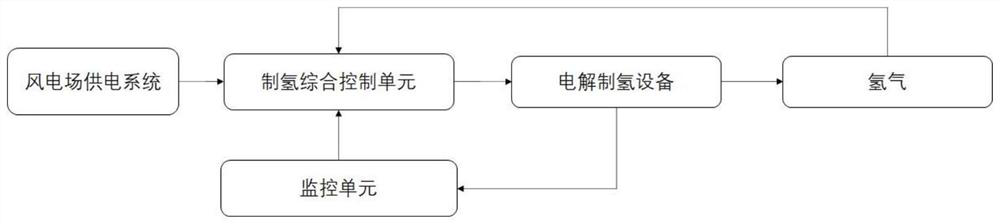

High-efficiency and low-cost proton exchange membrane water electrolysis hydrogen production control method self-consistent with renewable energy sources and control method thereof

A technology of renewable energy and proton exchange membrane, applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve the problems of cost rise, price rise, restriction of popularization and application, etc., and achieve the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

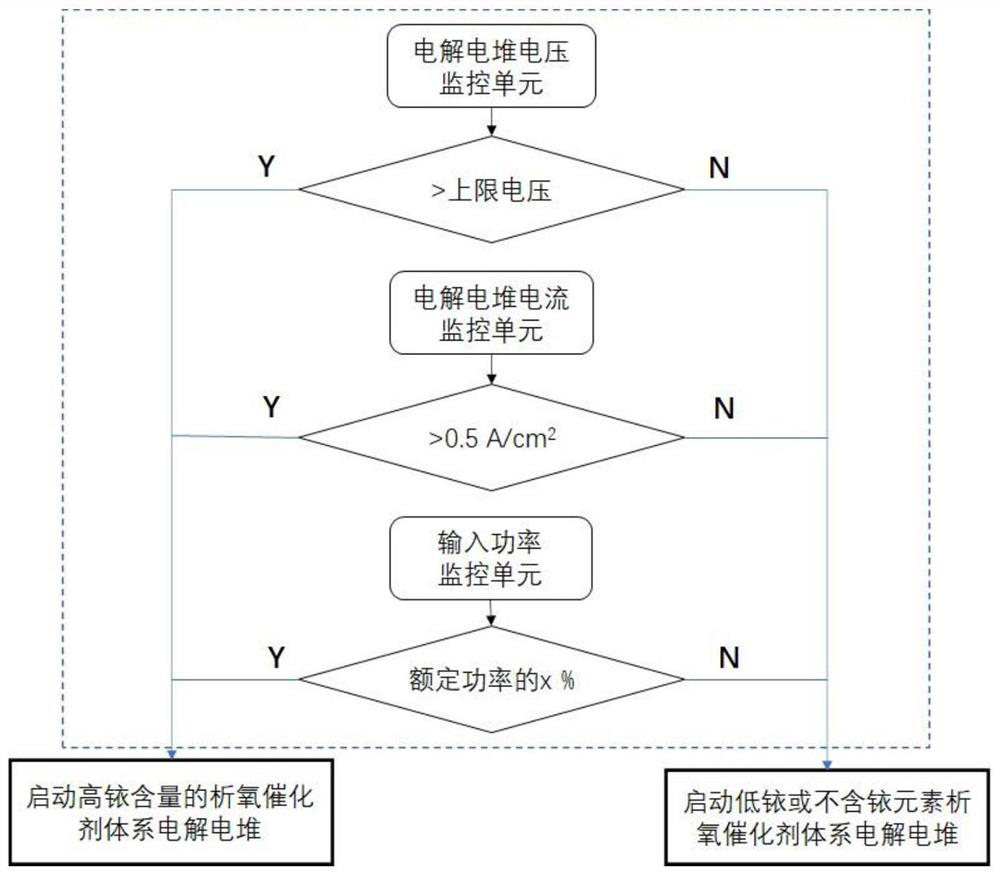

Embodiment 1

[0061] Example 1: Monodisperse Ir-MnO 2 As an anode catalyst for PEMWEs operating at low voltage

[0062] MnO 2 The corrosion dissolution potential is 1.75V vs. RHE, based on which a single-atom Ir-doped MnO 2 Catalyst (Ir-MnO 2 ), wherein the atomic ratio of Ir is 0.87%. Using it as an OER catalyst in acidic environment, at 10mA cm -2 It can run stably for more than 600h under the current density. with Ir-MnO 2 As PEMWEs anode catalyst material, assemble electrolysis water pool. Set the system protection voltage to the single-chip electrolysis voltage of 1.75 V. When the single-chip input voltage is greater than 1.75 V, the high-iridium content oxygen evolution catalyst system PEM electrolytic stack unit operates to produce hydrogen by electrolysis; when the single-chip input voltage is less than 1.75 V, the single-chip Disperse Ir-MnO 2 Oxygen evolution catalyst system PEM electrolysis stack unit runs electrolytic hydrogen production.

Embodiment 2

[0063] Example 2: Ti-doped RuO 2 As an anode catalyst for PEMWEs operating at low voltage

[0064] RuO 2The corrosion dissolution potential is 1.5V vs. RHE, and it is modified by Ti doping to obtain Ti-doped RuO with high activity at low potential. 2 Material (Ti-RuO 2 ), the current density exceeds 100mA cm at 1.43V vs. RHE potential -2 . Using it as an OER catalyst in an acidic environment, at 10mA cm -2 It can run stably for more than 30h under the current density. Ti-RuO 2 As a PEMWEs anode catalyst material, an electrolytic water pool is assembled. Set the system protection voltage to the monolithic electrolysis voltage of 1.5V. When the monolithic input voltage is greater than 1.5V, the high iridium content oxygen evolution catalyst system PEM electrolytic stack unit runs electrolytic hydrogen production; when the monolithic input voltage is less than 1.5V, the Ti doped RuO 2 Oxygen evolution catalyst system PEM electrolytic stack unit runs electrolytic hydrogen...

Embodiment 3

[0065] Example 3: MnO 2 As an anode catalyst for PEMWEs operating at low voltage

[0066] MnO 2 The corrosion dissolution potential is 1.75V vs. RHE, which is directly used as an OER catalyst in an acidic environment, at 10mA cm -2 It can run stably for more than 8000h under the current density. MnO 2 As PEMWEs anode catalyst material, assemble electrolysis water pool. Set the system protection voltage to the single-chip electrolysis voltage of 1.75 V. When the single-chip input voltage is greater than 1.75 V, the high-iridium content oxygen evolution catalyst system PEM electrolytic stack unit operates to produce hydrogen by electrolysis; when the single-chip input voltage is less than 1.75 V, the MnO 2 Oxygen evolution catalyst system PEM electrolytic stack unit runs electrolytic hydrogen production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com