Heat resistant beta-amylase-trehalose synthase fusion enzyme, expression gene of heat resistant beta-amylase-trehalose synthase fusion enzyme, engineering bacterium secreting fusion enzyme, and application

A trehalose synthase and gene expression technology, applied in the field of genetic engineering, can solve the problem of high production cost, achieve the effects of fast reaction speed, simplified production process and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Thermostable β-amylase-trehalose synthase recombinant plasmid construction, the steps are as follows:

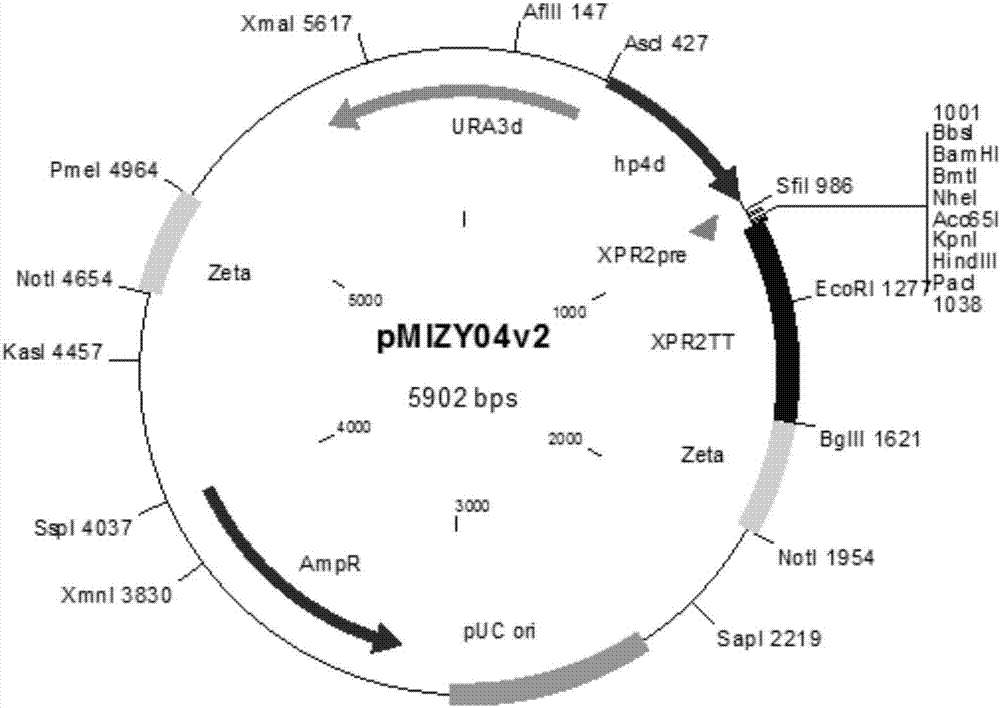

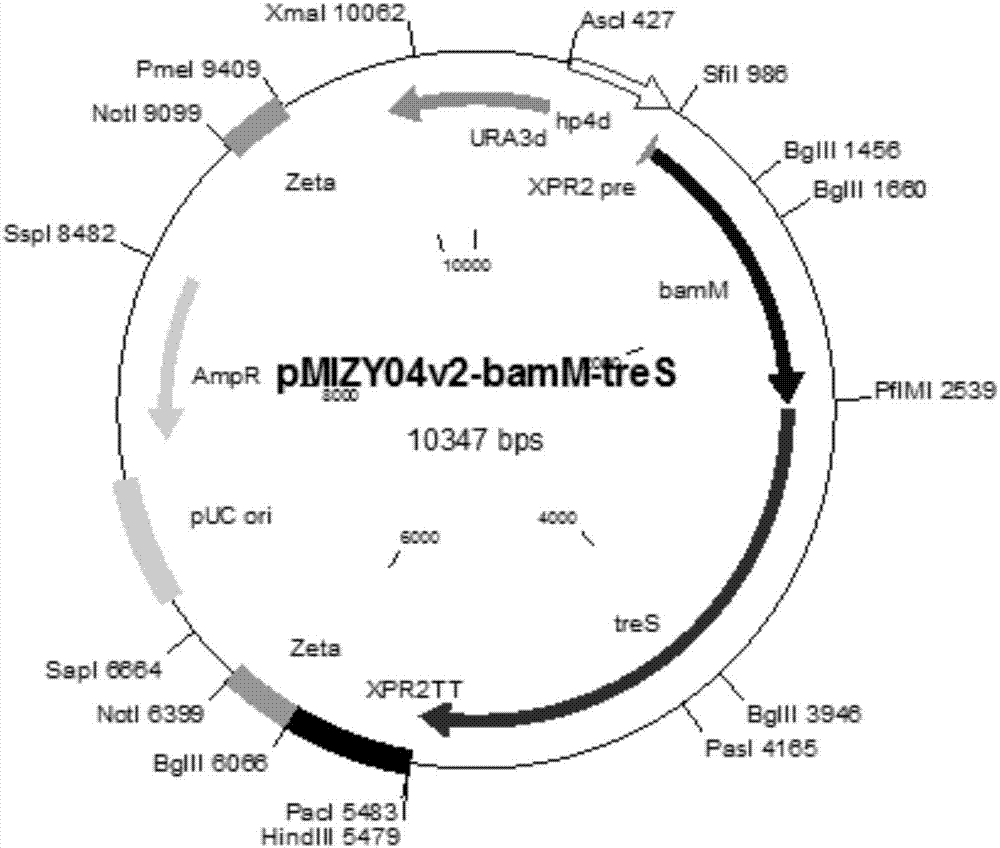

[0046] Design the nucleotide sequence shown in SEQ ID No.2 (encoding the amino acid sequence shown in SEQ ID No.1), synthesized by a third-party company and cloned into the pUC57-simple vector to obtain the pUC57S-bamM-treS plasmid, After being digested by BbsI / HindIII restriction endonuclease, the target fragment was recovered and connected to the corresponding site of the pMIZY04v2 expression vector digested by BbsI / HindIII restriction endonuclease, and the obtained recombinant plasmid was as follows: figure 2 shown.

[0047] The amino acid sequence shown in SEQ ID No.1 is as follows:

[0048] SIAPNFKVFVMGPLEKVTDFNAFKDQLITLKNNGVYGITTDIWWGYVENAGENQFDWSYYKTYADTVRAAGLKWVPIMSTHACGGNVGDTVNIPIPSWVWTKDTQDNMQYKDEAGNWDNEAVSPWYSGLTQLYNEFYSSFASNFSSYKDIITKIYISGGPSGELRYPSYNPSHGWTYPGRGSLQCYSKAAITSFQNAMKSKYGTIAAVNSAWGTSLTDFSQISPPTDGDNFFTNGYKTTYGNDFLTWYQSVLTNELANIASVAHSCFDPVFNVPI...

Embodiment 2

[0070] Obtaining of recombinant strains, the steps are as follows:

