Negative oxygen ion sanitizer and preparation method and application thereof

A negative oxygen ion, disinfection and sterilization technology, applied in the direction of disinfectants, bactericides, separation methods, etc., can solve the problems of short duration, unsuitable for air purification, easy volatility, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

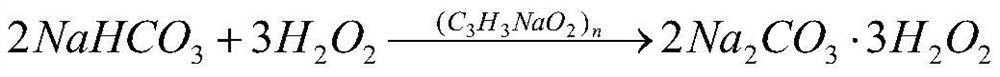

Method used

Image

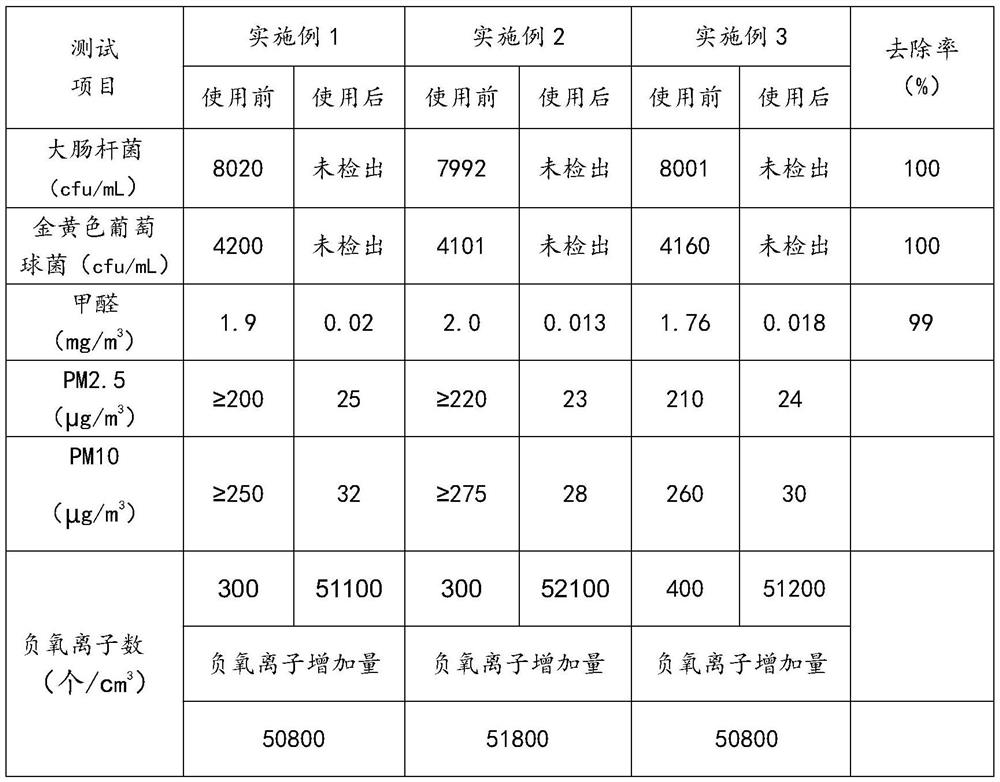

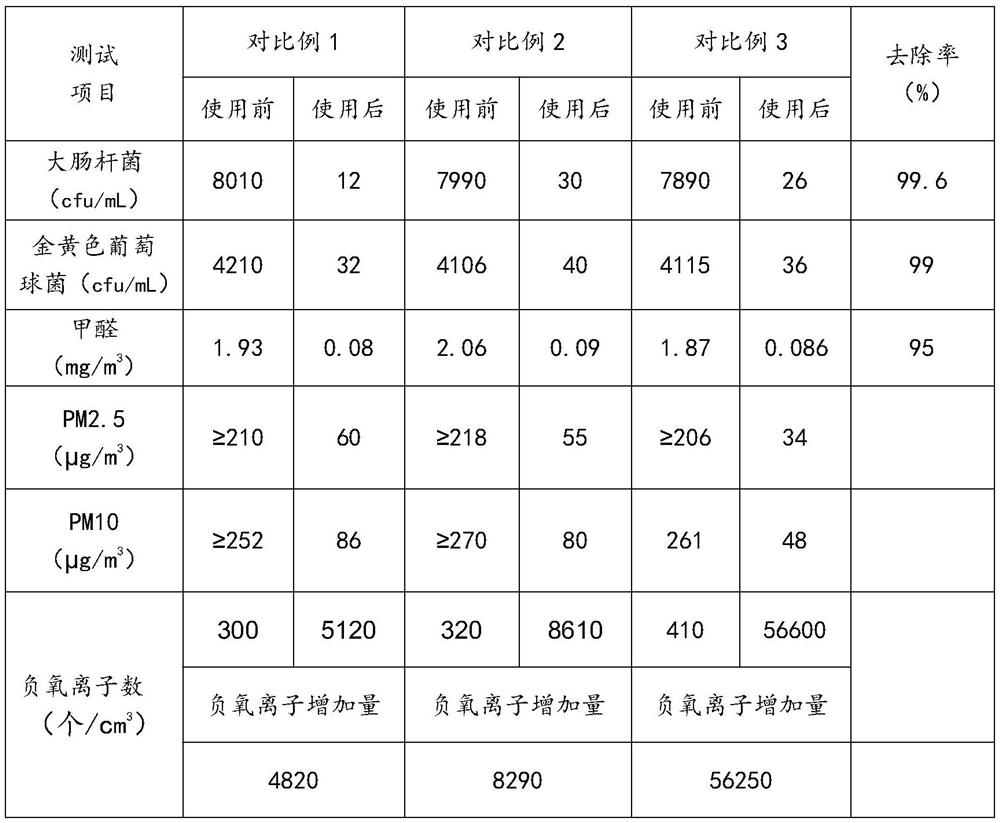

Examples

Embodiment 1

[0086] The negative oxygen ion disinfectant of the present embodiment is made of negative ion mixed solution, stable oxygenation mixed solution and disinfection and sterilization solution in a mass ratio of 1:1:1, wherein the negative ion mixed solution is made of raw materials of the following quality Formation: calcined tourmaline powder 15kg, nano cerium oxide 0.02kg and deionized water 84.98kg; the stable oxygen-increasing mixed solution is made of the following quality raw materials: anhydrous sodium carbonate 10kg, sodium polyacrylate 3kg, hydrogen peroxide 8kg and 79kg of deionized water; the disinfection solution is made of the following quality raw materials: Kudingcha extract 1kg, Pulsatilla pulsatilla extract 1kg, dandelion extract 1kg, Chlorophytum extract 1kg, lotus leaf extract 1kg and deionized water 95kg .

[0087] The preparation method of above-mentioned negative oxygen ion disinfectant, comprises the steps:

[0088] Step 1: Prepare the negative ion mixture ...

Embodiment 2

