner:NANKAI UNIV +1

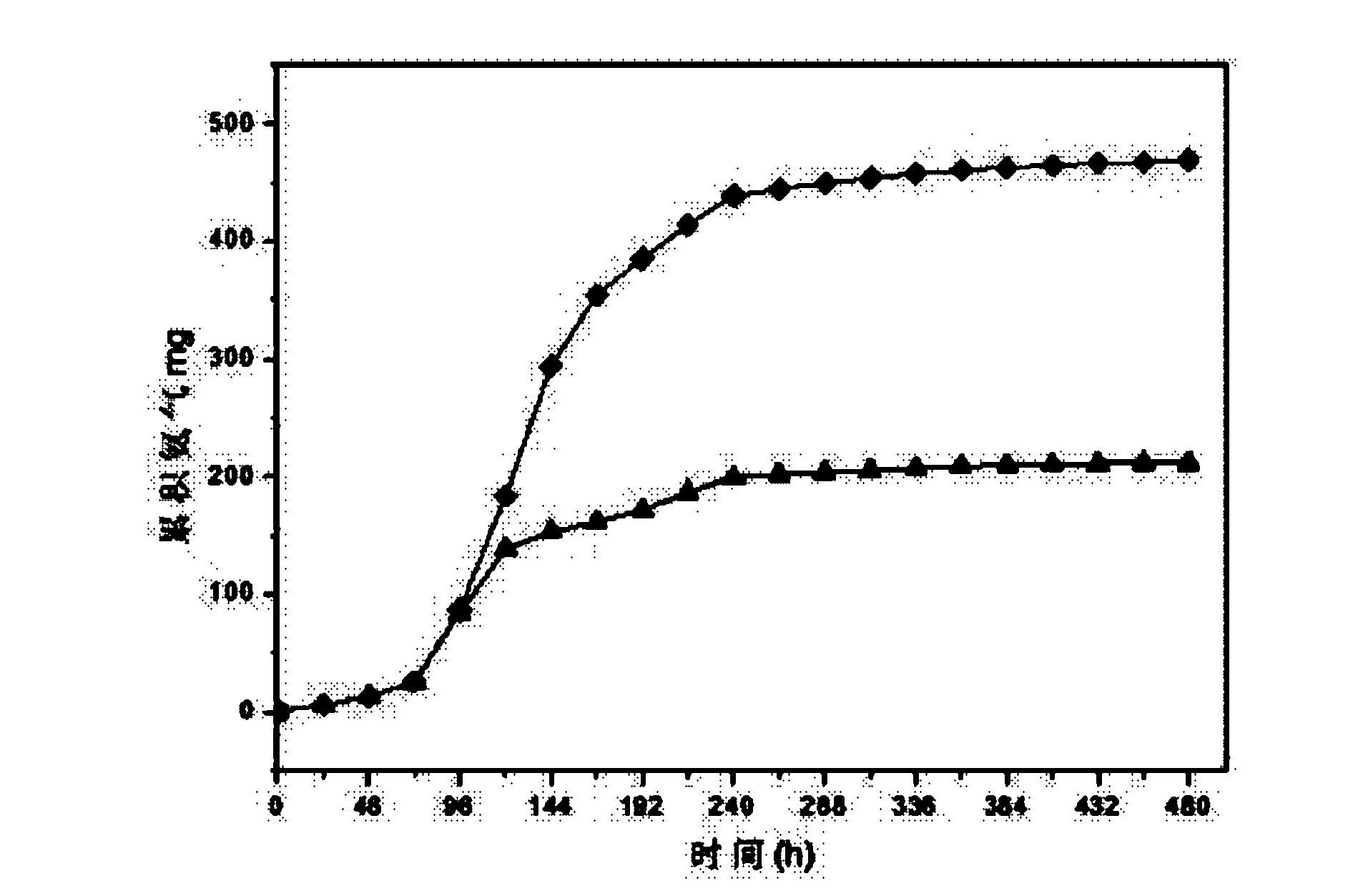

Composting method used for increasing humic acid content through phased adding of humic acid precusor substances

ActiveCN110156499AIncrease contentIncrease productionBio-organic fraction processingExcrement fertilisersFiberSugar

The invention discloses a composting method used for increasing humic acid content through phased adding of humic acid precusor substances. The composting method is used for solving a problem in the prior art that humic acid content is not high. The composting method comprises following steps: 1, protein organic waste and fiber organic waste are subjected to composting, at composting temperature increasing period, MnO2 is added, and a low concentration polyphenol waste is added; 2, before composting high temperature period, in each time of overturning of the protein organic waste, a sugar containing waste, a polyphenol waste, and a carboxyl waste are added, in each time of overturning of the fiber organic waste, the protein organic waste and the carboxyl waste are added; 3, at composting high temperature period, a humic acid containing precursor waste is packaged with textile bags, and is embedded in high temperature period compost; and 4, at composting temperature reduction period, ahumic acid containing precursor waste processed through harmless treatment is added into compost for at least one time. The composting method is used in the field of composting.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