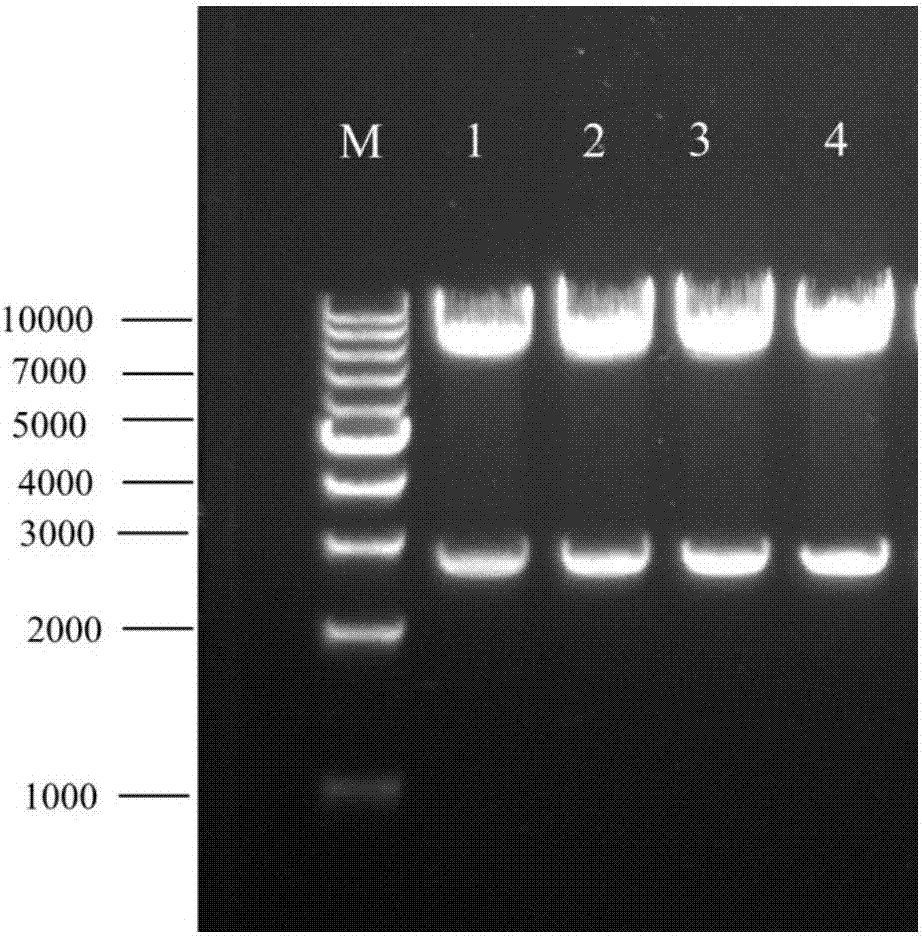

[0071] (1) Preparation of recombinant fragments The pMIZY04v2-bamM-treS recombinant vector was digested with NotI restriction endonuclease, detected by agarose gel electrophoresis, and the large fragment was recovered for future use. After digestion of pMIZY04v2-bamM-treS, two fragments are expected to appear, the sizes of which are 7.6kb and 2.7kb respectively. Recombinant vector NotI digestion and electrophoresis results are as follows: image 3 As shown, the two fragments are consistent with expectations.

[0072] (2) Yeast Competent Cell Preparation Inoculate the Yarrowia lipolytica PO1h strain on YPD solid medium and culture overnight at 28°C; pick a single colony and inoculate it in 5.0mL liquid YPD medium, and culture overnight at 28°C with shaking ; at a final concentration of 5.0×10 6 Cells / mL were inoculated in 50.0mL liquid YPD medium, cultured at 28°C with shaking at 200rpm for 4h;) at 4°C, cen...

Embodiment 3

[0076] To verify the ability of recombinant strains to produce trehalose, the steps are as follows:

[0077] (1) Pick a single colony of the recombinant bacteria and inoculate it in 5.0 mL of YPD liquid medium, culture it with shaking at 28°C overnight, and this is the seed solution.

[0078] (2) Take 1.0 mL of seed liquid, transfer to 50.0 mL of PPB medium, and culture with shaking at 25°C for 3-5 days.

[0079] (3) Centrifuge at 1500×g for 5 minutes, collect 40 mL of the supernatant to obtain a crude enzyme solution, add amylose at a final concentration of 1%, adjust the pH to 6.5, and react at 65° C. for 12 hours.

[0080] (4) Dilute the reacted solution by 10 times, filter it with a 0.22 μM aqueous phase membrane, and detect it by thin-layer chromatography (TLC) and high-pressure liquid chromatography (HPLC), respectively. TLC and HPLC detection results such as Figure 4~5 shown. Figure 4 Among them, lanes G, M, T and S are glucose, maltose, trehalose and amylose respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com