Preparation method of liquid potassium ferrate by utilizing ultrasonic electrolysis

A potassium ferrate, ultrasonic technology, applied in the electrolysis process, electrolysis components, cells and other directions, can solve the problems of reducing the current efficiency, cumbersome process, unfavorable stability, etc., to improve the electrolysis efficiency, improve current efficiency, good degassing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

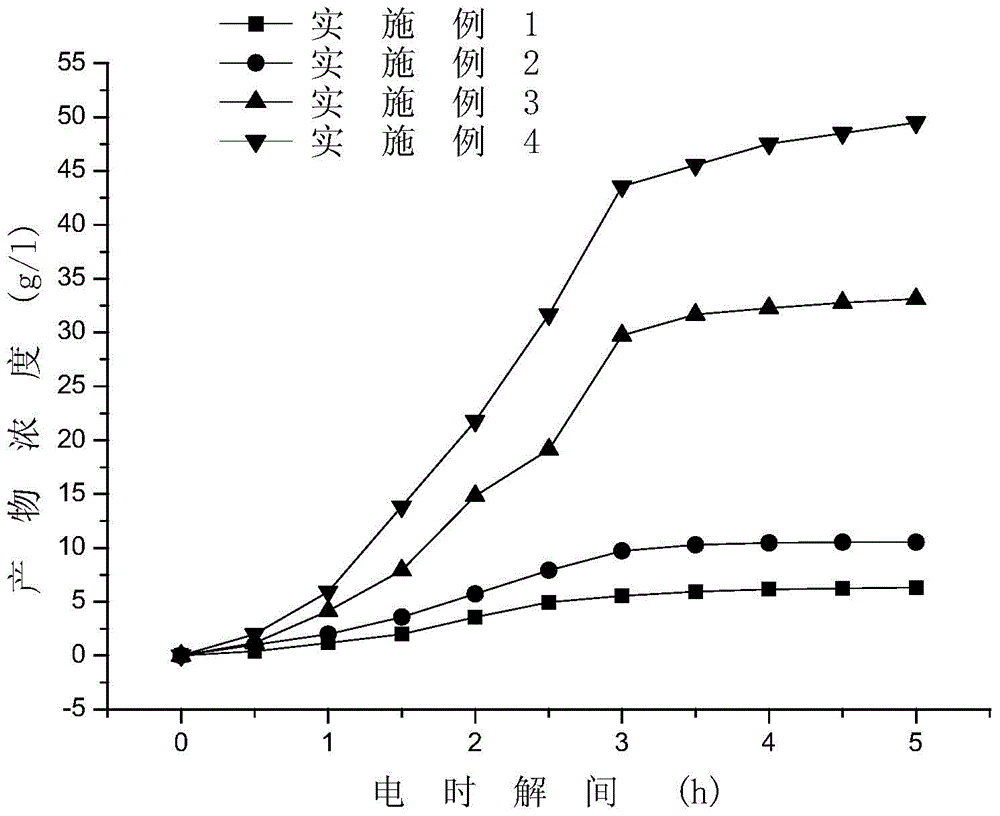

Embodiment 1

[0049] An electrolysis device is adopted, and the electrolysis device comprises: an ultrasonic generator: an electrolytic cell placed in the ultrasonic generator, and the electrolytic cell is separated into a cathode chamber and an anode chamber by a perfluorinated ion membrane;

[0050] Configure 16mol / L potassium hydroxide solution as anolyte, 2mol / L potassium hydroxide solution as catholyte, adopt perfluorinated ion membrane, use one cathode compartment and one anode compartment. The cathode is placed in the cathode chamber, the anode is placed in the anode chamber, the cathode is made of pure nickel plate, the anode is made of iron mesh, the catholyte is added to the cathode chamber, and the anolyte is added to the anode chamber; The voltage is 12V, the power of the ultrasonic generator is 600W, and the frequency is 40kHz. Inside the anode chamber, there is a cooling pipe surrounded by a spiral, and cold water is introduced into the cooling pipe to keep the temperature of ...

Embodiment 2

[0052] An electrolysis device is adopted, and the electrolysis device comprises: an ultrasonic generator: an electrolytic cell placed in the ultrasonic generator, and the electrolytic cell is separated into a cathode chamber and an anode chamber by a perfluorinated ion membrane;

[0053] Configure 16mol / L potassium hydroxide solution as anolyte, 2mol / L potassium hydroxide solution as catholyte, adopt perfluorinated ion membrane, use one cathode compartment and one anode compartment. The cathode is placed in the cathode chamber, the anode is placed in the anode chamber, the cathode is made of pure nickel plate, the anode is made of iron mesh, the catholyte is added to the cathode chamber, and the anolyte is added to the anode chamber; The voltage is 12V, the power of the ultrasonic generator is 600W, and the frequency is 40kHz. Inside the anode chamber, there is a cooling pipe surrounded by a spiral, and cold water is introduced into the cooling pipe to keep the temperature of ...

Embodiment 3

[0055] Using an electrolysis device, the electrolysis device includes:

[0056] Ultrasonic generator:

[0057] Placed in the electrolytic cell of the ultrasonic generator, the electrolytic cell is separated into a cathode chamber and two anode chambers by two perfluorinated ion membranes, and an anode chamber is distributed on both sides of the cathode chamber, that is, the two perfluorinated ion membranes will The electrolytic cell is divided into three parts, which are the anode chamber, the cathode chamber and the anode chamber in sequence.

[0058] Configure 16 mol / L potassium hydroxide solution as the anolyte, 2 mol / L potassium hydroxide solution as the catholyte, add potassium chloride in both the cathode and anode chambers, and the concentration is 1 mol / L, using perfluorinated ion membrane, One cathode compartment and two anode compartments are used. The cathode is placed in the cathode chamber, the anode is placed in the anode chamber, the cathode is made of pure ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com