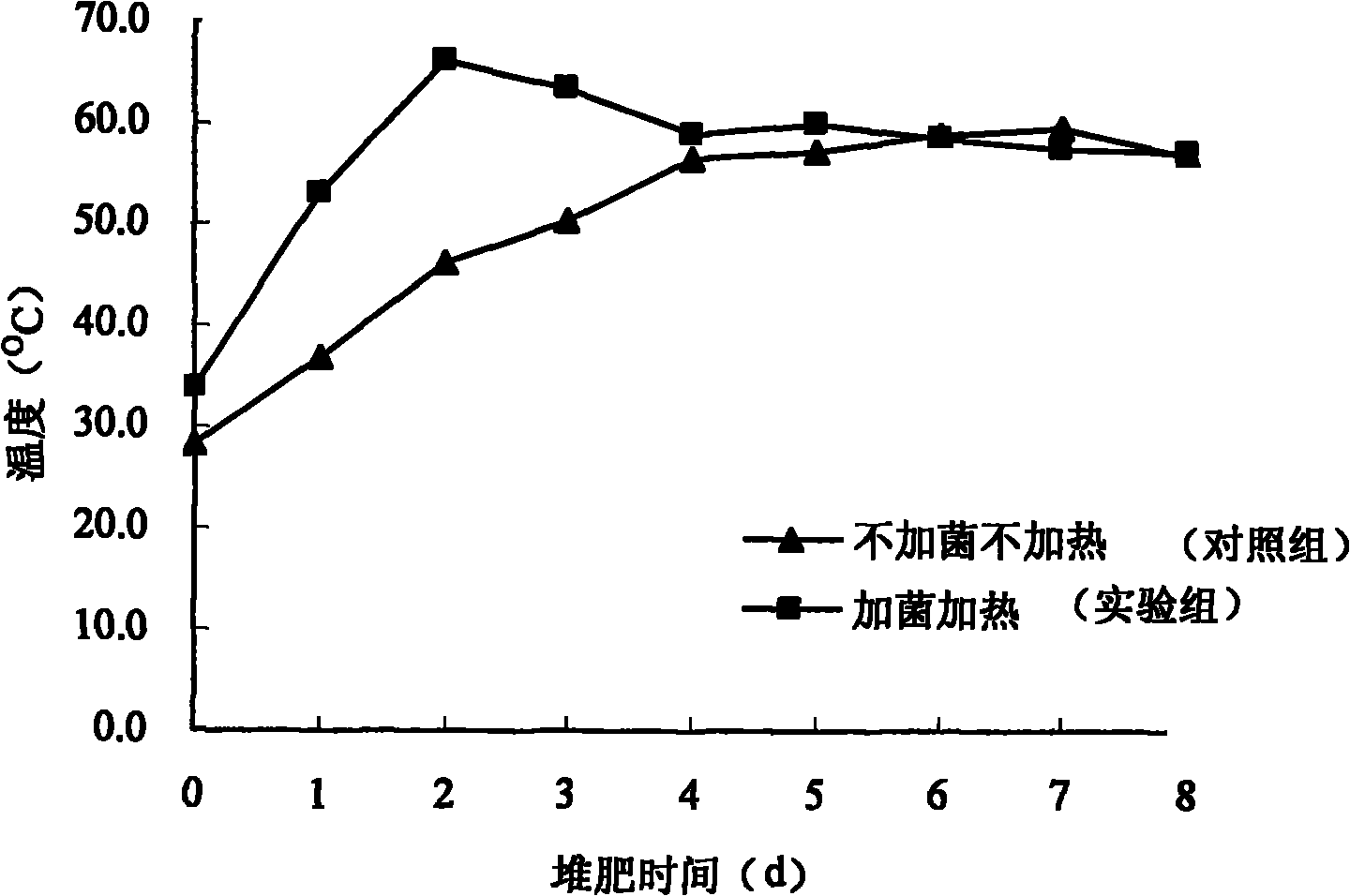

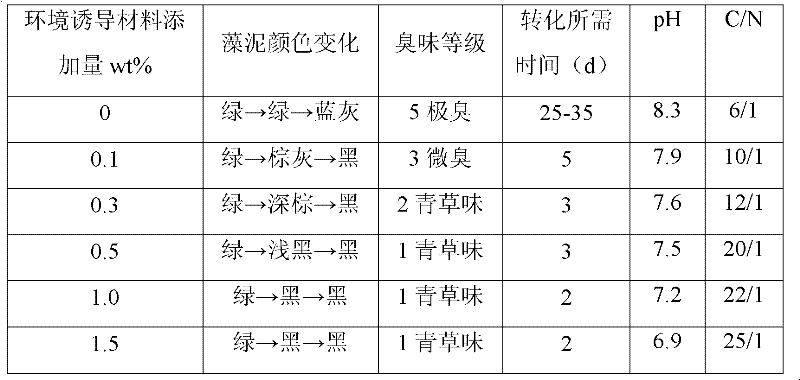

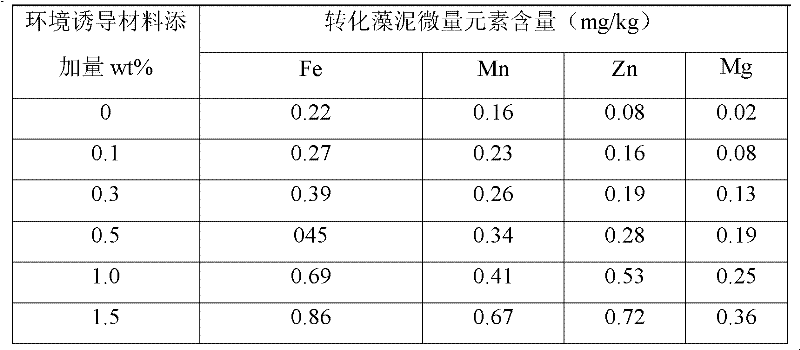

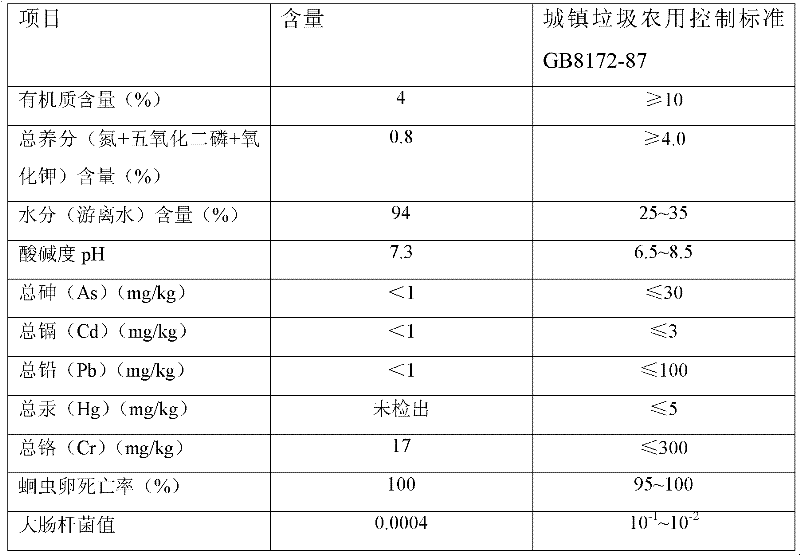

Method for converting blue algae mud into organic fertilizer by thermal composting

InactiveCN102503596ARapid inactivationPromote rapid proliferationClimate change adaptationSewage/sludge fertilisersPathogenic bacteriaOrganic fertilizer

The invention discloses a method for converting blue algae mud into an organic fertilizer by thermal composting, which comprises the following steps: concentrating the drained the blue algae mud until the water content is 90-95%, thereby obtaining the concentrated algae mud; adding an environmental induction material, which accounts for 0.1-1.5 wt% of the concentrated algae mud, into the concentrated algae mud; and uniformly stirring, and carrying out thermal composting in a dark place for 3-5 days, thereby obtaining the organic fertilizer. The method disclosed by the invention overcomes the defects of long time, great loss of available nutrients, pathogenic bacteria, viruses, microbial poison accumulation, heavy metal concentration and secondary pollution in the simple composting fermentation, lowers the transportation and storage cost, saves the occupied area and equipment investment, thoroughly implements harmless treatment, and solves the problem in large-scale conversion from wide-resource organic pollutants into the organic fertilizer.

Owner:合肥市东方美捷分子材料技术有限公司

Preparation method for producing organic fertilizer by use of organic waste to adsorb pig excrement

InactiveCN106588286ASolve pollutionLabor savingBio-organic fraction processingExcrement fertilisersOxygenCo composting

The invention discloses a preparation method for producing organic fertilizer by use of organic waste to adsorb pig excrement. The method comprises the following steps: collecting pig excrement and wastewater for washing a hog house to a collecting pool to form excrement; taking organic waste as an adsorption raw material, and adding probiotics in the adsorption raw material to perform primary fermentation, thereby forming an adsorption material after removing excessive moisture in the adsorption raw material; mixing the excrement and the adsorption material in a proportion of 1:(2-3), and sufficiently blending through a material mixer to prepare a fermentation raw material; conveying the fermentation raw material to a compost workshop to perform compost treatment according to a compost production process; and then conveying the composted material to a fermentation workshop to perform high-temperature aerobic fermentation through temperature control and humidity control fermentation, thereby preparing the organic fertilizer. The raw materials of the invention all adopt the waste materials, so that the aims of dealing waste by waste and turning the waste into wealth are achieved, and secondary pollution can be avoided.

