Method for converting blue algae mud into organic fertilizer by thermal composting

A technology of cyanobacteria and organic fertilizer, applied in the direction of organic fertilizer, sewage/sludge fertilizer, fertilization device, etc., can solve the problems of difficult storage, long time, insufficient environmental stacking capacity, etc., and achieve high fermentation maturity, low cost, Comprehensive utilization and processing of simple and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The main materials and tools in this embodiment are: cyanobacterial algae mud, environment-inducing materials, warm heap pools, flexible storage bags, straw curtains, moso bamboo, nylon nets, sunscreen nets, bamboo rakes, and the like.

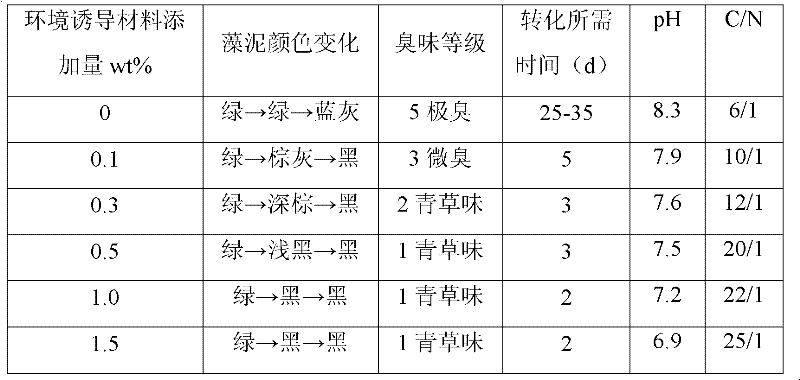

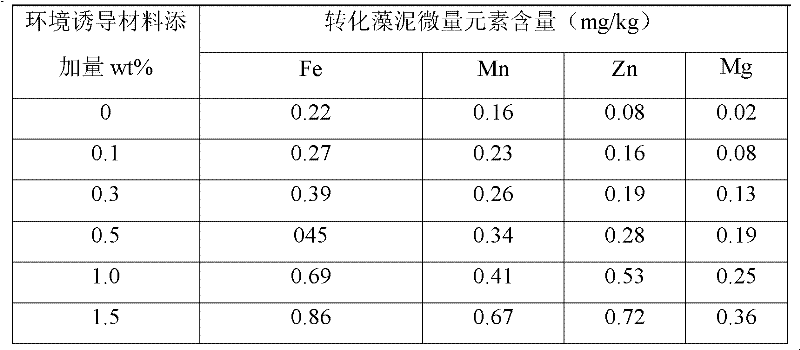

[0026] Transformation process: After concentrating and dehydrating 500kg of fresh cyanobacteria, the water content of the algal mud is 90-95wt%, and the algal mud is directly added according to 0%, 0.1%, 0.3%, 0.5%, 1.0% and 1.5% of the quality of the algal mud or diluted 20 times with water. Spray and add environment-inducing materials, stir evenly, and then transport to a storage tank or flexible bag, and naturally avoid light and thermopile transformation, temperature 25-35 ℃, humidity 65-100g / m 3 , Under the air pressure of 1atm, it can be completely transformed in 3-5 days. There is no obvious algal odor, the algal mud turns black, and the surface has white mildew spots.

[0027] The composition of the environment-inducing material...

Embodiment 2

[0033] Application method 1: The transformed organic fertilizer prepared in Example 1 is directly diluted with water as an organic fertilizer, and is fed to catfish, crucian carp, and snail. Under continuous topdressing, the pH value of the water body floats between 6.9 and 7.8, and the snails grow well.

[0034] Application method 2: The transformed organic fertilizer prepared in Example 1 is directly diluted with water as an organic fertilizer, planted with Chlorophytum, Dripping Guanyin, turf, and water lilies, under continuous top dressing, the Chlorophytum leaves increased, the Dripping Guanyin leaves were light green, and the turf and the water lilies grew vigorously.

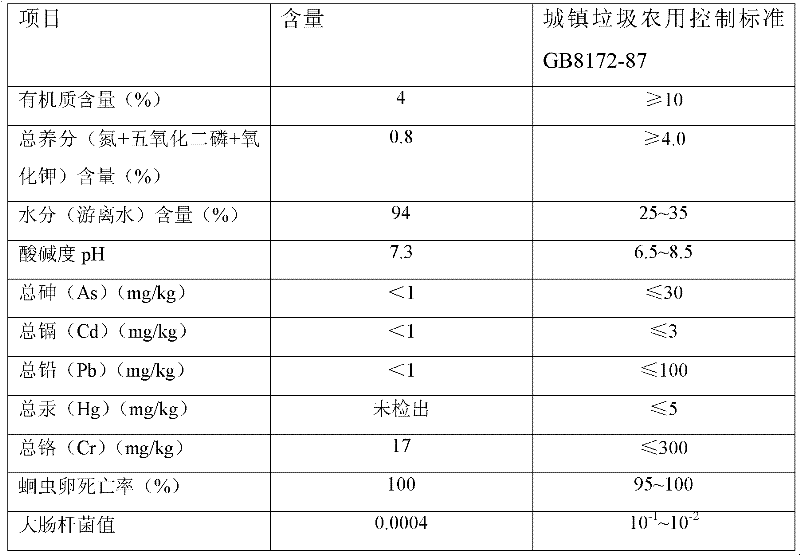

[0035] The algal mud organic fertilizer fertilizer effect components of the present invention are as follows:

[0036]

[0037] The fertilizer components of the algal mud organic fertilizer refer to the urban garbage agricultural control standards. The content of various heavy metals, the death rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com