Method for efficient production of biogas from straw

A straw and biogas technology, applied in the field of high-efficiency biogas production from straw, can solve the problems of low fermentation efficiency, low utilization rate of biogas residue and biogas slurry, and low efficiency, and achieve the goal of solving environmental pollution, improving utilization rate, and increasing gas production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

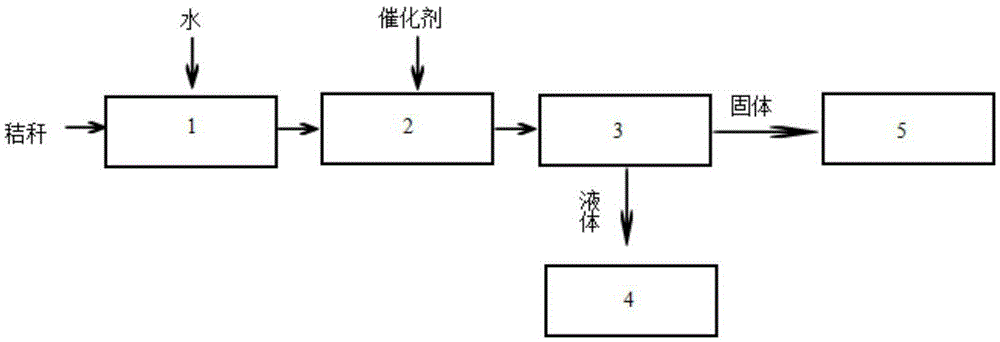

Image

Examples

Embodiment 1

[0026] Example 1 Take 10kg of fresh straw, grind it into 0.5cm straw particles with a pulverizer, then add 1000kg of 60°C aqueous solution containing 0.05mol / L cobalt chloride to the straw particles, mix well, Soak for 8h. After completion, the solid-liquid mixture enters the solid-liquid separator for pressing to separate the solid from the liquid. Liquid COD obtained by pressing process Cr It can reach 50000mg / L, and it can produce 400m3 per ton of straw dry matter by using UASB high-efficiency anaerobic reactor for anaerobic fermentation to produce biogas. 3 Biogas yield, solid residues are composted.

Embodiment 2

[0027] Embodiment 2 Get 20kg of air-dried stalks, utilize a pulverizer to be crushed into 1.0cm straw granules, then add 1000kg to the stalk granules, an aqueous solution containing 0.25mol / L ferric chloride and 0.25mol / L cobalt chloride at 80°C, Mix well and soak for 4h under the condition of stirring at 50r / min. After completion, the solid-liquid mixture enters the plate and frame filter press for pressing to separate the solid from the liquid. Liquid COD obtained by pressing process Cr It can reach 35000mg / L, and use UASB high-efficiency anaerobic reactor for anaerobic fermentation to produce biogas, which can reach 200m3 per ton of straw dry matter 3 The yield of biogas, solid residues are incinerated.

Embodiment 3

[0028] Example 3 Take 100kg of fresh straw, the mixture of air-dried straw and silage straw, use a pulverizer to crush it into 2.0cm straw particles, and then add 1000kg to the straw particles, 100 ° C containing ferric chloride, cobalt chloride and chlorine The concentration of nickel chloride is 0.5mol / L aqueous solution, mix evenly, soak and stir for 1h under the condition of stirring at 100r / min. After completion, the solid-liquid mixture enters the solid-liquid separator for pressing to separate the solid from the liquid. Liquid COD obtained by pressing process Cr It can reach 43000mg / L, and use EGSB high-efficiency anaerobic reactor for anaerobic fermentation to produce biogas, which can reach 320m3 per ton of straw dry matter 3 The yield of biogas, solid residues are composted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com