Owner:湖南大辰环保股份有限公司

Method for manufacturing organic granular fertilizer by municipal waste compost

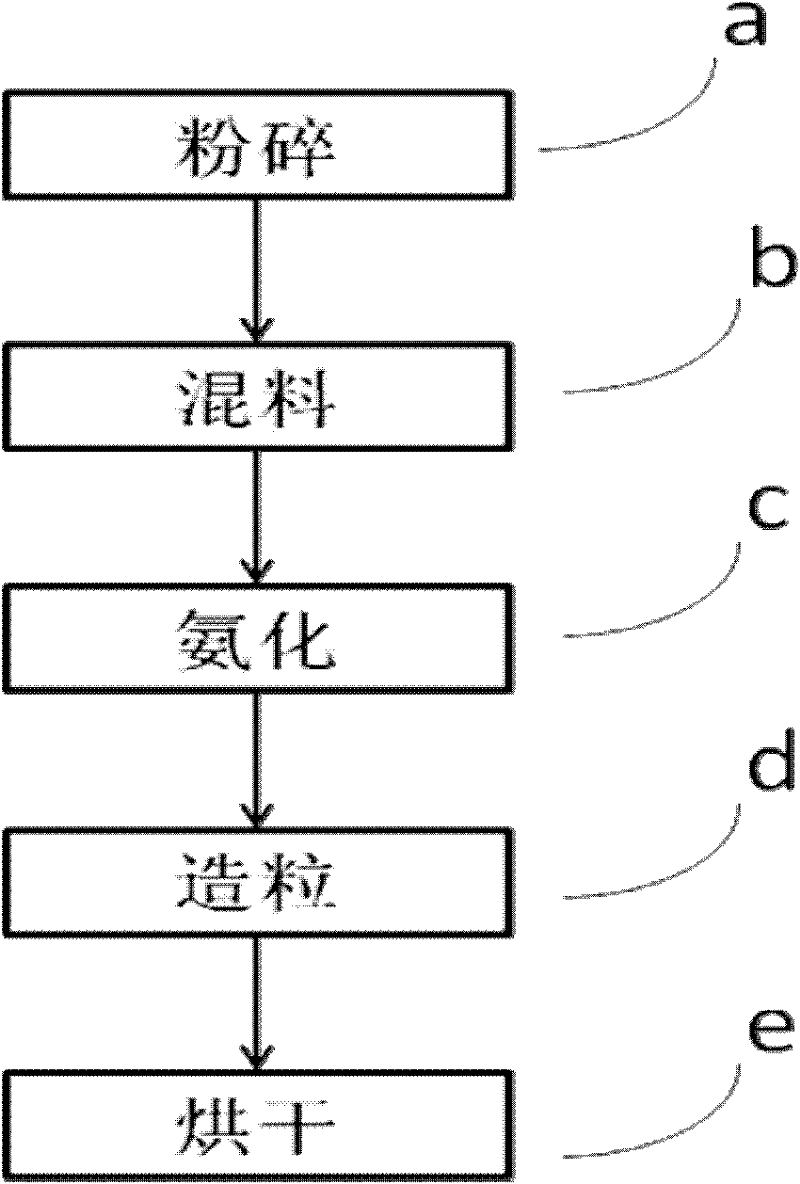

ActiveCN102249780AImprove fertilizer efficiencyStorage and transportationClimate change adaptationOrganic fertilisersPrillCo composting

The invention discloses a method for manufacturing an organic granular fertilizer by municipal waste compost, comprising the following steps: taking municipal waste compost as a main raw material; taking weathered coal, ammonium bicarbonate and urea as assistant materials; and smashing, mixing, aminating, prilling, drying and the like by the ammoniation granulation technology to manufacture the municipal waste compost into the organic granular fertilizer. In the ammoniation granulation process, humic acid and other macromolecular organic matters are converted into the free state from the polymerization state under the alkaline environment formed by ammonium bicarbonate; the humic acid and ammonium nitrogen react to generate ammonium humate; a carbonyl group and an amino group in urea react with the carbonyl group, hydroxide radical, the carbonyl group and other functional groups in organic matters to form a hydrogen bonding relationship so as to adsorb and fix nitrogen nutrition to perform the effect of slow release; meanwhile, the cohesiveness of the material is improved, which is favourable for improving granulation rate and product storage and transportation property; the method has a simple technology and can process the waste compost on a large scale; and the manufactured organic granular fertilizer has the advantages of long fertilizer effect, storage and transportation resistance and the like and is convenient to apply.

Owner:SOUND ENVIRONMENTAL RESOURCES

Sludge composting and fermenting integrated treatment device

PendingCN107353044ARipe fastImprove conversion rateClimate change adaptationSewage/sludge fertilisersMicroorganismThermal insulation

The invention discloses a sludge composting and fermenting integrated treatment device used in the sludge composting field. The device comprises a fermentation tank and a deodorization component, wherein the fermentation tank is provided with a feeding hole and an exhausting hole, a sealing part is detachably arranged at the feeding hole, the exhausting hole is formed in the top of the fermentation tank and is connected with the deodorization component; a stirring component and an air distribution component are arranged in the fermentation tank, and the air distribution component is located at the bottom; an outer layer and an inner layer are arranged on the tank wall of the fermentation tank, and the space between the outer layer and the inner layer is filled with thermal insulation materials. By arranging the thermal insulation materials at the tank wall of the fermentation tank, the temperature of a compost body is conveniently controlled, and the compost body can be rapidly composted, so that the composting time is shortened, and the composting efficiency is improved; particularly, the composting temperature is rapidly increased through organic matter composting when the environmental temperature is relatively low, so that a proper growth temperature can be provided for microorganisms, the microbial activity can be maintained, organic matters can be adequately decomposed, the conversion rate of nitrate nitrogen in the sludge can be effectively increased, and the problems of an existing sludge composting that the temperature increase is slow, the temperature of the compositing body is not high enough, and the compositing cycle is long are solved.