[0099] The negative oxygen ion disinfectant of the present embodiment is made of negative ion mixed solution, stable oxygenation mixed solution and disinfection and sterilization solution in a mass ratio of 1:1:1, wherein the negative ion mixed solution is made of raw materials of the following quality Formation: calcined tourmaline powder 18kg, nano cerium oxide 0.05kg and deionized water 81.95kg; the stable oxygen-increasing mixed solution is made of the following quality raw materials: anhydrous sodium carbonate 15kg, sodium polyacrylate 4kg, hydrogen peroxide 10kg and 71kg of deionized water; the disinfection and sterilization solution is made of the following quality raw materials: Kudingcha extract 2.5kg, Pulsatilla pulsatillae extract 2kg, Dandelion extract 2.6kg, Chlorophytum extract 1.8kg, Lotus leaf extract 1.5kg and 89.6kg of deionized water.

[0100] The preparation method of above-mentioned negative oxygen ion disinfectant, comprises the steps:

[0101] Step 1: P...

Embodiment 3

[0112] The negative oxygen ion disinfectant of the present embodiment is made of negative ion mixed solution, stable oxygenation mixed solution and disinfection and sterilization solution in a mass ratio of 1:1:1, wherein the negative ion mixed solution is made of raw materials of the following quality Formation: calcined tourmaline powder 23kg, nano cerium oxide 0.12kg and deionized water 76.88kg; the stable oxygen-increasing mixed solution is made of the following quality raw materials: anhydrous sodium carbonate 20kg, sodium polyacrylate 8kg, hydrogen peroxide 15kg and 57kg of deionized water; the disinfection solution is made of the following quality raw materials: Kudingcha extract 4kg, Pulsatilla pulsatilla extract 5kg, dandelion extract 4kg, Chlorophytum extract 3kg, lotus leaf extract 3kg and deionized water 81kg .

[0113] The preparation method of above-mentioned negative oxygen ion disinfectant, comprises the steps:

[0114] Step 1: Prepare the negative ion mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com