Owner:广州市净水有限公司

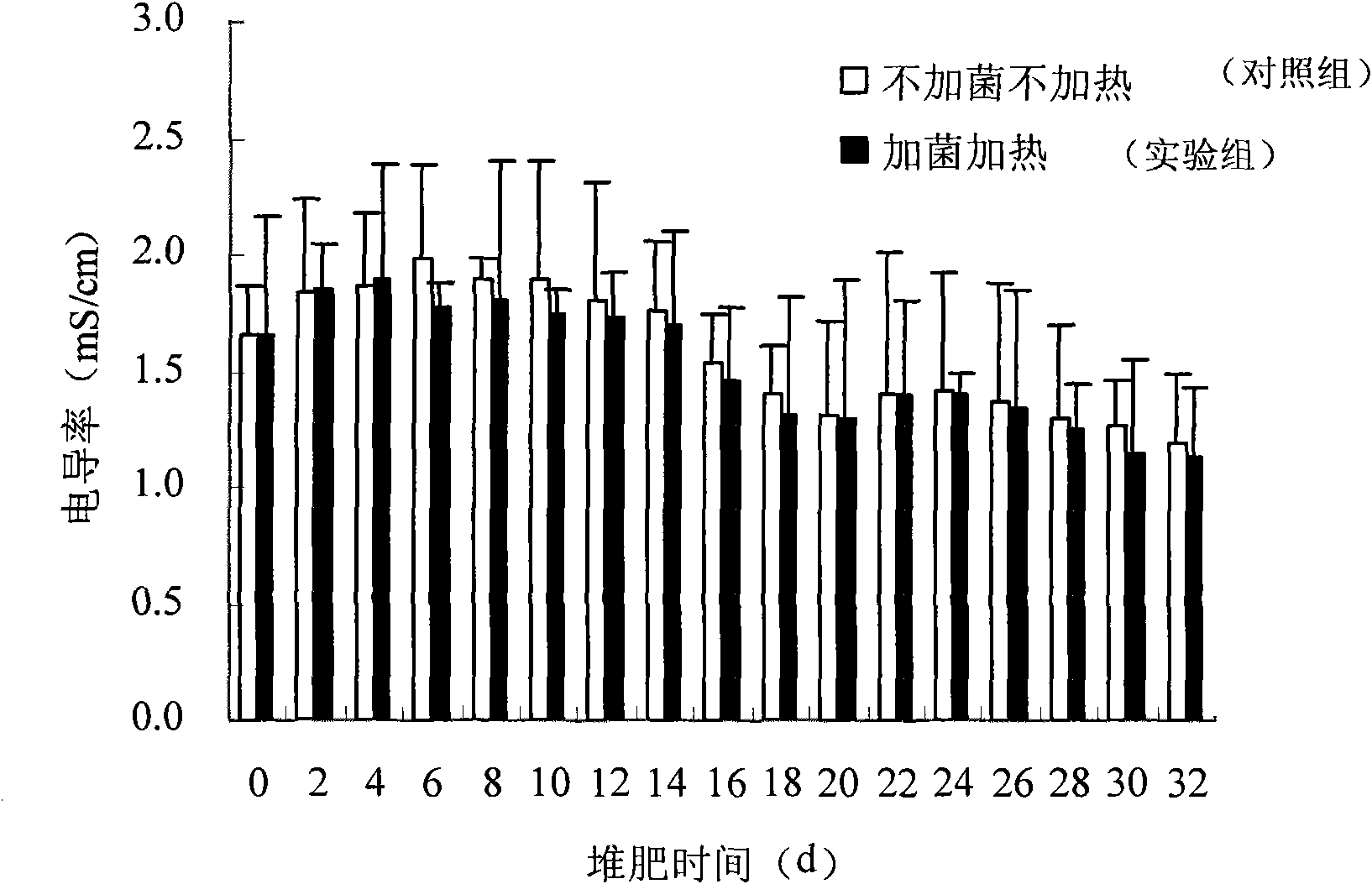

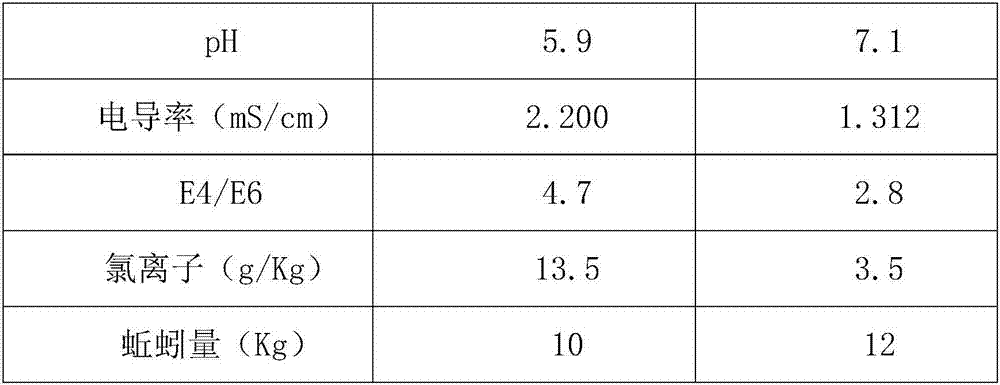

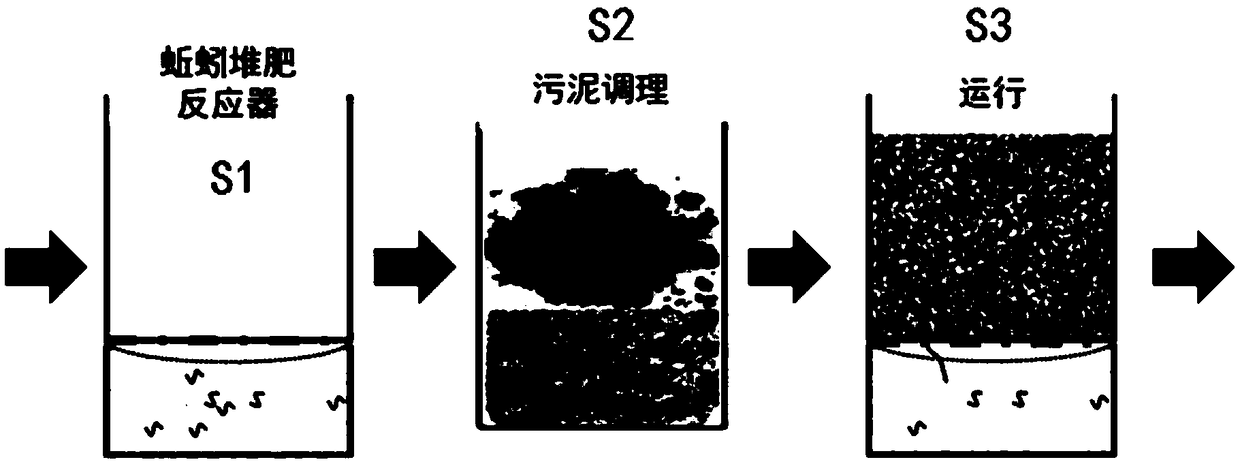

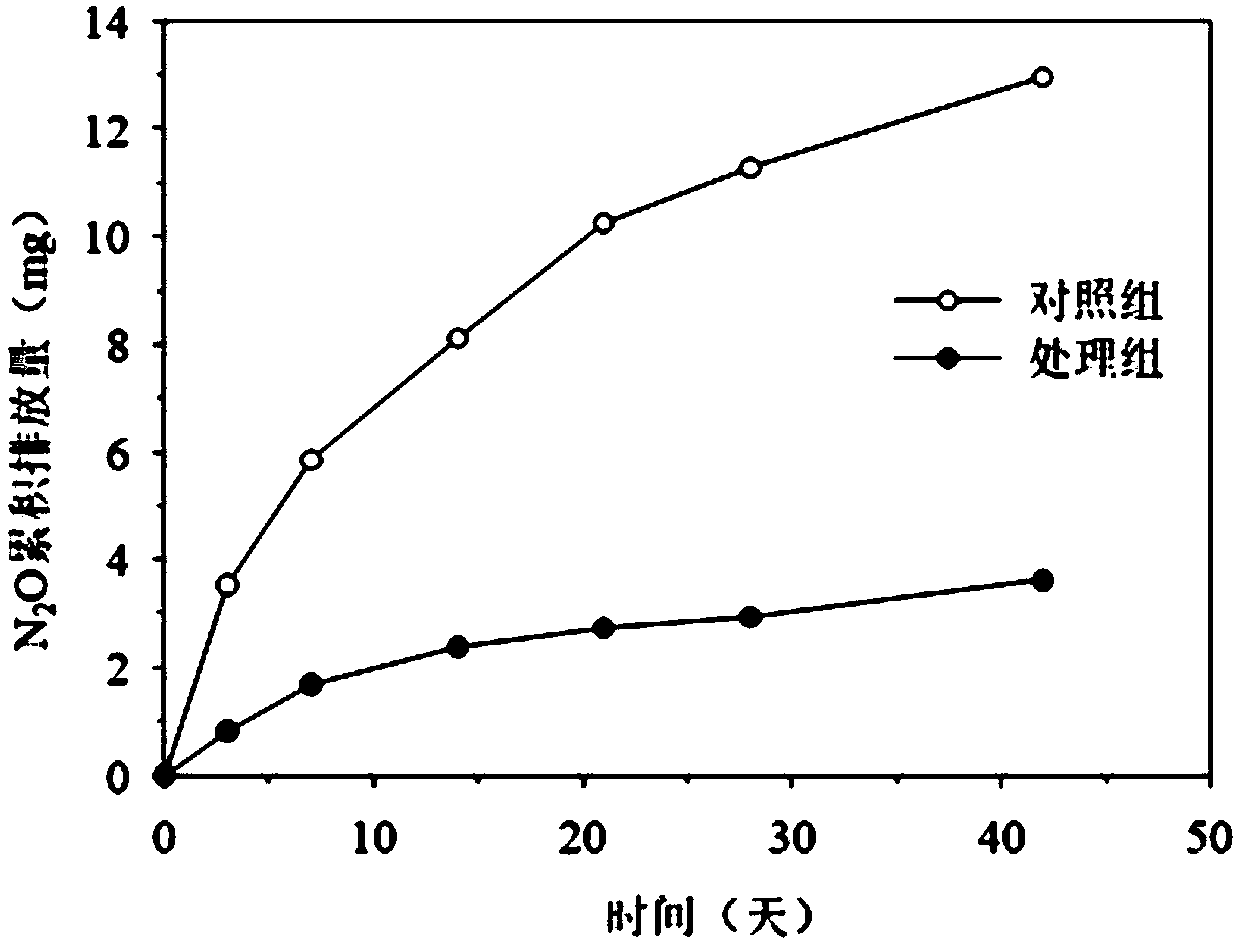

Method for reducing emission of potent greenhouse gas N2O in sludge earthworm composting

InactiveCN109503225AEmission reductionIncrease carbon to nitrogen ratioBio-organic fraction processingExcrement fertilisersFecesMoisture

The invention discloses a method for reducing emission of potent greenhouse gas N2O in sludge earthworm composting. The method comprises the following steps: step 1, arranging a buffer layer and adding earthworms into the buffer layer, wherein a matrix of the buffer layer is fermented and decomposed feces of livestock and poultry, and the conductivity of the matrix is below 5.0mS / cm; step 2, arranging an isolation net with a plurality of through holes on the buffer layer; step 3, adding sludge on the isolation net to form a reaction zone, wherein the earthworms can move between the buffer layer and the reaction zone through the through holes. According to the method, by adjusting the parameters such as the carbon-nitrogen ratio, the moisture content, the density and the like of the earthworms in the sludge earthworm composting, stabilization and reclamation of the sludge are realized, and the emission of the greenhouse gas in the process of sludge earthworm composting is greatly reduced. The method has the advantages of being high in efficiency, low in consumption and low in operating cost, achieving eco-environment protection and reducing the emission of the potent greenhouse gasN2O, therefore, the method has actual application value in reduction of secondary pollution in sludge treatment processes of sewage treatment plants in medium and small towns.

Owner:SHANGHAI MARITIME UNIVERSITY

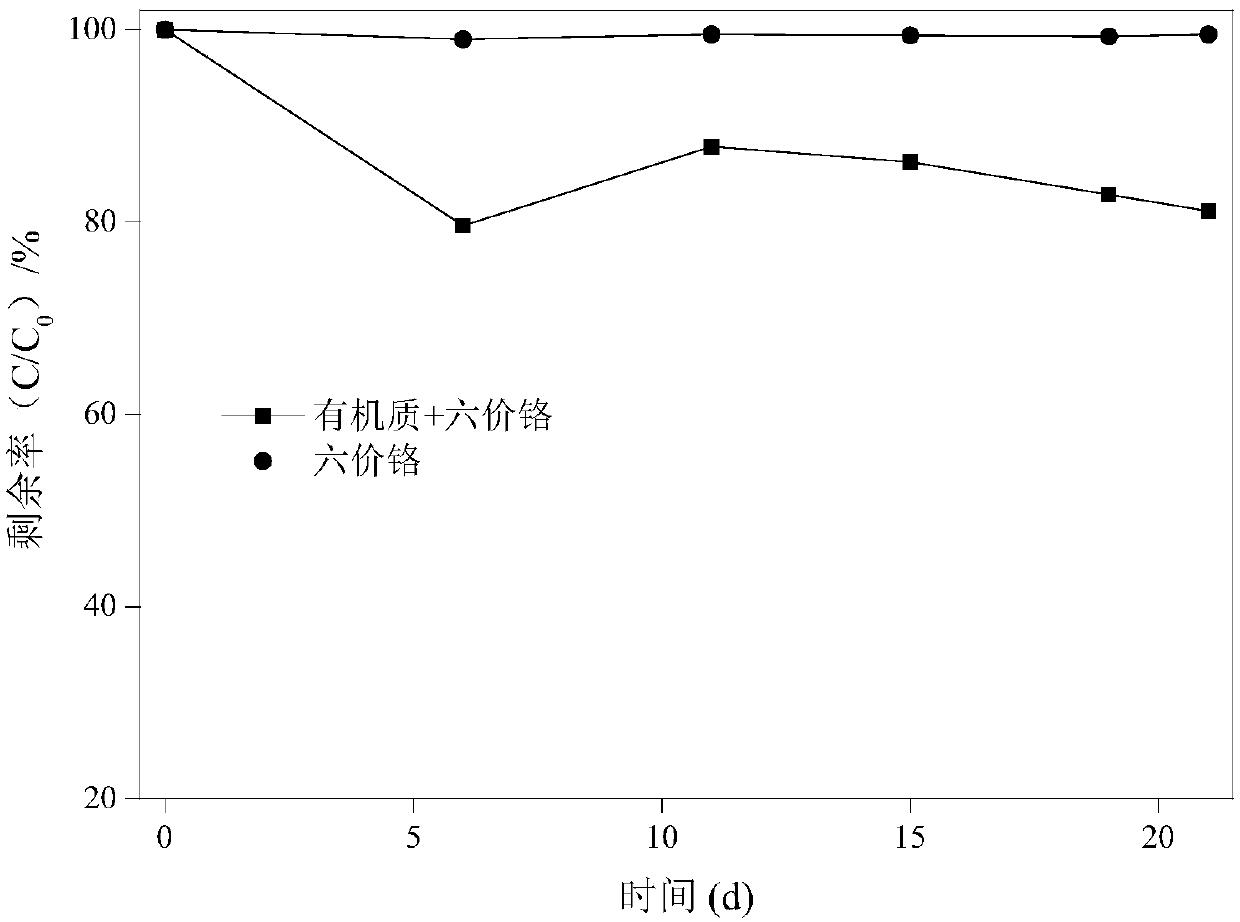

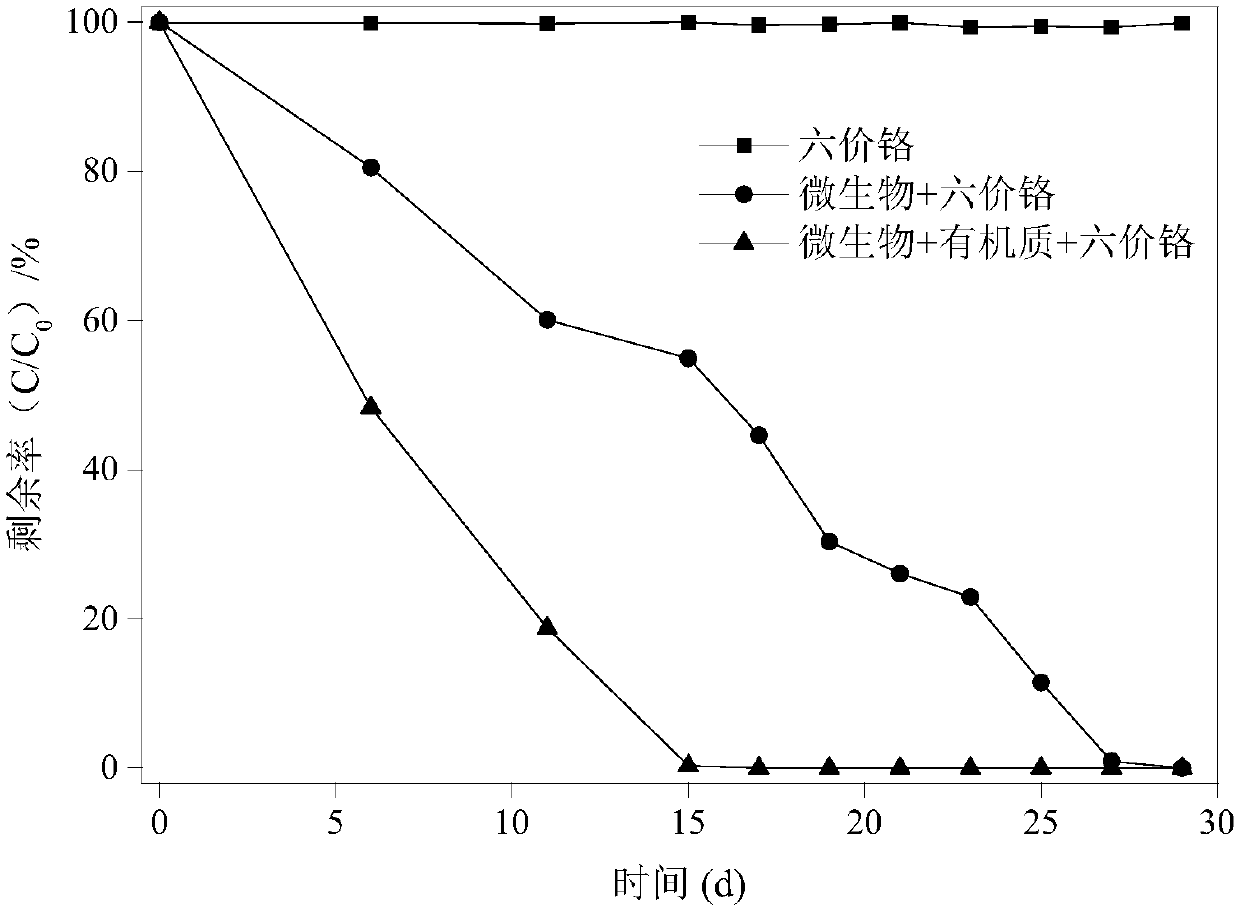

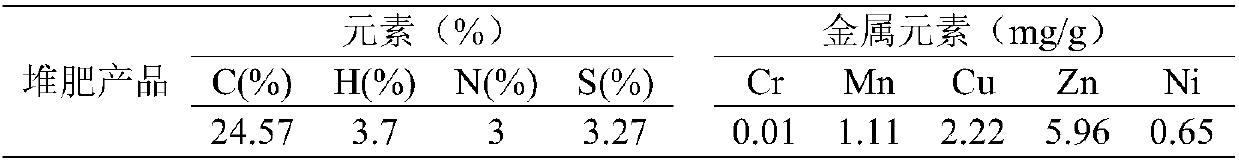

Method for remedying chromium contaminated soil through mineralized rubbish and/or compost products

InactiveCN107626732AWide variety of sourcesEasy to makeClimate change adaptationContaminated soil reclamationLitterDual effect

The invention discloses a method for remedying chromium contaminated soil through mineralized rubbish and / or compost products. The method comprises the following steps that (1) the mineralized rubbishand / or compost products are obtained; (2) the mineralized rubbish and / or compost products are applied to the chromium contaminated soil, uniform mixing is carried out, and water is supplemented; and(3) standing stacking is carried out, and by means of the complexing and reducing capacity of organic matter in the mineralized rubbish and / or compost, reducing and fixing of hexavalent chromium are achieved. According to the method, the remediation cost of a contamination field can be greatly reduced, resource utilization of waste can be achieved, the dual effects of high-added-value treatment and resource utilization of organic waste are achieved, and wide application prospects are achieved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Multifunctional organic fertilizer prepared by utilizing tannery sludge and wood fibers and preparation method and application thereof

ActiveCN105198511ALess quantityReduce heavy pollutionBio-organic fraction processingClimate change adaptationFiberFiltration

The invention discloses a multifunctional organic fertilizer prepared by utilizing tannery sludge and wood fibers and a preparation method and application thereof. The multifunctional organic fertilizer is prepared from, by weight, 100 parts of tannery sludge and 300-800 parts of wood fibers. The multifunctional organic fertilizer is prepared by using sludge-containing sewage of a tannery as a raw material, conducting flocculation, precipitation, plate-frame filtration or concentration by means of a self-discharging centrifugal machine on the sewage to obtain the tannery sludge, mixing the tannery sludge with the smashed wood fibers and then performing air drying or compost fermentation. The wood fibers are preferentially edible fungus residues, a certain parts by weight of molasses and a certain parts by weight of phosphate can be further selectively added into the materials to prepare the multifunctional organic fertilizer which can be selectively applied to passivation and toxicity attenuation of tailings in a metallic ore area and alkaline passivation and microorganism adsorption of polluted soil in a common ore area or can be directly applied to garden flowers, resource utilization of the tannery sludge, the edible fungus residues and other waste is achieved, and the effect of using the waste to treat pollution is achieved.

Owner:湖北驹龙园茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com